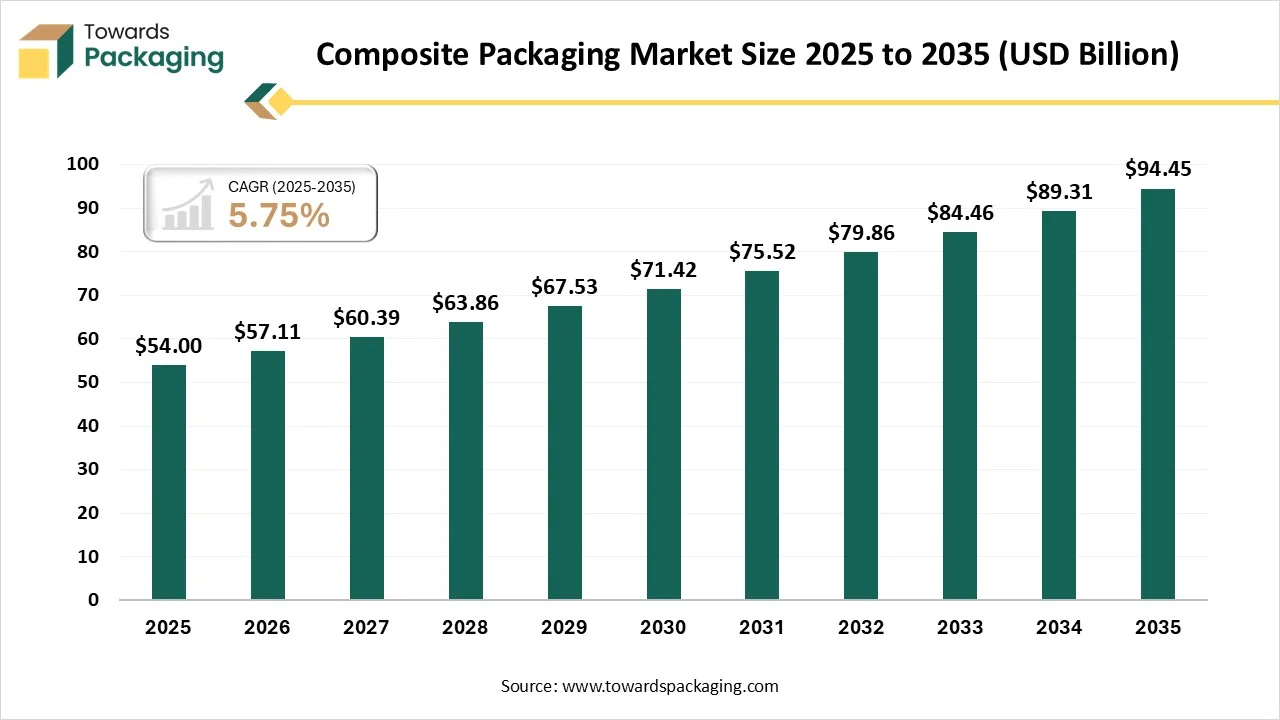

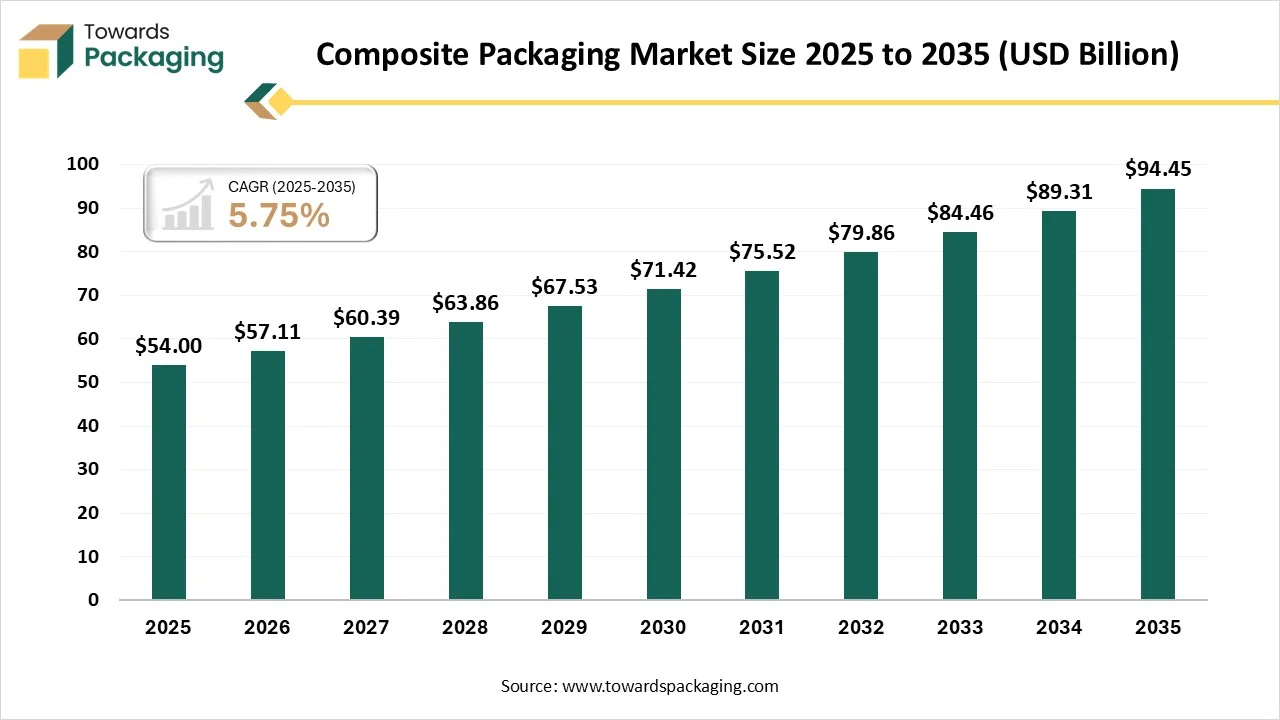

The composite packaging market is forecasted to expand from USD 57.11 billion in 2026 to USD 94.45 billion by 2035, growing at a CAGR of 5.75% from 2026 to 2035. The growth of such packaging is being driven by its potential to integrate materials for a convenience list like durability, superior barrier protection, cost-effectiveness, and the lightweight design, which is important for pharma safety, food shelf-life, and e-commerce shipping.

Composite packaging is one of the current and smooth packaging solutions that maximally protects products while developing brand value. With a different form created from various layers of different materials, composite packaging serves the perfect integration of aesthetics, protection, and convenience. It is becoming an excessively popular selection that surrounds industries from pharmaceuticals and food to consumer products and cosmetics.

Nanocellulose is a nature-like polymer that has nanostructures, which have attracted significant attention from scientists globally due to its excellent mechanical properties, biocompatibility, barrier performance, and biodegradability. Nanocellulose is initially being made from two main sources: plants such as cotton, cell walls of wood and wheat straw, and other sources are microorganisms, which are kombucha cultures. Nanocellulose is generated by processing cellulose into a single linear fiber that has a diameter below 100nm. While holding the initial characteristics of cellulose, nanocellulose is totally insoluble in water or common organic solvents at room temperature.

The plastic material segment dominated the composite packaging market in 2025, as polyethylene is a thermoplastic resin that is produced by polymerization of ethylene. In the sector, it also counts copolymers of ethylene and very little alpha olefins. They are non-toxic, odorless, and sense like wax, which has a perfect lower range of temperature resistance, good chemical stability, and can firmly withstand most alkali erosion and acidic environments. Insoluble is a common point at room temperature, high-quality electrical insulation, and low water absorption.

The paperboard segment is projected to experience the fastest CAGR during the forecast period. Composite paper cans are a cutting-edge pattern of sustainable milk powder packaging that is crafted to serve both eco-friendliness and product protection. Such cans are created of several layers to ensure airtightness and durability while lowering the environmental impact. Milk powder brands have regularly depended on metal and plastic containers, but such materials provide mainly environmentally unfriendly waste. With a growing user urge for sustainable milk powder packaging, brands should discover eco-friendly alterations that track the product integrity. The worldwide shift towards sustainable milk powder packaging is unmatched. Composite paper cans prefer an airtight packaging, brand classification, and airtight packaging, which makes them the perfect alteration for milk powder brands whose aim is for long-term success.

The food and beverage segment dominated the composite packaging market in 2025 as composite containers show the changes of packaging technology that combines multiple materials to make packaging solutions, which serve advantages that are not possible with single materials. The adaptability of compost containers is inspiringly recognizable as they can effectively package solid foods like instant coffee, powdered milk, and protein supplements. Additionally, semi-solid products such as puddings, yogurt and soft cheese seek ideal prevention in terms of composite packaging. Liquid products such as dairy products, fruit juices, and liquid nutritional supplements are regularly packaged in composite containers. Such flexibility across a product makes composite packaging heavily insightful for food producers.

The household products segment is expected to experience the fastest CAGR during the forecast period. PLA (Polylactic Acid) is a plant-derived plastic that comes from sugarcane or cornstarch, which has been a major player in environmentally friendly packaging, but its sensitivity restricts its usage for products. PLA-wooden composite eco-bottle factories are being tailored to accurately mix such a mixture, which makes them an easy option for brands that need full workability of plastic with an eco-cred for any natural materials.

Asia Pacific dominated the composite packaging market in 2025 as the composite packaging industry is expected to experience main development over the next 10 years, which is being driven by growing user demand, supportive regulatory frameworks, and technological developments. There are developing acceptance solutions, and changing user choice has been accepted to stretch the market size, which shows the fastest development.

Supply side potential, which counts distribution links and production range, is developing and allows organizations to align with growing demand effectively. Overall, the industry offers constant possibilities for funding and step-by-step development, which serves players and focuses on adaptability, invention, and tracking emerging trends to remain ahead of a quickly rising ecosystem.

How is the Composite Packaging Market Growing in India?

Infrastructure and construction remain a leading use space, which accounts for around one-third of the industry. Across every top-use area, the selected procedure is pultrusion, which has more than 50 uses in the manufacturing line. Apart from construction, ground transportation is developing as a crucial segment. There is a development in online retail stages like local against Alibaba, which has made a huge demand for protective packaging, which ensures that product reliability is maintained during transit. There are also rigid government bans on the regulation and sustainability of single-use plastics that are encouraging producers to shift to recyclable composite alternatives like paper-based cans and tubes.

North America expects the fastest growth in the market during the forecast period, driven by digital updates and accelerated automation initiatives that are changing inventory optimization, capacity utilization, and the smoothness of trade execution. The capital infusion is excessively focused on high-level production systems, data-driven trade stages, and smart logistics design due to margin stability and pricing visibility. The import activities are predicted to support value-matched sourcing and favor strategic stability.

Why is Canada using the Composite Packaging Market Importantly?

The growth is driven by the region’s growing digital investment, fast acceptance of cloud-based technologies, and growing smartphone expansion. The sector is also witnessing major changes due to growth in artificial intelligence, machine learning, and big data analytics. Such technologies are allowing businesses across Canada to receive real-time insights and have predictive checking on developing user behavior, which enables brands to create more precise data-driven decisions.

By Material

By Application

By Region

February 2026

February 2026

February 2026

February 2026