AI in Sustainable Packaging Market Size, Share, Trends and Forecast Analysis

The global AI in sustainable packaging market is accelerating, with forecasts predicting hundreds of millions in revenue growth between 2025 and 2034, powering sustainable infrastructure globally. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing sustainable packaging. The market is growing rapidly, driven by increasing demand for eco-friendly solutions and efficiency in production.

AI technologies optimize material usage, reduce waste, and enhance packaging design for recyclability. They also support smart supply chain management and predictive maintenance. Brands are adopting AI to meet sustainability goals and regulatory compliance. Integration of machine learning and computer vision further improves quality control and automation. This market is poised for strong growth across industries like food, beverages, cosmetics, and e-commerce.

Key Insights

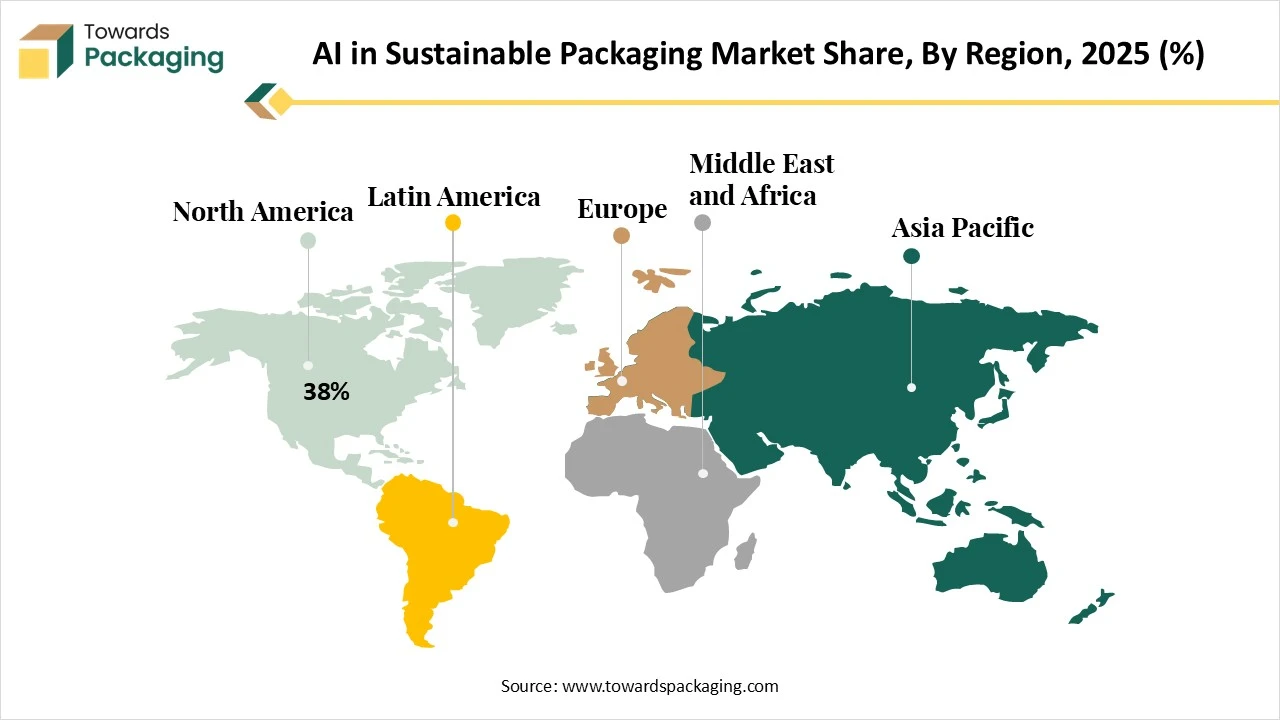

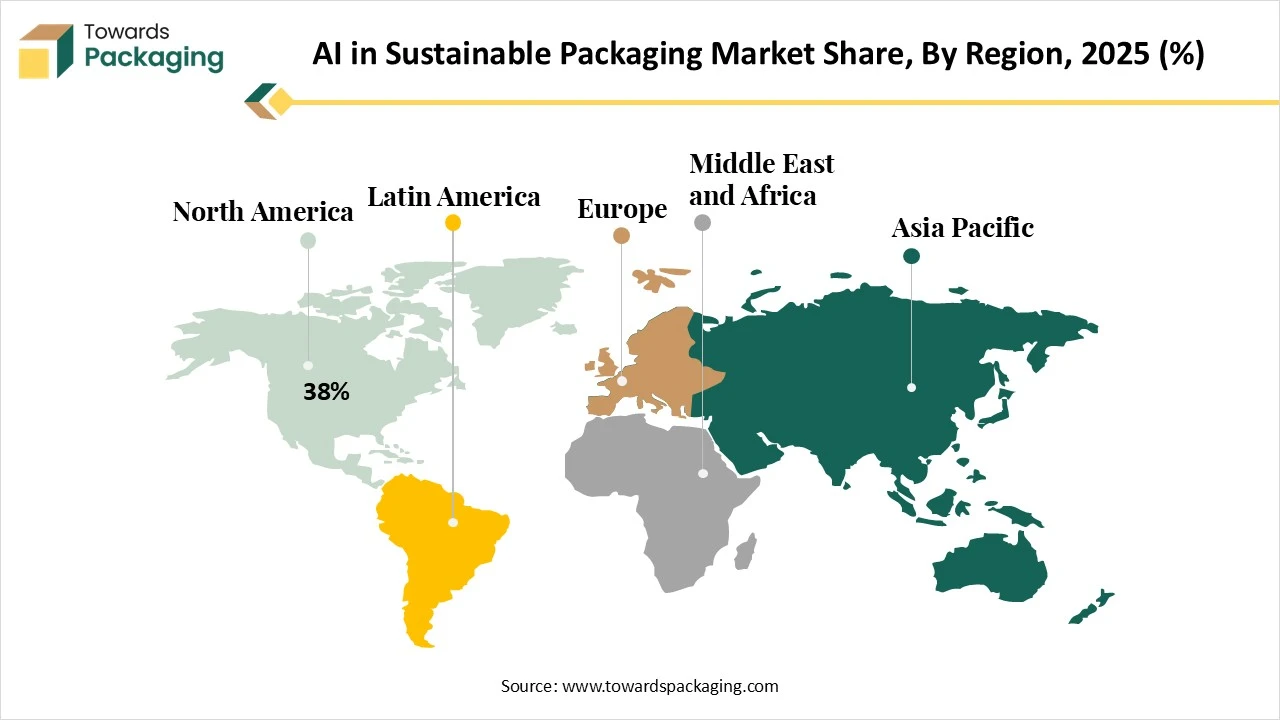

- North America dominated the global AI in sustainable packaging market in 2024.

- Asia Pacific is expected to grow at a significant CAGR during the forecast period.

- The European market is expected to grow notably in the foreseeable future.

- By AI technology type, the machine learning algorithms segment dominated the market in 2024.

- By AI technology type, the natural language processing (NLP) segment is expected to grow at the fastest CAGR during the forecast period of 2025 to 2034.

- By application, the packaging design and optimization segment held the largest revenue share in 2024.

- By application, the supply chain and logistics segment is expected to grow at the fastest CAGR between 2025 and 2034.

- By end-use industry, the food and beverage segment dominated the market in 2024.

- By end-use industry, the pharmaceuticals and healthcare range segment is expected to grow at the fastest CAGR in the forecast period.

Market Overview

AI in sustainable packaging refers to the use of artificial intelligence technologies to develop, optimize, and manage eco-friendly packaging solutions. It involves applying AI tools like machine learning, computer vision, and data analytics to:

- Design packaging that uses less material and is easier to recycle

- Predict demand and reduce overproduction or waste

- Improve supply chain efficiency to cut emissions

- Detect defects in packaging during production

- Support circular economy practices

Key Metrics and Overview

| Metric |

Details |

| Key Growth Driver |

E-commerce Expansion & Automation – AI enables smart, right-sized packaging and logistics efficiency |

| Leading Region |

North America |

| Market Segmentation |

By AI Technology Type, By Application, By End-Use Industry and By Region |

| Top Key Players |

IBM Corporation, Microsoft Corporation, Google (Alphabet Inc.), Amazon Web Services (AWS), Amcor Plc, Mondi Group, DS Smith |

What are the New Trends in the AI in Sustainable Packaging Market?

- Smart Packaging with Embedded Tech

NFC/ RFID sensors, QR codes, and digital tags deliver real-time data on freshness, temperature, and recyclability, boosting consumer transparency and supply chain traceability. Innovations like battery-free, stretchable smart packages monitor spoilage and actively release preservatives, prolonging shelf life (e.g., fish packaging).

- AI-powered Packaging Design and Optimization

Machine learning optimizes material selection, shape, and density to minimize waste and carbon footprint. AI-driven quality control and vision systems detect production defects in real time, reducing waste.

- AI in Intelligent Logistics and Upskilling

Automated warehouses with AI and robotics improve pack sizing and reduce plastic use while humans collaborate with machines for improved efficiency. Ranpak’s systems, for example, combine computer vision with automation to right-size boxes and minimize materials.

- Circular Economy with Advanced Sorting and Carbon Labeling

AI-powered recycling facilities use smart sorting to boost recycled material quality and efficiency. New startups and standards are introducing carbon footprint labels and blockchain-backed traceability to inform conscious consumers.

- Innovation in Biodegradable and Smart Materials

AI supports faster development and testing of sustainable materials (e.g., plant-based, compostable, or edible packaging) through simulation and data analysis.

- Biodegradable, Edible, and Plant-based Materials

Plant-sourced packaging (e.g., mushroom mycelium, seaweed, cornstarch, edible millet cups) is gaining traction. AI supports lifecycle analysis and compostability forecasting.

How Can AI Improve the Sustainable Packaging Market?

AI integration is revolutionizing the sustainable packaging industry by improving efficiency, reducing waste, and promoting eco-friendly innovation. It enables optimized packaging design by analyzing data to minimize material use while maintaining product integrity. AI also assists in selecting sustainable materials through life cycle analysis, supporting the use of recyclable and biodegradable options. In manufacturing, AI-driven quality control systems detect defects in real time, reducing production errors and waste. It enhances supply chain efficiency by forecasting demand, reducing overproduction, and optimizing logistics. Additionally, AI improves recycling through smart sorting technologies and engages consumers via smart packaging with sustainability information. Overall, AI supports lower carbon emissions and more responsible packaging practices, making it a key driver in achieving sustainability goals across industries.

Market Dynamics

Driver

Expansion of E-Commerce and Logistics

The booming e-commerce sector needs sustainable, right-sized, and efficient packaging to support automation and customization at scale. The growth of e-commerce and logistics is a major driver for the AI-sustainable packaging industry due to several interconnected factors. With the surge in online shopping, there is an increasing need for efficient, lightweight, and eco-friendly packaging to protect goods while minimizing waste. AI helps in designing right-sized packaging, reducing excess material, and lowering shipping costs. It also supports automated packaging systems that improve speed, accuracy, and energy efficiency in fulfillment centers. In logistics, AI optimizes routing, storage, and inventory management, reducing carbon emissions. Additionally, as consumers demand sustainable and smart packaging solutions, brands use AI to enhance product traceability, recyclability, and environmental transparency. Together, these needs fuel innovation and growth in AI-powered sustainable packaging tailored to e-commerce and logistics.

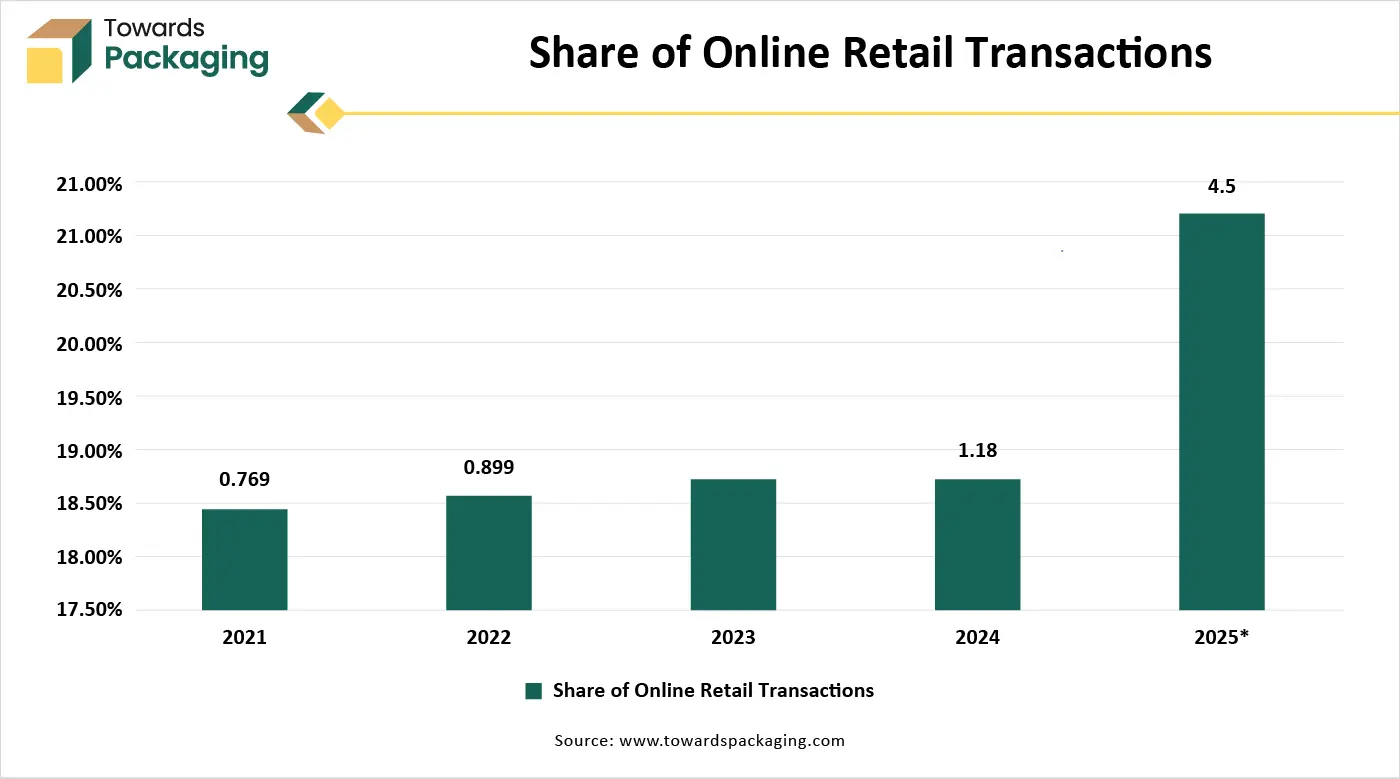

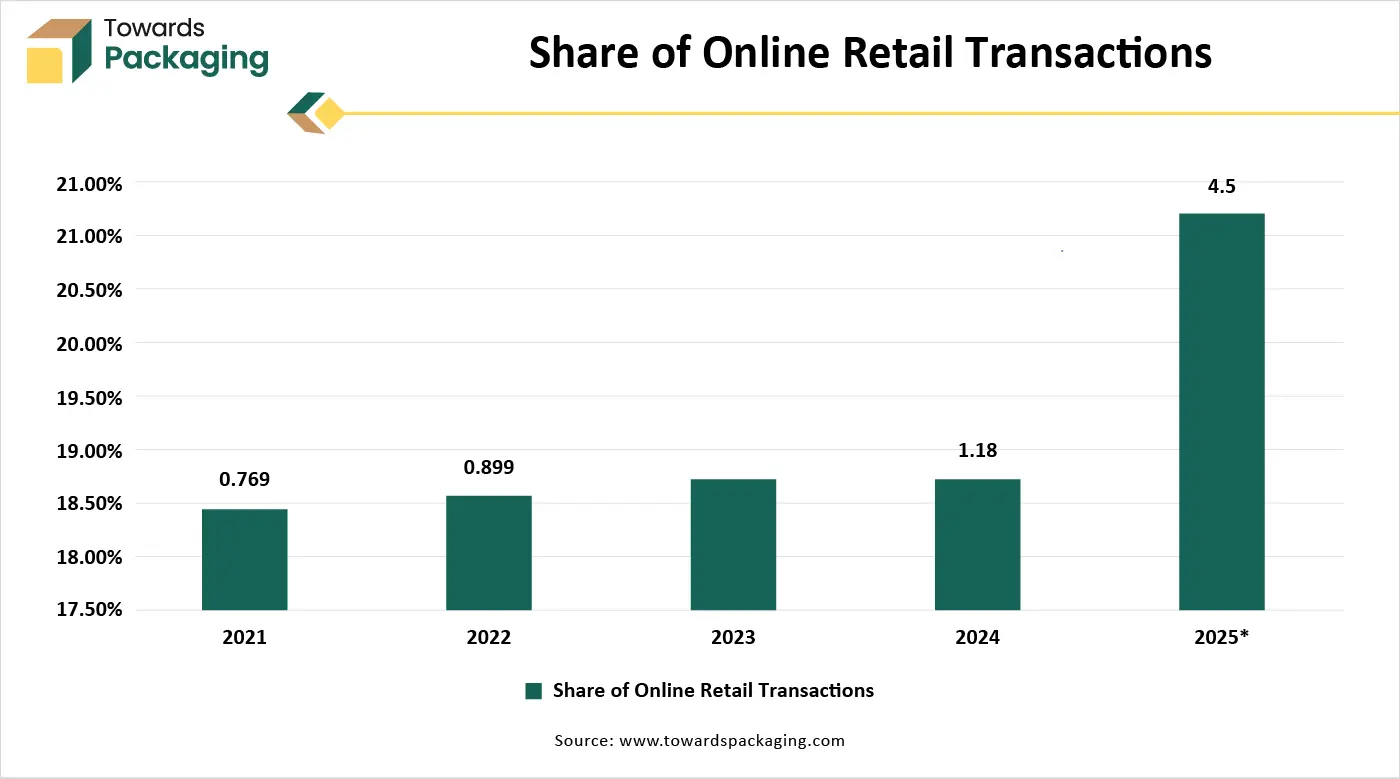

- In January 2025, according to the data published by the E-commerce Council 2025, e-commerce sales will account for 21% of retail sales, the largest percentile share to date. By 2027, it is anticipated that 22.6% of all retail transactions will take place online. Since 2021, the percentage of retail purchases made online has increased by an average of 0.32% per year. By 2025, the global e-commerce market is expected to reach USD 6.86 trillion. In 2025, global commerce sales will total USD 6.86 trillion, an 8.37% increase over 2024.

Restraint

Lack of Technical Expertise and Resistance to Change

The key players operating in the market are facing issues due to data privacy, lack of technical expertise, and resistance to change, which is estimated to restrict the growth of the market. Many packaging companies lack the in-house expertise to develop, operate, and maintain AI-driven systems effectively. In developing regions, poor digital infrastructure and inadequate access to advanced technologies hinder AI adoption.

Opportunity

Adoption of Circular Economy Models

AI can enhance material recovery, reuse, and recycling through smart waste sorting, predictive analysis, and packaging lifecycle tracking. AI enhances this model by enabling smart waste sorting. AI-powered vision systems and robotics improve the separation of recyclable materials, increasing recovery rates and reducing contamination. AI helps to track packaging materials through production, use, and disposal, enabling better material flow and transparency.

Segmental Insights

Why do Machine Learning Algorithms Segment Dominate the AI in Sustainable Packaging Market?

The machine learning algorithms segment holds a dominant presence in the market due to its predictive capabilities and customization, and design optimization. Machine learning (ML) excels at analyzing large datasets to forecast demand, optimize packaging design, and reduce overproduction, leading to less waste and more sustainable operations. Machine learning algorithms help to create right-sized, eco-friendly packaging by learning from historical data and consumer trends, minimizing material usage, and improving efficiency. Machine Learning computer vision systems detect defects in packaging in real-time, reducing rework, saving materials, and maintaining consistent sustainability standards. Machine learning aids in identifying recyclable materials, improving waste sorting, and enhancing packaging lifecycle analysis, which aligns with circular economy goals.

The natural language processing (NLP) segment is expected to grow at the fastest rate. Natural Language Processing (NLP) helps manufacturers extract and interpret complex sustainability regulations, packaging standards, and environmental policies across global markets to ensure compliance. NLP enables efficient processing of supplier contracts, sustainability reports, and certifications, helping companies assess environmental risks and select greener vendors. NLP streamlines the generation of ESG and sustainability reports by summarizing vast amounts of internal and external data in clear, report-ready formats. NLP-powered systems improve communication between research and development, design, and compliance teams by extracting insights from technical documents, patents, and industry research.

Which Application Type Dominated the AI in Sustainable Packaging Market in 2024?

The packaging design and optimization segment accounted for the dominant revenue share of the AI in sustainable packaging market in 2024. AI algorithms analyze product dimensions, weight, and shipping requirements to create right-sized packaging, reducing excess material use and lowering costs. AL helps design packaging that meets eco-friendly criteria such as recyclability, biodegradability, or minimal carbon footprint, supporting circular economy practices. Machine learning and generative design tools automate and accelerate the packaging design process, reducing time-to-market for new products. AI supports personalized and localized packaging designs, especially useful in e-commerce and marketing, without compromising sustainability or efficiency. By optimizing structure, material choice, and production processes, AI minimizes production waste, transportation costs, and energy use.

The supply chain and logistics segment is expected to grow at the fastest rate in the market during the forecast period of 2025 to 2034. AI analyses historical data, market trends, and real-time signals (e.g., weather, events) to accurately predict product demand, helping avoid overproduction or stockouts. AI systems automate inventory management by determining optimal stock levels, reducing waste, storage costs, and product obsolescence. AI-powered logistics platforms identify the fastest, most fuel-efficient delivery routes, lowering transportation costs and carbon emissions. AI enables smart warehousing through robotics, computer vision, and real-time data analysis, increasing accuracy and reducing labor costs. AI predicts potential disruptions (e.g., supplier delays, geopolitical issues) and suggests alternative sourcing or routing strategies to maintain resilience. AI continuously processes data to support fast, adaptive decisions, especially crucial in global, just-in-time logistics models.

Why Does the Food and Beverages Segment Dominate the AI in Sustainable Packaging Market?

The food and beverages segment dominates the market due to shelf-life optimization and supply chain efficiency. AI helps design packaging that extends product freshness by analyzing temperature, humidity, and spoilage patterns, reducing food waste. AI creates data-driven packaging designs that use minimal material without compromising product protection, supporting sustainability, and cost savings. AI enables intelligent packaging with sensors or QR codes that monitor freshness, track supply chain conditions, and provide recyclability instructions to consumers. AI assists in navigating complex food safety and environmental regulations, ensuring packaging meets both health and sustainability standards. AI improves forecasting, inventory management, and distribution in the food sector, ensuring sustainable packaging is used efficiently and at scale.

The pharmaceuticals and healthcare industry segment is growing rapidly due to rising demand for patient safety and reducing environmental impact. AI ensures accurate dosing and right-sized packaging for medicine, reducing material waste and improving sustainability without compromising safety. AI helps to navigate complex pharmaceutical packaging regulations and sustainability standards, ensuring materials meet environmental and safety criteria globally. AI enables intelligent packaging with features like temperature sensors, tamper detection, and digital instructions, improving patient safety and reducing wastage due to spoilage. AI analyses material performance and environmental performance, and environmental impact to help develop recyclable, biodegradable, or reusable packaging for drugs and medical devices.

Regional Insights

Which Region Dominated the AI in Sustainable Packaging Market in 2024?

North America held the largest share of the AI in sustainable packaging market in 2024, owing to advanced technological infrastructure and the strong presence of key market players. North America, especially the U.S. and Canada, has a well-established AI ecosystem with strong R&D capabilities, advanced manufacturing facilities, and high adoption of Industry 4.0 technologies. Leading packaging, AI, and automation companies are headquartered or operate extensively in North America, accelerating innovation in sustainable packaging solutions. Government policies such as the U.S. Plastic Pact and Canada’s single-use plastics ban push companies toward AI-enabled sustainable practices to meet compliance goals. Corporations in North America are heavily investing in AI to meet ESG targets, reduce their carbon footprint, and adopt circular economy models.

U.S. Market Trends

The U.S. AI in sustainable packaging market is driven by the strong technological infrastructure in the country, widespread use of automation and AI in manufacturing, and the presence of major players like IBM, Microsoft, WestRock, and Amcor. There is significant investment in smart packaging, especially in food, pharmaceuticals, and e-commerce. Additionally, regulatory pressure through the U.S. Plastic Pact and state-level bans on single-use plastics are pushing companies to adopt AI-driven sustainable solutions. The U.S. also sees rising consumer demand for eco-conscious and intelligent packaging, fueling rapid adoption.

Canada Market Trends

Canada is emerging as a key market driven by government initiatives such as the ban on single-use plastics, strong support for the circular economy, and growing awareness among consumers. Canadian companies are increasingly using AI to develop eco-friendly packaging materials, optimize logistics, and reduce food and medical waste. The country benefits from partnerships between research institutions and industries to develop AI-enabled sustainability innovations. Canada’s transparent policy framework and focus on environmental accountability further support market growth.

What Promotes the Growth of the Asia Pacific AI in Sustainable Packaging Market?

The Asia Pacific market is expanding rapidly due to the growing due to booming e-commerce and manufacturing sectors in the region. Rapid growth in online shopping and large-scale manufacturing, especially in countries like China, India, and Southeast Asia, drives demand for efficient, eco-friendly packaging solutions that AI can optimize. Regional governments are implementing policies to reduce plastic use and promote circular economy practices, encouraging industries to adopt AI for material optimization and waste reduction. Countries like China, South Korea, Japan, and India are heavily investing in AI and automation, integrating these technologies into packaging design, manufacturing, and logistics. Asia Pacific’s large electronics, food, and pharmaceutical sectors demand sustainable, smart packaging, driving the adoption of AI safety, traceability, and efficiency.

China Market Trends

The Chinese AI in sustainable packaging market is driven by strong government support and environmental regulations. China’s government has implemented strict plastic bans, waste reduction policies, and circular economy initiatives, pushing industries to adopt AI-based solutions for eco-friendly packaging design and material optimization. China is a global hub for AI research, investment, and innovation, with leading companies like Alibaba, Huawei, and Baidu actively developing AI-driven logistics, manufacturing, and packaging technologies. Urban Chinese consumers are increasingly eco-conscious, creating demand for smart, recyclable, and minimalistic packaging. Brands are turning to AI to analyze consumer behaviour and deliver sustainable packaging solutions. China’s status as a global manufacturing powerhouse supports the integration of AI-powered automation in packaging production, enhancing efficiency and reducing waste.

Europe’s Stringent Regulatory Laws to Support Notable Growth

The Europe region is expected to grow at a notable rate in the foreseeable future. Europe leads globally in environmental policy. Initiatives like the European Green Deal, Plastic Strategy, and Extended Produces Responsibility (EPR) force companies to adopt AI to meet recyclability, carbon reduction, and packaging waste targets. Europe leads globally in environmental policy. Initiatives like the European Green Deal, Plastic Strategy, and Extended Producer Responsibility (EPR) force companies to adopt AI to meet recyclability, carbon reduction, and packaging waste targets. European countries actively promote circular economy models, where AI is used for material recovery, smart waste sorting, and lifecycle tracking to minimize environmental impact.

AI in Sustainable Packaging Market Key Players

Latest Announcements by Industry Leaders

- In 2025, Bryan Boater, Global Managing Director of Automation at Ranpack, and Cory Connors, Host of the Sustainable Packaging Podcast, took place on March 17 at 2:30 p.m. as part of the ProMat 2025 conference agenda for an enlightening discussion on sustainability, packaging automation, and brand storytelling. After this talk, attendees will know the most important aspects to take into account when assessing packaging automation and how the best unboxing experience is driven by the appropriate warehouse technology. At ProMat 2025, the leading trade show for the packaging and material handling sector, which took place on March 17-20 at McCormick Place in Chicago, IL, Ranpak Holdings Corp., a global leader in sustainable paper-based packaging automation solutions for e-commerce and industrial supply chains, is poised to make waves. (Source: Business Wire)

- In June 2025, during the opening keynote address of Esko World 2025, Esko President Joel Deprenet formally unveiled a slew of innovations that use cloud computing and artificial intelligence (AI) to provide enhanced sustainability, central data storage, third-party integration, and increased productivity in task and process management. At the St. Louis Union Station Hotel in St. Louis, Missouri, Joel opened the 2025 packaging technology event in front of over 500 packaging and labels converters, brand representatives, and packaging experts. Esko President Joel Deprenet explained how the six new innovations address the rapidly changing business environment and regulations. (Source: Esko World)

New Advancements in the Market

- In May 2025, Intec Bioplastic, Inc. announced the introduction of EarthPlus Hercules Bioflex Stretch Wrap, the latest environmentally friendly packaging that can be used for both food wrap and pallet wrap. The Intec Bioplastic, Inc. company is the most practical, affordable, and environmentally friendly stretch wrap available worldwide. (Source: PR Newswire)

- In March 2025, the Plastics Recycling Show Europe (PRSE), which took place in Amsterdam, the Netherlands, from 1-2, demonstrated how artificial intelligence (AI) is revolutionizing the recycling of plastics through its exhibition on conference. (Source: Packaging Gateway)

Global AI in Sustainable Packaging Market Segments

By AI Technology Type

- Machine Learning Algorithms

- Natural Language Processing (NLP)

- Computer Vision

- Robotics and Automation

By Application

- Packaging Design and Optimization

- Supply Chain and Logistics

- Waste Management and Recycling

- Quality Control and Inspection

- Inventory Management

- Customer Engagement and Personalization

By End-Use Industry

- Food and Beverage

- Pharmaceuticals and Healthcare

- Consumer Goods

- E-commerce and Retail

- Manufacturing and Industrial

- Others (Automotive, Electronics, etc.)

By Region

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait