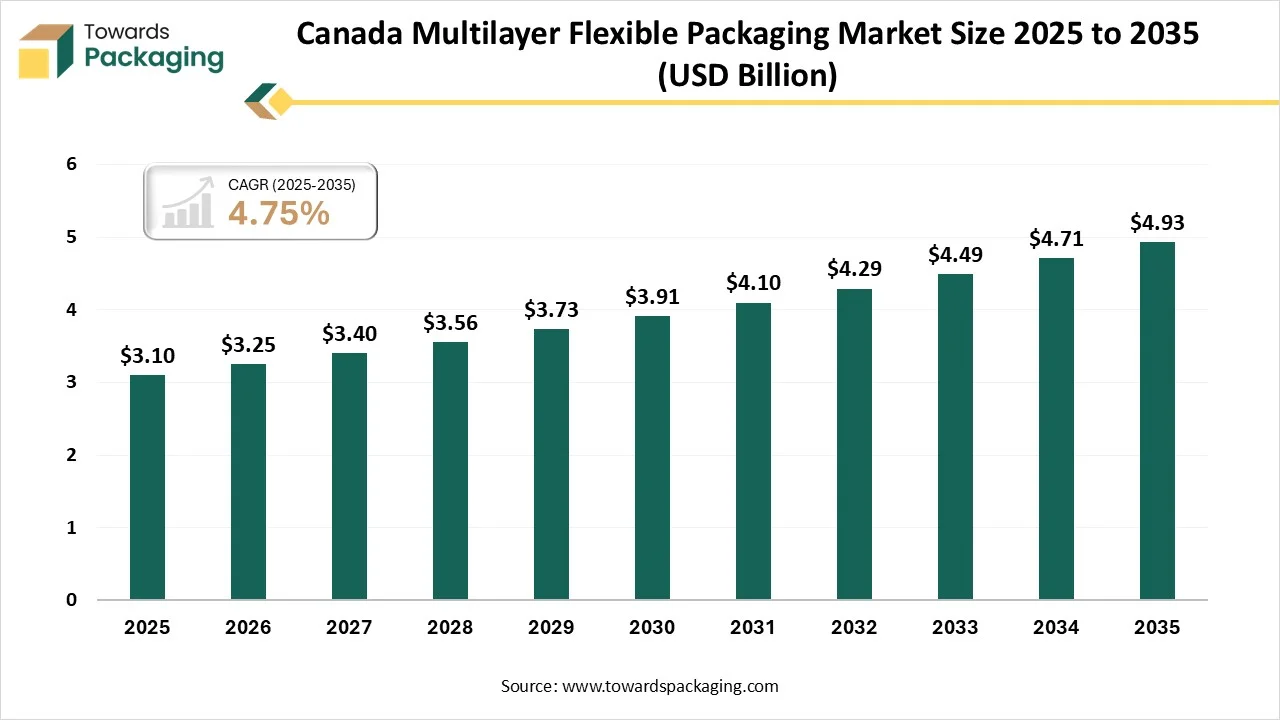

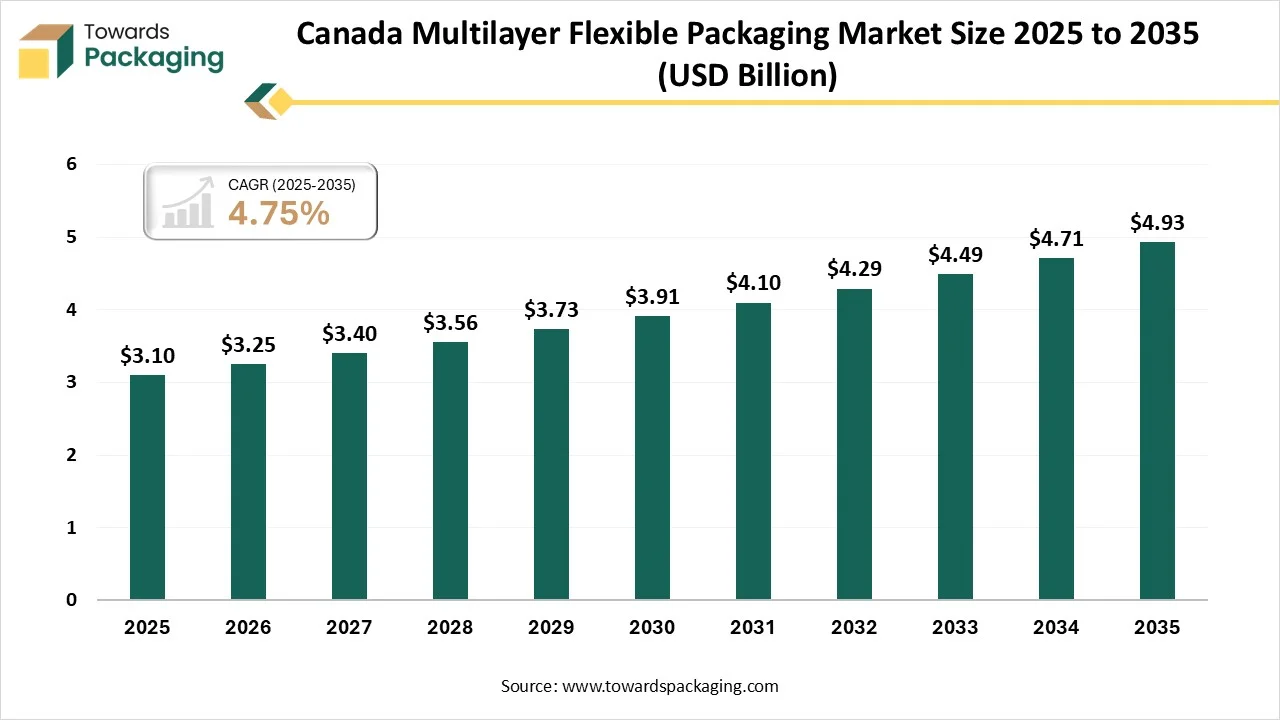

The Canada multilayer flexible packaging market is forecasted to expand from USD 3.25 billion in 2026 to USD 4.93 billion by 2035, growing at a CAGR of 4.75% from 2026 to 2035. The demand in well-settled e-commerce and retail distribution is developing the demand for packaging that can withstand various stress and temperature conditions surrounding it.

The multi-layer flexible packaging is becoming the peak choice for organizations that find solutions that serve exceptional prevention and a stretched shelf life. By integrating various materials such as PP, PET, and PE, aluminum foil, and others, laminated films provide an exact barrier against oxygen, light, and moisture. This is the reason why such packaging lines are excessively famous across different industries, including chemicals, food, fashion, cosmetics, and FMCG. Multi-layer packaging is the actual future of packaging solutions.

Multilayer flexible packaging producers are dedicated to checking compostable and biodegradable flexible packaging. Such materials are hoped to decompose after discovery under eco-friendly conditions, and this is a strategy to lower the landfill wastage. Despite the current uses which are constantly confined to a particular kind of product or the geographical space, they symbolize a main achievement on the current path to packaging invention and its match with the global sustainability goal.

Developments in technology are stimulating the encouragement of the complete process of generating flexible packaging. Supervised printing procedures, and energy-efficient production lowers the cost of manufacturing without compromising quality.

Food and Beverage uses in both retail and institutional is being recorder by 60% applications for the growing demand of convenience food and snacks in small or large-sized sections that has developed the fund on cereal bars and bakery products and lastly for the short-run fun foods.

Stand-up pouches have become one of the most selected flexible packaging products which links to features and versatility like high barrier materials against oxygen and moisture with less material consumption and lastly with cost-effectiveness nature.

Flexible Packaging is one of the main elements projected to experience main development over the future years that connects to developing middle-class populations and growing disposable incomes.

Package Design and Prototyping: Design for advanced separation technology and recyclability are two capable ideas that are closely tied to further multilayer plastic recycling. Brand owners in a circular globe are moving to the making of packaging with complete mono-material laminates, as the complete packaging has only one kind of polymer as a foundation in terms of PP or PE.

Recycling and Waste Management: The prevalent types of multi-layer composites, such as paper-plastic combinations, integrate the structural pattern of paper that has chemical opposition and moisture of plastics like polypropylene or polyethylene. They are widely used in dry goods and liquid cartons because of their durable and lightweight nature. Regardless of the advantages. Classifying the paper from plastic during the recycling period remains labor-intensive.

Logistics and Distribution. The supply chain systems of the current scenario need effective, cost-effective, and adaptable solutions that range to meet updated demands. The flexible packaging is assisting in changes in waste management, logistical optimization, and product protection. On the other hand, growth in material science has led to more flexible packaging films, which enable manufacturers to align with demands of the medical, food, and pet-food sectors.

The plastics segment dominated the Canada multilayer flexible packaging market in 2025, as plastics are high-level compound packaging that has a perfect design to ensure there is high-level functionality. They are generated by combining many classified layers, while in some landscapes, they range up to 12 layers of different materials. These layers are usually glued together by using extremely strong adhesives and thus cannot be detached by any mechanical means. The characteristics of such a pattern create products that are not conveniently adjusted but pose the main challenge to the regular multi-layer plastic reprocessing plants.

The paper segment is projected to witness the fastest CAGR during the forecast period. A multi-layer metallized paper-based material comprises an outer polymeric surface, an adhesive layer, a paper layer, and lastly the metallization layer. Such a design develops barrier properties while tracking high recyclability, which makes them perfect for both liquid and dry food products. Some of the packaging solutions count on compostable and biodegradable materials like Polybutylene succinate (PBS) and polylactic acid (PLA), enabling home composting and solving the eco-friendly issues offered by regular non-biodegradable materials.

The pouches and sachets segment dominated the Canada multilayer flexible packaging market in 2025, as flexible pouches and sachets' precise power relies on combining various films into a tailored multilayer laminate design. By methodically layering materials such as EVOD, PE, and the oriented PP brands, they can make high-impact pouches personalized to their product’s unique demands. It is flawlessly ideal as it maximizes the shelf life of sensitive foods by serving as a protective barrier for pharmaceuticals.

The laminates segment is expected to witness the fastest CAGR during the forecast period. Laminates undoubtedly have several good elements, hence the partnering of a polyethylene film with a PET or a PP-dependent film results in a flexible film that cannot be recycled. The typically used laminate in the flexible packaging industry consists of two crucial webs. Primary web is an exact co-extrusion film that is predominantly made of polyethylene, which has various layers and between them a tie surface and a barrier layer against gases and humidity, like os oxygen. The secondary web in several cases is developed from BOPET or BOPP that delivers the terminal film its mechanical features, strong nature and power, and additionally UV protection and blockage.

The 3-layer segment dominated the market in 2025 as three-layer packaging generally points to flexible laminated films or pouches made from three different layers, which deliver barrier, product connection, and print prevention. This construction is prevalent in medical sachets, snack pouches, and personalized barrier films. The usual structure of a 3-layer laminate includes an inner layer that consists of polyethylene or other food-secure material that ensures hermetic seals. Secondary layers are middle layers like aluminium foil or EVOH that provide moisture and oxygen to expand the shelf life, and the third layer is the outer layer of PP, PET, or metallized films for a printable surface and mechanical protection.

The 5-layer segment is expected to witness the fastest CAGR during the forecast period. This layer is well-known for its developed barrier characteristics and reliability, which makes it perfect for different uses. The Outermost layer serves the step-by-step durability and integrity of the tube. It serves as complete protection against external factors like moisture, physical damage, and UV radiation. Such ayer also gives an initial layer for decoration and printing, which enables good-quality branding and graphics. On the other side, the binding layer ensures rigid adherence between the central barrier layer and outer PE layer, and finally, the central barrier layer is necessary for delivering superior prevention against gases like solvents, oxygen, and other pollutants.

The food and beverages segment dominated the Canada multilayer flexible packaging market in 2025, as cleanliness and food safety are big concerns in the retail food industry, and the flexible packaging technologies play a substantial part in aligning with such criteria. Multilayer flexible packaging selections make a strong barricade against moisture, pollutants, and oxygen, which ensures that food products remain safe and fresh to consume. Additionally, flexible packaging selections can include resealable closures and tamper-evident seals to help protect pollutants and develop the shelf life of sensitive commodities.

The personal care and cosmetics segment is expected to experience the fastest CAGR during the forecast period. These packaging bags are extremely flexible in a container format that carries, protects, showcases, and transports the cosmetic product. Their materials, forms, and designs are classified greatly, relying on the product type, sales channel, and brand positioning. Packaging bags have hugely survived aim in the current beauty sector, which delivers as the main carriers of main marketing tools, brand identity, and the primary links for the user experience. The future growth of the cosmetic multilayer flexible packaging will have a big impact on the mixing of surrounding intelligence, prevention, and emotionalization.

The multilayer flexible packaging market is seen to grow notably in Canada because the urge is initially being driven by the development of various industries that have constant growth towards environmentally friendly products. User alertness campaigns and government policies for market sustainability, which are encouraging buying behaviors and packaging selections. The regulatory elements count on provincial and federal compulsions on waste reduction, recyclability, and chemical safety rules. The Canadian Environmental Protection Act (CEPA) and the provincial waste tracking regulations have identified needs that match with biodegradable and recyclable packaging solutions.

With an instance of this

By Material

By Product

By Layer Structure

By End-Use

February 2026

February 2026

February 2026

February 2026