Sidel Laser Leap: Redefining PET Packaging with Precision, Speed and Sustainability!

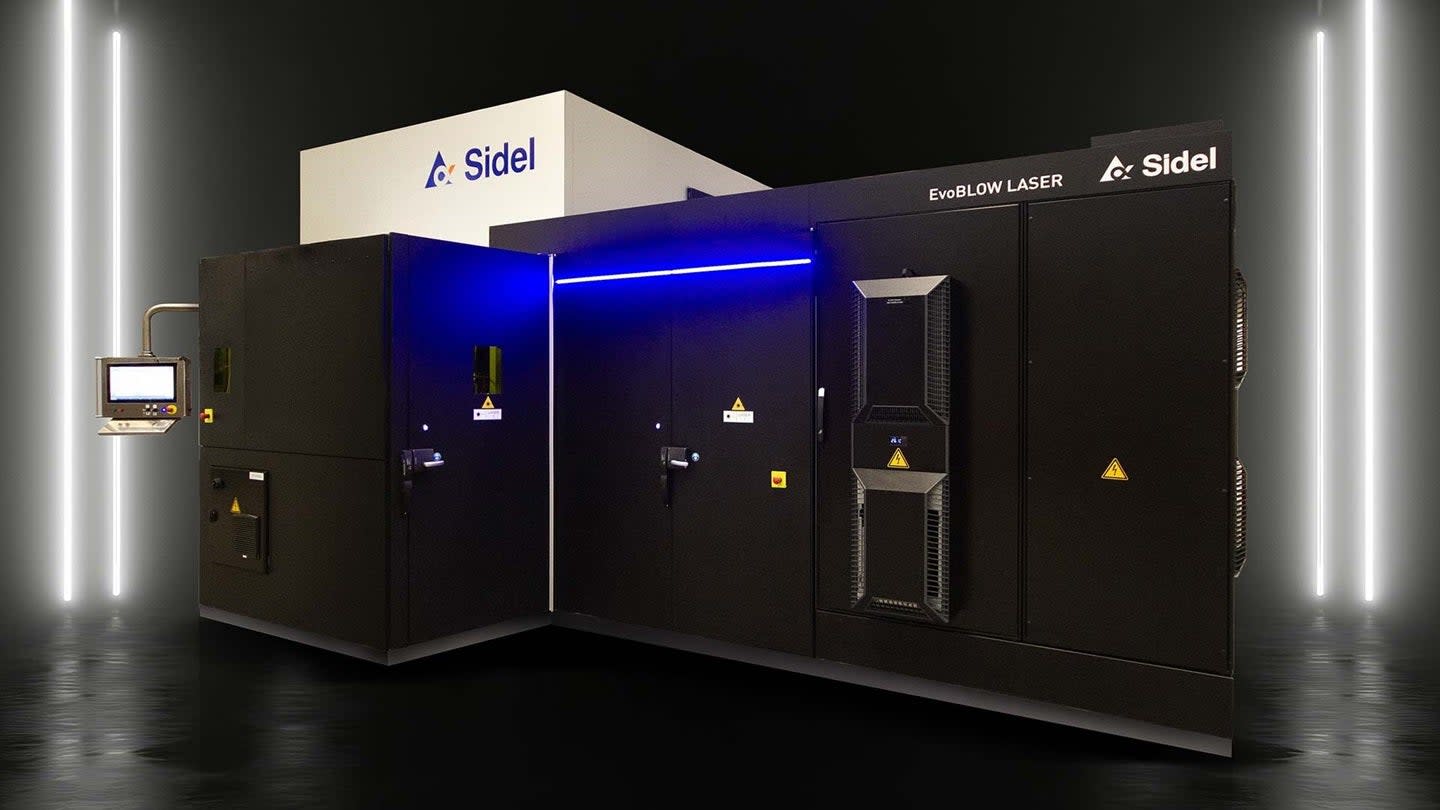

Sidel, a global leader in packaging solutions, has introduced a groundbreaking laser technology aimed at revolutionizing the food and beverage packaging industry. This innovation marks a significant departure from traditional halogen-based heating systems, offering enhanced precision and efficiency in the production of PET and recycled PET containers.

Unlike halogen systems, which typically use eight zones of heating lines, the new laser-powered system uses up to 36 zones, providing precise control over the distribution of materials. By making it possible to produce stronger yet lighter bottles, this development meets the industrys need for environmentally friendly packaging options. It also makes it easier for invisible power rings to form inside the bottle structure, which increases durability without using more material.

Stability and consistency are two of the best qualities of laser technology. The laser system ensures consistent quality from the first to the last bottle produced by maintaining uniform heating, unlike halogen systems that are sensitive to environmental conditions and need frequent adjustments. Production downtime is decreased, and operator intervention is less necessary due to this dependability.

The systems ability to cold start improves operational efficiency even more. It reduces energy consumption and enables instant production startup by doing away with the need for preheating. Additionally, the technology facilitates live speed modulation, which allows production speeds to be adjusted in real time in response to shifting circumstances, maximizing throughput.

Sustainability is at the core of this innovation. The laser technology precision heating allows for better handling of rPET materials, which are often inconsistent in quality. This capability not only supports the use of recycled materials but also reduces performance waste and the overall size of the oven, contributing to a more sustainable production process.

In collaboration with Refresco, the worlds largest independent beverage bottler, Sidel has successfully field-tested this technology, paving the way for its widespread adoption in the industry.

Top Stories

- A Simple Guide to Understanding Benefits of Rigid Boxes

- A Packaging Guide for Artisanal and Handmade Product Brand

- UFLEX Expands PET Recyclable Woven Polypropylene Food Packaging to Mexico

- Tetra Pak Launches India’s First Carton Packaging with Certified Recycled Polymers

- PepsiCo Reinforces pep+ Strategy with Sustainable Packaging Goals