Die-Cut Boxes Market Share and Trends, Import & Export Analysis

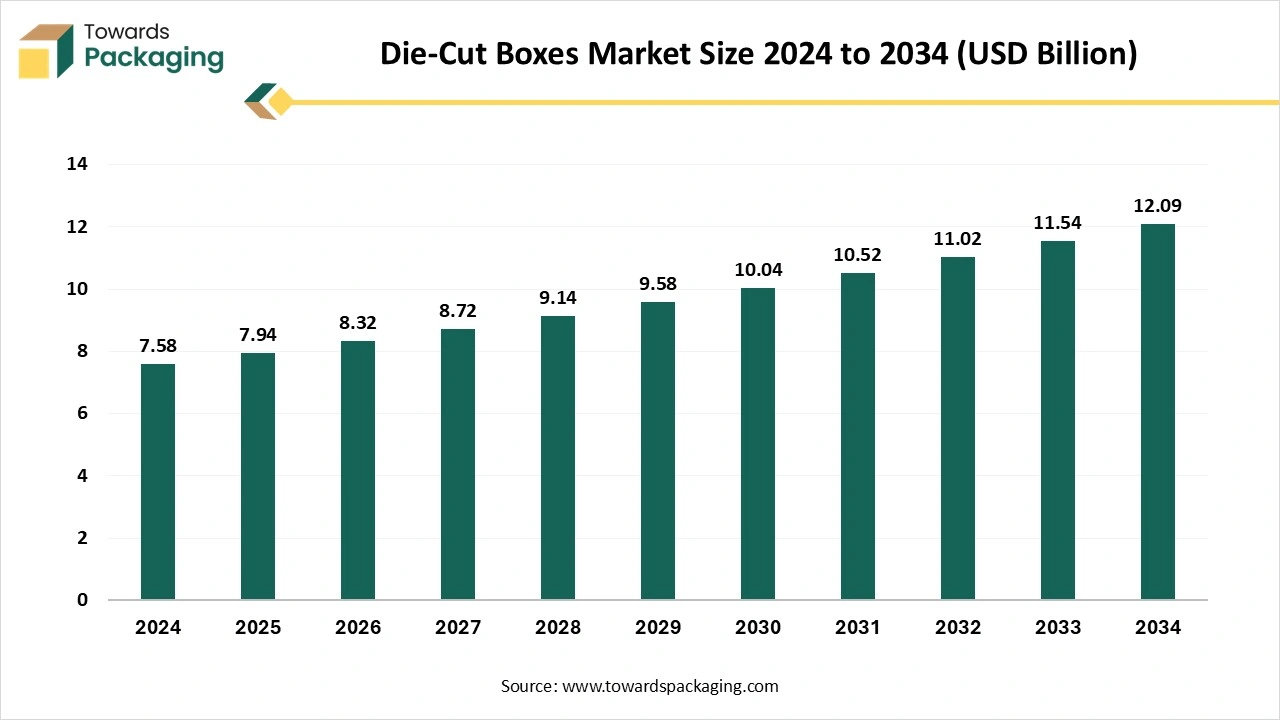

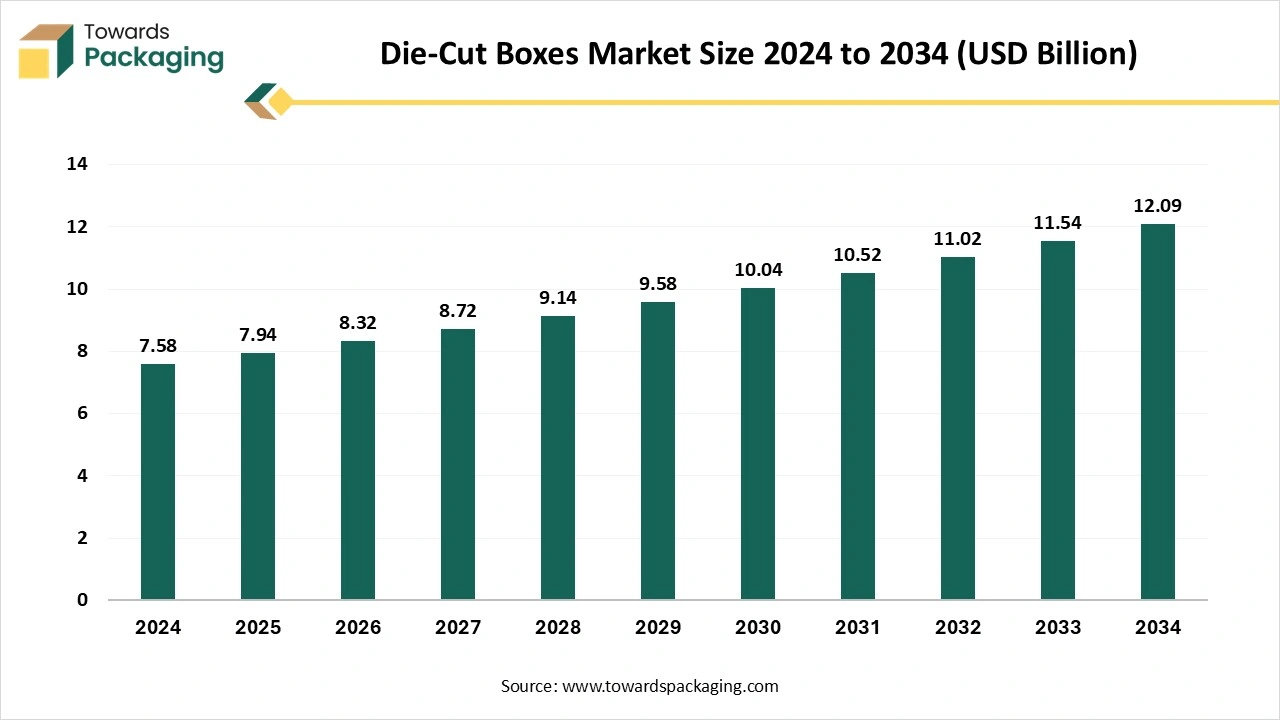

The die-cut boxes market is forecasted to expand from USD 8.33 billion in 2026 to USD 12.70 billion by 2035, growing at a CAGR of 4.80% from 2026 to 2035. This growth is driven by the rapid shift toward customized packaging and the adoption of digital and AI-enabled die-cutting systems. In 2024, regular die-cut boxes accounted for the largest share, while window die-cut boxes are projected to grow fastest through 2034.

Regionally, Asia Pacific held the dominant position in 2024, benefiting from strong e-commerce and manufacturing, while North America is forecast to register the highest CAGR. The report also integrates competitive intelligence covering companies like Mondi, Smurfit Kappa, WestRock, and DS Smith, along with full value chain mapping, raw material flows, and global import–export trends.

Key Takeaways

- In terms of revenue, the die-cut boxes market is valued at USD 7.94 billion in 2025.

- The market is projected to reach USD 12.09 billion by 2034.

- Rapid growth at a CAGR of 4.80% will be observed in the period between 2025 and 2034.

- Asia Pacific dominated the global market in 2024.

- North America is expected to grow at the fastest CAGR in the forecast period.

- By type, the regular die-cut boxes segment dominated the market in 2024.

- By type, the window die-cut boxes segment is expected to grow rapidly over the studied period.

- By material, in 2024, the cardboard segment led the global market.

- By material, the Kraft paper segment is expected to show the fastest growth over the forecast period.

- By application, the food and beverage segment held the largest revenue share in 2024.

- By application, the electronics segment is expected to grow rapidly in the coming years.

- By end-user, the e-commerce segment led the global market in 2024.

- By end-user, the retail packaging segment is expected to grow rapidly over the studied period.

Key Metrics and Overview

| Metric |

Details |

| Market Size in 2025 |

USD 7.94 Billion |

| Projected Market Size in 2035 |

USD 12.70 Billion |

| CAGR (2025 - 2035) |

4.80% |

| Leading Region |

Asia-Pacific |

| Market Segmentation |

By Type, By Material, By Application, By End-Use Industry and By Region |

| Top Key Players |

Midlands Packaging Corporation, A M Packaging, Mondi, Smurfit Kappa Group, WestRock, A-One Packaging Corporation. |

A Custom Packaging Solution Rooted in Precision and History

Die-cut box is a kind of cardboard box created with custom and complex cuts to receive a specific design. If any specific user wants a custom box for an e-commerce business, he is seeking a mailer box, and if any customer wants to pack their wine, then they are searching for a wine die-cut box. This box got its name from a slotter container, which bears its name from the machine accountable for its creation: the die-cutter. The machine allocates more complicated and unusual cuts to the box, which makes the box much more tailored to specific needs.

The process includes mounting box blanks onto a wooden frame, which is then twirled in a circular and continuous motion. During this process, accurate cuts and creases are established, and the die-cut box is fully ready to use. Die-cutting commenced in the 1300s when dies were used to cast or stamp metal coins. This word originated from the Latin word “ datum, “which means given, put, or placed. Primarily, the word “ die cutting “means to cut or shape. Until the 1800s, the word die was used to note some things that were generated by machines.

Die-Cut Boxes Market Trends

- The future of die-cutting is being shaped by rising consumer demand and the latest wave of technological growth that shows the capability to set the latest standards for productivity, speed, and versatility.

- Like regular die-cutting technique, which depends on physical dies, digital die-cutting utilizes laser technology and digitally grown mechanical creasing, which offers a more flexible and effective approach to the cutting procedure. This high-level technology allows levels of accuracy and convolution that cross rotary and platen die cutting, and push the limits of packaging design.

- The industrial Internet of Things ( IoT) has also played an important role in growing rotary die-cutters by linking machines to networks for developing data analysis and operational insights. With IoT, operators can now track machine performance in real time, which gives insightful data on wear and tear, production rates, and energy exploitation.

- Structural upgrades like bearing and cutting drums, and bolster frames have grown the durability and expanded the lifespan of rotary die cutters, which specifically reduce maintenance requirements. This not only provides lower operational costs but also ensures high-quality cuts.

- High-level anvil technology, such as urethane anvil blankets and automatic anvil trimmers, also works to strengthen the lifespan of the cutting surface and to ensure constant quality.

Artificial intelligence proposes transformative potential for die-cutting. It can bring greater efficiency and accuracy to the production procedure, which allows machines to automatically adjust settings depending on actual time analysis. This acceptability will open the door for less downtime, less waste, and updated resource utilization. By incorporating AI-driven machine learning algorithms, corrugated machines can recognize patterns, foretell maintenance needs, and identify faults early in the production stage, reducing cost errors and improving product quality. Artificial intelligence can also simplify predictive analysis, assisting companies in forecasting demands, automating order parts, and adjusting manufacturing schedules accordingly.

A die-cutting machine outfitted with an AI Image recognition system utilizes high-resolution cameras to entrap nature entering the manufacturing line and automatically recognizes the material type (such as thick paper, corrugated paper, thin paper, etc) using a deep learning algorithm. This system can robotically adjust the die-cutting machine settings depending on the identification outcome, such as cutting depth and speed of the die.

Die-cut boxes Market Dynamics

Driver

Customized packaging solution

Creating tailored shapes is important in packaging boxes and in the packaging industry. And, die-cutting is one of the most effective procedures to create required boxes, which drives the die-cut box market. The importance of this cutting procedure cannot be ignored in the industry. If one wants to tailor the shape of the boxes and be different in that, die-cutting can assist with this demand. It can take advantage of personalized die-cutting service to create a product box in our desired shape.

As beauty brands shift toward sustainability, personalization, and visually striking aesthetics, die-cut packaging emerges as a perfect solution. Die-cutting boxes are not just perfect for making product boxes in our desired shape, but can also help you add attention-grabbing add-ons to boxes. Its potential to serve custom shapes, intricate designs, and eco-friendly materials meets perfectly with current consumer demand. These trends not only enhance product presentation but also support brand storytelling and environmental responsibility.

Restraint

Manufacturing-related challenges

Some parts of the product are not fully cut through, which results in lasting connections that need extra space to separate. Inconstant cutting depth not only affects the product's display but also causes complexities in following folding and assembly procedures that reduce production effectiveness. The cutting edges are rough with noticeable fraying and tearing marks that affect the product's look and quality. On the other hand, multi-layered paper structures are not clearly cut with fiber pulling, which affects the final product's trustworthiness and quality. Apart from this, excessive creasing causes damage or cracks to the paper surface that affect product structural honesty and aesthetics.

Opportunity

Versatility and Appeal of Die-Cut Boxes in Modern Packaging

Die-cut boxes are familiar for making customized packaging that outlines a product’s shape, which makes them perfect for items like candles, soaps, and electronics. Their lightweight but rigid structure prevents brittle goods, but their compact design saves space during shipping and assembly. Highly personalized, die-cut packaging includes colors, logos, and designs that make it the attention-grabbing choice for retail flaunt. Their eco-friendly materials, such as corrugated and cardboard paper, serve as a cost-effective and durable solution in terms of packaging products of different sizes, from everyday products to luxury goods like jewelry and watches. Easy to assemble and responsible for shipping, die-cut boxes develop both product protection and brand display. Their creative design assists businesses from competitors that give both visual appeal and practicality.

Segmental Insights

Regular Die-Cut Boxes Dominated the Market in 2024

Regular die-cut boxes' main goal of production is to safely supply products to their required destination. Die-cut packaging includes encasing products with strong corrugated boxes that are customized to the specific designs and dimensions of the item. This custom-built verifies the top protection of goods during transportation, protecting them against collisions and capable damage. These boxes even carry reliability and durability despite their lightweight nature. The usage of lightweight cardboard material in their design makes sure they are not as bulky as they look.

On the other hand, window-die-cut boxes are gaining popularity. They are also known as “see-through” packaging made from an association of paperboard and clear plastic. The box is generally created from cardboard or corrugated board, while the window is made from a thin sheet of plastic such as PET. The toys, cosmetics, and electronics industry currently showcases window box packaging. The apparent window makes a preview of what the user can expect from the product, which makes it more enticing and gives a sense of urgency to purchase.

Cardboard Material Dominates the Market

Cardboard boxes are a kind of dry packaging product. It also supports the prevention of moisture accumulation within the package. Cardboard boxes also serve as a medium amount of flexibility. The box is able to transform and misrepresent to a minute degree, and still protects the content. Harder packaging will not be disrupted without bending, whereas softer plastics serve the product less protection. Manufacturing of cardboard boxes enables the boxes to save a regulated shape, such as rectangles and squares, which helps in packaging and storage. By die-cutting cardboard boxes, box producers can make several tailored to the box shape, meaning they can be packed in different ways and complement the industry of the product inside.

The use of Kraft paper in packaging is growing rapidly in the market. These are tailored boxes created by Kraft into specific shapes using a machine die-cut. The die is a technical tool having sharp steel blades that form a design or template. Die-cut packaging of kraft is a perfect selection for packaging products because it can be personalized to set the product perfectly and have a more high-class look than regular box packaging. It is not only a packaging material but also an influential tool that combines durability, luxury, and sustainability in one common solution. Its brilliant and smooth surface makes a promoted and high-level presentation of the product.

Food and Beverage Sector Growth Drives Market

Die-cut boxes provide great protection for food and beverages, which ensures product safety and freshness, too. The stout design of the boxes protects against any external factor from spoiling the contents inside. This is specifically crucial for sensitive items that require being kept at certain temperatures and conditions to maintain their quality. The cartoon material behaves as a barrier against light, moisture, and oxygen, which prevents contamination and maintains the taste and texture of the food and beverages.

Electronics packaging is witnessing rapid growth. The electronics industry comprehensively uses die-cut boxes to ensure the secure, safe, and efficient packaging of delicate components and high-value products. These boxes are accurately cut to fit the unique shapes and sizes of several electronic devices, from smartphones and tablets to circuit boards and accessories. Die-cut packaging serves superior protection by reducing movement during transport and reducing the risk of damage caused by static, shock, or vibration. Furthermore, die-cut boxes assist in organizing multiple elements neatly, improving unboxing experiences and inventory handling. With the growth of e-commerce and the growing demand for eco-friendly and safe packaging, die-cut boxes have become a vital solution in the electronics industry.

E-Commerce Dominance Due to Related Advancements

The e-commerce industry depends heavily on die-cut boxes to enhance product protection, improve customer experience, and streamline logistics. These boxes are tailored to fit products accurately, minimizing movement during transit and reducing the risk of damage. Die-cut packaging enables fast and effective packaging, saves time, and reduces labor costs. It also grows the unboxing experience as an important factor in user satisfaction and brand perception by serving neat presentations and frequently includes tailored inserts or compartments. Furthermore, die-cut boxes can be easily branded with designs and logos.

Retail packaging solution greatly benefits brand image. The accurate cuts and clean edges make them perfect for shelf display, which helps products stand out and catch consumer attention. Retailers use die-cut windows or different structural designs to attract customers to display and communicate with the product without opening the packaging, growing trust and buying intention. Also, die-cut boxes assist in effective brand storytelling. With huge space for logos, graphics, and product descriptions, they help convey a brand’s identity clearly and constantly.

Asia-Pacific Dominated the Market in 2024

In Asian countries, die-cut boxes have become an important part of packaging across different sectors, specifically due to the region’s booming manufacturing, e-commerce, and retail industry. These boxes are heavily favored for their cost-efficiency, personalized, and eco-friendliness. In countries like India, China, Japan, and South Korea, die-cut packaging is widely used for cosmetics, textiles, food items, and regular products too.

With the growth of sustainable packaging awareness, several Asian brands are shifting to recyclable die-cut boxes made from paperboard or corrugated materials. The rising middle-class population and fast digitalization have further boosted demand for die-cut packaging, especially in e-commerce and retail, which makes it a main driver of the packaging industry in the area.

North America to Host the Fastest-Growing Market in the Coming Years

North American consumers constantly give importance to convenience. The popularity of on-the-go lifestyles and the pressure to capture more comfort and work in a similar amount of time is growing. The demand for portable and easy packaging patterns that include single-serve, resealable, and ready-to-use products and outcomes in downsizing, like minute unit sizes, leads to an overall rise in packaging demand. As users become more health-conscious, they are selecting better-for-you products, making transformations in product selection. At the same time, packaging must protect product probity, especially for supplements, food, and cosmetics. Sustainability remains big on the agenda for many worldwide brands as growing consumer awareness, state-level legislation, and inventions in recyclable mono materials and big mixtures are creating momentum.

Die-Cut Boxes Market Key Players

Latest Announcements by Market Leaders

- On 29 May 2024, Highcon, which is a developer of digital cutting and creasing systems for different substrates, formats, and uses, revealed a difference at Drupa in the year 2024. The stress is the Highcon Beam 3 digital die-cutting machine and the Highcon Beam Writer for offline writing of DART Foils. (Source: The Packman)

Recent Development

- On 1 February 2025, Conway Machine displayed its gripper bars for Bobst 102 and 106 die cutters, as the company has been serving the industry with after-market solutions since 1972. (Source: Print Week)

- On 21 April 2025, AstroNova, who is a top inventor in digital print technology, revealed the launch of two new high-performance digital label presses and a direct-to-package printer at FESPA Global Print Expo 2025 in Berlin, Germany. (Source: Business Wire Inc.)

Die-Cut Boxes Market Segments

By Type

- Regular die-cut box

- Window die-cut box

- Die-cut mailer box

- Cake box

- Custom die-cut box

By Material

- Cardboard

- Kraft paper

- Plastic

- Corrugated material

- Recycled material

By Application

- Food and beverage

- Electronics

- Cosmetics

- Retail

- Pharmaceutical

By End-Use Industry

- E-commerce

- Retail packaging

- Industrial packaging

- Food packaging

- Pharmaceutical packaging

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa