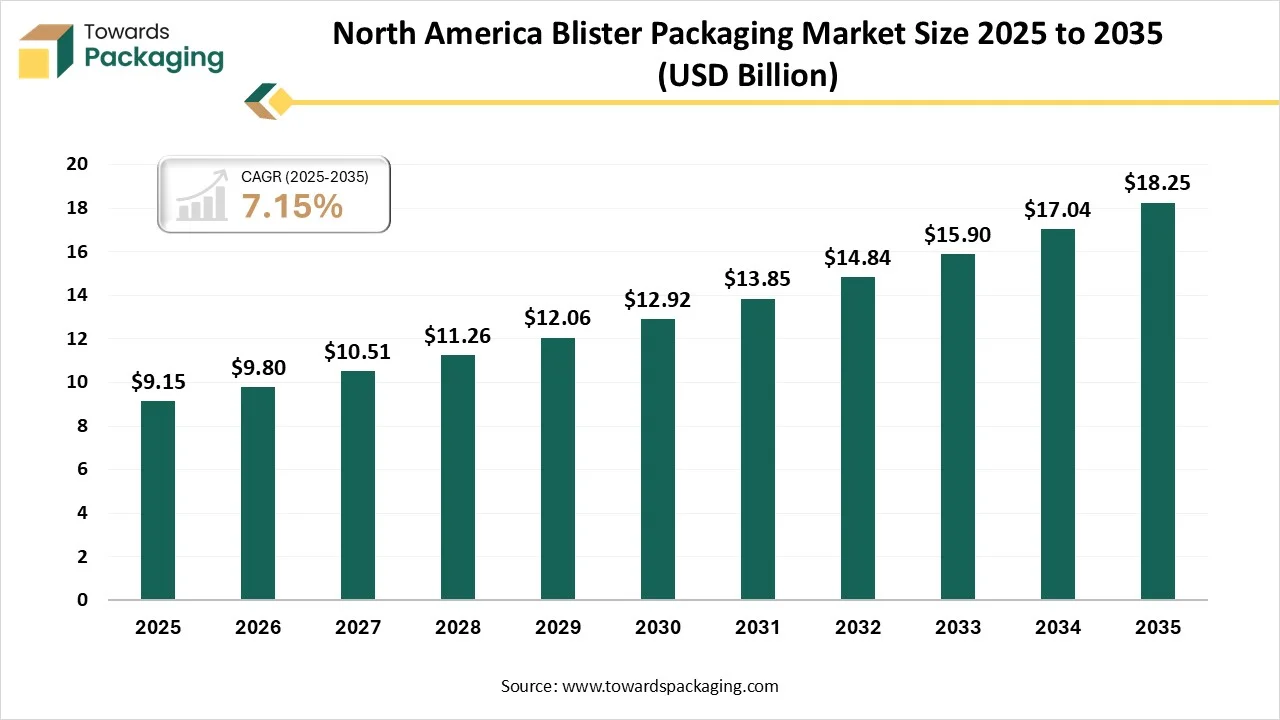

The North America blister packaging market is forecasted to expand from USD 9.8 billion in 2026 to USD 18.25 billion by 2035, growing at a CAGR of 7.15% from 2026 to 2035. The demand for healthcare alertness has integrated with a growing demand for unit-dose packaging, which has kept blister packs as a selected choice for drug packaging because of their potential to serve barrier protection and extended shelf life.

The North America blister packaging market refers to the industry segment involved in the production and distribution of blister packaging solutions across the United States, Canada, and Mexico. Blister packaging consists of thermoformed plastic cavities sealed to a backing material like paperboard or aluminum foil. It is widely used to package pharmaceuticals, consumer goods, electronics, food products, and healthcare items.

The initial function of blister packaging is to prevent products from external elements such as light, moisture, and physical damage. Inventions in blister packing technology have concentrated on product protection and constant line, which ensures the reliability of the packaged ingredients over a period. One main growth in such space is the main application of barrier materials that serve as developed prevention against oxygen and moisture, which expands the shelf life of a pharmaceutical product and fragile goods.

The thermoforming segment dominated the market with approximately 66.9% share in 2025 because thermoforming points to a production procedure in which a plastic sheet is heated to a reliable forming temperature, which is formed into a particular shape in terms of mold, and trimmed to make a usable product. With respect to pharmaceutical packaging, thermoforming is initially used to generate blister packs or medical device trays, which are compulsory for hygienic and safe packaging of capsules, pills, and other medication forms.

The cold forming segment is projected to witness the fastest CAGR during the forecast period. This packaging is a kind of packaging utilized in the pharmaceutical sector. It is an integration of plastic blisters and laminates created from plastic and aluminum material. The laminate is created by using a procedure called cold forming, in which the aluminum is designed at room temperature, instead of being heated. Such procedures assist in retailing the material’s thickness and power, by serving excellent barrier characteristics to protect the product.

The plastic films segment dominated the market with approximately 61.4% share in 2025, as PVC (polyvinyl chloride) is the most prevalent blister film because of its low cost and perfect clarity. PVC blisters are convenient to thermoform into complicated shapes as they display tablets attractively. Producers frequently laminate PVC with other plastics or any coatings to develop performance and results. For example, PVDC is often co-extruded or covered on PVC to generally encourage oxygen and moisture opposition.

The paper and paperboard segment is projected to witness the fastest CAGR during the forecast period. Recycled paperboards serve several benefits with a high percentage of recycled paper ingredients, which is a more sustainable packaging selection. Recycled paperboard serves many other advantages, such as sustainability, which is chosen by organizations that select recycled paperboard for their blister pack backing, which are selecting a product produced with more sustainable materials and step-by-step methods to develop their corporate responsibility.

The healthcare segment dominated the market with approximately 64% in 2025 as blister packaging markets unit-dose packaging, which assists precise dosing and develops patient adherence to prescribed diagnosis regimens. The segments assist the patients and caregivers in managing medication consumption by lowering the chances of overdosing or skipping doses. Some of the blister packs also count calendar rules or printed principles, which are particularly helpful for elderly patients, and ultimately encourage medication compliance.

The unit-dose medicine segment is expected to experience the fastest CAGR during the forecast period. Clamshell packaging has two halves that link together. Such resilient designs prevent heavy products perfectly, as producers can pack clamshells by using radio frequency, heat, or UV light for tamper resistance and add snap-shut buttons for reuse. On the other hand, tri-fold clamshells utilize two hangers, which makes a huge triangular bottom when it is folded.

The standard blister segment dominated the market with approximately 65% share in 2025 because wallet blister packaging or an “blister wallet” is a tailored kind of packaging which is used in pharmaceutical production, which combines standard blister strip (foil container and unit-dose plastic) into a preventive fold card created from plastic or paperboard. This wallet-style packaging makes an integration of perfect product user-friendliness, prevention, and a developed informational area. Each of the booklets can provide detailed product information, dosage instructions, and linked details, too.

The smart blisters (NFC/QR) segment is expected to experience the fastest CAGR during the forecast period. This packaging uses conductive materials, embedded sensors, NFC chips, and printed electronics to track and dose removal in a smooth way. Whenever the dose is consumed, such a step is recorded and transferred in real-time via Wi-Fi, Bluetooth, and cellular links to connect stages or caregiver apps. Technologies such as printed electronics, conductive traces, and RFID send actual time consumption rules for cloud stages that serve valuable insights into a patient's performance.

The United States dominated the North America blister packaging market with approximately 82% to 85% share in 2025, as it is being driven by growing procurement designs, regulatory scenario adjustments, and automation wave acceptance. The import trends show a gradual move towards sustainable and high-quality materials that reflect both economic moves and sustainability shifts in the industry, which favors eco-conscious supply chain directions. Production updation, specifically through high-level digital integration and robotics, is developing operational smoothness and lowering the lead times during pricing scenarios, which are being pushed by raw material reliability and power cost changes. Technology discovery is central to designing market possibilities with smart packaging serialization and an accurate machine reconfiguring manufacturing workflow.

Trend of Blister Packaging Market in Mexico

The development of the Mexican blister packaging market is initially being driven by the development of healthcare and pharmaceutical product manufacturing, which urges smooth packaging solutions. There is growing user alertness about medication safety and compliance with regulatory standards, which further develops the urge for advanced blister packaging machinery. Furthermore, the growing commonness of chronic disease and the stretched pharmaceutical sector in Mexico are important. The move towards eco-friendly and sustainable packaging materials encourages machinery acceptance and invention.

By Technology

By Material

By End-User Industry

By Feature

February 2026

February 2026

February 2026

February 2026