UV-Resistant Films Market Segmentation, Key Players, and Competitive Landscape Analysis

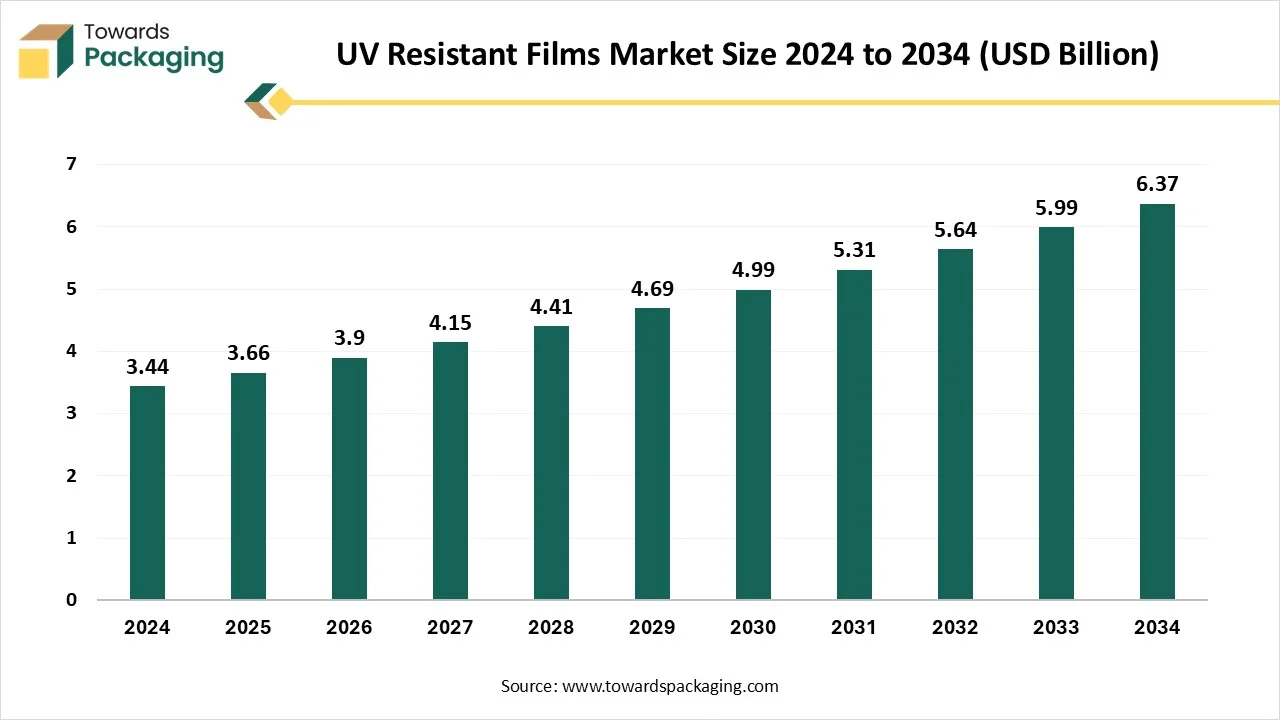

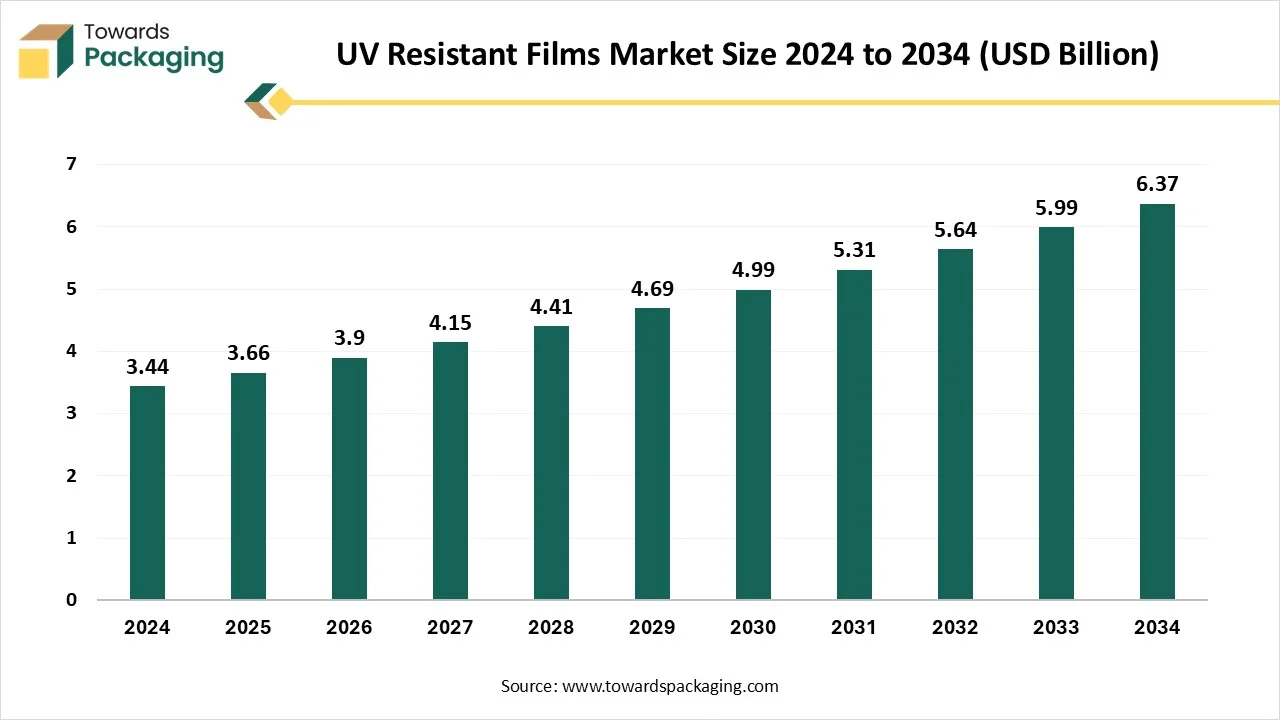

The UV-resistant films market is forecasted to expand from USD 3.90 billion in 2026 to USD 6.83 billion by 2035, growing at a CAGR of 6.43% from 2026 to 2035. This report provides an in-depth analysis of the market trends, including rising adoption in automotive and building applications, and explores regional insights where Asia Pacific dominates and North America is the fastest-growing market.

The study covers detailed segmentation by type, application, and end-use, along with competitive analysis of leading players such as Eastman Chemical Company, 3M Company, and Toray Industries. Trade data, manufacturers’ strategies, and value chain insights are also discussed to provide a comprehensive market perspective.

Key Takeaways

- In terms of revenue, the market will be valued at USD 3.66 billion in 2025.

- The market is projected to reach USD 6.83 billion by 2035.

- Rapid growth at a CAGR of 6.43% will be observed in the period between 2025 and 2034.

- Asia Pacific dominates the global UV-resistant films market.

- North America is expected to host the fastest-growing market in the coming years.

- By type, polyester types dominate the UV-resistant film market.

- By type, the polycarbonate segment will grow at a significant CAGR between 2025 and 2034.

- By application, automotive applications dominated the market in 2024.

- By application, the building and construction segment will grow at a significant CAGR between 2025 and 2034.

- By end-user industry, residential will dominate the market in 2024.

- By end-user, the commercial segment will grow at a significant CAGR between 2025 and 2034.

Market Overview

Ultraviolet (UV) rays from the sun have a direct effect on materials exposed to light with the help of glass surfaces. They result in premature aging of surfaces, fading of objects, and can even cause risks to human skin. In sectors like furniture, retail, and museums, protecting showcased items is crucial. Resistant films are a high-level solution that filters these rays while tracking optimal transparency. They are very different from " normal" plastic films in that they have special characteristics that increase their resistance. This means that these special films are specifically resistant to heavy usage and external influences. These include UV light, chemicals like acids and alkalis, cleaning agents and solvents, mechanical influences, and temperatures.

Several good-quality technical plastic films are only perfect for outdoor use to a limited extent because they are not resistant to aging. UV-resistant plastic films are completely weatherproof and allow outdoor usage. Examples are front panels, fascia panels, instrument panels, and keyboards, which are exposed to UV radiation, as well as operating systems in automotive interiors. UV-resistant films can be processed in different ways, depending on the material and design. Usually, no special accessories or tools are needed. They can be punched, cut, glued, and lasered. Many products can be printed well and constantly use different printing procedures.

Key Metrics and Overview

| Metric |

Details |

| Market Size in 2025 |

USD 3.66 Billion |

| Projected Market Size in 2035 |

USD 6.83 Billion |

| CAGR (2026 - 2035) |

6.43% |

| Leading Region |

Asia Pacific |

| Market Segmentation |

By Type, By Application, By End-Use and By Region |

| Top Key Players |

Eastman Chemical Company, 3M Company, Toray Industries, Inc., Saint-Gobain Performance Plastics, SKC Co., Ltd, Mitsubishi Chemical Corporation, DuPont Teijin Films |

What are the New Trends in the UV-Resistant Films Market?

- Smart Window Films: One of the most expected growth areas in the UV-resistant films industry is the development of smart window films. These films can drastically adjust their tint levels depending on external light conditions, which serves optimal comfort and energy effectiveness.

- Nanotechnology-Enhanced Films: Nanotechnology is ready to change window tinting by serving films with developed properties. These films can serve superior UV and infrared injection, increased durability, and better clearness. Nanotechnology-enhanced films will also be thinner and lighter, which makes them convenient to install and more aesthetically pleasing.

- Solar Energy Harvesting Films: A game-changing invention in UV-resistant film technology is the growth of solar energy harvesting films. These films can transform sunlight into electricity, delivering renewable energy sources for offices and homes.

- Advanced Security Films: Security films are now net, but the future carries improvements in their functionality and strength. The latest materials and production techniques will generate films that offer better protection against break-ins, ballistic threats, and natural disasters, too. These high-level security films will be a necessary addition to both commercial and residential properties.

- Optimal Indoor Environment: With acceptive light control and superior heat rejection, future UV-resistant films will ensure a more comfortable indoor environment. Homeowners and office workers will benefit from reduced glare, improved overall comfort, and consistent temperature.

- Improved Safety and Security: High-level security films will serve as enhanced protection against different threats, offering peace of mind for businesses and homeowners alike. The additional layer of security can also reduce insurance premiums and liability issues.

Market Dynamics

Driver

Invisible Shield: UV Window Films for Skin and Interior Protection

UV-resistant films are very effective and are frequently used in sun protection solutions. It is also known as solar window film or UV window tint. When UV-resistant films are applied to windows of vehicles, offices, or homes, they can block more than 99% of UVA and UVB light. Window glass blocks most of the UVB rays, but not UVA rays. The front windshields of cars are covered with glass, treated to defend drivers from some UVAs. Hence, the glass on the side, back, and sunroof windows is created of tempered glass that does not block UVA rays efficiently. In order to protect our skin when one is in the vehicle, we can have window UV film installed on driver and passenger side windows and the sunroof.

UV-resistant films are available for both commercial and residential spaces, as they come in different tints and opacities to allow for customization. UV window films are very effective for up to a decade. All UV-resistant films can serve a degree of UV protection, but several films are only for design or darkening. The appearance of films is marketed particularly for "UV window film", "Solar Window Film", or "UV window Tint".

Restraint

Price Constraints

While professional installation is suggested, the procedure can be complicated, and inexperienced installers may leave bubbles or wrinkles on the film. Improper installation can affect the effectiveness of the film and the outcome in achieving a desirable look. Over the period, UV-resistant films may undergo issues like peeling or bubbling, specifically if subjected to extreme weather conditions. This not only criticizes the visual look but can also lessen the film's effectiveness in preventing heat and UV rays. Some regions have regulations linked to the darkness of UV-resistant films, and increasing these limits may lead to legal problems. Particular types of UV-resistant films can hamper electronic signals, such as those utilized for GPS, radio, or mobile devices. It's important to select a film that lowers these capability disturbances, especially if our vehicle depends heavily on electronic systems.

Opportunity

The Bright Future of UV-Resistant Films

Sustainable UV-resistant films will invest in greener buildings with less energy consumption and a reduced environmental impact. High-level UV-resistant films can serve superior protection from UV rays, glare, and heat, while also providing security and safety. With a huge variety of functional and decorative options, UV-resistant films can reveal future possibilities for designers and architects. The capability of UV-resistant films expands far beyond regular windows. To track the temperature and avoid sun damage to artwork and furniture, skylights can also be filled with heat control and UV protection films.

The future of UV-resistant films is bursting with possibilities. This growth carries the immense capability to make it more sustainable, visually appealing, and functional too, which effectively contributes to a comfortable and greener future. On the other hand, smart UV-resistant technology is changing how users view UV-resistant films. These films accept their opacity depending on sunlight or driver chives, either automatically or manually, and can even mix with the vehicle's smart systems like climate control.

Segmental Insights

How will Polyester Types Dominate the UV-resistant Film Market in 2024?

Polyester films are flexible and thin sheets created from polyethylene terephthalate, as they have huge chemical, physical, and optical properties. It is available in different variants. Biaxially oriented Polyester films, or BOPET, are created by stretching the film at 90-degree angles to develop clarity, strength, and barrier characteristics. Polyester film is utilized in a huge series of printing, packaging, electronics, and solar energy as some industries have been heavily using it. It is recognized as a selected material for sun protection films for a perfect reason. It serves a great combination of durability, flexibility, and resilience. These characteristics make it a perfect choice for both residential and commercial uses, where continuity and constant performance are necessary.

Polycarbonate (PC) is prevalently known for its excellent impact resistance and durability, too. It is an advanced and high-performance solution perfect for heavy protection needed for both industrial uses and automotive. Also, it is a high-performance thermoplastic polymer made through a fascinating chemical procedure, created when bisphenol A (BPA) and phosgene join forces to make long, extremely rigid molecular chains. What exactly distinguishes polycarbonate from regular materials is its exceptional capacity to absorb impact without breaking. Also, the reaction adds to the material exceptional mechanical and thermal characteristics.

How will Automotive Applications Dominate the UV-resistant Film Market in 2024?

UV-resistant films are chemical compounds that absorb toxic UV radiation, transforming it into harmless heat energy, which assists in avoiding the damage that UV light can cause to coatings and plastics. These absorbers are specifically added to plastic formulations to develop their resistance to sun-induced degradation. In automotive applications, UV-resistant films are specifically crucial for materials exposed to harmful outdoor conditions, such as trims, bumpers, and dashboards. Automotive coatings and plastics, which often have polymer, are sensitive to degradation when exposed to UV light. The energy from UV rays can break down the chemical bonds into polymer chains, which results in losing their mechanical strength and look. UV absorbers efficiently work by filtering out the most toxic UV wavelengths, which enables the preservation of both the quality, aesthetics, and structural integrity of automotive plastics.

Sustainable designs are everything from material choices to energy-saving approaches in current architecture. Architects and construction designers must seek paths to create buildings more eco-friendly to match environmental standards and lower energy costs. "UV-resistant film" is frequently known to assist in meeting these goals. UV-resistant films have built-in UV absorbers. , that is layered with an adhesive level. These UV absorbers make the window film 99% efficient in blocking toxic UV rays. UV-resistant films have an added layer that makes them glossy and shows some of the sun's heat, assisting in reducing the solar heat gain. These films are heavy-performance window treatments that help regulate indoor temperature, prevent interiors from sun damage, and boost energy efficiency.

How will Residential End-users Dominate the UV-resistant Film Market in 2024?

One of the remarkable points of view of UV-resistant film is how it changes our living and working surroundings into more comfortable spaces. By blocking up to 99% of toxic UV rays, UV-resistant films not only protect our furnishings but also provide significant energy savings, protecting air conditioning systems from working over long periods. UV-resistant films develop privacy without sacrificing natural light, an important component of current design concepts. Whether it is a busy office environment or a home space, we all need our personal space, as these films can have ambiguous outside visibility while still enabling sunlight to penetrate our interiors. The aesthetic and functional developments offered by UV-resistant films are transformative. UV-resistant films do more than just improve our interior comfort; they also secure the safety of our spaces. By implementing solar heat gain, these films assist in maintaining a constant temperature, making our environment more welcoming but also safer.

The growing demand for UV-resistant films stems from their potential to enhance privacy and develop energy, efficiency, and power security while tracking a sleek and contemporary design. Privacy UV-resistant films, frosted UV-resistant films, and tinted UV-resistant films are heavily utilized to create functional yet stylish spaces. These spaces enable natural light to illuminate interiors by avoiding unwanted visibility, lowering glare, and adding an extra layer of protection. Beyond comfort and privacy, UV-resistant films play an important role in terms of UV protection. Protracted sun exposure can cause flooring, furniture, and artwork to vanish.

UV protection films (UV resistant films) block up to 99% of toxic UV rays, protecting the interiors of commercial spaces while making sure a healthier environment for users. For organizations, UV-resistant films improve security, branding, and customer experience. Decorative films with custom designs change storefronts and show windows into visually engaging marketing spaces. To protect merchandise, UV-resistant films prevent fading caused by sun exposure. At the same time, one-way reflective films and privacy serve security after business hours, which makes sure that valuables remain safe during working hours.

By Region

Why Does Asia Pacific Dominate the UV-Resistant Film Market?

The demand for UV-resistant film is very high and offers a wide variety of sunscreens in different textures. It is achieved through differently developed technology that includes UV protection ingredients (UV absorbers and UV scattering agents), which are usually water-soluble and dispersed in the aqueous phase of a water-based formulation. Summarizing all UV absorbers has made it possible to constantly integrate a huge variety of ingredients in the aqueous phase of formulation, which heavily strengthens the capability for adding new textures and functions.

- On 2 May 2025, Cosmo First Ltd started production for its innovative window films commercially under the Cosmo Sunshield brand. The firm blocks up to 90% of damaging infrared (IR) and ultraviolet rays (UV) from sunlight while it enters natural light and floods interior spaces because of nanotechnology. (Source: Manufacturing Today India)

North America

The sun sends energy to Earth in many different ways,e in terms of visible light which one can see, infrared radiation that causes heat, and UV radiation rays which can't be seen. Fortunately, the Earth's atmosphere protects us from most UV radiation. According to the U.S Environmental Protection Agency, the EPA's Sunwise program was an environmental and health program that taught children how to protect themselves from overexposure to the sun. In the year 2016, the unwise program was mixed into the programs run by the National Environmental Education Foundation.

For instance,

- As the longest summer day comes nearer, XPEL, which is a top company in protective films and coatings, reminds consumers to remain protected from sun-related heat and UV exposure, particularly as melanoma and skin cancer diagnoses constantly grow. (Source: Business Wire)

UV Resistant Films Market Key Players

Latest Industry Leader Announcements

- On 28 January 2025, Garware Hi-Tech Films, which is a top leader in paint protection and Sun Control Films, disclosed dynamic initiatives whose goal is to revolutionize automotive protection in India. The company disclosed two advanced products -Coloured Paint protection film and Head and light glass protection film, along with strategic alliances. (Source: Times of India)

Recent Developments

- On 20 January 2025, ALP disclosed its new Paint Protection Film (PPF) product line at the Bharat Mobility Global Expo, as the organization has revealed three variants -Armor-Defender and Ranger -created to protect vehicle surfaces from environmental damage. (Source: Autocar Professional)

- On 8 May 2025, IPG, which is a top leader in terms of high-performance tapes and films, revealed the launch of its new Polyethylene Surface Protection Film. This low-tack and clean-removal PE tape is crafted to design a variety of soft and rough surfaces across different industries. (Source: IPG)

UV Resistant Films Market Segments

By Type

- Polyester

- Polycarbonate

- Polyvinyl Chloride

- Polyethylene Terephthalate

- Others

By Application

- Automotive

- Building and Construction

- Packaging

- Electronics

- Others

By End-Use

- Residential

- Commercial

- Industrial

By Region

- Asia Pacific

- North America

- Europe

- Latin America

- Middle East and Africa