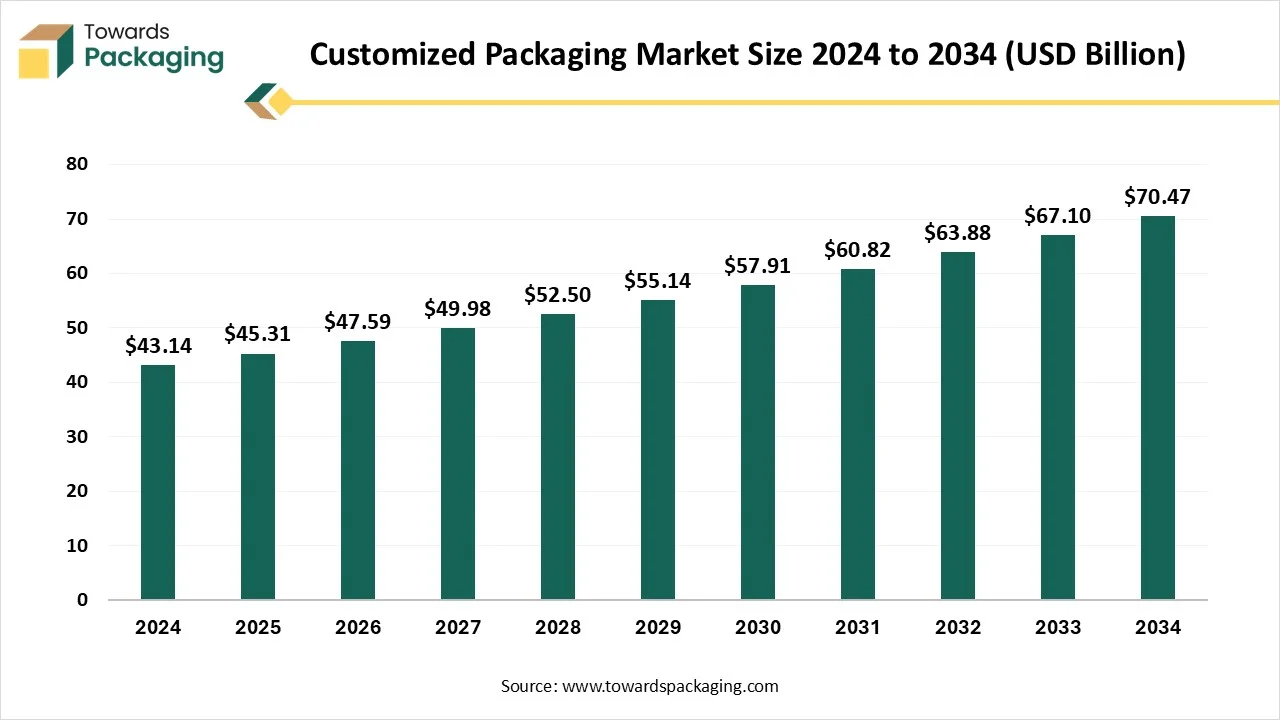

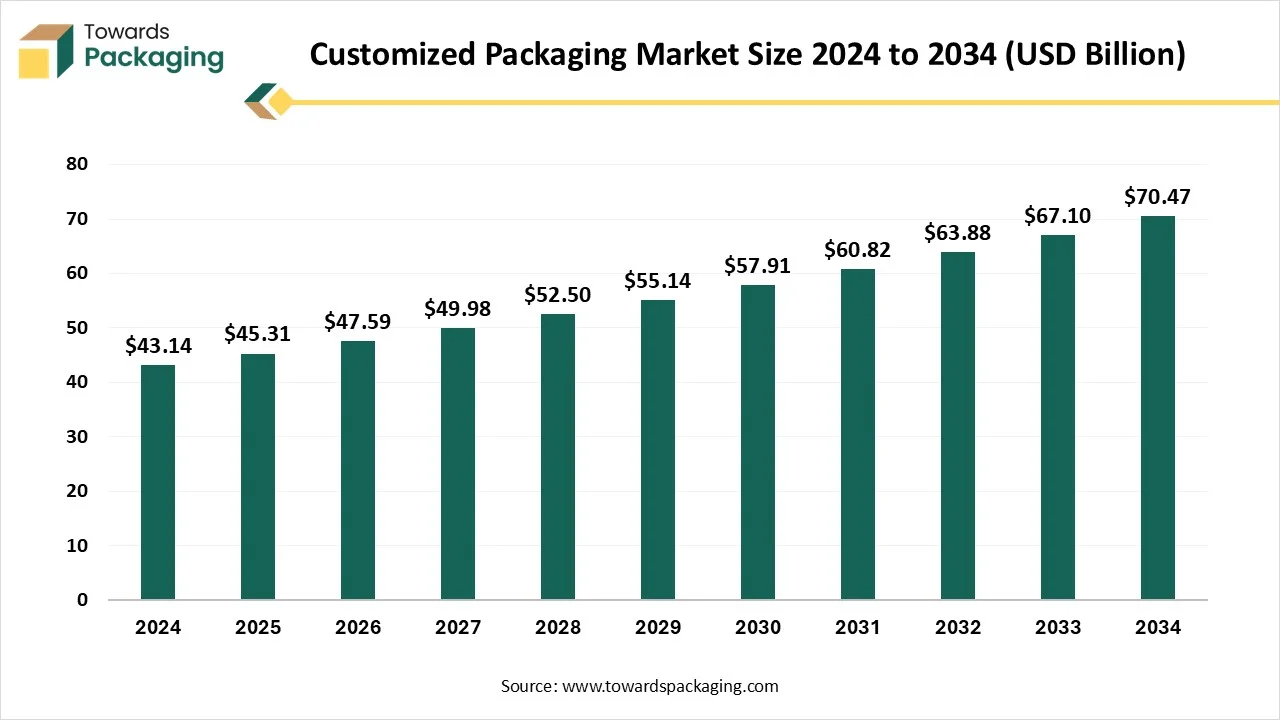

The customized packaging market is expected to increase from USD 47.59 billion in 2026 to USD 74.01 billion by 2035, growing at a CAGR of 5.03% throughout the forecast period from 2025 to 2034. Market growth is driven by rising e-commerce, increasing brand differentiation strategies, demand for sustainable and innovative packaging solutions, and growing consumer preference for personalized products.

The customized packaging market covers the manufacturing and distribution of packaging solutions designed to meet specific brand, product, and consumer requirements. Customized packaging includes unique shapes, sizes, materials, colors, printing, and labeling for products across food & beverages, personal care, pharmaceuticals, e-commerce, electronics, and luxury goods industries.

Custom packaging plays an important role in how a brand appears on the shelf. It's called a primary touch that allows users to share their story about the used product. A unique package, shape to color, can assist products in standing out on the crowded shelf. Custom design delivers brands the tool to make packaging that communicates with users directly to every customer. Personal touches like QR codes for instant engagement, custom printed QR codes, and thank you notes can make buyers feel valued. Small details like these create moments of happiness, creating loyalty and trust over time. Delighted customers are more likely to share their experience on social media, become repeat buyers, and suggest the brand to others.

Apart from this, with Custom design, packages are personalized for both brand effect and retail convenience. Characteristics like reinforced corners, easy-open trays, and bold graphics make headlines and shopping easier. Retail-ready design stores shelves clean and products attention-grabbing, saving time for both shoppers and staff members.

Advancements Drive The Customized Packaging Market

Custom packaging is a perfect way to display your brand to a much larger audience. By utilising different colours and logos on your cardboard boxes, it will become an advertisement for any organization and push people to discover products. By exemplifying the brand's identity, packaging accessories can assist in boosting brand awareness. Every package served in a custom box is an opportunity to confirm brand recognition and keep your business popping up in everyone’s mind. In current days, the packaging we use plays a crucial role in the complete experience customers have with any brand. By utilising high-quality cardboard boxes which are tailored to the particular products we sell, one can grow their expectations of your customers. Making an unboxing experience will grow customer satisfaction and commitment, and even push people to tell others about your brand.

Limited Use of Operations

The very primary and most crucial challenge is that product customization includes the fundamental rethinking of operations. From Web design to order management, shipping, and the way the operations are run, there needs to be planning in advance. Using and setting up the product customization procedure can change things at a very fundamental level of any print business. For every tailored product, one demands a different logistics procedure, as it will have its own shape, design, and size. Also, controlling custom packaging across several suppliers can be complicated. Every supplier may have different challenges, production timelines, and minimum border quantities.

Custom packaging particularly demands more time to generate than standard options. This can expand our complete lead times by 2-4 weeks, depending on the complexity and supplier potential.

Eco-Friendly Customization Is The Key To Growth

Eco-friendly packaging practices include choosing sustainable materials or reducing the use of materials that are more challenging for the environment. For instance, plastic particles have been used over time, resulting in a huge spread of ocean contamination and leading to a serious situation. Bioplastics are a kind of eco-friendly material, unlike the past polymers, which were generally made from petroleum. Mushroom-based packaging can be created using less energy than regular plastic packaging and will decompose naturally in landfills. Apart from these, these materials can be used to create biodegradable films that are water-soluble and edible. It is used for freshness seals because of its capability to protect against oxygen effectively.

How Did The Paper And Paperboard Segment Dominate The Customized Packaging Market?

Paper and paperboard segment dominated the customized packaging market in 2024, as it is heavily recyclable, which lowers the demand for raw materials and lowers the strain on natural resources. Recycling paper assists in protecting forests, lowers greenhouse emissions, and reduces energy consumption. The paper, which is made from wood fibers, comes from trees. Just like fossil fuels, trees are a renewable resource. Sustainable forestry dealings can make sure that trees are being harvested responsibly and planted again to track ecological balance. Paperboard packaging, specifically, is hugely accepted in recycling programs and can be processed into the latest paper products, contributing to a circular economy. It is a thick, paper-based substrate created from cellulose fibers, crafted to be both lightweight and rigid. As compared to regular paper, it serves a more structural and rigid principle, which makes it perfect for packaging use that needs to stand up, protect content, and hold shape.

The biodegradable and plant-based products segments are expected to be the fastest-growing in the market during the forecast period. One of the prevailing base materials for this kind is Polylactic Acid, which is an eco-friendly material created from starch, sugarcane, and corn. PLA is primarily made from green or renewable sources, whereas the Biodegradable packaging is not recyclable. So, the Biodegradable PLA manufacturing is a famous idea that shows the fulfillment of the cost-effective and non-petroleum plastic manufacturing. The huge benefit of PLA as biodegradable packaging is its acceptability and the fact that it normally decomposes when exposed to the surrounding environment.

While plant-based packaging reduces dependency on fossil fuels, it also preserves non-renewable resources. Its manufacturing process is often more energy-smart and releases fewer greenhouse gases, aligning with worldwide sustainability goals and alleviating climate change. It uses renewable resources like sugarcane, corn, and potatoes. Just like fossil-fuel-based plastics, it ensures a sustainable supply chain and markets regenerative agricultural practices.

For instance, to this,

How Did The Rigid Packaging Segment Dominate The Customized Packaging Market?

Rigid packaging segment dominated the customized packaging market in 2024 as it can be easily customized with respect to dimensions, ensuring an accurate fit for the product being packaged. Whether it's a rectangle, square, custom-shaped box, or cylinder, the shape and size can be personalized to accommodate the product. It can be conveniently customised with structural designs such as dividers, windows, compartments, inserts, and magnetic closures, too.

These characteristics ensure the functionality, enable product visibility, and make a distinctive unboxing experience. Rigid packaging can be tailored by selecting the proper materials to match the branding and product needs. Prevalent materials include chipboard, paperboard, specialty materials, and corrugated cardboard. Material confirmation can be completed relying on factors like eco-friendliness, durability, texture, and look.

The flexible packaging segment is predicted to be the fastest-growing in the network during the forecast period. Customized flexible packaging is an inventive solution that integrates convenience and sustainability, making it a popular choice for various user products. From textiles to food items, dynamic material option serves different opportunities for business. It can be easily customized into the required size, shape, and designs, allowing brands to make visually attention-grabbing packages that stand out on shelves. From stand-up bags to resealable pouches, the options for format available enable brands to meet with different customer choices.

How Did The Food And Beverage Manufacturers Segment Dominate The Customized Packaging Market?

The food and beverage manufacturers segment dominated the customized packaging market in 2024 as this industry shifts at a fast pace. Products are very sensitive; in such cases, safety is important, and shelf presentation directly impacts user behavior. Off-the-shelf packaging options frequently fail to align with growing needs. So, in such a case, custom boxes play a crucial role as they are customized to the demands of food and beverage organizations. They allow for perfect branding, updated logistics, and developed product protection. Food-grade custom boxes packaging must meet strict safety and hygiene standards. Many packaging materials utilize food-safe materials, certified, which protect items during transit and storage. It is convenient to tailor moisture resistance, ventilation, and insulation properties to align with product specifications.

E-commerce retailers segment predicted be the fastest-growing segment in the market during the forecast period. A packaging that feels personal, whether through a customer’s name, small freebie, or custom message, which can importantly develop the unboxing experience. Retailers can count on product care tips, thank-you notes, or QR codes that link to a playlist or link that meets the product’s nature. Custom packaging, which consists of delights or surprises users, naturally paved the way to word-of-mouth marketing, particularly in the digital age. Retailers who officially promote in visually attractive and innovatively crafted packaging shift to customers, which then the brand suggests. Apart from these. Social media platforms like Instagram are filled with “ unboxing experience” in which users display their aesthetically pleasing packaging.

How Did Direct Sales Segment To Companies Dominate The Customized Packaging Market?

Direct-to-consumer (DTC) segment dominated the market in 2024 as customized packaging utilised by brands that ship products directly to customers, bypassing mediators. Successful direct-to-consumer brands comprehend that packaging design must hit hard because a balance between function and aesthetics is necessary. From custom-printed boxes to branded tissue paper, minimalist inserts, and thank you notes, every minute detail matters.

Surpassed visual appeal, packaging must also protect the product during shipping and be convenient to open and close, too. Intelligent designs ensure durability without heavy materials, which assist eco-friendly values while tracking the honesty of the item's interior. Technology also allows personalization at scale. Data-driven printing and fulfilment systems enable DTC brands to customise packaging without having excessive costs.

Online and E-commerce channels segments are expected to be the fastest in the market during the forecast period. E-commerce completely depends on packaging, which makes the lasting impression. It’s crucial to craft attractive packaging. It should construct confidence among users before they open the box. Customers frequently look for a unique unboxing experience. Attention-grabbing packaging attracts users. It directly develops social media platforms as it boosts brand reputation. Apart from these, custom printing on one’s packaging transforms a regular shipping experience into everlasting branding tools. Digital printing serves bright and strong labels without the need for order needs and demands.

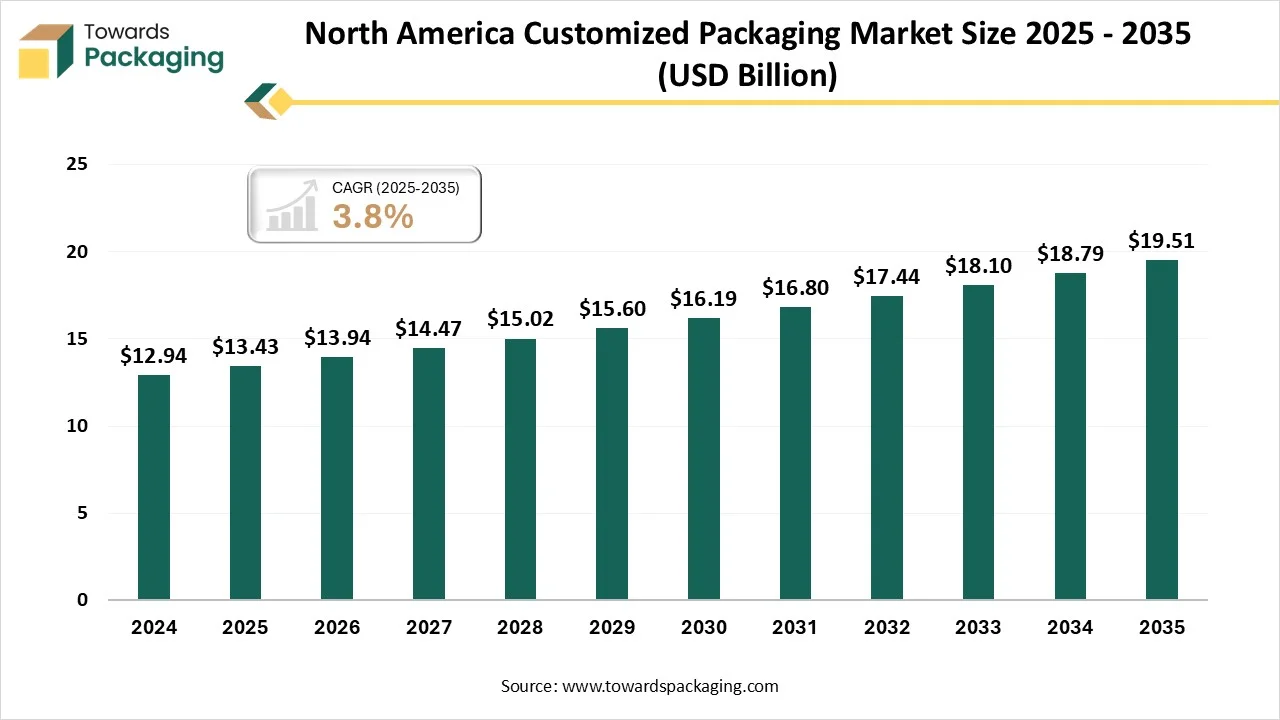

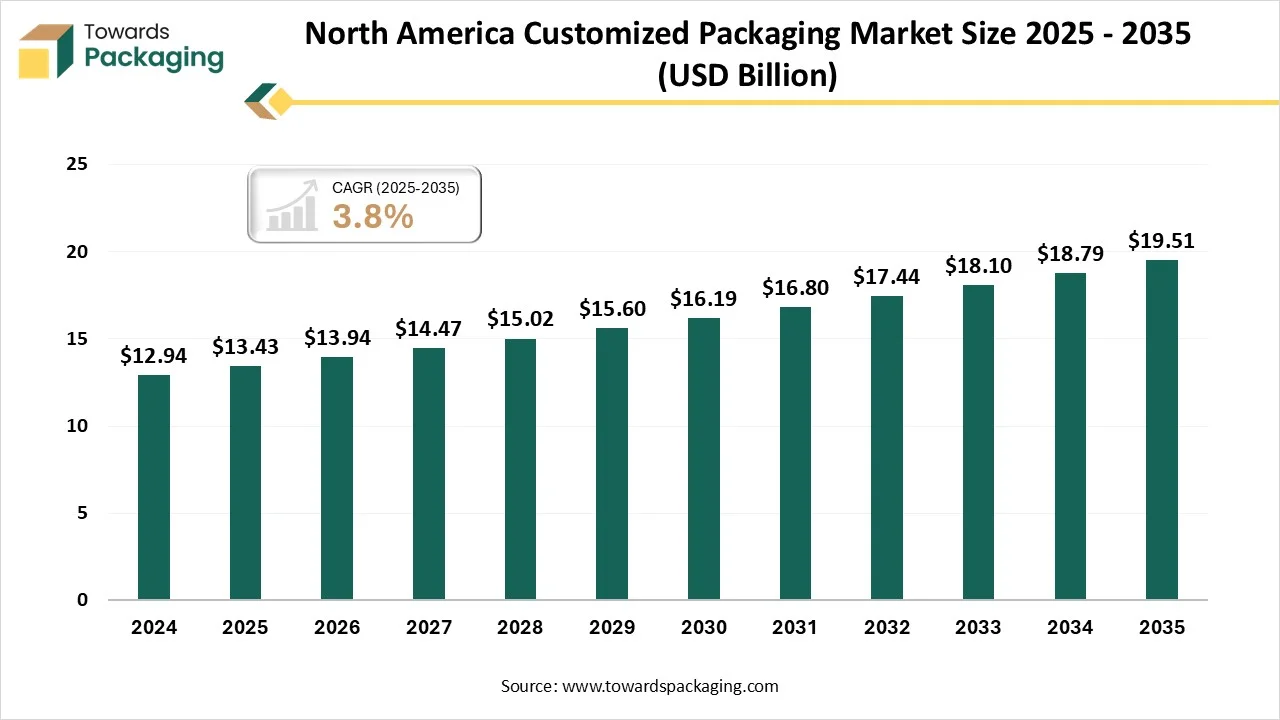

North America dominated the customized packaging market in 2024, as there is huge demand for unboxing marketing, which is a procedure closely attached to consumer-packed good packaging. It sometimes means unboxing influencer marketing, which uses customised packaging materials that are particularly crafted to make a memorable experience for the user. Such an unboxing marketing method goes far beyond the main functionality of general branded packaging. Despite this, the concentration is on aesthetics, complete sensory experience, and personalization, in which the custom packaging is opened. So, a premium unboxing experience. A premium unboxing experience is specifically crucial in the context of e-commerce, where it often delivers as the only communication with customers that they have with the brand. By developing the physical touchpoint, brands can differentiate themselves from other competitors, boost emotional connection with customers, and drive word-of-mouth marketing through social media and other channels.

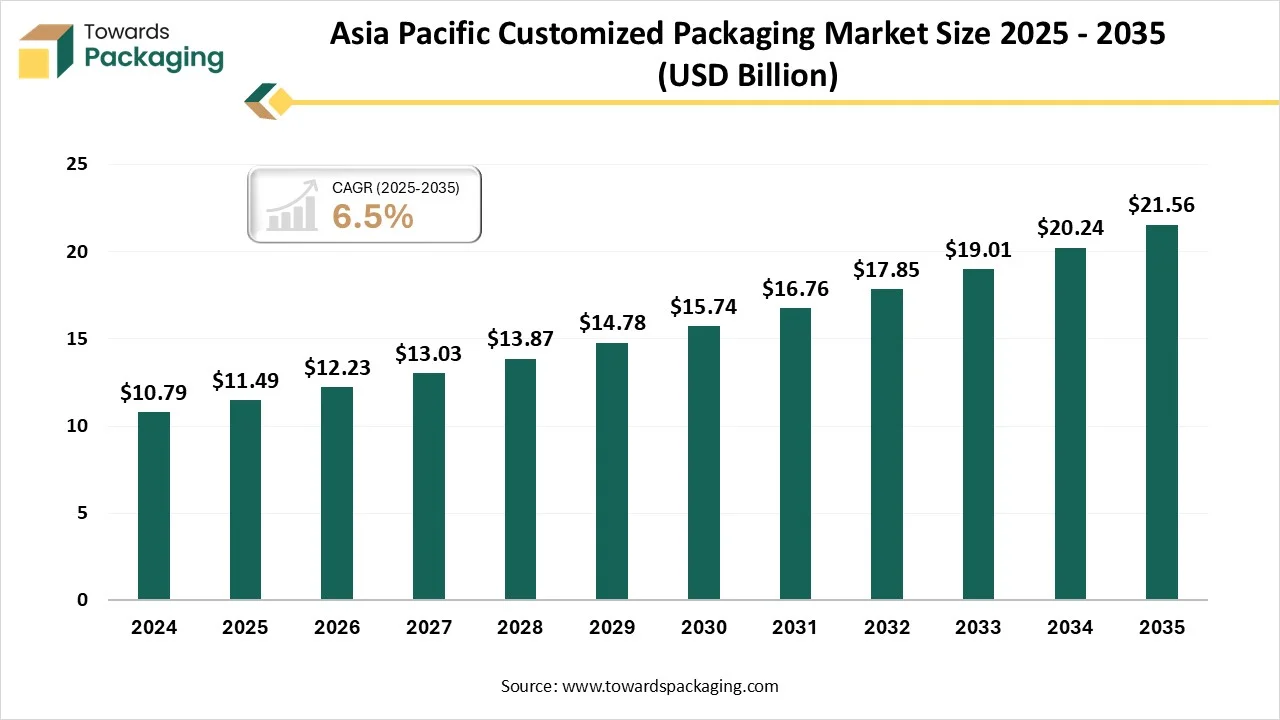

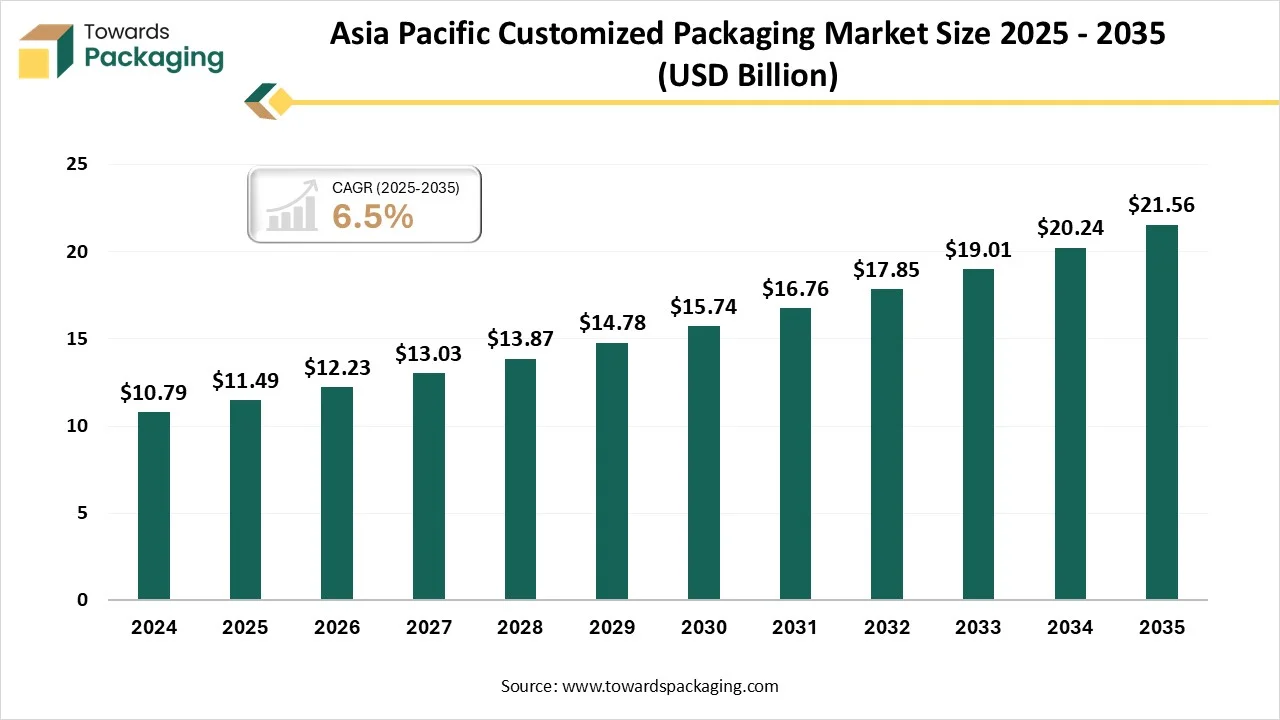

Asia Pacific is predicted to have the fastest growth in the market during the forecast period. In this region, there is a huge demand for two-piece boxes, which are mostly used in the luxury rigid boxes type. Perfumes, electronic consumer goods, cosmetics, and jewellery have fueled the demand for this product. At the same time, boxes with magnetic closures are expected to catch 45% of the overall market in 2024. Apart from these luxury features and look, their appearance comes from ease of use and developed product protection. Asia Pacific will be conveniently at the center stage of premium packaging development as the region constantly witnesses the latest cosmetic and fashion trends. Moreover, other big brands are accepting sustainable materials. Brands will continually align with packaging in which buyers will highlight the surrounding consciousness by using plastic-free materials.

Material Processing and Conversion: Customized packaging is the procedure of transforming raw materials into finished packaging products that are ready for application in the sector. It counts multiple stages, including raw material preparation, cutting, printing, assembly, and folding to make functional and visually appealing packaging solutions. So, die-cutting cuts material into sizes and shapes. Alternatively, sitting cuts large rolls of material into minute, more manageable sizes for further procedure or direct usage.

Package Design and Prototyping: A customized packaging prototype is a kind of mock-up, or initial example of what your fully printed graphical package will look like before mass production. It is often created by hand and embroidered by specialized prototyping machines. A packaging prototype presents a unit of packaging without the expanse of mass manufacturing and offers you the possibility to request a transformation in the design.

Logistics and Distribution: Custom packaging isn’t about just protection, but also the demand to mix neatly how two goods shift. For palletised loads, thoughtful design can affect how many units fit per pallet, how weight is distributed, and whether the packaging contributes to safer packaging. When it comes to courier goods, cushioning and compactness are perfect.

By Material

By Packaging Type

By End-User Industry

By Distribution Channel

By Region

February 2026

February 2026

February 2026

February 2026