Vial Cap Sealing Machine Market Size, Trends and Innovations

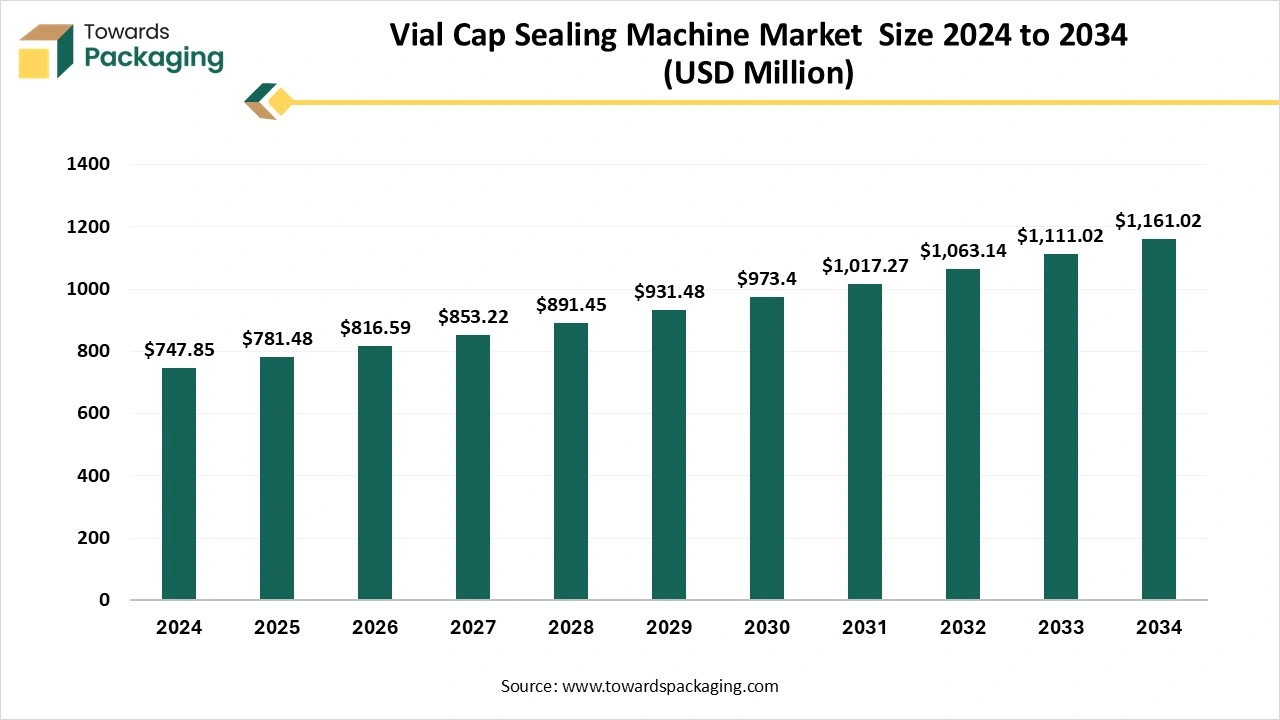

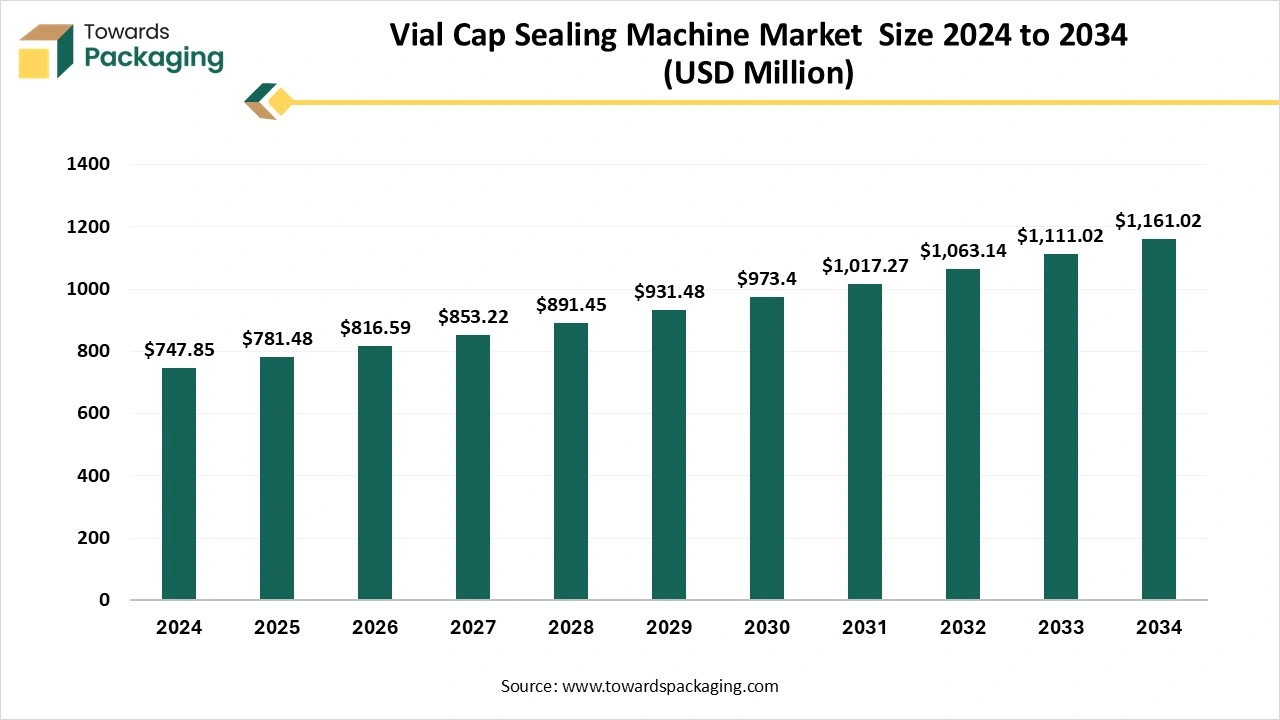

The vial cap sealing machine market delivers a complete view of the industry by covering market size growth from USD 781.48 million (2025) to USD 1,161.02 million (2034) at a 4.5% CAGR. This report includes detailed segmentation by technology and application, full regional analysis across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, and competitive profiling of companies like Syntegon, Groninger, Cozzoli, ARxIUM, and NJM Packaging. It highlights global trade patterns, value chain structure, manufacturing ecosystem insights, and supplier networks supporting the rise of automation in vial sealing systems.

Key Takeaways

- North America dominated the vial cap sealing machine market in 2024 as production procedures and inventive technology are experiencing a solution in the pharmaceutical sector in North America.

- Asia Pacific is expected to experience rapid growth as it boasts enormous capability in the pharmaceutical industry due to growing populations, aging societies, and the urge to strengthen healthcare services.

- By technology, the automatic cap sealing machines segment dominated the market. These include a type of high-speed cap sealing machine available with several sealing heads, enabling high-speed manufacturing based on particular requirements.

- By technology, the semi-automatic vial sealing machine segment is expected to grow rapidly due to its comprehensive solution characteristics for users who seek a compact and easy-to-use capping machine.

- By application, the pharmaceuticals segment dominated the market as they widely utilize viable cap-sealing machines for vaccines, antibiotics, hormones, insulin, etc.

- By application, the personal care and cosmetics segment is expected to witness the fastest growth due to its importance in sealing products with the right safety measures.

Vial Cap Sealing Machine Market Overview

perfect for flip-flop cap sealing of injectable glass vials. This vial sealing machine is widely used in the veterinary and pharmaceutical industries for performance and good manufacturing practice (GMP) demanding customers. Making sure the machine’s sealing component is in contact with the vials is the primary mechanism of a vial cap sealing machine. The goal of the stainless-steel component is to allow the machine to link a variety of caps to the vials.

The fluid-filled vial is shifted to another location where the perfect amount of fluid level is appraised after the dial indexes of the vial cappers are dismissed from the machine. The filled vials are instantly capped once they have been properly examined in the vial cap sealers, and a vial with a malfunction or improper capping is cancelled. To make the machine process safely and efficiently, the sealing cap location is carefully regulated.

Key Metrics and Overview

| Metric |

Details |

| Market Size in 2024 |

USD 747.85 Billion |

| Projected Market Size in 2034 |

USD 1161.02 Billion |

| CAGR (2025 - 2034) |

4.5% |

| Leading Region |

North America |

| Market Segmentation |

By Technology, By Application and By Regions |

| Top Key Players |

Syntegon, Groninger, NJM Packaging, AIPAK, Cozzoli, ARxIUM |

Vial Cap Sealing Machine Market Trends

- Smart technology integration: There has been a rising trend of putting smart technology in bottle capping machines due to the Internet of Things (IoT). IoT allowed machines to serve actual-time performance data, anomaly examining as well as remote checking and troubleshooting options.

- Environmentally friendly designs: As the problem of sustainability continues to grow, producers are coming up with capping machines that use less energy and generate less waste. Inventions consist of reusable materials, energy-saving motors, and designs that assist in decreasing the ecological output.

- Faster changeover improves flexibility: The development in capping technology has made machines acceptable for a great number of various bottle shapes and sizes, as well as cap types. This elasticity allows industries to change between products more quickly without experiencing much decline.

- Increased automation: New machines filled with fully integrated systems that achieve every step from the assignment of bottles up to capping and sealing, which have contributed to the automation process. Due to this, this reduces human invention as well as speeds up the pace of manufacturing.

- Synergy with other systems: Capping machines are designed to coordinate well with other packaging equipment, like fillers or labelers. Hence, integration gives rise to a complete manufacturing line, which outcomes in higher efficiency while also making the complete process easier.

- Remote operation and troubleshooting: Current capping machines can be used and analyzed at a distance. This authorizes instant changes to be created, with the preference of solving issues instantly without going to the place of operation to reduce delays.

AI Integration in Vial Cap Sealing Machine Market

High-resolution cameras and Vision AI Systems capture detailed images of seals and examine them with detailed learning models. These models are then trained on different datasets, recognizing real-time conflicting defects or capable contamination. Image preprocessing procedures, such as contrast adjustments, noise reduction, and geometric modification, enhance the visual data before analysis to improve precision.

A convolutional neural network identifies each seal based on predetermined quality criteria, deciding whether it meets production standards. Once the examination is complete, outcomes are immediately communicated to a Programmable Logic Controller that makes programming decisions. Accepted seals continue through the production line, while faulty ones are instantly rejected.

Every inspected data point is stored in a database that serves traceability and valuable insight for procedure optimization. An actual-time dashboard enables operators to track key metrics, including the number of seals injected, complicated alerts, and rejection ranges that allow shift invention whenever needed.

Vial Cap Sealing Machine Market Dynamics

Driver

The Crucial Role of Vial Cap Sealing Machines in Pharmaceutical Manufacturing

The risk of contamination, moisture, and other environmental factors is transforming this industry and is driving the vial cap sealing machine usage. In order to guarantee an airtight seal, the vial cap sealing machine safeguards the drug or medicine from the previously mentioned factors. This procedure is important to ensure the safety and efficacy of injectable drugs, which makes the vial cap sealing machine a foundation of pharmaceutical manufacturing.

Pharmaceutical companies bargaining with sterile injectables must follow strict regulatory standards, and vial capping machines assist in aligning these urges by ensuring consistency, precision, and safety in the capping procedure. This technology is important in different stages of manufacturing, which makes sure that medicines are properly packaged before reaching healthcare providers and ultimately patients.

Restraint

Avoiding Downtime: The Importance of Reliable Capping Systems

Capping machine dependability directly affects the overall efficiency of our production line. A badly calibrated or malfunctioning machine paves the way for bottlenecks, rejected batches, and increased operational costs. As per the study done by the Association for Packaging and Processing Technologies, nearly 30% of production downtime in manufacturing is attributed to packaging equipment collapse, which includes capping machines. Misaligned caps are frequently due to improper synchronization between the capping machine and the conveyor system. Unpredictable torque paves the way to over-tightened caps or loose caps that lead to leakage. The tertiary challenge is that machine jams are frequent because of damaged caps, conveyor misalignment, and residue buildups on the guide.

Opportunity

Sustainability in Focus: The Growth of Eco-Friendly Double-Ended Vial Solutions

Growing environmental awareness and the marketing of sustainable development goals will drive the production of double-ended vials to pay more attention to the recyclability of materials and the environmental protection of the manufacturing procedure. With the development in research and development in terms of bioplastics and biodegradable materials, double-sided vials may utilize two different acids called PLA (Polylactic acid) and PHA (Polyhydroxy fatty acid ester) and another biodegradable plastic, which not only sustains perfect mechanical characteristics and durability but can also be immediately decomposed after usage to lessen the effect on the environment.

Segmental Insights

By Technology

The automatic cap sealing machines segment dominates the vial cap sealing machine market. The automatic cap sealing machine, which is a type of high-speed cap sealing machine, is available with several sealing heads, which enables high-speed manufacturing based on particular requirements. Every sealing is filled with a sealing roller which pertains to constant pressure and prevents cap distortion and lessers particle generation. The machine is crafted to integrate various vial sizes, which makes it an evergreen solution for pharmaceutical producers. It consists of rigid stainless-steel construction as it is created from AISI 304 Stainless Steel, the machine is corrosion-resistant, easy to clean, and long-lasting, which aligns with GMP guidelines.

The semi-automatic vial sealing machine segment is witnessing the fastest growth in the vial cap sealing market, due to its comprehensive solution characteristics for users who seek a compact and easy-to-use capping machine. It is perfect for those who are currently stretching the caps manually using their hands. This machine serves as a perfect engineering result for startup industries that find an economical but reliable procedure for the perfect hermetic sealing of vials.

By Application

The pharmaceuticals segment dominated the vial cap sealing machine market in 2024. The pharmaceutical industry widely utilizes viable cap-sealing machines for vaccines, antibiotics, hormones, insulin, etc. These are satisfied under cautious conditions. As these injectable medications go into the blood flow, minute drops of germs can be a huge deal for health. In this sector, filling vials with medications using a vial filling line is highly required. These devices fill the viable with accuracy and have a long-term lifespan. Furthermore, many filling heads on the machines are operated to fill vials, which enables high rates and hence greater production.

Following this, the personal care and cosmetics segment is expected to grow at the fastest rate due to its importance in sealing products with the right safety measures. It not only prevents products from pollutants and damage but also serves as a main term in branding and the user's point of view. Consumers expect personal care products to be user-friendly, safe, and attention-grabbing. Whether it's a glossy shampoo bottle or an easy-to-use tube of hand cream, the packaging must align with high standards of hygiene, design, and durability. Furthermore, with the rising acceptance of packaging solutions, sustainability must also align with eco-friendly practices.

By Region

North America Dominated the Vial Cap Sealing Machine Market in 2024

Production procedures and inventive technology are experiencing a solution in the pharmaceutical sector in North America. Data-driven results and automation equipment are utilized in the manufacturing of different bottles, vials, and tablets. Hence, rules made it compulsory that businesses depend on best practices. Linear vial washing machines, injectable vial powder fillers, and many more products include programmable elements for a tailored experience.

On the other hand, the U.S. pharmaceutical market, which is one of the largest in the world, is experiencing growth in the manufacturing of injectable drugs, specifically in response to growing healthcare demand and advancements in biologics. Top pharmaceutical centers like Boston, New York, and San Francisco are home to several biotech companies that are stretching their injectable drug profile.

Asia Pacific Expected to Host the Fastest-Growing Market

There is an enormous capability in the Asia Pacific pharmaceutical industry due to growing populations, aging societies, and the urge to strengthen healthcare services. A progressive middle class and rising awareness of health and wellness in several regional markets are driving crucial demand for dietary supplements and pharmaceutical capsules. Pharma industries within Asia Pacific -whether generic or inventive, domestic or foreign are likely to develop as a result.

India has found itself as a worldwide pharmaceutical production hub, providing a large portion of generic drugs in the world. Indian organizations are heavily concentrating on generating injectable drugs for both domestic and export markets, specifically in response to the growing demand for acceptable healthcare solutions.

China’s pharmaceutical sector is expanding rapidly, with a growing concentration on the manufacturing of injectable drugs and vaccines. The Chinese government's focus on healthcare innovation and self-sufficiency in drug manufacturing has grown the demand for current pharmaceutical equipment that includes injectable liquid vial filling lines. The country’s drive to become top in biologics and advanced medical solutions is pushing producers to accept the current filling technologies to meet worldwide standards.

Recent Developments

- On 10 March 2025, Marchesini Group Beauty offered the beauty industry several different solutions for making a complete packaging line, which begins with a filling machine and capping machine for fragrances generated from the Axiomatic brand. (Source: HPCi Media Limited)

- On 16 May 2024, SEE accepted the LiquidBox Universal Self-sealing cap closed-loop system as businesses can cut food and packaging waste while reducing CO2 emission by having part control, which lessens over pouring and residual waste as compared to regular bottles and cartons. (Source:Packaging Europe)

- On 30 January 2023, Mespack and Hoffer Plastics revealed the market launch of the P-15 spout and cap for stand-up pouches, which are crafted to be compatible with both monolayer materials and Mespack’s horizontal form-fill-seal machines, which are lightweight and include 20% less plastic than past designs. (Source: Packaging Europe)

Vial Cap Sealing Machine Market Key Players

Latest Announcements by Market Leaders

- On 17 October 2024, Zalkin which is a top company in capping machinery and cap handling systems revealed its participation at PACK EXPO 2024, which took place from November 3-6 at McCormick Place in Chicago, Illinois where it displayed its state-of-the-art equipment and explanation crafted to grow quality, efficiency, and sustainability for different packaging uses. (Source: Zalkin)

- On 7 June 2024, Syntegon grew its pharmaceutical process and packaging business with the acquisition of Azbil Telstar to date as part of the Japanese Azbil Corporation, which is listed on the Tokyo Stock Exchange Prime Market. (Source: Syntegon News)

- On 2 October 2024, ProMach, which is a top company in the packaging and processing industry and related solutions, revealed that it has secured HMC products, a leader in refurbishing, manufacturing, and servicing of horizontal form fill seal machines. (Source: Promach)

Vial Cap Sealing Machine Market Segments

By Technology

- Automatic Cap Sealing Machine

- Semi-Automatic Vial Sealing Machine

- Manual Vial Cap Sealing Machine

By Application

- Chemical

- Pharmaceutical

- Food and Beverages

- Personal Care and Cosmetics

- Other

By Regions

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa