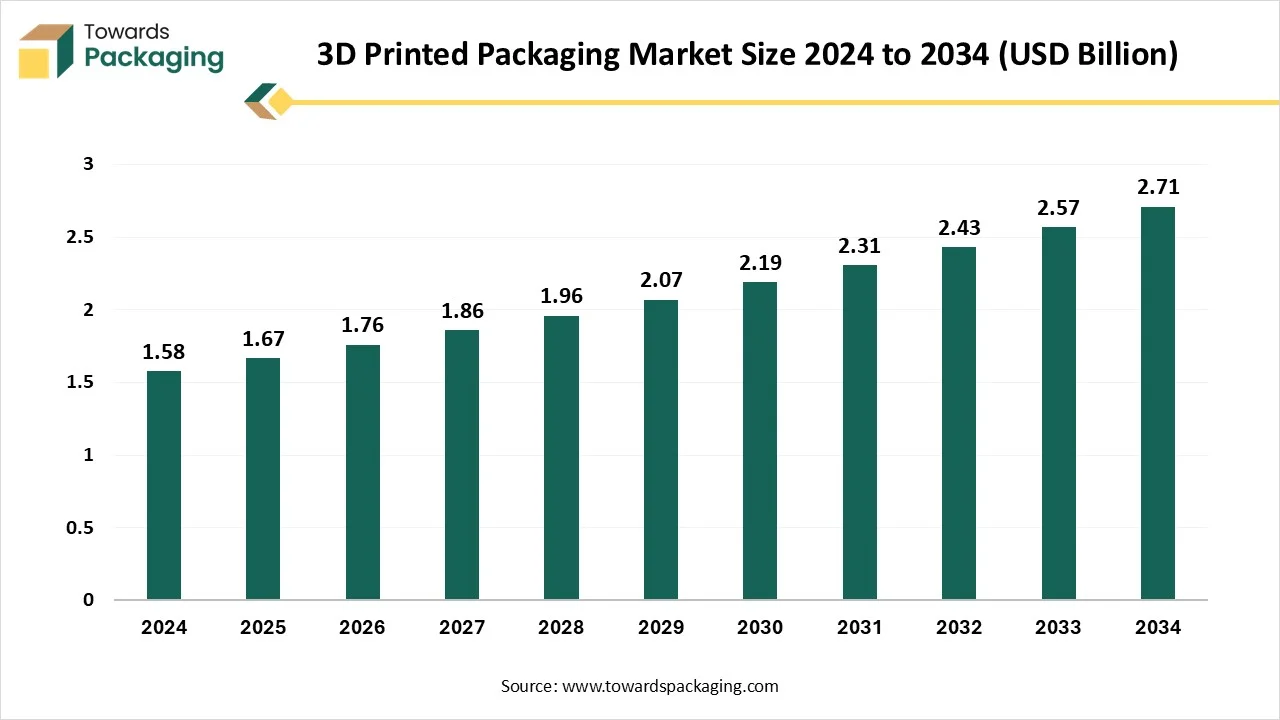

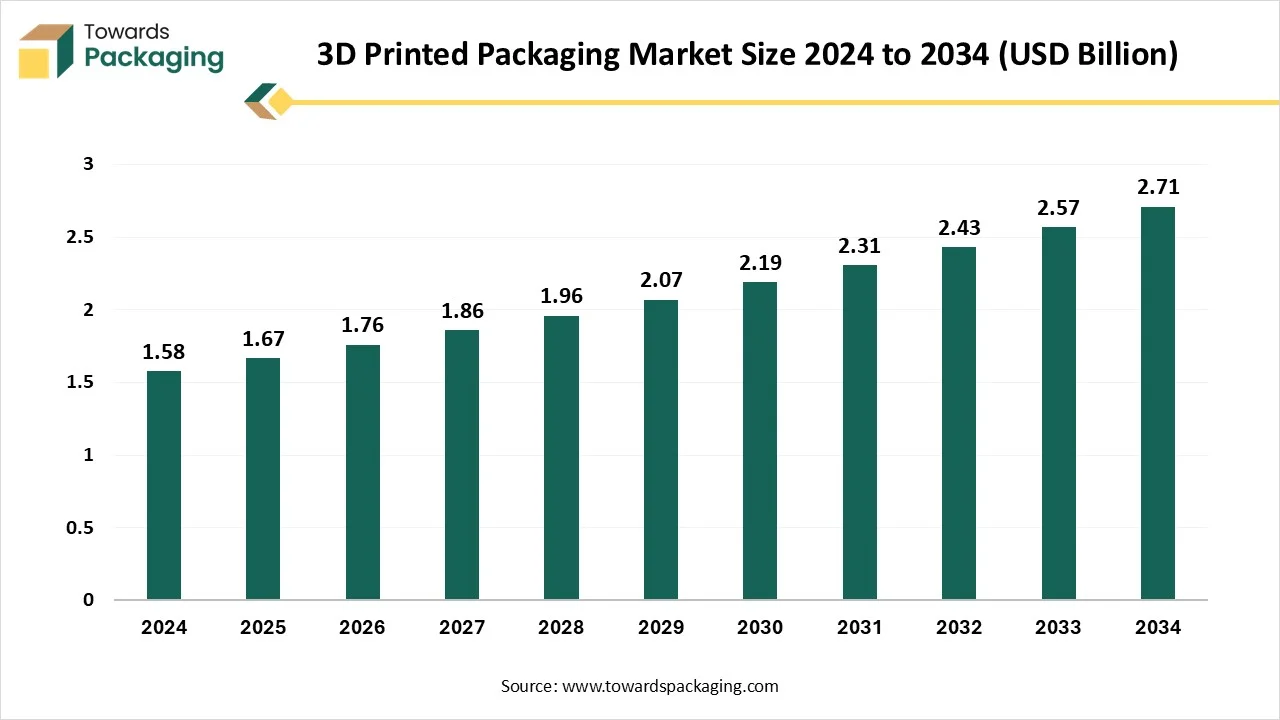

The 3D printed packaging market is forecasted to expand from USD 1.76 billion in 2026 to USD 2.86 billion by 2035, growing at a CAGR of 5.53% from 2026 to 2035. It provides complete regional insights across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, including country-level performance.

The study details the value chain, production ecosystem, trade flows, supply–demand gaps, and raw material availability, while also profiling leading manufacturers such as Stratasys, 3D Systems, Materialise, EOS, Nexa3D, Protolabs, and others.

The global 3D printed packaging market emphasizes the development of customized, lightweight, and innovative packaging with additive manufacturing methods to serve industries such as food & beverages, cosmetics, pharmaceuticals, and logistics. The 3D printed packaging segment benefits from the ability to create prototypes quickly and cost-effectively, produce small batch runs, and allow for sustainable packaging with little waste. Key market drivers include increasing demand for sustainable packaging, lower lead times, and improved supply chain efficiencies.

As advancements have accelerated with new printing materials and processes, for example, biodegradable polymers, multi-material printing, and a wide delivery spectrum, 3D printing is growing in the industry. Companies have begun exploring prospects associated with the personalization of products and brand differentiation by using complex and attractive packaging. Expansion of applications in regions with growing e-commerce and manufacturing sectors is are potential opportunity. Using AI, automation, and IoT applications with 3D printing processes has improved accuracy, scalability, and cost savings for end users.

Artificial Intelligence (AI) can support the global 3D printed packaging industry by improving design processes, bettering material selection, and reducing waste. Machine learning algorithms are at the ready to anticipate stress points as well as improve structural integrity. Generative design will provide the best packaging by producing lightweight packages while still accomplishing the tasks the package was designed for. Automated systems driven by AI will allow for full automation of the packaging workflow from prototype to commercial production.

AI will not only improve automation, but it will also improve human-led decision-making by better understanding how consumers make decisions and creating packaging designs that are tailored to the data received. Improved packaging, aided by real-time data analytics, can ultimately provide cheaper packaging, better customization, and faster production while increasing overall production efficiencies and responsibility of 3D printed packaging practices.

Increasing Demand for Customization by Brands

Customizable packaging is one of the major forces driving growth in the global 3D printed packaging market. Brands are increasingly looking for ways to provide customers with unique and personalized experiences, particularly in the cosmetics, food, and luxury products segments. The 3D printing process enables packaging to be readily produced or designed as complex, customized designs can be processed quickly and produced without the need for costly molds or tools. Using 3D printing will allow companies to economically and efficiently design and prototype different shapes, sizes, and branding on the products as a way to stabilize the ideal brand attribute to be tested. As consumer expectations of exclusivity increase, particularly in the online and niche markets, companies are looking for innovative ways to stand apart on shelves and maximize the brand value of the product.

High Equipment and Material Costs of 3D Printers

While 3D printed packaging has its advantages, its biggest limitation for the global 3D printed packaging market is the high cost. The cost of industrial 3D printers and specialized materials is currently very high, for example, biodegradable polymers. The equipment and materials the product market uses, including food-grade resins, can be unique materials that are not placed in a reasonable price range. The biggest problem for a small or medium-sized business adopting additive manufacturing is the initial expense of investing in the equipment.

As the business starts 3D printing, it will encounter operating expenses like maintenance, skilled labor, and the need for additional materials. Manufacturers will not transition to additive manufacturing until there is competitive pricing on manufacturing, meaning either greater scale is driving prices down or some breakthroughs. In particular, a manufacturer based in a cost-conscious region and manufacturing a cost-sensitive product will likely not shift to a much more expensive packaging solution.

Expansion of 3D Printing Packaging in E-commerce Packaging

The rapid increase in e-commerce sales has given the 3D printed packaging market a tremendous opportunity, as online shopping continues growing, brands will look for effective, lightweight, and attractive packaging that protects their products during shipping and improves consumers’ unboxing experiences. 3D printing can produce packaging more rapidly and to specifications that account for each product’s dimensions and the respective visual branding. This will enable brands to create favorable packaging for subscription boxes, limited edition launches, and for fragile products. Importantly, as sustainability is a priority, 3D printed packaging with recycled or compostable materials provides e-commerce businesses with the opportunity to lessen their impact on the environment and cater to consumers who are concerned about environmental sustainability.

The plastics segment holds a dominant presence in the market as they are highly versatile, durable, and functional with basically all 3D printing technologies. They allow for flexibility in design, are low weight, and are cost-effective. Popular plastics, including PLA and ABS, are being developed for rapid prototyping and final packaging in the food and cosmetic industries.

The paper and paperboard segment is expected to grow at the fastest rate. Paper-based materials are expected to increase at a very fast rate as global demand for biodegradable materials continues to rise based on environmental concerns. They allow for sustainable, lightweight packaging materials for dry food and consumer goods, and are in line with worldwide trends toward green packaging. Governments are also regulating the reduction of single-use plastic, which is improving the sustainability of paper products relative to plastics.

Stereolithography (SLA) is the technology leading the 3D printed packaging industry, due to its high-resolution outputs with smooth surface finishes corresponding to the needs of high-definition, high-quality prototypes and molds. This technology is commonly used in industries such as cosmetics and luxury goods, wherein cosmetic packaging functionality and aesthetics are necessary.

The supply chain and logistics segment is expected to grow at the fastest rate in the market during the forecasted period. Supply chain and logistics are rapidly adopting 3D printed packaging as a method of literally improving protective packaging to minimize packaging weight and lessen overall shipping costs. This custom-fit packaging not only improves the product's safety during transportation but also offers an efficient use of available storage space while fostering its implementation across global logistics applications, one of the fastest-growing sectors.

The food and beverages segment dominates the market due to shelf-life optimization and supply chain efficiency. AI helps design packaging that extends product freshness by analyzing temperature, humidity, and spoilage patterns, reducing food waste. AI creates data-driven packaging designs that use minimal material without compromising product protection, supporting sustainability, and cost savings. 3D printing helps brands to produce unique customized packaging

The pharmaceuticals and healthcare industry segment is growing rapidly due to rising demand for patient safety and reducing environmental impact. AI ensures accurate dosing and right-sized packaging for medicine, reducing material waste and improving sustainability without compromising safety. AI helps to navigate complex pharmaceutical packaging regulations and sustainability standards, ensuring materials meet environmental and safety criteria globally.

North America dominated the global 3D printed packaging market, primarily because of the existing manufacturing infrastructure, advanced technology, and efforts towards sustainable packaging. There is significant investment for research and development, key 3D printing players, and positive development in e-commerce in the region. The U.S. is leading the growth of the market because of demand in the food & beverage and healthcare sectors. Canada is increasingly using sustainable materials and packaging by small-scale businesses. Mexico is growing, largely from its automotive and consumer goods industries. Overall, North America will benefit from developing regulations, as well as its innovation-friendly space, which defines the future of 3D printed packaging.

U.S. Market Trends

The U.S. is the leading player in the North America 3D printed packaging market, aided by technology innovations, wide industrial use, and demand for sustainable packaging materials. The U.S is also benefiting from quick e-commerce growth, forcing companies to use flexible and on-demand packaging solutions, thereby reducing environmental footprint and lead time.

Europe is the fastest-growing region in the 3D printed packaging market, driven by rules around sustainability and a demand for sustainable packaging solutions. Countries such as Germany and the Netherlands are leading in investments for additive manufacturing technologies. The UK and France are beginning to adopt it for luxury packaging and in food. Furthermore, the European Union is promoting a reduction in plastics and circular economies to reduce waste, which has increased the use of biodegradable 3D printed materials. These factors have given Europe a substantial advantage in global packaging innovation.

The 3D printed packaging market in the Asia-Pacific region is witnessing significant growth as a result of increasing manufacturing bases, high urbanization, and rising demand for cost-effective packaging solutions. China leads the region in 3D printed packaging because of high levels of investment in both 3D printing research and development, as well as adoption across multiple industries. Japan also has some level of focus on high-precision applications, considering its technology adoption related to electronics and the healthcare packaging industry. The presence of India as an emerging market related to high growth in e-commerce and food delivery is also beneficial to the growth trajectory of 3D printed packaging. Further government initiatives promoting digital manufacturing will further assist regional market expansion.

By Material Insights

By Technology Insights

By End-Use Industry

By Region

February 2026

February 2026

February 2026

February 2026