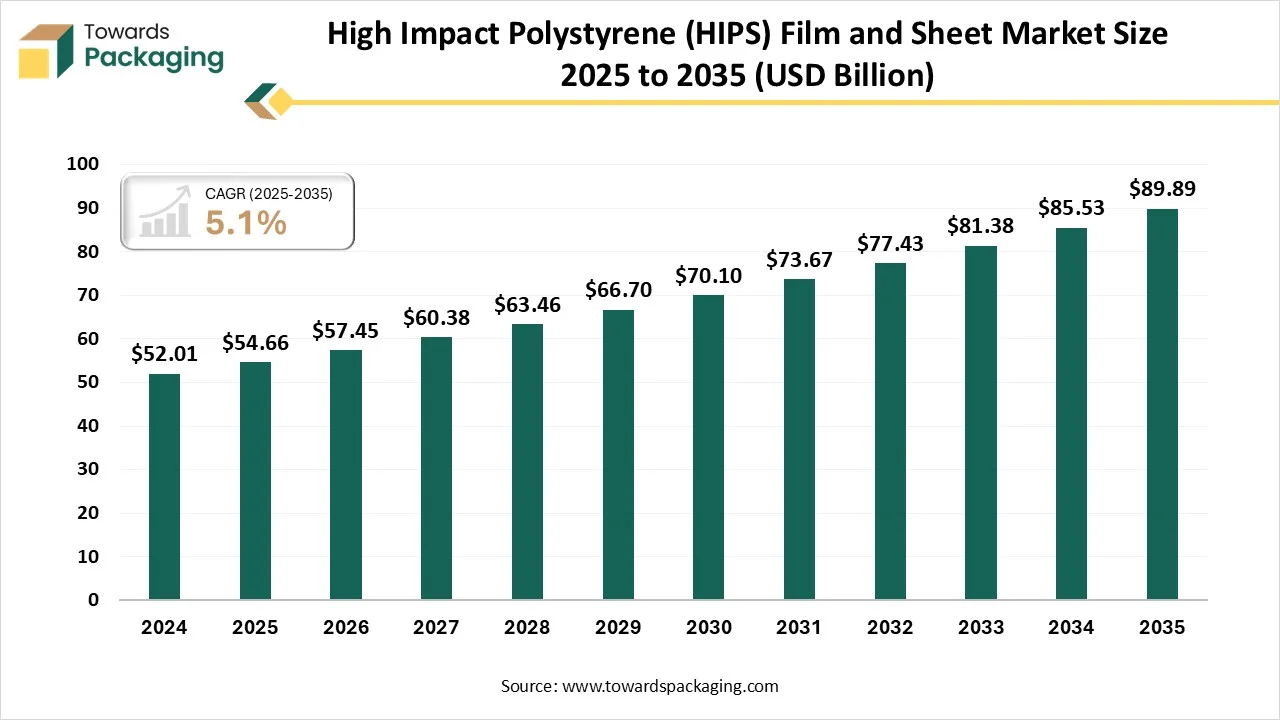

The high impact polystyrene (HIPS) film and sheet market is projected to reach USD 89.89 billion by 2035, growing from USD 57.45 billion in 2026, at a CAGR of 5.1% during the forecast period from 2026 to 2035. This market is majorly influenced due to its versatility, suitability, cost-effectiveness, and superior resistance. The rapid growth in the e-commerce sector has raised the demand for the market.

High impact polystyrene (HIPS) film and sheet is a cost-effective, durable, and lightweight plastic produced by addition rubber to average polystyrene, significantly improving its toughness and impression resistance, making it suitable for usages requiring rigidity and formability such as point-of-sale displays, food packaging (trays), signs, toys, and samples, as it's effortlessly thermoformed, fabricated, and printed.

Technological transformation in the market plays a significant role in its expansion. Advanced technologies, comprising chemical recycling, are enhancing the capacity to recover HIPS from multifaceted waste streams and change post-consumer surplus into superior-quality HIPS, generating a circular economy. The incorporation of the Internet of Things (IoT) and Artificial Intelligence (AI) enhances production processes, permitting for real-time displaying, predictive care, and enhanced quality control. Progressions in masterbatch expertise and surface finishes permit for easier coloring as well as printing with improved color constancy and adhesion, which is important for display and packaging usages.

The major raw materials utilized in this market are HIPS granules/ pellets or recycled pellets. It is derived from crude oil and rising focus on sustainable/recycled content.

The component manufacturing in this market comprises packaging, construction, automotive, and electronics.

This segment majorly depends on a mixture of third-party wholesalers/ distributors and direct sales to link the gap between producers and varied end-use sectors.

The extrusion HIPS segment dominated the market with highest share in 2025 due to its affordability and versatility demand in packaging. It is influenced by packing, appliances, and retail monitors, using single or twin-bolt extruders for cost-operative to huge-scale manufacturing. Increasing demand for impact-resistant, versatile, and progressively sustainable packing resolutions. Rising ecological concern boosting for sustainable and recycling practices. Enhanced focus towards development of material has influenced the demand for this segment.

The injection molding HIPS segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to its high-volume and cost-effectiveness. It is majorly influenced by its balance of presentation and low charges. It allows for manufacturing of intrinsic structures which has influenced the demand for this segment. It provides superior impact strength, rigidity, chemical durability, and superior thermal insulation which is making it versatile product. This segment offers affordable, strong, and shapely apparatuses for everyday goods.

The packaging segment dominated the market with highest share in 2025 due to its impact resistance and thermoforming ease. The huge growth in food delivery and online shopping generated high demand for defensive, durable, and visually attractive packing. It provides superior cushioning as well as durability at a lesser charge, vital for shielding delicate products such as electronics and food at the time of transportation. Its capability to be effortlessly thermoformed into tradition form and its compatibility with branding and printing manufactured it a go-to for stores. It offers a hygienic space, printability, and consistent color, important for food facility and customers goods branding.

The consumer goods segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to its protective properties and versatility in packaging. The huge development in online shopping generated necessity for strong packaging to safeguard goods during transportation. Its superior cushioning, moisture barrier, and capability to protect damage make it ideal for subtle consumer goods, confirming product quality. It is utilized from food trays, blister packs, household products, to cosmetic containers, consisting of a huge spectrum of customer needs.

The food and beverage segment dominated the market with highest share in 2025 due to its potential of enhancing shelf life. It offers a strong resistance, shielding food from spoilage and pollution, encompassing shelf life, an important aspect with enhanced food safety concern. Increasing ingestion of ready-to-eat products, frozen food items, and snacks straight enhances the demand for ideal packaging. It provides a robust presentation at a lesser charge compared to exclusive plastics which is manufacturing it an appealing choice for mass food packaging.

The healthcare segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to its high impact resistance and durability. It provides an important balance of goods that are extremely appreciated in medical equipment. Rising worldwide demand for dependable, sterile, and cost-operative medical packaging choices. It requires consistent, superior-quality materials to ensure goods integrity and patient security. This type of films and sheets offering a cost-operative choices without negotiating on crucial performance needs.

Asia Pacific held the largest share in the market share in 2024, due to rapid urbanization and construction. Escalating cities influence demand for these films and sheets in infrastructure and construction projects. An increasing middle class and enhancing disposable earning has raised the consumption of packed products which has enhanced the demand for this sector. Less operational charges and abundant raw resources availability has enhanced the production of these films and sheets. This market is widely used as shielding foam for clamshells, electronics, and food trays.

Presence of huge consumer base has enhanced the demand for market in China. It provides superior strength at a less charge which is making it suitable for huge-volume, cost-delicate goods such as toys, food containers, and appliance liners. It is important for customer electronics, refrigeration, household products, and luxurious packaging. Presence of huge manufacturing industries has also influenced the growth of this market by enhancing production process.

Rapid expansion of packaging sector has driven the demand for the market. It is majorly influenced by influenced by strong demand from the automotive, packaging, and electronics sectors because of its durability, sturdiness, and ease of managing. This is also considered as noteworthy progressions in technology and invention, nurturing a favourable surrounding for innovative usages. It is cost-operative, rigid, one-time use products such as food trays, cups, and plates. Growing customer demand for environment-friendly choices are boosting producers to revolutionize.

Increasing consumer goods and electronics has driven the development of the market in the U.S. Its affordability in comparison of several resources retains it competitive industries. Continuous inventions improving properties and high-speed handing out technologies fuelling efficiency. Strength of these films and sheets supports building elements, with developed in construction schemes offering to enhanced demand. Its affordability in comparison with other resources retains it competitive industries.

The primary factors influencing the growth of market are versatile performance, enhanced packaging performance, improved recyclability options. The development of the e-commerce sector and food delivery platforms has suggestively enhanced the requirement for shielding and insulating packing choices. Companies are introducing transparent recycled films and sheets designed for packaging of direct food which enhance the demand for production process. This packaging it ideal for a wide variety of industries such as construction, automotive, consumer goods and electronics.

Presence of strong industrial base has fuelled the development of market. Strong manufacturing companies need films and sheets for lightweight components, durable, housings, and defensive packaging. Increasing ecological concern and robust guidelines support this market as a recyclable resource, inspiring its utilization in sustainable packing and goods. It provides superior impact barrier, rigidity, and processability, creating it versatile for strong applications.

Middle East & Africa expects the substantial growth in the market. Increasing earnings and healthcare expenses fuel demand for moisture-barrier, compliant packing for food, cosmetics, and pharma. It provides superior protection at a lesser cost than substitute, making it suitable for packaging fragile items. Rising online shopping and cities raised the demand for defensive, tailored packaging for food delivery, electronics, and FMCG.

Rising end-user industry and material advancements are the major reason behind the rapid growth of the market in Saudi Arabia. Quick development in online shopping generates huge demand for packing that saves goods at the time of transportation, it is excellent because of its strength and inclusive barrier. Rising food and beverage, customer goods, and electronics industries need defensive packaging which boost the demand for this market. It provides good printability, affordability, lightweight properties, pattern flexibility, and superior thermoforming potential which is making it suitable for current packaging requirements. It is a key polymer manufacturer, embracing nationwide sustainability aims, and exploiting on increasing customer demand for products.

Strict regulatory environment has influenced the growth of the market in Latin America. Changing guidelines inspire the usage of acquiescent, high-presentation resources, with regional emphasis on local distribution. Customers and producers support this market due to its recyclability, capability to be custom-moulded, and its visual appearance which is making it ideal for advertising displays. It provides a balance of presentation and affordability such properties making it appealing for several applications. Enhanced spending, huge local manufacturing of medical equipment, and firmer quality standards influence demand for dependable HIPS packaging.

Huge economic viability and increasing sustainability focus has raised the demand for market in Colombia. It is inexpensive, providing a balance of value and charge which is making it appealing for huge market usages. Easy handing out through thermoforming and extrusion permits for intricate patterns, while good printability helps in branding. The resource is recyclable, suitable in packaging policies of Colombia encouraging a circular economy existing in plastic packaging. It is highly accepted because of its strength, light weight, ease of moulding to help its mushrooming packaging, customer electronics, and building sectors.

By Product Type

By Application

By End-User Industry

By Region

January 2026

January 2026

January 2026

January 2026