Nanocrystal Packaging Coating Market Size and Regional Production Analysis

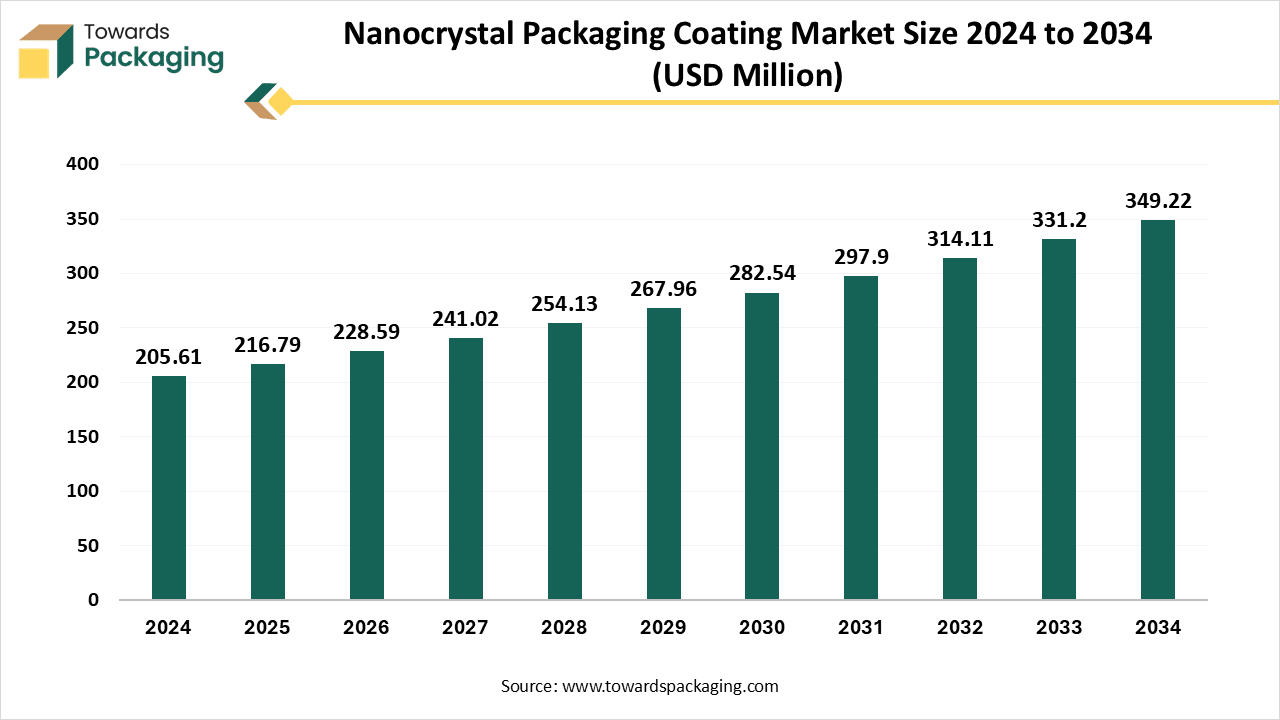

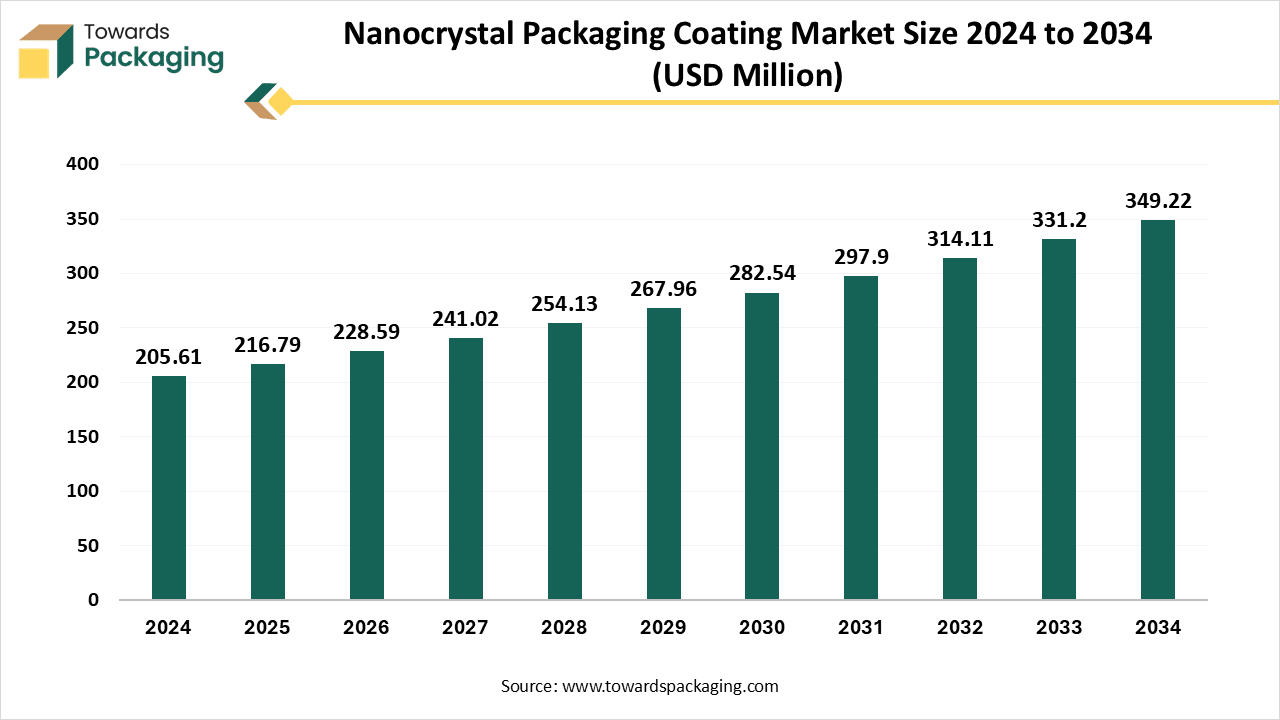

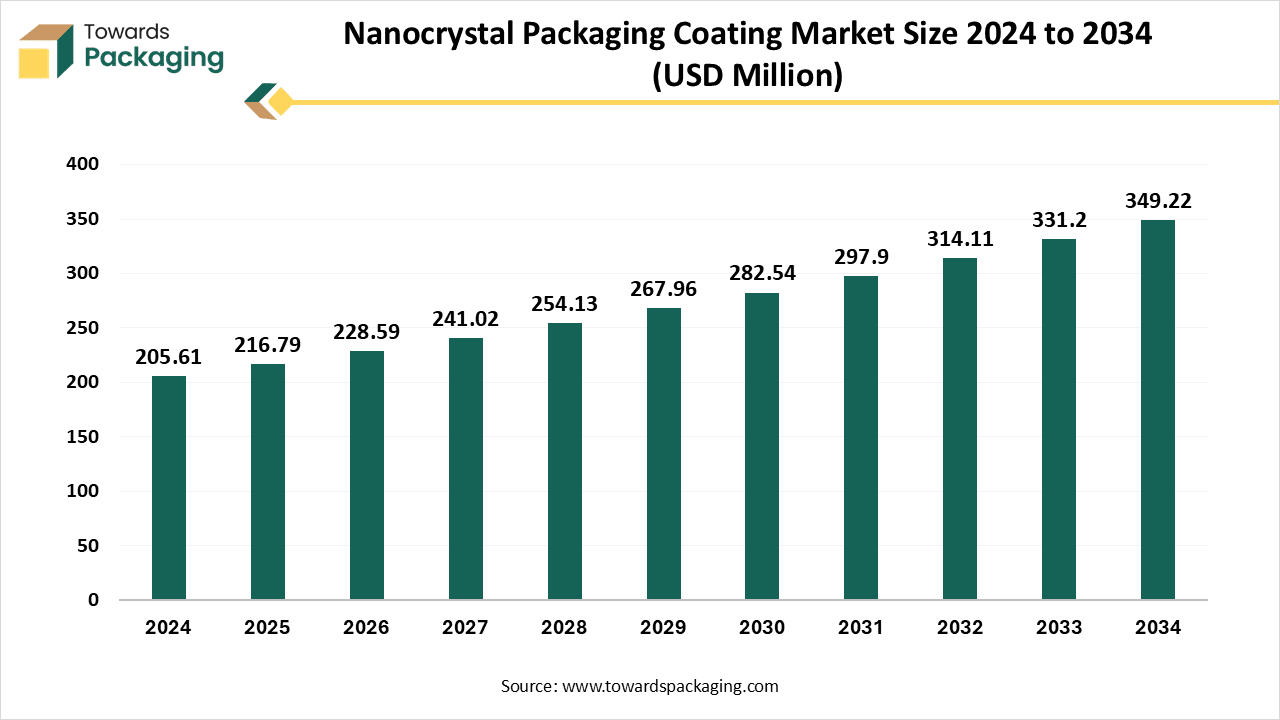

The nanocrystal packaging coating market is forecasted to expand from USD 228.59 billion in 2026 to USD 368.22 billion by 2035, growing at a CAGR of 5.44% from 2026 to 2035. The report covers all major trends including sustainability adoption, miniature electronics growth, and rising food safety standards.

It includes segmentation by type (barrier, antibacterial, anti-scratch), technology (PVD, CVD, sol-gel, electrospinning), and end-users (F&B, healthcare, electronics, cosmetics). Comprehensive regional data spans North America, Europe, Asia-Pacific, Latin America, and MEA, along with production analysis, trade flows, import–export statistics, competitive landscape, value chain mapping, and profiles of global manufacturers and suppliers.

Key Takeaways

- North America led the nanocrystal packaging coating market with the highest share in 2024.

- By region, Asia Pacific is expected to witness the highest CAGR during the forecast period.

- By type, the barrier coating segment dominated the market share 2024.

- By technology, the physical vapor deposition (PVD) segment has dominated the market share.

- By end-user, the food & beverages segment dominated the market share 2024.

Market Overview

Nanocrystal coatings are continuously getting popular because of their extraordinary barrier nature, biodegradability, and potential to improve the shelf life of the product. These are the thin layers used in the packaging material that adds small crystals and increase their capacity to create a barrier against adverse condition to protects packages, biodegradability, and flexibility. The growing demand for supportable packaging choices is a main catalyst in the nanocrystal packaging coating industry. With customer and supervisory entities inserting a finest on ecological management, market players are evolving to reduce carbon footprints and waste.

These packaging coatings, with their enhanced barrier nature and effectual, thinner layers, decrease resource surplus. The major market players such as BLUE GOOSE BIOREFINERIES INC., Navillum Nanotechnologies, Nanoco Group plc, Quantum Materials Corp, CelluForce, and many others are significantly working towards the innovation of nanocrystal packaging coating. The continuous changes in the supervisory bodies have forced market players to develop eco-friendly packaging using resources which are biodegradable.

The growing demand for miniature electronic devices has raised the demand for such coating in the packaging of delicate products to provide extra safety and boost the development of the market.

Nanocrystal Packaging Coatings Market Trends

- The increasing demand for Miniature electronic devices has influenced the demand for nanocrystal packaging of products.

- The rising demand for nanocrystal packaging coating in the semiconductor industry has encouraged this market to grow significantly.

- The rising preference of the customers for eco-friendly coatings on the packaging has evolved this market to grow.

- The growing demand for maintaining the quality of the products while transporting influence the demand for the market.

- The upsurge in enhancing the packaging of the products for enhanced safety of the products.

AI Integration in the Nanocrystal Packaging Coatings Market

In the nanocrystal packaging coatings market, there is a huge impact of AI in improving the quality of the packaging coating. The packaging business is changing significantly to boost the safety quality to reduce the risk of damage to the products of various industries. It is mainly utilized in choosing the resources of the packaging to confirm the high-quality protection from damage during transportation of the products from several adverse ecological condition.

The incorporation of advanced technology such as artificial intelligence help to raise if any error occurs in the packaging coatings which increase the reliability of the nanocrystal packaging coatings industry. These nanocrystal packaging coatings improve the packaging protection and decrease the risk of damage of products and addition of smart technology to this market. By utilizing technologies such as machine learning, artificial intelligence, and others it becomes convenient for market players to bring innovation in this market.

Market Dynamics

Driver

Rising Ecological Concern and Governmental Regulations: Market’s Driver

The growing ecological concern among customers and governmental supervision has influenced the nanocrystal packaging coating market. Strict ecological guidelines focus on decreasing carbon emission and encourage the usage of eco-friendly resources for the production of packaging coating. These coating deliver a sustainable substitute to traditional packaging resources that make them an ideal choice. Governments and administrations in the world are progressively striking strict guidelines to decrease plastic waste and encourage the usage of biodegradable resources.

This has resulted in a rise in the demand for nanocrystal packaging coating, which serve high-quality barrier possessions while being ecologically friendly. Additionally, progressions in nanotechnology have allowed the growth of advanced nanocrystal preparations and driving market development. One more noteworthy driver of this market contributing towards the development is the growing usage of nanocrystal packaging coating in the food & beverage sector.

These nanocrystal packaging coating provide higher protection against oxygen, moisture, and various other pollutants, thereby enhancing the shelf life of packaged products. Furthermore, the increasing trend of suitability foods and ready-to-eat food products has enhanced the demand for effectual packaging choices. Nanocrystal packaging coatings are also getting popular in the pharmaceutical industry because of their capability to protect the effectiveness and quality of sensitive drugs by giving strong barrier facilities against exterior factors such as gases, light, and moisture.

Opportunity

Rising Development of Sustainable Options: Market’s Potential

The rising development for sustainable packaging coating options plays a major role in the enhancement of the potential of the market. As customers and regulatory supervisors progressively enhance the ecological accountability, businesses are looking for innovative methods to decrease their carbon footprint and reduce waste. Nanocrystal packaging coatings propose a promising option by providing improved barrier possessions with thinner, more effectual layers, dropping the requirement for excess resources.

As a consequence, the demand for such innovative coatings is anticipated to develop enhance the potential of the market. The rising necessities of the food and beverage sector are an important factor in this market. As customer demand for enhanced shelf life, freshness, and product safety increase the pressure of the manufacturers to accept advanced packaging choices that fulfil these expectations.

Nanocrystal packaging coatings offer higher barrier properties, defending products from oxygen, moisture, and other pollutants, confirming quality preservation.

Moreover, these packaging coatings deliver to more effectual packaging, dropping the necessity for huge resources while improving sustainability. This arrangement with the evolving requirements of the market is boosting the acceptance of nanocrystal packaging coatings and raising the industry’s potential.

Restraint

Fluctuation in the Charges of the Raw Materials

The continuous fluctuation in the charges of the raw materials of the nanocrystal packaging coating has hinder the growth of the market as the constant change in prices decrease the reliability of small to medium scale business. Such issues restrain the initiative of these businesses which disturb the growth of the market. Due to fluctuation in the raw material costing, there is a low business set up availability which hamper the development of the market.

Segmental Insights

Protection from Ecological Adversities: Barrier Coating Led in 2024

The barrier coating segment dominated the market in 2024 due to its protective quality against the adversities of the environment such as moisture, light, and oxygen. These coatings are primarily used in protection of food and beverages, electronical devices, and pharmaceutical products. These coatings over the packaging of the products enhance the shelf life of the food products. These are the most durable and sustainable coating for the packaging of the products and hence make it most suitable choice.

Chemical Vapour Deposition and Electrospinning: Physical Vapour Deposition (PVD) Segment Led in 2024

The physical vapour deposition (PVD) segment dominated the market in 2024 due to the chemical vapour deposition, electrospinning, physical vapour deposition rising production and application process. These have quality to generate enhanced, uniform, and thin coatings and these are considered as durable as well as high adhesion quality. This technology permits for detailed control over the composition and thickness of the coating, improving the shelf life of the packaged products. Moreover, PVD procedures are eco-friendly and support the shift of the industry towards sustainable practices.

Safety and Extended Shelf Life of Products: Food & Beverages Segment Led in 2024

The food & beverages segment dominated the market in 2024 due to the extension of shelf life and safety concern of the food products. These nanocrystal packaging coating are highly used in the food & beverages industry as it protects products from light, oxygen, and moisture to preserve the freshness of the food products. The growing demand for efficient and sustainable packaging options with nanocrystal technology which make it an important and dominating segment. The rising concentration towards reduction of waste fuels and improve the quality of the products enhance the adoption of this market.

Regional Insights

Sustainable and Advanced Packaging Choices: North America to Sustain as a Leader

North America held the largest share in 2024. This is due to the rising sustainable and advanced packaging choices of the customers. The growing impact of using eco-friendly products and high-quality protection to the food products has raised the usage of nanocrystal packaging coating. There are various industries such as electronics, food & beverages, and healthcare are widely using this nanocrystal packaging coating in countries like the U.S. and Canada. The strict government supervision over packaging industry raised the utilization of products that can be recycled and biodegradable.

Emerging Economies in Several Countries: Asia Pacific to be the Fastest Growing Region

Asia Pacific is expected to grow at the fastest rate during the forecast period. This is due to the emerging economical condition of the countries such as China, India, Japan, South Korea, and Thailand. There are various factors influencing this market to grow are growing demand for durable and lightweight resources. The growing middle-class people and changing customer likings in the direction of ease foods and enhanced-quality of products are boosting the influence of nanocrystal packaging coatings. Moreover, the occurrence of a strong industrial base and suitable government guidelines endorsing sustainable packaging options are anticipated to drive market development in this region.

Nanocrystal Packaging Coating Market Key Players

- Mitsubishi Chemical Corporation

- Constantia Flexibles Group GmbH

- Cima NanoTech Inc.

- DuPont de Nemours, Inc.

- Huhtamaki Oyj

- Dow Chemical Company

- FKuR Kunststoff GmbH

- Hybrid Plastics Inc.

- Arkema Group

- Blue Nano Inc.

- Evonik Industries AG

Latest Announcements by Market Leaders:

- In April 2022, Chairman and Chief Executive Officer of Bready, Mr. Liu Yong, expressed, “We have had great success as a long-term partner of Nanosys in bringing QDEF™ quantum dot technology to market for our tier one customers in China, Korea, Japan and in the US. Now, we are the first company to provide xQDEF Laminate without the need for barrier films while also delivering the same high standard of reliability as the QDEF, the industry standard. This is a perfect example of successful collaboration between two industry leaders in China and the US. We continue to enjoy the benefits of our close relationship with Nanosys.”

Recent Developments:

- In November 2022, Melodea announced the plans to expand its eco-friendly solution to more areas.

- In April 2022, Nanosys, Inc. collaborated with Nanjing Bready announced the launch of mass production of the world’s first line of completely air-stable, barrier-free, laminated quantum dot film components xQDEF™ Laminate deliver no-compromise quantum dot color and brightness for displays in a new, lower-cost package, expanding the market for quantum dot displays.

Nanocrystal Packaging Coating Market Segments

By Type

- Barrier Coating

- Antibacterial Coating

- Anti-Scratch Paint

- Other

By Technology

- Physical Vapor Deposition (PVD)

- Chemical Vapor Deposition (CVD)

- Sol-Gel Processing

- Electrospinning

By End User

- Food & Beverage

- Healthcare

- Electronics

- Personal Care & Cosmetics

- Others

By Region Covered

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait