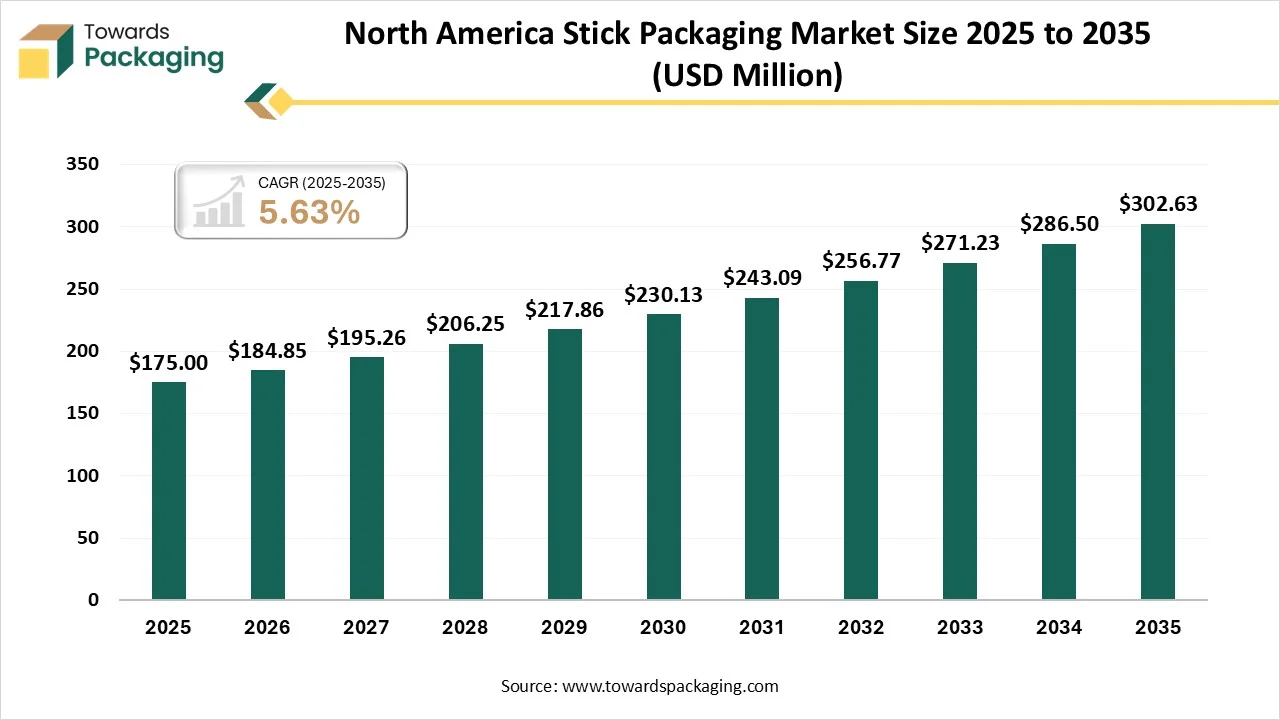

The North America stick packaging market is forecasted to expand from USD 184.85 million in 2026 to USD 302.63 million by 2035, growing at a CAGR of 5.63% from 2026 to 2035. The growth is due to single-serve packaging, which has become a selected design across sectors, from food and beverages to nutritional supplements and pharmaceuticals.

The North America stick packaging market refers to the production and supply of narrow, elongated, flexible pouches used for single-serve and portable applications. This market serves as a critical solution for "on-the-go" consumption, providing precise portion control for powders, liquids, and granules in the food, pharmaceutical, and cosmetic industries across the United States and Canada.

Sustainability remains a main theme in the growth of stickpack and sachet packaging technologies. Turpack machinery is loyal to investing in a greener globe by developing in the sector of environmentally friendly packaging solutions. By discovering alternative materials, developing energy efficiency, and lowering waste, we are setting the latest standards for the sector. The move to more sustainable packaging practices is not just a response to regulatory pressures; it's an overall reflection of updating user values. As the alertness and issues surrounding develop, the need for sustainable packaging options will continue to develop, by showing the direction for the future of the packaging sector.

Package Design and Prototyping: Stick pack packaging is a flexible and cylindrical package design created from a flexible film, which is usually utilized for single-serve dry powders or a single section of supplements or vitamins. Stick pack machines generate them by using one folded strip of a laminated film, packed on three sides. They are easy for folks on the go and serve as a sleek alternative to regular packaging formats.

Recycling and Waste Management: Although the pallets get the most attention, other materials like packaging deliveries and the shelving units are equally insightful for recycling. For example, metal shelving can be melted down and utilized to make the latest products. To lower the waste, likely reusable or recyclable packing materials, such as plastic wrap, foam, and cardboard, can be used.

Logistics and Distribution: The logistics for a stick packaging gives importance to space smoothness and the cost -effective transporting because of the design’s tubular and lightweight design. This single-serve design, which is prevalently used for liquids, powder, and granules, is frequently tracked through automated production lines.

The BOPP (Biaxially oriented polypropylene) segment has dominated the market with approximately 51.2% share in 2025, as it is biaxially oriented, which creates a film that is constant and more dimensionally constant, which is mono-oriented. This means that BOPP packaging opposes tearing and retains its shape during display and transport. BOPP also serves higher gloss and clarity; it serves products with a more luxurious appearance. Its layer can be corona -managed for perfect ink adhesion, which results in sharper and more brilliant printing as compared to OPP. This is the reason why BOPP is greatly used for rice, snack bags, and coffee packaging, and for labels, where both visual appearance and reliability matter.

The paper segment is projected to witness the fastest CAGR during the forecast period. Over the last few years, the beauty sector, including lip balms, sun sticks, foundations, and fragrances, has experienced major development. Their several features, like stems and their compact size and convenience for usage, have gained praise. The inventive paper stock solves all those issues, while also delivering producers with different personalized selections. It operates as per the simple rule: the customer needs to just peel off the packaging in a spiral design.

The food and beverages segment dominated the market with approximately 43.5% share in 2025, as they have gained popularity in the food and beverage sector because of their portability and ease. Several food and beverage products are currently available in stick pack design, which includes tea, sugar, spices, sauces, and snacks, making it perfect for on-the-go usage. Food and beverage producers also have advantages, as it lowers the material waste for smooth manufacturing. Stick packs also serve an expanded shelf life for the products, as they serve as a barrier against oxygen, light, and moisture.

The pharmaceutical and nutraceutical segment is projected to witness the fastest CAGR during the forecast period. Stick pack packaging is widely used in the pharmaceutical and healthcare sectors. Several pharmaceutical products are currently available in stock pack design, which includes granules, powders, and liquids. Stick pack packaging serves many benefits for the pharmaceutical and healthcare producers. Stick pack packaging serves as an easy and hygienic solution for single-serve pharmaceutical and healthcare products.

The powder segment dominated the market with approximately 65% share in 2025, as the structural pattern for stick packaging has naturally matched with the elements of granule and powder products. The stretched and slim shape enables smooth product flow and constant filling, which makes them perfect for free-flowing and lightweight formulas. For small-dose products, particularly for functional powders, pharmaceutical granules, and quick beverage powders, the stick pack packaging provides higher smoothness and a perfect usage experience as compared to regular pouch designs.

The liquid & semi-liquid segment is expected to witness the fastest CAGR during the forecast period. Liquid stick pack needs films that have perfect power in order to prevent leaks, as no one wants a sticky mess in their bag from the store shelf. Such uses frequently call for tailored sealant layers and precise considerations of any filling machines, whether anyone is using volumetric filler or a liquid pump. Beyond any product continuation, the regulatory needs may restrict any selections. Some industries have particular limitations on the materials, such as PVDC coverings, which are prevalent in the cellophane-dependent structures.

The vertical form fill seal segment has dominated the market with approximately 72% share in 2025, as such machines are constructed in a mono-block and heavy-duty steel frame, which are being crafted to deliver free availability to every side of the machine as well as promote the maintenance steps. The vertical packaging machinery is completely protected with an interlocked magnetic protective switch. A stick-pack is a perfect display for powder, granules, liquids, and pieces. Such stick pack machines are widely used for different products, such as diet or food products, personal care, and home care.

The digital printing segment is projected to witness the fastest CAGR during the forecast period. Digital print in packaging is a printing procedure that uses digital technology in order to print high-quality graphics, text, and images directly into packaging materials. Like regular printing methods, which require a costly setup amount and long lead period, digital print technology allows businesses to make tailored packaging materials quickly, and they are cost-effective. It also serves perfect reliability, and the speed, compared to regular printing methods, as digital printers do not need the use of printing plates and setup time.

The United States dominated the North America stick packaging market with approximately 82% share in 2025, as it is driven by growing user choice, developing the urge for smooth and compact packaging solutions, and technological developments across different sectors like pharmaceuticals, food and beverages, and, lastly, personal care. As organizations seek to update the packaging procedure, develop the product’s shelf life, and lower the waste, the acceptance of inventive stick pack machinery has become of strategic importance. The market’s growth is also fueled by the developing trend of easy packaging, which is linked with the demand for cost-effective and sustainable packaging options.

Trend of Stick Packaging Market in Canada: It is classified by its tailored focus on a vertical form-fill-seal technology which is personalized for stock pack sues. This industry initially delivers fields such as food and beverages, pharmaceuticals, personal care, and nutraceuticals in which the demand is smooth, growing, and for hygienic packaging solutions that are developing. The sector design is made of a mix of well-developed machinery producers, regional distributors, and developing automation technology servers. The market has a high degree of technological invention, which is being driven by the demand for increased manufacturing capacity and compliance with strict health and safety standards.

By Material

By End-User

By Product Form

By Technology

February 2026

February 2026

February 2026

February 2026