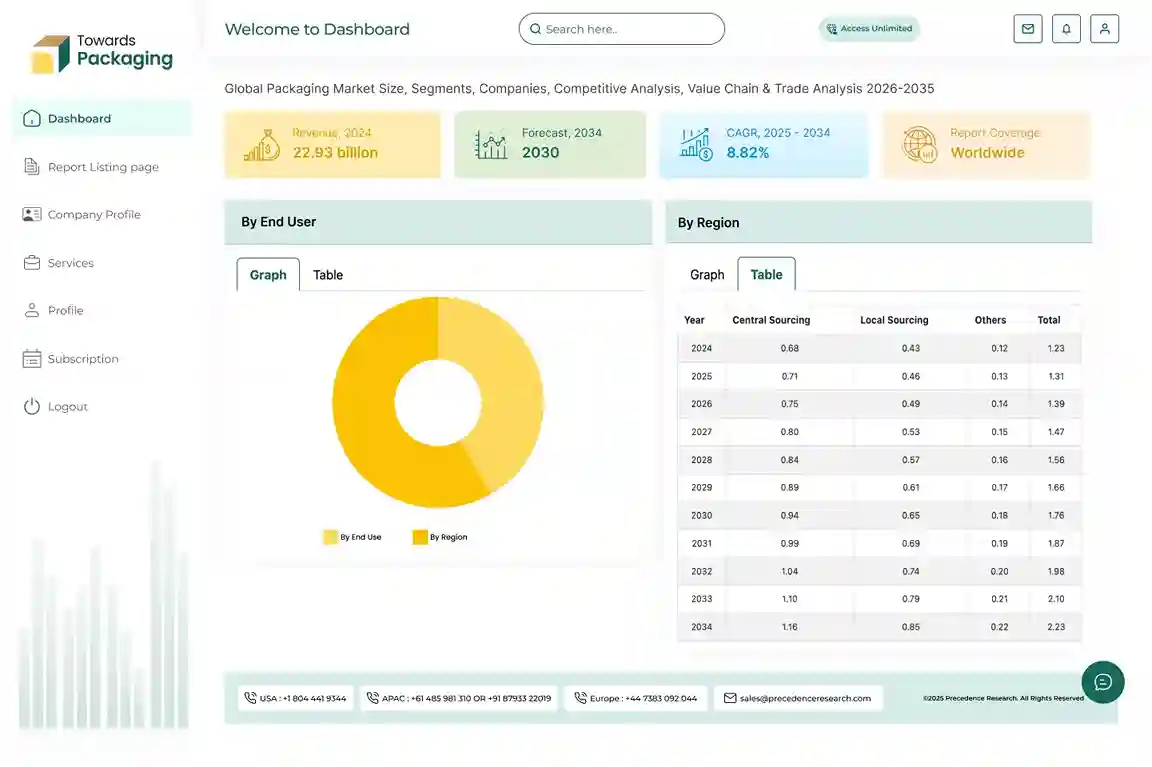

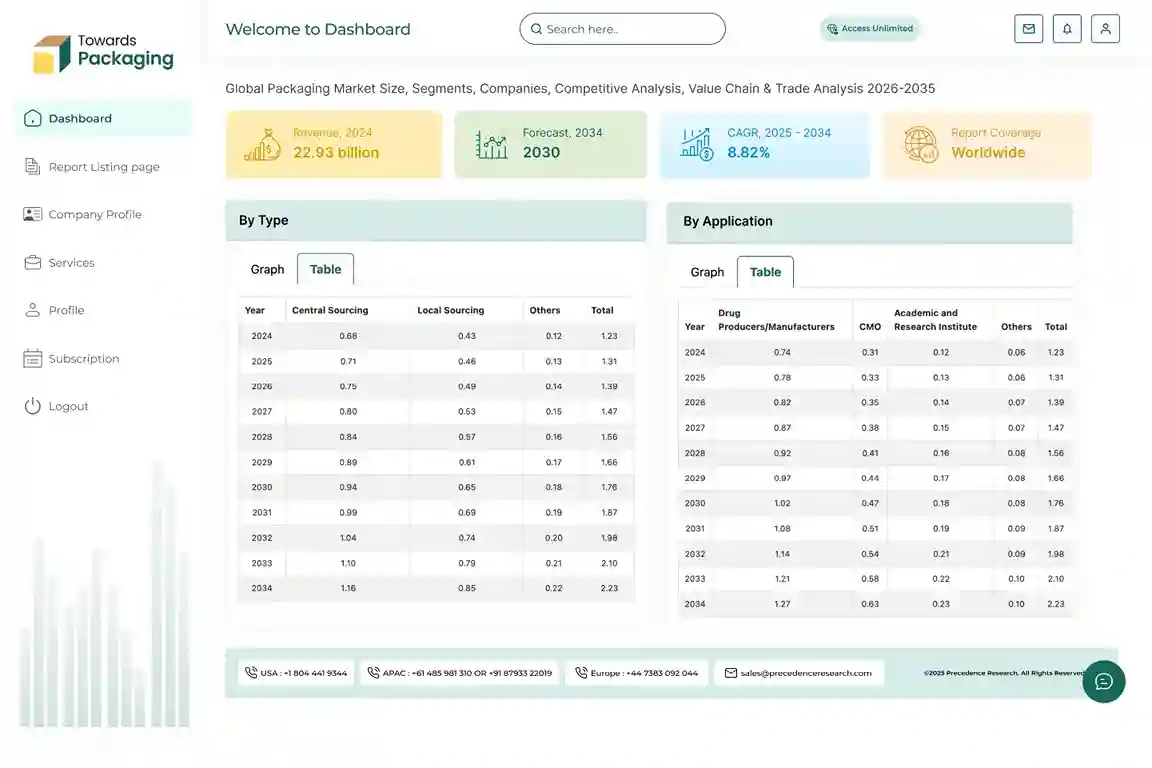

Plastic Airless Packaging Market Growth Outlook, Demand Drivers, Regional (NA, EU, APAC, LA, MEA) Statistics & Trade Analysis

The plastic airless packaging market is comprehensively analyzed in terms of market size, demand growth, and forecast trends, covering all major segments such as packaging type, mechanism, materials, and end-use industries. The study includes regional insights across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, detailing 2024–2034 share trends including APAC’s ~30% dominance and MEA’s fastest CAGR. It also highlights competitive analysis, profiling global leaders such as AptarGroup, Berry Global, Lumson, Albea, and Quadpack.

The report further covers value chain assessment, manufacturing ecosystem, supplier landscape, trade movements, import–export flows, and distribution channels, ensuring all statistical data and segmental figures are clearly outlined for strategic decision-making.

Key Takeaways

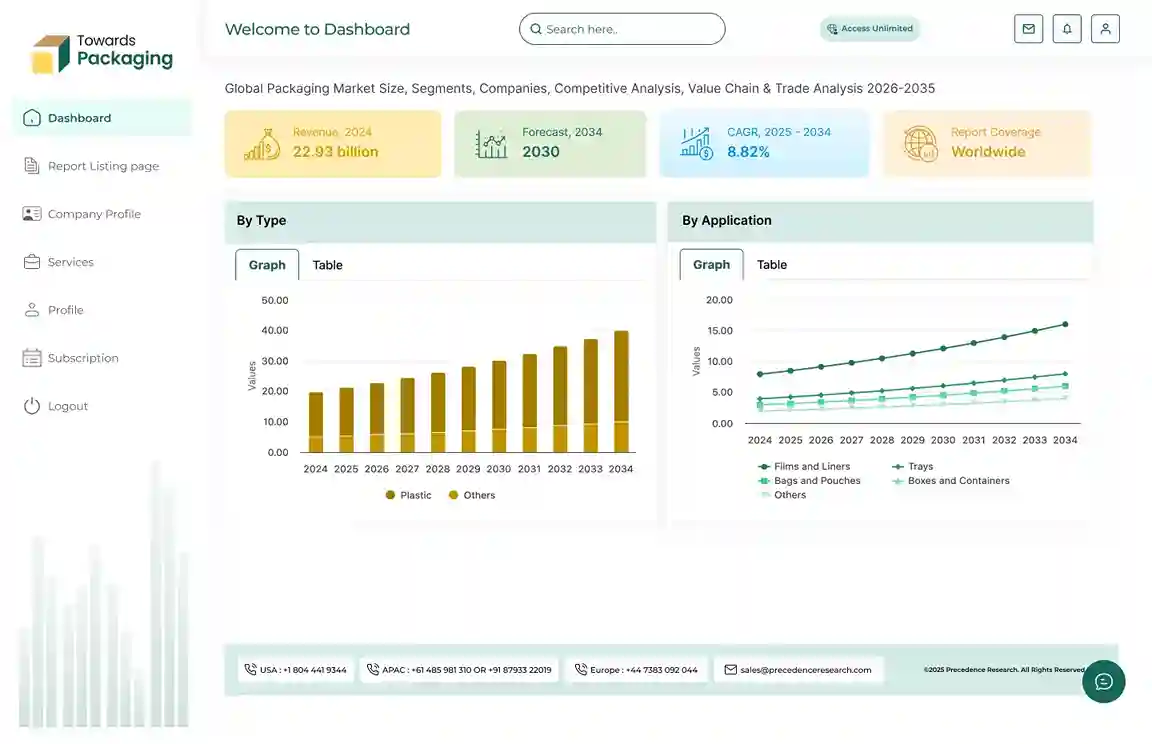

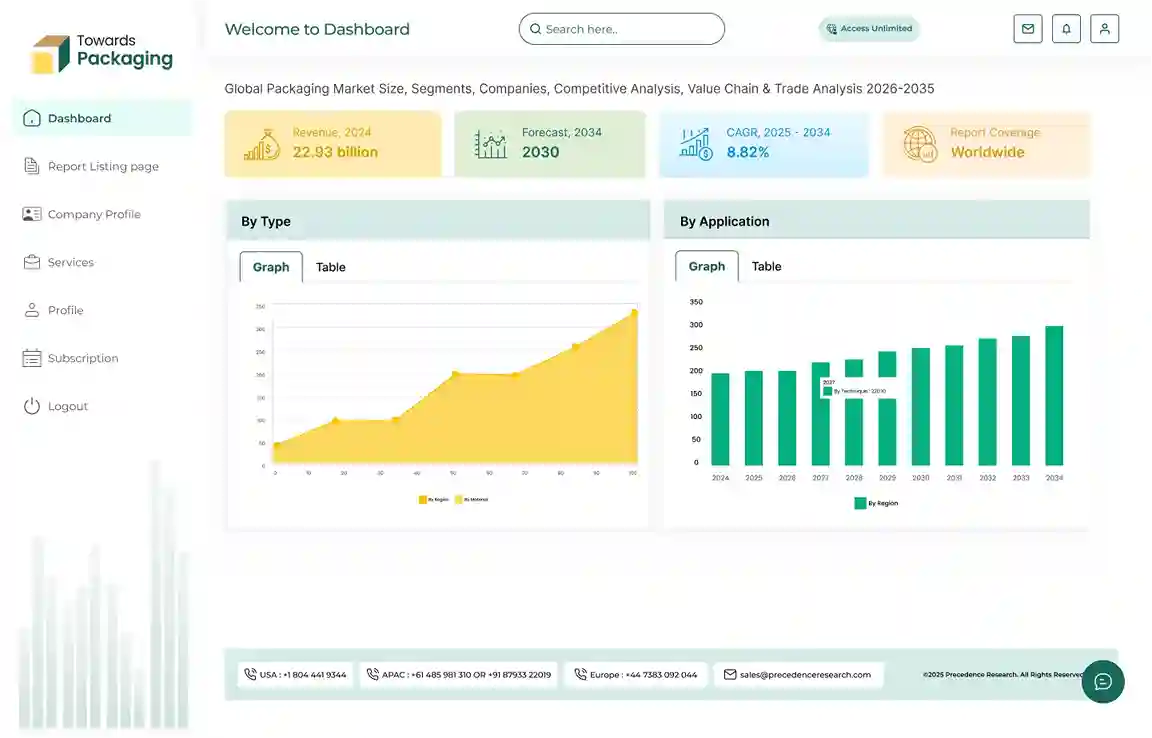

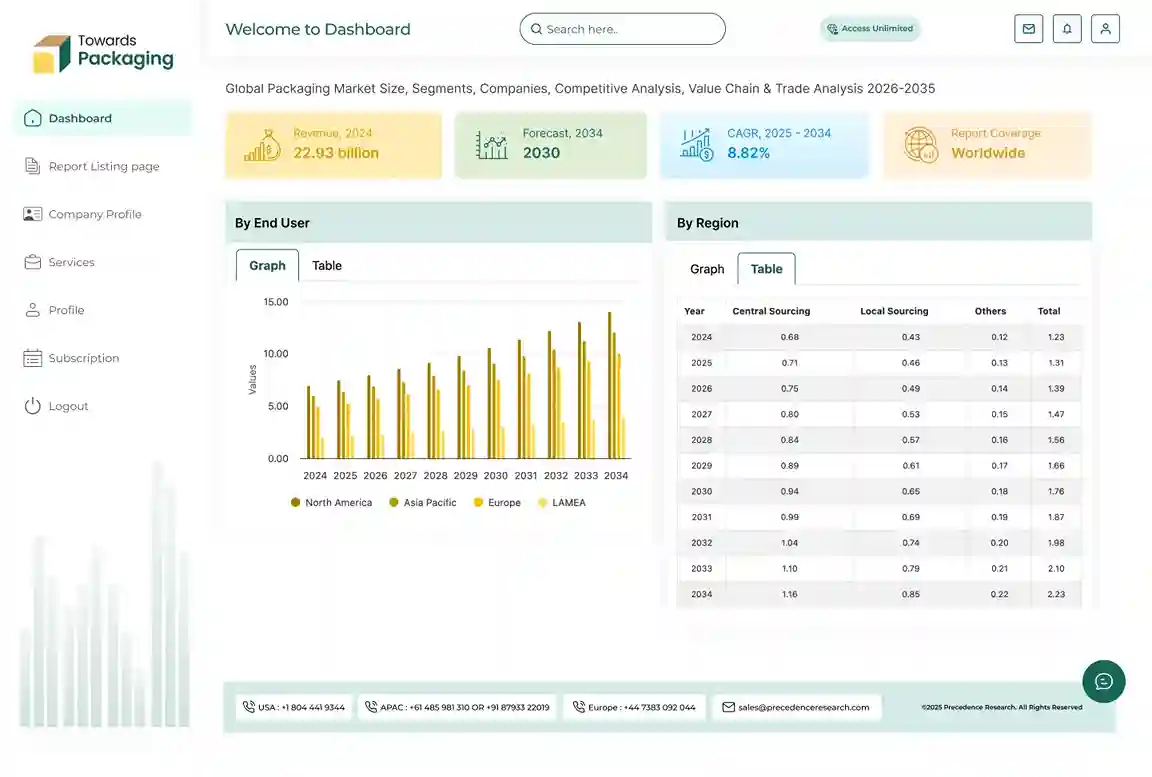

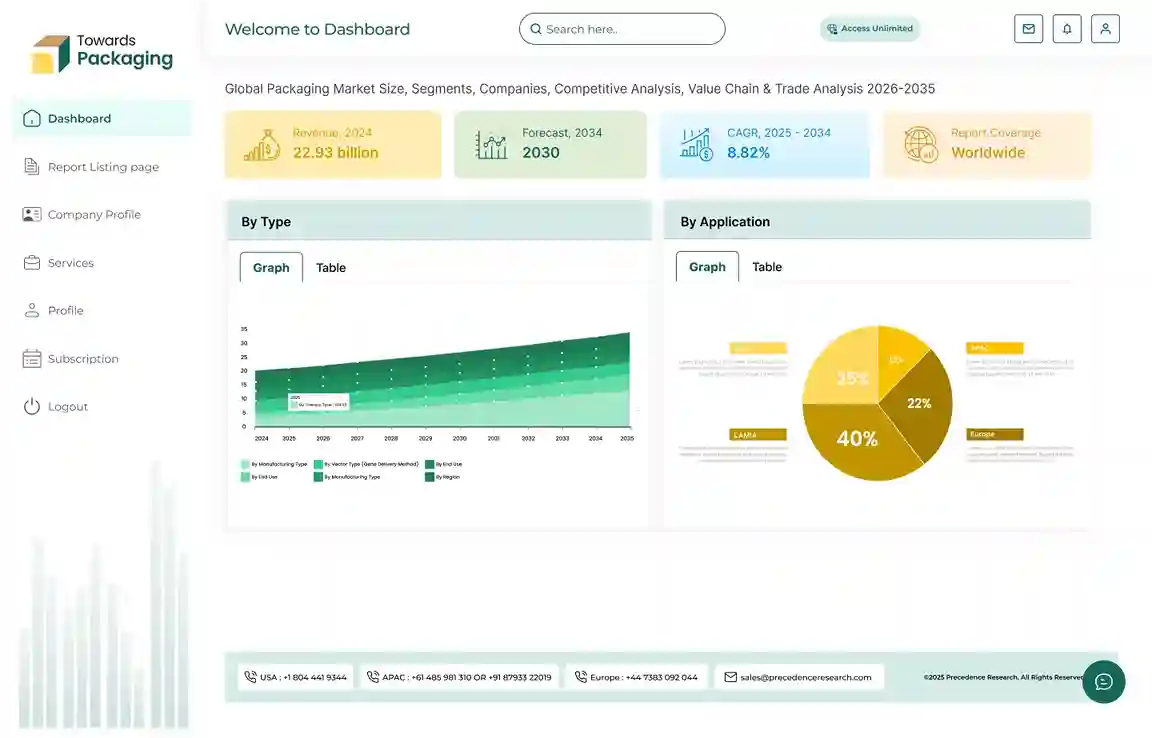

- By region, Asia Pacific dominated the market with approximately 30% share in 2024.

- By region, Middle East and Africa are expected to grow at a notable CAGR between 2025 and 2034.

- By packaging type, airless pump bottles segment contributed to the largest share of approximately 45% in 2024.

- By Packaging type, airless tubes segment expected to expand at a significant CAGR between 2025 and 2034.

- By mechanism /technology, vacuum pistons segment contributed to the largest share of approximately 50% in 2024.

- By mechanism/technology, spring-actuated segment expected to expand at a significant CAGR between 2025 and 2034.

- By material, polypropylene segment contributed to the biggest share of approximately 35% in 2024.

- By material, PET and PETG segment expected to expand at a significant CAGR between 2025 and 2034.

- By end-use industry, skincare segment contributed to the biggest share of approximately 30% in 2024.

- By end-use industry, the pharmaceutical industry segment expected to expand at a significant CAGR between 2025 and 2034.

Market Overview

Plastic airless packaging market refers to the global market concerned with the manufacturing, distribution, and sale of plastic-based packaging systems that dispense product (typically cosmetics, personal care, pharmaceuticals, etc.) without air intrusion commonly using vacuum-pump, piston, or spring-actuated mechanisms to protect product integrity, extend shelf life, and enhance user convenience.

Furthermore, the plastic airless packaging bottles solution is assisting brands in lessening product waste and developing user satisfaction. It meets well with consumer expectations for perfect value. In several designs, the piston as the base encourages content in an upward direction, to make sure the product is being dispensed completely and cleanly. This kind of packaging has high demand in skincare, healthcare, and pharmaceuticals. So, skincare ingredients are very sensitive, and hence the packaging has to be intelligent. Formulas like antioxidants, probiotics, and peptides completely lose power when exposed to air. This urge has pushed packaging craftsmen to give priority to sealed, non-vented systems like airless bottle packaging solutions.

Emerging Trends in Plastic Airless Packaging Market

- Minimalist Design: One of the main cosmetic packaging trends is minimalistic design, which concentrates on simple, clean, and elegant packaging styles. This strategy often utilises neutral colors, uncluttered layouts, and straightforward fonts, which provide products with a standard and sophisticated appearance. Minimalist packaging is attention-grabbing as it transfers the message of transparency and purity, aligning with user experience for clean beauty.

- Sustainable Packaging: Sustainable packaging is one of the main packaging trends in cosmetic packaging, driven by a growing demand among users for eco-friendly organic portions. People are greatly aware of the environmental effects of plastic waste and expect brands to take responsibility for reducing it. As a result, companies are now transitioning towards sustainable materials like glass, recycled plastics, and biodegradable options.

- Technological Advancements: Technological advancements are now changing cosmetic packaging trends, with D printing coming out as an inventive tool for making custom designs. 3D printing enables cosmetic brands to generate unique, intricate packaging shapes that differentiate on shelves, aligning with user demand for creativity.

- Refillable Packaging: Another main cosmetic packaging trend currently is refillable packaging, which concentrates on lowering waste and attracting eco-conscious users. Alternatively to purchasing the latest product containers every time, users can simply buy refills, making it a more sustainable option. Refillable packaging generally uses durable materials crafted to last through multiple refills, lowering the use of single-use plastics, which results in waste in landfills.

- Innovative Dispensing Experience: Cosmetic packaging is rapidly growing, with inventive dispensing packaging that takes place in the central part. Latest Dispensing technologies, like spray pumps, airless pumps, and dropper bottles, serve not only developed functionality but also assist in tracking product quality.

- Multi-Sensory Experience: Multi-sensory experiences in cosmetic packaging are gaining popularity, as a brands goal is to make every product feel different and memorable. One strategy is to use textured paper, which can add a luxurious or natural feel while holding. Out-of-the-box printing procedures like embossing or foil stamping add visual or tactile interest, making the packaging unique.

How Has Artificial Intelligence Developed The Plastic Airless Packaging Market?

By implementing blockchain technology with AI, organizations can establish a transparent and immutable journal of each transaction and step in the supply chain. Blockchain serves as a secure and transparent path to check whether these raw materials meet social, environmental, and ethical standards such as accountable environmental stewardship and impartial labor practices.

This enables retailers, users, and regulators to check the claims created by beauty brands about the origin and ethical sourcing of their ingredients. Furthermore, AI-driven diagnostic tools are updating personalized product growth by examining data in order to make a tailored skincare schedule. This system collects several data to make its personalised data. High-level computer vision and AI Algorithms examine facial images to track different skin conditions, from hyperpigmentation to fine lines.

Market Dynamics

Market Driver

Features Of Plastic Airless Packaging

Airless packaging specifications are technologically standard packages that are assembled and moulded with accuracy to protect formula integrity. Airless packaging specifically includes a mechanical pump engine having a dispensing actuator button and a piston or disc situated at the bottom of the packaging. So products that are committed to skincare elements, like in liquid foundations, cream blushes, concealers, and suncare products, are doubling with the inclusion of hyaluronic acid, SPF, vitamins, and anti-ageing ingredients too. Airless tubes, bottles, and jars are differently constructed in order to pack formulas that are capable of preventing oxidising characteristics from the products primary due to its current. And mentioning its last usage, airless packaging also has an inherent capability to check nearly every drop of product from the package with accurate dosing. Another benefit for packaging brand developers and suppliers is that airless packaging can smoothly track products with both thick and thin consistency, which can be challenging in order to dispense with regular di tube packaging.

Market Restraint

Different Industries Face Many Challenges With Airless Packaging

Plastics are very vulnerable to distortion at high temperatures, limiting their usage in high-temperature surroundings. For cosmetics, which demand heated environment processing, such as heated oils or creams, plastic packaging may not align with storage needs. Under the push of heat and light, plastics can degrade and become delicate. This may result in a decrease in the power of packaging bottles, even causing them to pause, which affects the security of cosmetic transportation and storage. The surface rigidity of plastic packaging bottles is particularly low, which makes them more prone to wear and scratches. This not only affects product aesthetics but may also lead to a decrease in packaging performance that affects the quality of cosmetics.

Market Opportunity

Sustainability Plays A Crucial Role

The future of plastic airless packaging lies in the growth of cutting-edge materials that balance performance with sustainability. Brands are heavily shifting to biodegradable and compostable materials, such as bioresins and plant-based plastics, to lower environmental impact without compromising functionality. Furthermore, developments in material science are allowing the making of lightweight but reliable packaging solutions that provide developed protection and consistency for cosmetic formulation.

As users become heavily conscious about their environmental footprint, brands are implementing sustainability practices that organize circular economy principles. This counts designing packaging which is easily reusable, recyclable, and refillable too, as well as accepting lower packaging waste through the supply chains.

Segmental Insights

Packaging Type Insights

How Did The Airless Pump Bottles Segment Dominate The Plastic Airless Packaging Market?

Airless pump bottles segment dominated the market in 2024, as it has gained popularity in the skincare and beauty packaging for their potential to prevent sensitive products like serums, creams, and lotions from air exposure. Just like regular bottles, airless pump bottles utilise a vacuum mechanism to dispense product, tracking the quality and freshness of the formulation inside. This packaging solution delivers a premium appearance and is smoothly functional, which makes it a selected choice for brands seeking to develop their product display look.

So, the working of airless pump bottles rotates around a vacuum-based system. Whenever the pump is being pressed, a disc or piston grows from the bottom, encouraging the product in an upward direction without letting air into the container.

The airlines tubes segment is expected to be the fastest in the plastic airless packaging market during the forecast period. It is a current packaging solution crafted for convenient and clear dispensing of skincare and cosmetic products. Just like regular pump tubes, it avoided the demand for a dip tube and instead used a vacuum-based system to promote the product upward. This protects air exposure, ensuring a longer shelf life and managing the formulas integrity. It is crafted for ease of mind, the portable design of an airless tube makes it accurate for on-the-go usage. Whether for gym, travel, or daily routine, this packaging is ideal for active lifestyles by serving a developed user experience. The impressive departure rate ensures that nearly all the product is being used, lowering waste.

Mechanism /Technology Insights

How Did The Vacuum Piston Segment Dominate The Plastic Airless Packaging Market?

Vacuum Piston segment dominated the market in 2024 as it is an advanced dispensing mechanism crafted to develop product protection and user experience. Unlike traditional pump bottles that depend on a dip tube, airless packaging with a vacuum piston works through a growing piston system. When the pump is pressed, a vacuum is created inside the container, and the piston at the base suddenly moves upward, pushing the product towards the dispensing nozzle. This avoids air intake, contamination, and prevents oxidation or microbial development, which is particularly vulnerable for sensitive formulations like serums, lotions, and pharmaceuticals.

Spring actuated segment is expected to be the fastest in the plastic airless packaging market during the forecast period. This technology is a widely used dispensing system that depends on a small internal spring to activate the pump mechanism. When the user presses the actuator, the spring compresses and applies pressure that pushes the product upward through the dispensing nozzle. Once it is released, the spring returns to its original position, which is ready for the upcoming returns to its original position, ready fir the next usage. Unlike traditional systems with dip tubes, airless spring-actuated designs still protect against air penetration into the container, protecting the formulation from contamination, oxidation, and evaporation.

Material /Construction Insights

How Polypropylene Dominated The Plastic Airless Packaging Market?

Polypropylene segment dominated the market in 2024 as this kind of material is lightweight, and they are ideal for budget-friendly cosmetic lines. They serve excellent protection for the product; on the other hand, they are opposite to the effect and many chemicals, though they lack the luxury look of glass. Additionally, this kind of plastic bottle is the ideal packaging for skin care products like lotion, gel, cream, cleanser, etc. Vacuum system storage can totally avoid contents that are being oxidized, and protect ingredients in fine condition.

PET and PETG segment are predicted to be the fastest in the plastic airless packaging market during the forecast period. PET resin serves as a perfect power while tracking, shatter-resistant, and lightweight, which makes it a practical alternative to glass bottles. This reliability assists in preventing damage during shipping or daily usage, too. PET bottles also help high-level decoration procedures like paint coating, hot stamping, and logo engraving. These potentials make PET packaging perfectly suited for products using airless pump mechanisms, cream jars, and high-quality pump bottles. Whether it is being used for skincare supplies or foundation packaging, PET aligns well with branding and functional demands.

On the other hand, PETG ( Polyethylene Terephthalate Glycol ) in plastic airless packaging is gaining attention due to its durability, clarity, and recyclability. Unlike standard PET, PETG is updated with glycol, which makes it more impact-resistant and less brittle, while maintaining excellent transparency. This kind of property enables brands, especially in personal care and cosmetics, to display the products color and texture directly through the container, giving it a luxury and high-end appearance.

Application/End-Use Industry Insights

How Did The Skincare Segment Dominate The Plastic Airless Packaging Market?

The skincare segment dominated the market in 2024, as it assists perfect hygiene practices by avoiding the demand to directly touch the serum lotion or gel, lowering the risk of pollutants. These characteristics not only have advantages but also ensure that the product stays smoother and secure to use for a longer time, lowering the efficiency of disposal and substitution. This type of packaging expands the shelf life of cosmetic products by preserving them from air, moisture, light, and contaminants. This protection lowers the demand for preservatives, which can have environmental uses, by tracking the probity of the product for a long period. Airless packaging counts as a packaging element, resulting in less frequent purchasing and subsequently less packaging waste.

The pharmaceutical segment is predicted to be the fastest in the plastic airless packaging market during the forecast period. The pharmaceutical sector makes use of airless packaging. Many pharmaceutical products require tracking the freshness, taste, and crispness. Airtight packaging in the form of containers, pouches, and even bags is becoming very popular, as they assist in protecting the flavour and taste of products. Airless packaging is likely preferred by the pharmaceutical industry, as it is especially perfect for sensitive medicines and formulas, which require tracking the stability of different ingredients to prevent deterioration, including vitamin C.

Regional Insights

How did the Asia Pacific Dominate the Plastic Airless Packaging Market?

Asia Pacific dominated the plastic airless packaging market in 2024 as the region is experiencing a sharp growth in the demand for plastic airless packaging, mainly fueled by the fastest-growing beauty, personal care, and healthcare sectors. With users becoming more brand-conscious and finding hygienic, premium, and long-lasting packaging solutions, brands are increasingly shifting toward airless systems that protect product integrity and expand the shelf life. From the production point of view, Asia-Pacific benefits from a strong network of local plastic converters and packaging manufacturers, who can produce inventive, cost-efficient, and customizable airless bottles, jars, and dispensers on a large scale. In addition to that, regional generators are quickly accepting eco-friendly practices by using recyclable plastics, PETG blends, and refillable designs to align with sustainability expectations.

The Middle East and Africa expects the fastest growth in the market during the forecast period. This region is experiencing a rising appetite for plastic airless packaging, driven by luxury sectors like cosmetics, skincare, and pharmaceuticals. Specific, South Africa leads regional manufacturing with its industrial maturity and export reach, while the UAE is growing as a key consumer market in beauty and hygiene products, broader regional dynamics -such as growing incomes, urbanization and heightened emphasis on product integrity -are fueling the urge for hygienic and aesthetically appealing, and eco-conscious dispensing solution, that are positioning MEA as a vibrant and upward -moving market for airless packaging.

Plastic Airless Packaging Market Value Chain Analysis

Material Processing and Conversion: In response to material processing and conversion, biodegradable materials break down through natural processes into smaller molecules, eventually shifting to nature, though they can leave behind microplastics and residues. Compostable materials experience a particular aerobic decomposition procedure that generates nutrient-rich compost, leaving no toxic residues behind.

Package Design and Prototyping: Once the demands are defined, packaging creators and designers make prototypes to test functionality, durability, and aesthetics too. In examples in which the co-packer has an internal design team, they can assist in refining or even make from scratch your packaging design. This stage is also used to test that the packaging fits perfectly and meets all agreed-upon needs.

Plastic Airless Packaging Market Top Companies

- Essel Propack

- AptarGroup

- Alpha Packaging

- Berry Global

- Silgan Holdings

- Albea (now part of Pochet)

- KKF (Kwangjin Precision Industry Co.)

- RPC / RPC M&H Plastics (now part of Berry) treating as RPC

- Kao (Kao Pack Division)

- Cosmo Pack

- Lumson

- Coverpla

- Pack in Style (Unipak)

- Quadpack

- Pirlo Plastics

- Omet

- Fisco Pak

- Novembal (Noven Group)

- Badger Air-Pulse Packaging Co.

Latest Announcements by Industry Leaders

- In April 2025, French dermocosmetics brand Laboratorie named SVR disclosed three latest treatments with Aptars Beauty extremely protective Micro airless in full plastic. It is crafted, manufactured, and personalized globally in dispensing systems, Aptar Beauty, which is micro airless and is ideal for sensitive dermatological beauty formulations.

- In October 2024, Lumson, which is a top player in premium airless solutions linked to pouch technology, is setting the latest trends in the airless packaging world with the revelation of XTAG, offering 15 ml and 30 ml glass bottles with an airless refill system that uses pouch technology.

Recent Developments

- In October 2024, Lancome, which is a latest refillable bottle for its different Eau De Parfum, Idole. It is a symbol of contemporary femininity; Lancôme is showcasing its loyalty towards more sustainability with the assistance of high-impact choices, such as a refillable bottle.

Segmentation of Plastic Airless Packaging Market

By Packaging Type

- Airless Pump Bottles

- Airless Tubes

- Airless Jars

- Airless Spray Systems

By Mechanism/Technology

- Piston-Disc (Vacuum Piston)

- Pump-Chamber (Vacuum Pump)

- Spring-Actuated

- Air-Free (Double-Wall, Compressed Air)

By Material/Construction (Plastic Type)

- Polypropylene (PP) Systems

- Polyethylene (PE – LDPE/HDPE)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene Terephthalate (PET / PETG)

- Polyoxymethylene (POM)

By Application/End-Use Industry

- Skin Care

- Make-Up / Cosmetics (Foundations, BB creams, etc.)

- Hair Care (Serums, Styling Products)

- Personal Care (Lotions, Hand Sanitizers)

- Pharmaceutical / OTC (Ointments, Gels, Creams)

- Food & Beverage (Condiments, Dressings)

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Brazil

- Mexico

- Argentina

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait

Tags

FAQ's

Select User License to Buy

Figures (1)