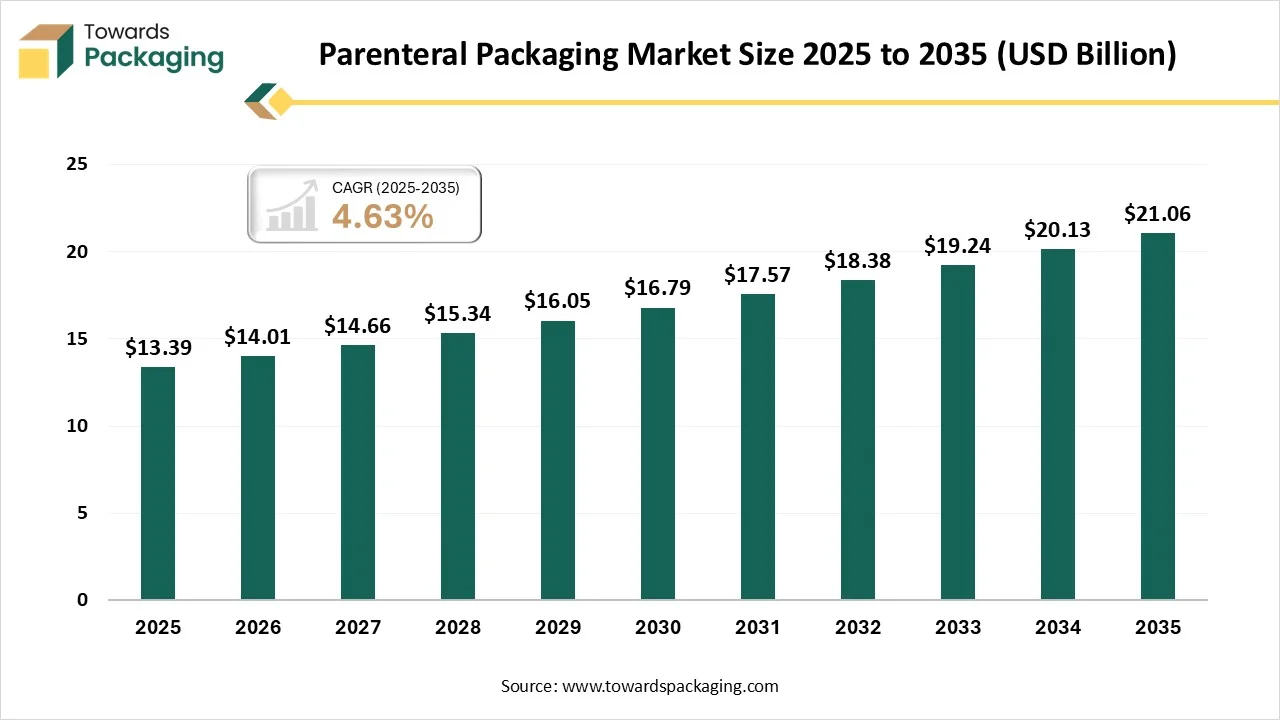

The parenteral packaging market is forecasted to expand from USD 14.01 billion in 2026 to USD 21.06 billion by 2035, growing at a CAGR of 4.63% from 2026 to 2035. We cover the complete landscape product segments such as vials, prefilled syringes, ampoules, bags and RTU systems; material segments including plastic, glass, PVC and polyolefin; and packaging formats like small and large volume containers. Our analysis spans all regions North America (largest market), Europe, Asia Pacific (fastest growth), Latin America and MEA. We also profile leading companies including West Pharmaceutical Services, Amcor, AptarGroup, Gerresheimer, SCHOTT AG, SGD Pharma, BD, Baxter, Uflex, and more.

The report includes competitive analysis, value chain mapping, global trade flows, production hubs, supplier networks, and manufacturing capacities, helping stakeholders understand opportunities in biologics, chronic disease treatment, and advanced drug-delivery packaging.

| Metric | Details |

| Market Size in 2025 | USD 13.39 Billion |

| Projected Market Size in 2035 | USD 21.06 Billion |

| CAGR (2025 - 2035) | 4.63% |

| Leading Region | North America |

| Market Segmentation | By Product, By Material, By Packaging Format and By Region |

| Top Key Players | West Pharmaceutical Services, AMCOR PLC, AptarGroup, Inc., Origin Pharma Packaging, Gerresheimer AG, SCHOTT AG. |

Parenteral packaging denotes the secondary packaging for pharmaceutical products for inhalation, injection, infusion, or implantation into the bodies of humans or animals. Because of their elements, also called active pharmaceutical ingredients (APIs), these pharmaceutical products, which are stored in primary packing, are sometimes temperature-sensitive. They are first packed in a freeze-dried or liquid state in an extensive variety of frequently delicate disinfected primary packaging, such as syringes, injectors, ampoules, vials, or inhalers, and are then packed as a successive phase with other components utilized for application, i.e., adapters, syringes, pens, injectors, or cannulas. Parenteral packaging is gaining progressively attention as the quantity of parenterally administered medicines increases across the globe, instances comprise vaccines as well as diabetes medicines, and weight loss shots.

Continuous innovation by the major market players to improve the quality of packaging and provide enhanced safety to the medicinal products has influenced the growth of this market.

The growing number of pharmaceutical products for advance treatment of chronic diseases has raised the demand for high-quality packaging to maintain the required atmosphere of the medicines.

The rising rate of drug delivery has enhanced the packaging of the medicines to maintain the integrity and effectiveness of the medicines.

