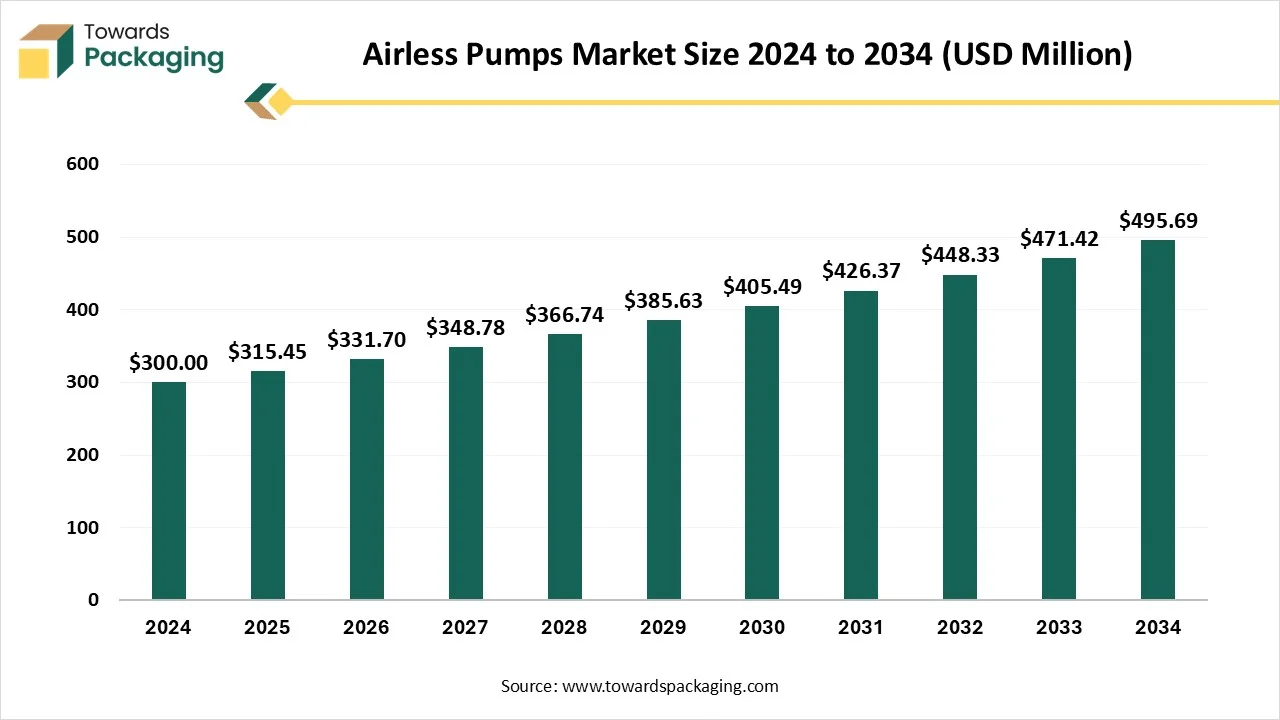

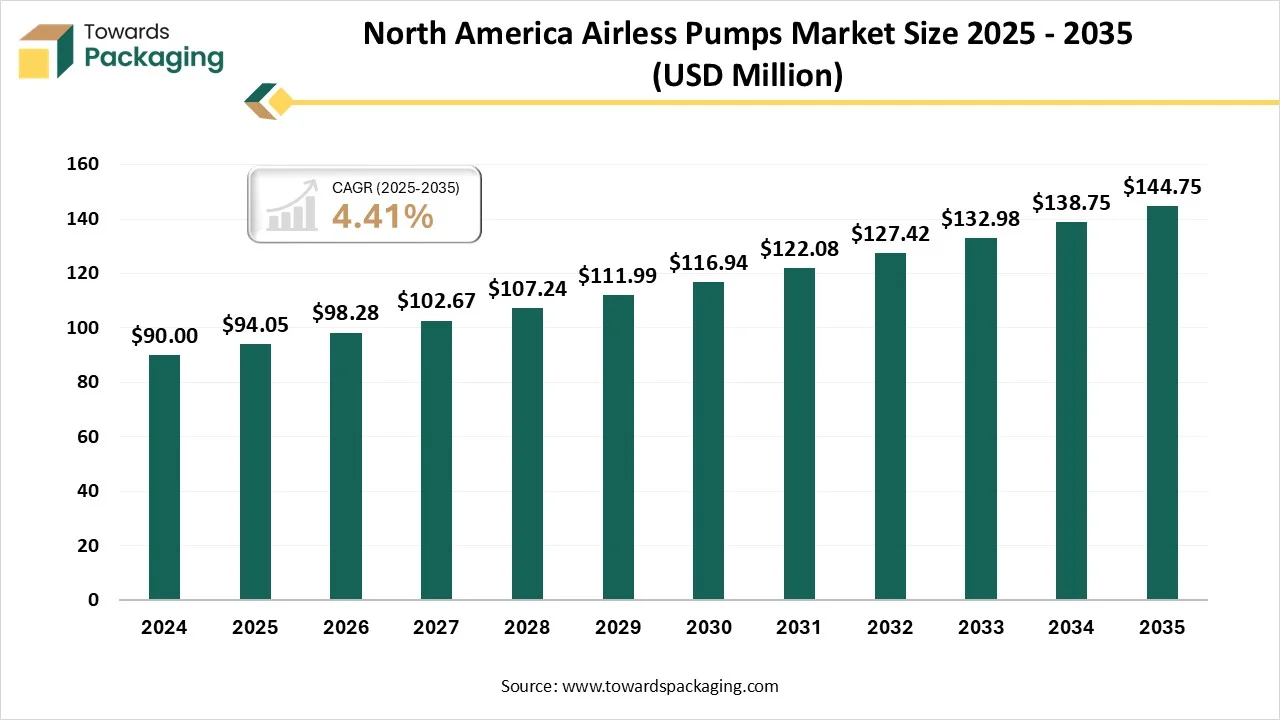

The airless pumps market is expected to increase from USD 331.7 million in 2026 to USD 521.22 million by 2035, growing at a CAGR of 5.15% throughout the forecast period from 2026 to 2035. Market growth is driven by the expansion of cosmetics & personal care, the rise in demand for preservative-free formulations, sustainability trends in packaging, and increasing use in pharmaceuticals and food products.

The airless pumps market refers to non-pressurized dispensing systems that use a mechanical pump instead of air pressure to dispense liquids such as cosmetics, pharmaceuticals, food products, and industrial solutions. Unlike traditional pump systems, airless pumps prevent oxidation, contamination, and product waste, ensuring precise dosing, extended shelf life, and premium packaging appeal.

Airless pump bottles are rising in popularity and are ideal for protecting the product quality by preventing air exposure, which makes them perfect for sensitive formulations. Airless technology creates a vacuum, encouraging the product without letting air get pushed back. These advantages products like serums, natural cosmetics, or creams that weaken fastly when exposed to oxygen.

Cosmetics Industry Drives The Airless Pumps Market

Private label cosmetics are progressively choosing the airless pump bottles because of their reliability in storing the products and being free from pollutants. These containers not only track the smoothness of the ingredient but also assist in expanding the product’s shelf life. With growing urge for skin-safe products and sustainable, several cosmetic companies are accepting the airless bottles for serums, eye creams, lotions, and SPF products too. The integration of longevity, hygiene, and smoothness makes airless bottles a sector favourite. Air exposure causes oxidation that can lower the active ingredient, like retinol, essential oils, and vitamin C, too. So airless packaging prevents these kinds of formulas and stores them potent for a longer period.

The Costs Of The Machine Lack The Airless Pumps

The manufacturing costs of an airless pump can be heavier than those of regular procedures. This denotes that several brands may delay making the transformation and updation. Hence, as technology develops and the urge grows, prices are likely to drop and make it an available option for each person. Also, some brands receive the desired balance between aesthetic appearance and functional airless systems in a competitive industry. Another challenge is the production of sluggish wage development, and downsizing has led to a flight of technical issues that the sector demands too. Several top-tier suppliers are enclosing the space by hiring exterior consultants.

Security And Protection Are The Future Of Airless Pumps

Preserving sensitive skincare compositions from contamination and oxidation is one of the main benefits of airless pumps. Air and light break down several of the active elements in the skincare components, including retinol, peptides, vitamin C and E, and more. Because airless pumps can lower the exposure, the important components are unable to retain their potency and efficacy for the period of the product’s life. The usage of skincare compositions may assist in vanishing the urge for additional preservatives by creating an airtight atmosphere.

Another opportunity in airless pumps is the revolution of airless pumps towards more sustainable options, which shows the main packaging trend in the beauty sector. As research and development in the space develop, growing usage of bio-based and fully recyclable materials, improved recycling infrastructure to handle complicated packaging, and advancements in reusable and refillable airless systems are also expected. With their benefits in product protection and waste reduction, these types of products are a perfect step towards the most sustainable skincare products.

Artificial intelligence allows predictive maintenance by tracking the data from historical records and data to predict when a pump will fail to work. This enables timely tracking, lowering the downtime and protecting against expensive failures. Its algorithm can even update pump performance by adjusting functional elements in real-time, depending on changing conditions. This ensures that pumps run at their highest efficiency, lowering the operational costs and saving energy.

On the other hand, IoT enables remote checking of pump systems. Technicians can make available actual time and diagnose problems without actually being present on the website, making the maintenance more organized and lowering the feedback time period. Furthermore, smart compressors utilise the data-driven insights in order to update their performance, further lowering the Energy consumption and developing the overall efficiency. Real-time monitoring makes sure that the compressor is always running at its peak performance.

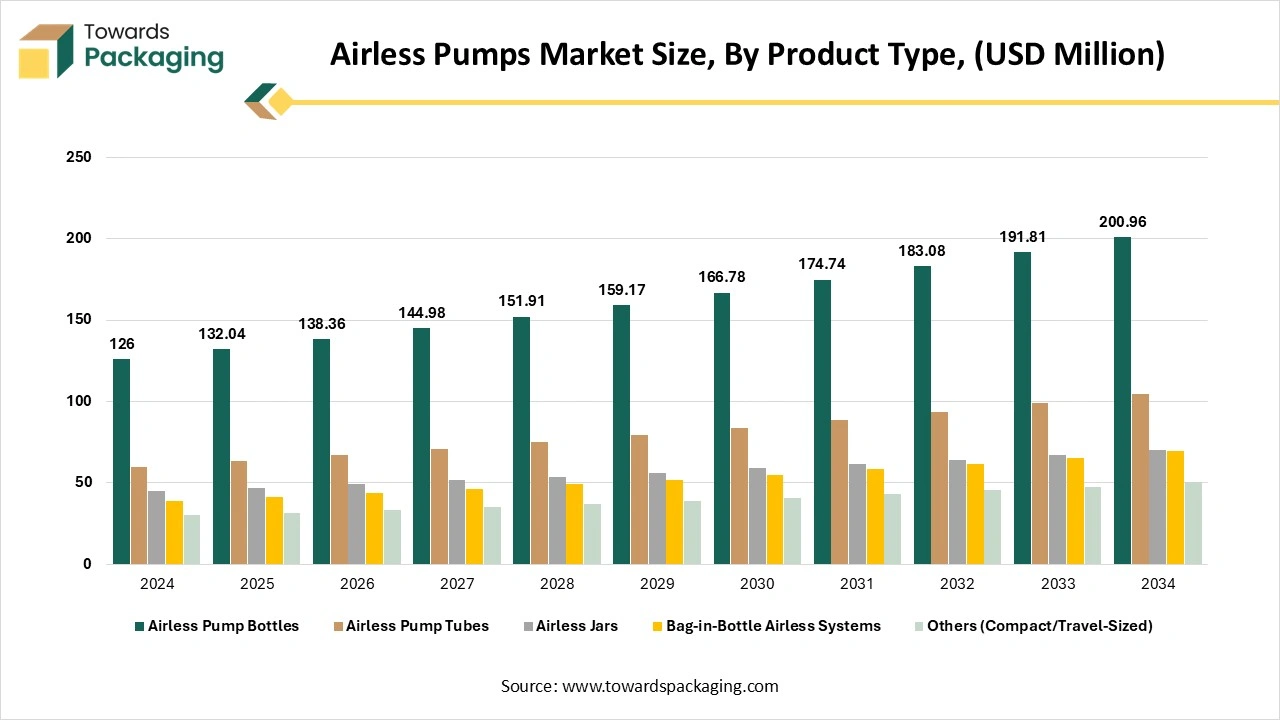

The airless pump bottles segment dominated the airless pumps market in 2024 as airless pump bottles are the kind of packaging solution that uses a vacuum mechanism to lower the air exposure, preventing the deterioration and oxidation, which directly expands the shelf life of the bottle. They deliver hygienic dispensing to avoid pollutants and enable accurate control of the amount needed, lowering the waste. Airless pump bottles have a current aesthetic and are extensively used for different uses and applications. It utilises the disc or piston which moves inside the bottle to dispense the product. Whenever the pump is being pressed, the piston shifts in an upward direction, creating a vacuum which attracts the product up from the very bottom of the container.

The bag-in-bottle airless systems are predicted to be the fastest in the market during the forecast period. Bag-in-bottle airless systems in the airless pumps market are gaining attention due to their potential to serve precise dosing, maximum product evacuation, and rigid protection against contamination. These kinds of systems utilise a flexible inner bag housed inside a strong outer bottle, making sure that the product is being dispensed without the air entering, which assists in maintaining the freshness, integrity, and shelf life of sensitive formulations like pharmaceuticals, cosmetics, and skincare products.

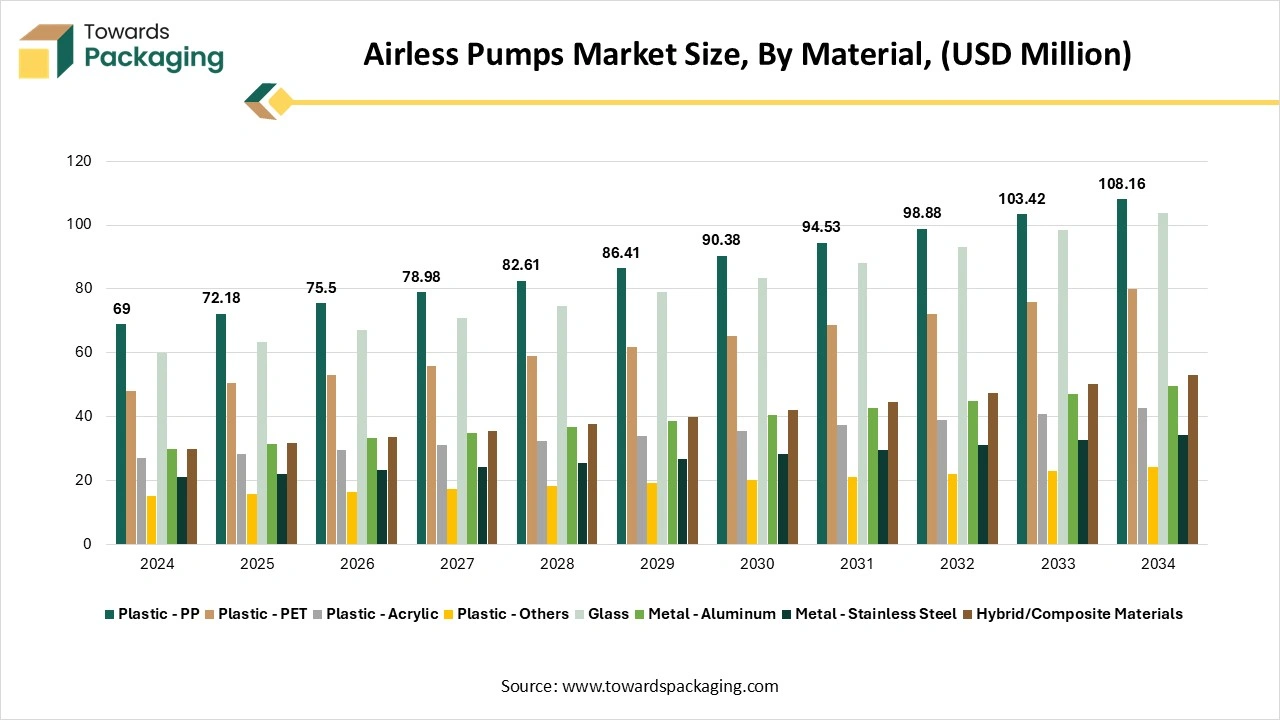

The plastic segment dominated the airless pumps market in 2024 as airless polypropylene packaging is perfectly suited for products that combine active ingredients sensitive to light and air, such as sunscreens, serums, and anti-ageing creams. Also, airless bottles and jars display an innovative solution for packaging, serving excellent product protection, lower waste, and a modern design too. While the costs can be higher, the benefit of maintaining the product integrity and serving accurate dispensing can exceed the starting investment, particularly for luxury brands. As invention and sustainability continue to update the packaging sector, airless packaging is likely to stay a popular choice for skin care products and high-end cosmetics, too.

The hybrid/composite materials segment is predicted to be the fastest in the market during the forecast period. This type of material in airless pumps is merging as innovative solutions to balance power, lightweight design, and sustainability. By combining plastics, metals, or bio-based composites, these pumps achieve higher durability, chemical resistance, and aesthetic appearance while lowering the overall material usage. Hybrid designs also develop precision dispensing, recyclability, and cost-efficiency, making them attention-grabbing for skincare, cosmetics, and pharmaceuticals applications.

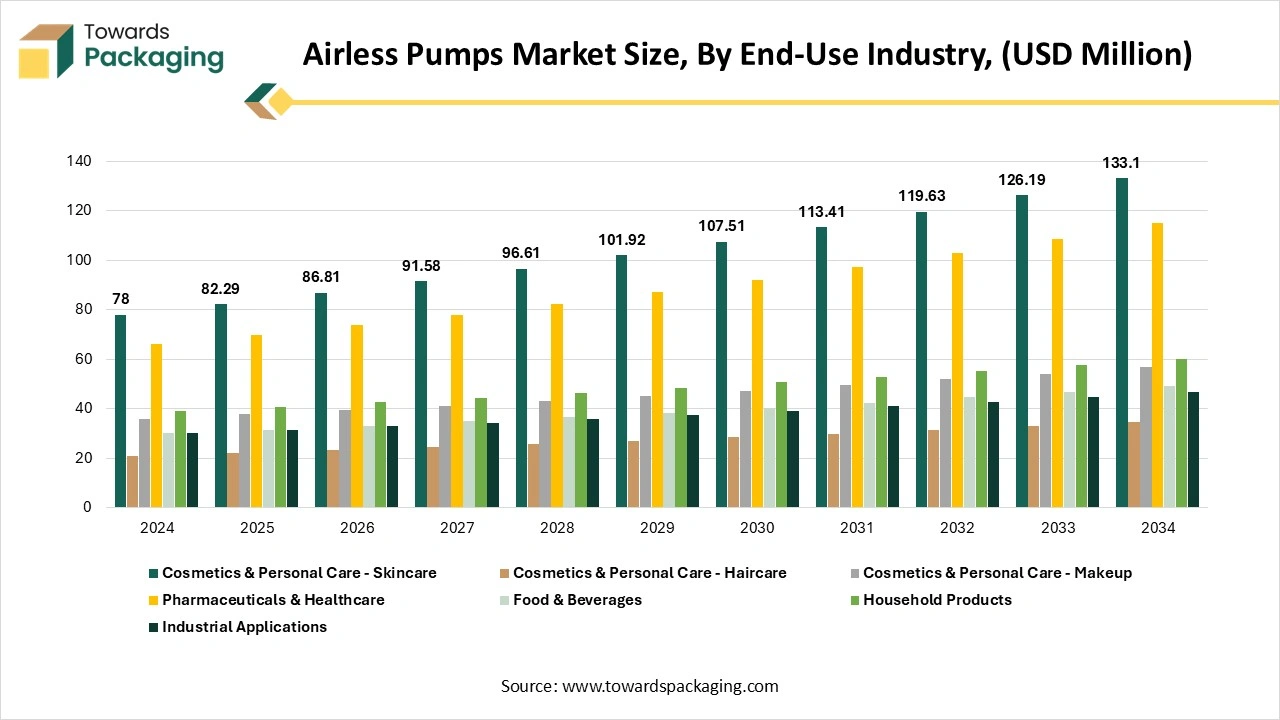

The cosmetics and personal care segment dominated the airless pumps market in 2024, as airless cosmetic and personal care packaging avoids oxygen from penetrating the cosmetic substance found in the packaging. It can expand the shelf life of the product by 15%. Airless containers consist of a small plate. Wherever it is being pressed by a pump, the plate comes out upwards. The given action encourages the substance conveniently to the top. In cosmetic packaging inventions, airless pump bottles have played an innovative role. It assists in protecting the skincare creams, serums, and foundations, and by preserving the air exposure to every container, including any substance. The high-level technology included in the airless pump bottles includes a diaphragm. It enables the substance utilised to maximise the level without anything left in it.

The pharmaceutical and healthcare segment is predicted to be the fastest in the market during the forecast period. There are several advantages for the pharmaceutical companies that select the airless pump systems. The durable dispensing systems protect the skin treatment product from pollutants and damage caused by both light and air, with the assistance of a complete product lifecycle. It delivers accurate dispensing, lowers the waste of expensive products, and the emptied dispensing system is more conveniently recycled by the user.

With a variety of actuators present in the market, airless pump systems can serve pharmaceutical companies with both brand and product classification in terms of the competitive skin treatment industry. Also, the airless semi-solid dispensing systems serve relevant and safe metered dispensing of several skin medication types while protecting them from air exposure. This type of system is perfect for protecting serums, gels, and lotion products as well as serving accurate skin treatment dosing of different consistencies.

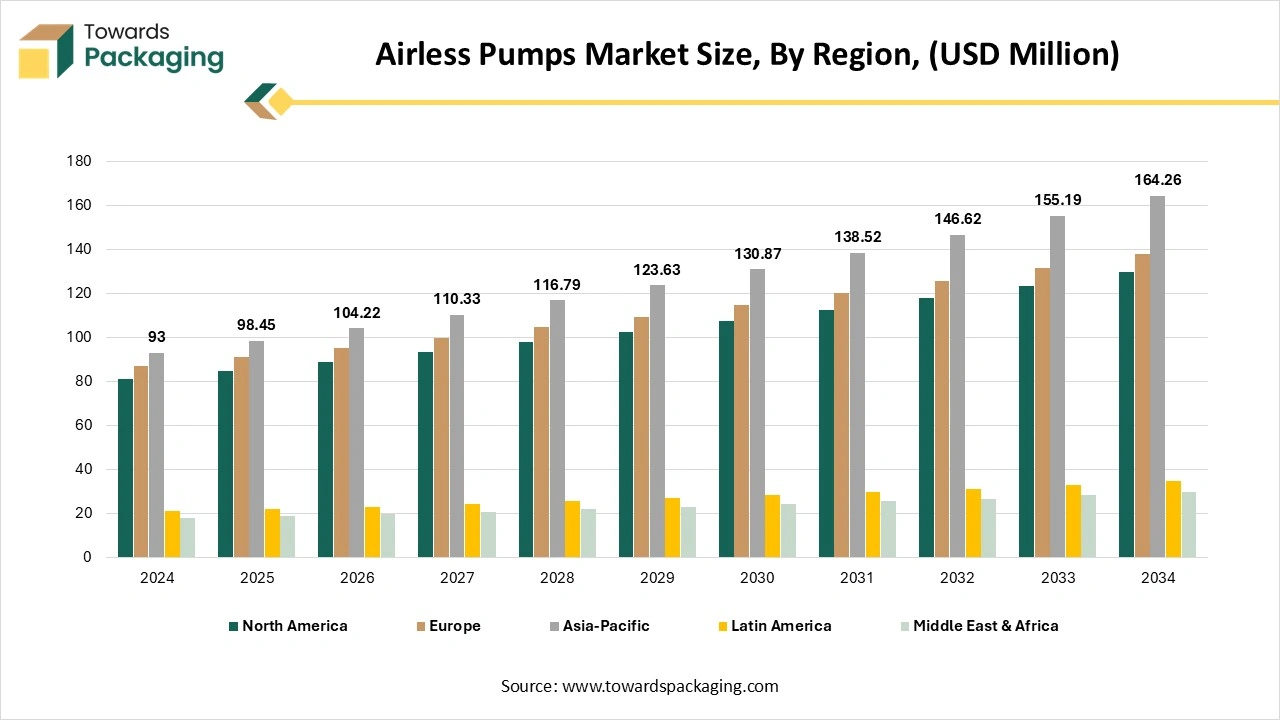

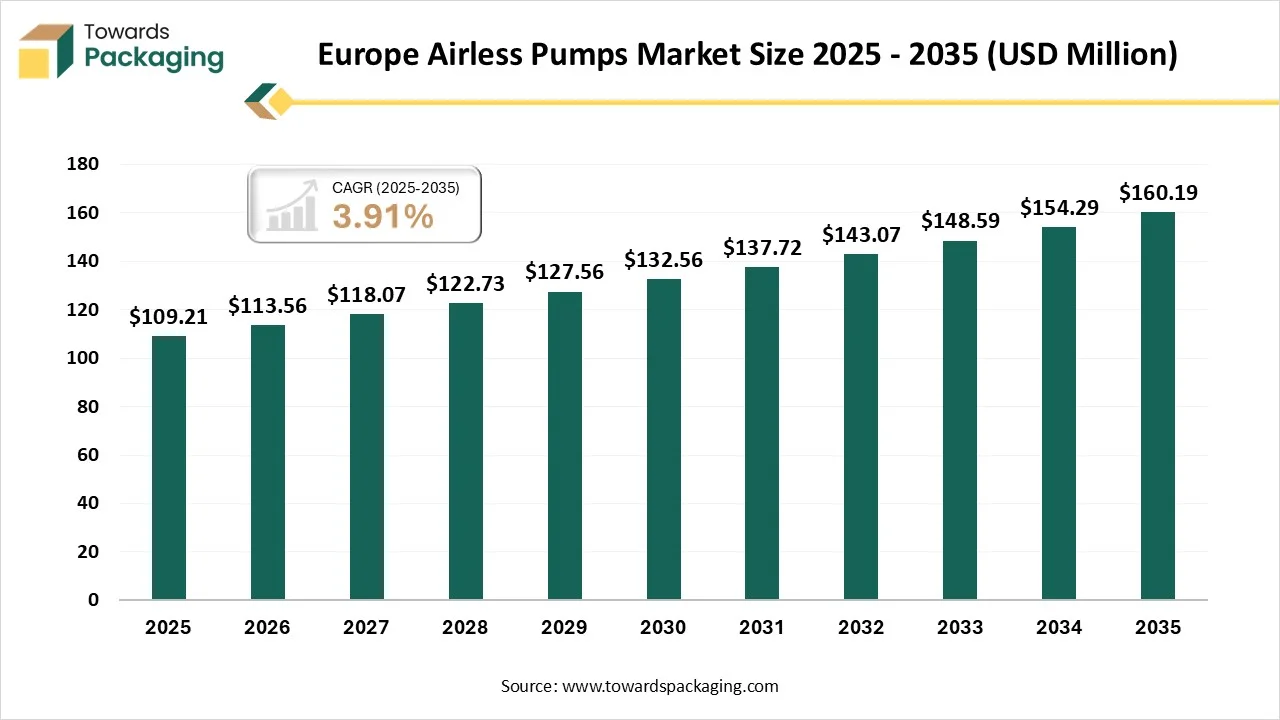

Europe dominated the airless pumps market in 2024, as one of the main reasons why shoppers appreciate buying airless pumps in skincare is that it has the potential to serve superior protection to their products. Regular packaging, such as tubes and jars, often exposes the product to light and air, which leads to oxidation, decreased effectiveness, and pollutants, too. With airless skincare packaging, the vacuum-sealed system ensures that the product stays airtight and is allocated without any discovery of external characteristics, which maintains its integrity and quality too. Additionally, airless packaging lowers the risk of contamination by preventing bacteria from penetrating the container. This is specifically crucial for products such as creams and lotions, which are applied directly to the skin.

Lumson is one of the best cosmetic packaging companies in Europe, which integrates fresh design ideas with green thinking. This company concentrates on airless glass bottles, tight-sealing closures, and refillable systems that give skincare, and beauty brands the high-quality packs they demand. This integration of good appearance and leak-proof protection actually matters for fragile or premium lines.

Asia Pacific is expected to be the fastest-growing region during the forecast period. In the region, the airless pumps market is growing rapidly, mainly due to the booming cosmetics, skincare, and pharmaceutical sectors. Rising disposable incomes, increasing urbanization, and a growing middle class are pushing demand for premium, hygienic, and contamination-free packaging. Countries such as China, India, Japan, and South Korea are in demand and production -China especially carries the biggest share in the region. Producers are scaling up local manufacturing of airless pump systems to meet domestic demand and export them. Invention in materials, increased e-commerce penetration, and user choice for longer shelf life have invested significantly.

The Regulations And Compliance Of The Airless Pumps Market Are As Follows

By Product Type

By Material

By End-Use Industry

By Region

January 2026

January 2026

January 2026

January 2026