Generative AI in Packaging Market Growth Forecast, Regional Breakdown, Value Chain and Manufacturer Insights With Key Statistics

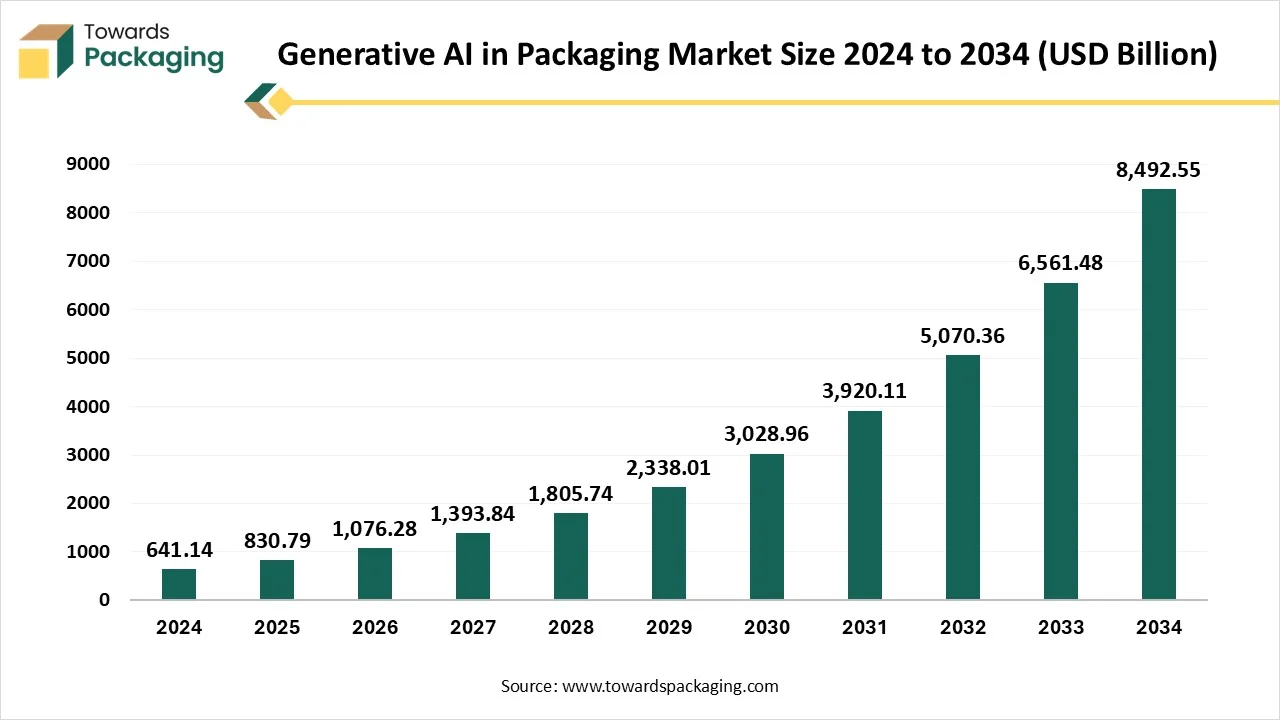

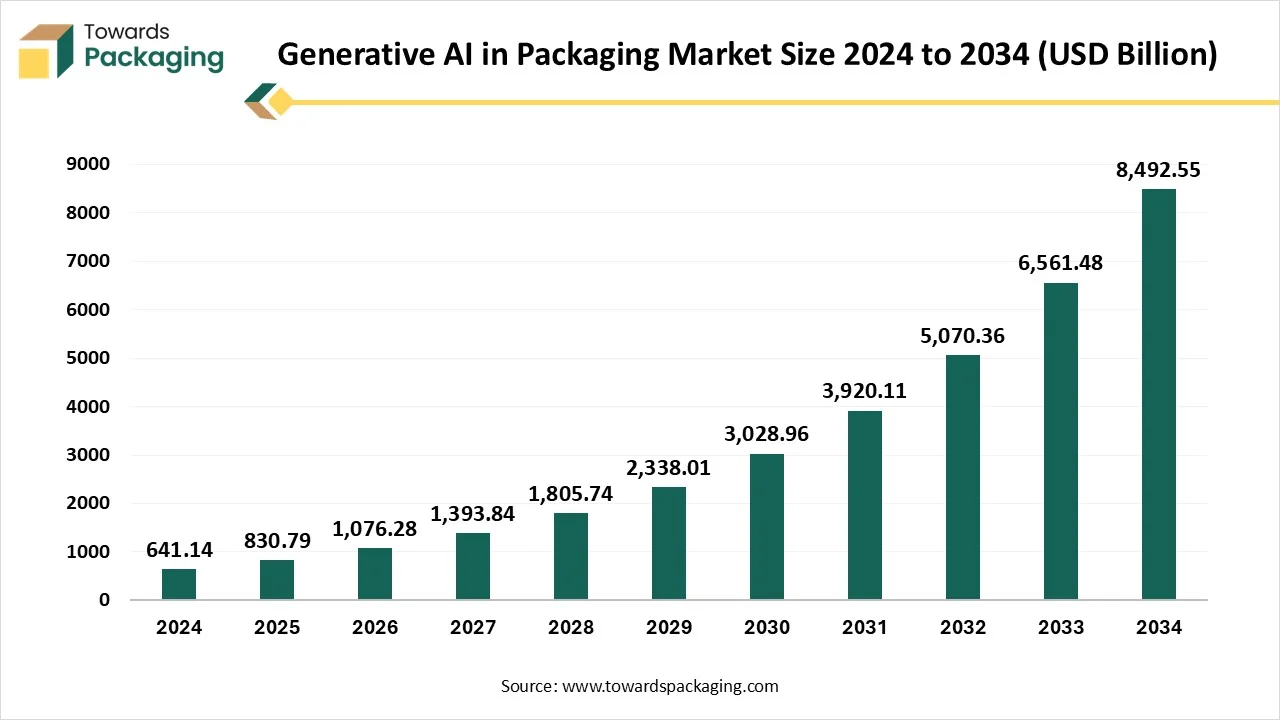

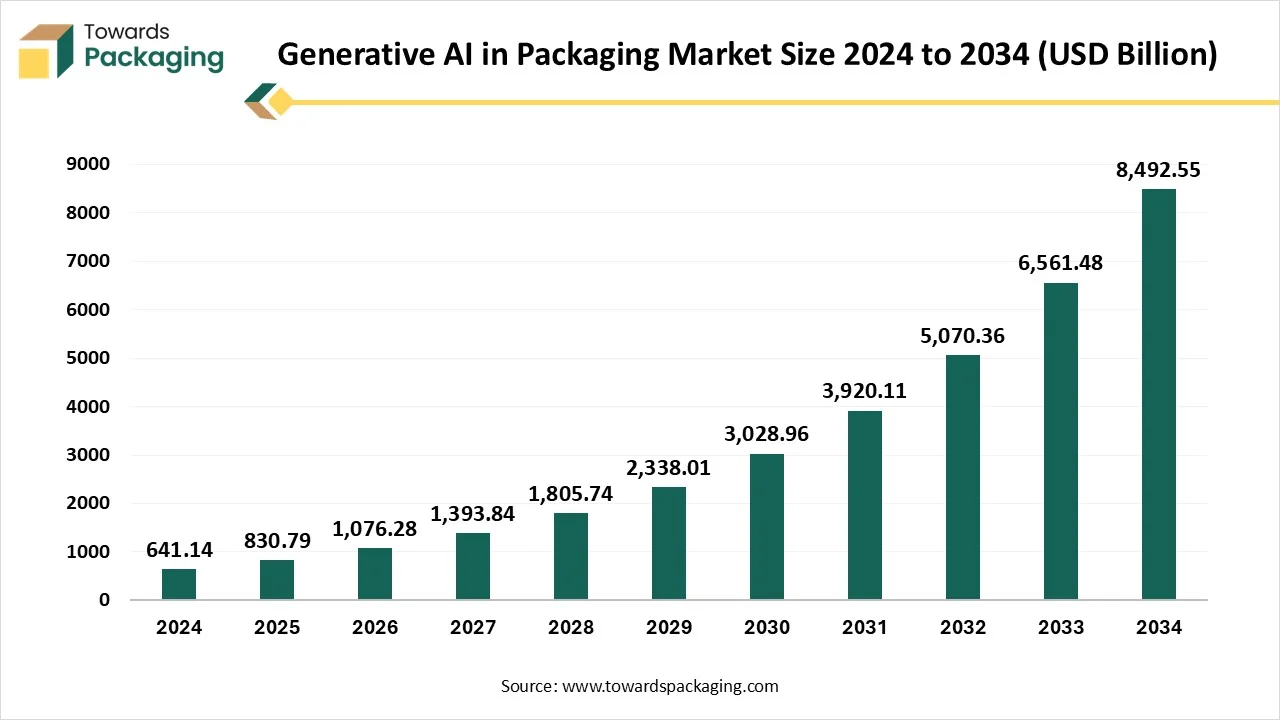

The generative AI in packaging market is forecasted to expand from USD 1,076.54 billion in 2026 to USD 11,088.44 billion by 2035, growing at a CAGR of 29.58% from 2026 to 2035. This market covers evolving trends such as automated packaging design, personalization, AI-powered simulations, predictive maintenance and logistics optimization. It includes a detailed segmentation by technology, application, deployment mode, and industry verticals like CPG, e-commerce, F&B, cosmetics, and pharmaceuticals. The report provides complete regional insights across North America (leading region), Europe, Asia Pacific (fastest growth), Latin America, and Middle East & Africa.

North America leads the generative AI in the packaging market. Generative design AI dominates by updating design procedures, with AI-powered simulation growing fast. Automated packaging design is the top use, while personalization is the fastest-growing. Cloud-based deployment tops because of its scalability, while on-premises deployment develops steadily for localized control. Consumer packaged goods dominate end-use, and e-commerce is the fastest growing, driven by real-time, AI-driven personalization.

Key Takeaways

- In terms of revenue, the market is valued at USD 830.79 billion in 2025.

- The market is projected to reach USD 11,088.44 billion by 2035.

- Rapid growth at a CAGR of 29.58% will be observed in the period between 2025 and 2034.

- North America dominates the global generative AI in packaging market.

- Asia Pacific is expected to host the fastest-growing market in the coming years.

- By technology, the generative design AI segment dominated the market in 2024.

- By technology, the AI-powered simulation and testing segment will grow at a significant CAGR between 2025 and 2034.

- By application, the automated packaging design segment dominated the market in 2024.

- By application, the personalization segment will grow at a significant CAGR between 2025 and 2034.

- By deployment mode, the cloud-based segment held the largest revenue share in 2024.

- By deployment mode, the on-premises segment will grow at a significant CAGR between 2025 and 2034.

- By end-use industry, consumer packaged goods will dominate the market in 2024.

- By end-user industry, the e-commerce segment will grow at a significant CAGR between 2025 and 2034.

The Packaging Industry Revolutionised with the Power of Generative AI

Generative AI includes machine learning algorithms to make realistic and coherent results based on raw data and training data. Generative AI models can include generative adversarial networks (GANs), recurrent neural networks, and diffusion models, among others. These models utilize large language models (LLMs) and natural language processing to create unique results, with uses ranging from image and video synthesis to speech and text generation.

The usage of generative models and machine learning models in packaging and e-commerce is becoming increasingly popular, with several businesses using generative AI tools to automate business functions such as product recommendations, order processing, and chatbots. These kinds of AI technologies assist in streamlining business procedures by reducing human labor, improving effectiveness, and enhancing customer experience by tailoring content and suggestions. Generative AI technology can develop search potential on e-commerce platforms, utilizing voice assistants and creating chatbots that can mimic natural language.

Key Metrics and Overview

| Metric |

Details |

| Market Size in 2025 |

USD 830.79 Billion |

| Projected Market Size in 2035 |

USD 11,088.44 Billion |

| CAGR (2026 - 2035) |

29.58% |

| Leading Region |

North America |

| Market Segmentation |

By Technology, By Application, By Deployment Mode, By End-Use Industry and By Region |

| Top Key Players |

OpenAI, Adobe Inc, Microsoft, Amazon, Canva, GE Digital, PackageX, Neurala |

What are the New Trends in the Generative AI in Packaging Market?

- Design and prototyping: AI is transforming the way packaging is crafted. Generative design algorithms can quickly create hundreds of capable packaging designs based on specified parameters like material constraints, product dimensions, aesthetic preferences, and cost targets. This drastically grows the design process, enabling companies to discover a huge range of options that would be possible with regular methods.

- Production and manufacturing: AI can examine real-time data from production machinery to identify optimal settings for temperature, speed, pressure, and other elements. This leads to grown throughput, fewer defects, and reduced energy consumption. AI-powered vision systems can detect packages for defects like incorrect labeling, misprints, or harm with far greater speed and precision than human inspectors. This makes sure that only good-quality packages reach users.

- Supply chain and logistics: AI algorithms can detect market trends, historical sales data, and other elements to predict future demand for packaging materials. This assists companies in updating inventory levels, avoiding stockouts, and reducing waste. AI-powered systems can update warehouse layout and inventory tracking, reducing storage costs and improving efficiency.

- Sustainability: AI can help organizations choose the most sustainable packaging materials depending on factors like biodegradability, recyclability, and carbon footprint. It can even optimize packaging design to lower material waste. Its AI-powered filtering system can improve the effectiveness of recycling facilities, allowing for more precision and efficient separation of several types of packaging materials.

Smart Packaging Starts with Generative AI Innovation

Generative AI is cutting-edge technology that utilizes high-level algorithms to design, create, and optimize the latest content by gaining patterns from huge data. Different from regular AI, it can simply examine current information, generative AI in packaging and paper can generate completely new results, from images to text, to generate designs and update paper solutions while constantly improving and learning from results and feedback.

From the design point of view, AI checks out package designs to make sure that they’re actually produced and no one wants another perfect design, which is not possible. In production, the continuous effectiveness expert tracks every pump, roller, and valve in the paper industry. As consumer behaviors and regulatory scenarios develop, the packaging industry faces a strange pressure to invent. E-commerce development has created a demand for a smart packaging sector that updates shipping effectiveness and ensures product protection.

Market Dynamics

Driver

Smarter Packaging, Greener Future

AI grows effectiveness and productivity by lowering human issues and reducing waste. In custom packaging, AI reveals infinite possibilities for invention and personalization to update both branding and customer experience. It also plays an important role in sustainability, assisting businesses to examine eco-friendly materials, update procurement, and simplify logistics to cut down on waste and environmental effects. Packaging designers are utilizing AI Tools like Midjourney to refine a good-quality packaging network in seconds. In seconds, at the same time, platforms like Pandora can immediately create structural designs that include 3D mockups, also refining the design procedure.

Restraint

To Lead with GenAI, Companies Must Modernize Within

As compared to the last technological moves like cloud computing or the internet, companies are specifically less prepared for generative AI. Implementing generative AI needs IT Leaders to build standard, multi-layered technology loads. Even the straightforward generative AI solution includes assembling 20 to 30 different components. These elements include data enrichment tools, a user interface, access controls and security protocols, and an API secret to connect with foundational models.

Mechanizing tasks like model testing and validation is important to completely unlock the capability of Generative AI. On the other hand, challenges lie in flawlessly combining GenAI tools with the current company IT structure, specifically legacy systems. However, organizations' mainframes carry huge amounts of insightful data that can be used to train AI models. Mainframes play an important role in driving AI advancement.

Opportunity

Generative AI Makes Personalized Packaging Scalable

Generative AI is a term for large-scale design personalization. Product packaging that is crafted to every customer’s taste makes them feel truly delighted. These AI capabilities allow not only personalization but also effective scaling, whether or not it’s a tailored product with a limited ongoing period and personalized packaging or a different design depending on customer data. Generative AI can specifically shorten the time needed to go from generation to market and reorganize the design procedure.

The AI programs assist us in quickly generating and updating packaging designs, which allows us to fulfill market expectations without sacrificing creativity and quality. Generative AI can assess huge amounts of data to drive your design selection, to make sure that packaging is not only online attractive but also functional. With these insights, one can make packaging that connects with the focused audience and provides improved results.

Segmental Insights

AI Tools Dominates the Market in 2024

AI tools can be heavily utilized which is utilized to optimize and automate the design procedure. Regularly, packaging designers can create prototypes and verify designs, which could take weeks or even months. With the assistance of Artificial Intelligence, designers can now utilize machine learning and algorithm models to quickly generate several design options, make real-time adjustments, and evaluate their feasibility. AI can assist designers in making packaging that meets both aesthetic and functional needs. Generative AI tools, linked with AI, allow machines to make design solutions that are not created by human designers. These AI-driven designs are most inventive, effective, and lightweight, which leads to perfect material use and reduced wastage.

AI-powered simulations forecast how a box will generate under particular conditions, considering factors like impact resistance, weight distribution, and stacking stability. These insights enable designers to make boxes that are not only durable but also more cost-efficient. Simulation enables us to move beyond basic tests and towards a wiser, more subtle understanding of packaging performance. Regularly, shipping integrity has been measured with the assistance of limited physical testing. But simulation integrates with multimodal artificial intelligence that serves a new level of insight.

Why Did the Automated Packaging Design Dominate the Generative AI in Packaging Market?

The automated packaging design segment leads the market as regular packaging optimization methods do not completely use the data available to develop sustainability, maximize brand appeal, and reduce costs. Packaging design and optimization heavily depend on human processes. While developing the packaging, designers and engineers utilized physical objects and created several iterations to get the essential functional and aesthetic outcomes. This procedure was often time-consuming, costly, and lacked flexibility. It also has an urge for substrate materials, manufacturability, and product distribution, which makes it hard for companies to update their design. Furthermore, regular packaging optimization procedures did not fully use the data available to improve brand appeal. Automation was mainly limited to basic work like labeling, filling machines, and material handling.

AI examines huge amounts of consumer data to predict behaviors and preferences. Thai enables brands to serve personalized promotions, suggestions, and content to create a more meaningful link with consumers. Scanning a QR Code on a package and receiving a personalized welcome, or compiling product suggestions based on past purchases. AI makes this conversation engaging and smooth. Smart packaging linked by AI can be accepted in real time. For instance, it can show different messages or offers depending on the time of location, day, or user choices. For instance, a beverage company uses AI to craft unique packaging that matches a particular demographic. Or a snack produced could twist flavors based on actual consumer feedback.

Why Does the Cloud-Based Segment Dominate the Generative AI in Packaging Market?

Cloud-based solutions dominate the market as they play a complicated role in assisting packaging companies to overcome the above limitations. By automating repetitive tasks, such as production workflows, prepress procedures, and job delivery between teams, organizations can reorganize operations and reduce the probability of human issues. This not only grows productivity but also develops accuracy and consistency across the manufacturing line and reduces the time to market. Furthermore, automation allows companies to scale their operations without the need for a specific increase in labor, developing efficiency, and making it easier for small businesses to develop and compete.

On-premises databases are a kind of data storage solution where the software, infrastructure, and hardware are maintained and hosted in the physical location of the business. All infrastructure characteristics and data on an on-premise database are under the control of the subscribing organizations. In contrast to cloud databases, on-premises databases allow organizations to completely accept the software and hardware depending on their particular operational needs. Hence, they are perfect for multifaceted uses and older systems. Conventional schemes demand costly pre-implementation software and hardware license costs and constant provision for repair, IT Personnel, and development of systems. On-premise databases enable complete control over data and infrastructure. Companies can change and manage each aspect of their database environment themselves and form a structure to access policies without depending on third-party services. Organizations need close management and this level of control.

Which End-User Dominated the Generative AI in Packaging Market in 2024?

The consumer-packaged goods (CPG) dominated the market. From worldwide enterprises to small startups, organizations are realizing the groundbreaking potential of AI and machine learning to change how they operate. Generative AI assists businesses in inventing quickly by examining large datasets on consumer choices and industry trends. For instance, a top consumer packaged goods (CPG) Company developed an internal AI platform to rechange its strategy to product invention. This tool intensified new product creation by quickly examining elements such as packaging, ingredients, and evolving consumer tastes.

By utilizing generative AI algorithms to make real-time, dynamic web content that engages customers in a different and optimized shopping experience, e-commerce companies will see greater engagement, increase conversions, and develop brand loyalty. It also enables businesses to examine customer data such as browsing patterns, buying history, and other main demographic information to create tailored suggestions and target offers to fly. This means that users are offered content that is perfect for them and their interests, which makes the shopping experience far more satisfying and engaging. Generative AI utilizes a variety of tailored software and algorithms to analyze, collect, and interpret data collected from buying behaviors and customer interactions.

- On 30 May 2025, BigGo, which is a Taiwan-based provider of search engine and price comparison technology, aims to expand its services by developing two generative AI-based products. By cooperation, these products could automate product descriptions and create new stories for retail businesses and e-commerce, too.

By Region

North America

Both disruptive and structural forces are enhancing North America’s packaging scenario. Even while the conditions for a capable tipping point leading to a more circular, lesser-impact packaging industry are quietly coming together, sustainability is growing further on the C-suite agenda. On the other hand, organizations can choose reactive strategies that double down on legacy substrates and short-term cost containment. On the other hand, they can choose proactive moves to build resilience, invest in inventions, and prepare for the likely long-term move toward sustainability that could reshape the market in the years to come.

Asia Pacific

Asia Pacific has registered notable development in embracing AI, with organizations leveraging AI and Machine learning in their business operations. With respect to Artificial Intelligence acceptance, South East Asia's Acceptance, of Asia Pacific share is somewhat higher than the overall Asia Pacific share (18%) in terms of businesses that have implemented AI and machine learning at a high level. Forerunners China and India are utilizing Gen AI to update sectors and develop talent. Some of the world's most effective technology is coming out of the region, as China’s Deepseek will eventually speed up the growth and lower the cost of training open-source large language models.

Top Companies in the Generative AI in Packaging Market

Latest Industry Leader Announcements

- On 18 June 2024, Hewlett Packard Enterprise (HP) and NVIDIA disclosed that NVIDIA AI Computing by HPE, a profile of co-developed AI Solutions and joint go-to-market integrations that allow enterprises to grow acceptance of generative AI.

- On 22 June 2024, Kraft Heinz created an internal generative AI whose goal is to serve employees with fast insights into different aspects of the business, such as supply chain dynamics and product sales. Helen Davis, SVP and Head of North America Operations, describes KraftGPT tools, which enable employees to ask questions like “Why are we selling so much bacon?”

Recent Developments

- On 11 June 2025, L’Oréal Groupe and Nvidia disclosed a new AI partnership at VivaTech, which is Europe’s biggest tech show. This collaboration enables new inventions, starting with Noli, a first-of-its-kind, AI-powered multi-brand beauty marketplace founded by L’Oréal.

- On 9 October 2024, Specright today revealed the latest AI Features within its Specifications Data Management platform, which includes a chatbot and smart document processing, changing how supply chain professionals digitize and interact with complicated packaging data and products.

- On 8 August 2024, Diageo brand Johnie Walker is inviting visitors to its Edinburgh, Scotland, Prince Street View place to participate in a generative AI-powered experience that lets them co-craft a personalized bottle of top-shelf Johnny Walker Blue Label Whisky.

- On 20 May 2025, Red Hat revealed that Red Hat Enterprise Linux 10 has the latest edition of the company’s distribution of the famous Linux operating systems with new potential that the organization says aligns with the demands of today’s hybrid cloud environment and AI Systems and protects against the cybersecurity threat of the future.

Generative AI in Packaging Market Segments

By Technology

- Generative Design AI

- Computer Vision

- Natural Language Processing

- AI-Powered Simulation and Testing

By Application

- Automated Packaging Design

- Material Optimization

- Personalization and segmentation of one

- Predictive Maintenance and Quality Control

- Supply Chain and Logistics Optimization

By Deployment Mode

By End-Use Industry

- Consumer Packaged Goods

- E-Commerce

- Food and Beverage

- Pharmaceuticals

- Cosmetics and Personal Care

- Others

By Region

- North America

- Europe

- Latin America

- Asia Pacific

- Middle East and Africa