Medical companies are now processing an essential alteration of pharmaceutical shield through AI packaging inventions that counter fabricating and supply chain intimidations and drug altering occurrences. The recognition of counterfeit medical packaging attained better consequences due to artificial intelligence technologies allowed deep learning representations to mine medicine packaging irregularities. Pharmaceutical producers attain improved pharmaceutical safety through the incorporation of machine learning, which assistances them in predicting and identifying, and halting imitation drug arrival into their distribution chains. Multifaceted pharmaceutical distribution chains generate problems for pharmaceutical businesses to monitor medication programs through their systems. Every medicine package becomes trackable from the beginning of production until its final distribution point through the execution of AI tracking utilizing a blockchain technique.

Continuous Rise of Chronic Diseases

The increasing prevalence of chronic diseases enhances the demand for the parenteral packaging market. Chronic circumstances, such as cancer, diabetes, and cardiovascular illnesses, frequently necessitate long-term treatment with injectable medicines, thus enhancing the demand for parenteral packaging solutions. Diabetes is a chief worldwide health problem, affecting millions of people worldwide. The management of diabetes frequently includes the use of injectable insulin, which requires safe and effective parenteral packing. The worldwide aging population is more vulnerable to chronic illnesses, resulting in amplified demand for healthcare services and treatment. Adults often need injectable medicines for the management of chronic situations, further pushing the demand for parenteral packaging solutions.

Strict Supervisory Needs and High Charges of Innovative Technology

Strict supervisory rules have hindered the growth of the parenteral packaging market. Governing bodies like the European Medicines Agency (EMA) and the U.S. Food and Drug Administration (FDA) have recognized inclusive strategies to safeguard the security, efficiency, and superiority of pharmaceutical packing. Corporations must conduct wide testing to prove compliance with supervisory morals, which can delay product promotions and upsurge expansion costs. Executing progressive packaging technologies needs considerable investments in devices, research, and expansion. Smaller pharmaceutical businesses may find it challenging to allocate the essential materials to accept these technologies, restricting their market involvement.

Modifications in Biopharmaceuticals

Biopharmaceuticals, which comprise biosimilars and biologics, are multifaceted, large-molecule medications resulting from living microorganisms. They need dedicated packing resolutions to preserve their sterility, stability, and efficacy, leading to amplified demand for parenteral packing. Biologics have developed an essential part of modern medication, offering targeted treatments for a variety of illnesses, including rare genetic conditions, cancer, and autoimmune disorders. Supervising chronic situations needs adhering to a reliable treatment strategy, and self-filled syringes have been steadily recognized to increase adherence to such schedules.

As the industry for biologics continues to expand, so does the necessity for progressive parenteral packaging solutions that can preserve the subtle properties of these medicines. This tendency has assisted the parenteral packing industry in developing more tools in the direction of precision, comfort, and enhanced customer satisfaction. Self-directed devices have transformed homecare and outpatient settings where patients are essential to utilize the apparatus without the support of a healthcare expert, further eradicating the probabilities of inappropriate self-medication or errors in medicine research.

The prefilled syringes segment held a considerable revenue share in 2024 due to its widespread practice in several surgical processes. The growing rate of chronic diseases such as cancer, brain stroke, and several other diseases has raised the number of surgeries performed, which has enhanced the demand for prefilled syringes. These are utilized for the packaging of highly sensitive drugs to maintain their integrity and reliability. Stockholders choose prefilled syringes in drug packing due to their properties such as high quality, cost effectiveness, and safety, which preserves standards until it is utilized.

On the other hand, vials have been growing steadily in the parenteral packaging market. Vials are utilized for a wide range of medicines, including antibiotics, vaccines, and various other injectable medicines in the market. Their adaptability makes them appropriate for both lyophilized (freeze-dried) and liquid formulations. Existing in both plastic and glass, vials offer choices based on medicine compatibility and stability, contributing flexibility to pharmaceutical producers.

The plastic segment held the dominant revenue share in 2024 due to its huge popularity and cost-effectiveness. There are several properties of plastics that attract a huge consumer base towards them, such as flexibility in designing, shatterproof nature, lightweight, and affordability. This is highly durable and reduces the risk of breakage while transporting, which causes a high preference for using these materials. The growing awareness about bioplastic has also raised the usage of this material for drug packaging as consumers are seeking for eco-friendly solution.

The usage of glass is growing rapidly in parenteral packaging due to its superior quality and high chemical resistance. This enhanced the long-term storage of the drugs in the glass containers. The high quality of the glass material has influenced the demand for glass packaging.

Small volumes of vaccines and other injectable drugs are in high demand as there is a continuous rise in demand for personalized medicines and treatment, which has led to a high success rate and requires lower dosages in accurate volumes. These small volume packages are convenient to use according to the pharmaceutical trends. The development is expected due to they are readily practical goods. Also, they are mainly utilized for the handling of lung-related infections and diabetes.

The large volume segment is expected to grow rapidly in the market. This is in high demand due to sterility and the growing surgical process, where fluid maintenance is essential at a large volume. Innovation in the packaging process has developed large volumes of bags, bottles, and pouches.

North America held the largest revenue share of the parenteral packaging market due to the growing number of biotechnology and pharmaceutical industries. In countries such as the U.S. and Canada has influenced the demand for high-quality drugs with a quick delivery system has raised the demand for parenteral packaging. The strong healthcare system in the United States has led to continuous innovation in the packaging industry to enhance safety while delivering products.

Asia Pacific is estimated to grow at the fastest rate in the parenteral packaging market during the forecast period. The growing cases of chronic and infectious diseases have raised the demand for parenteral packaging services. The rising number of patients has raised the demand for pharmaceutical vials and the vaccination process.

By Product

By Material

By Packaging Format

By Region

January 2026

January 2026

January 2026

January 2026