Egg Boxes and Trays Market Analysis Market Growth Trends, Regional Breakdown & Industry Value Chain

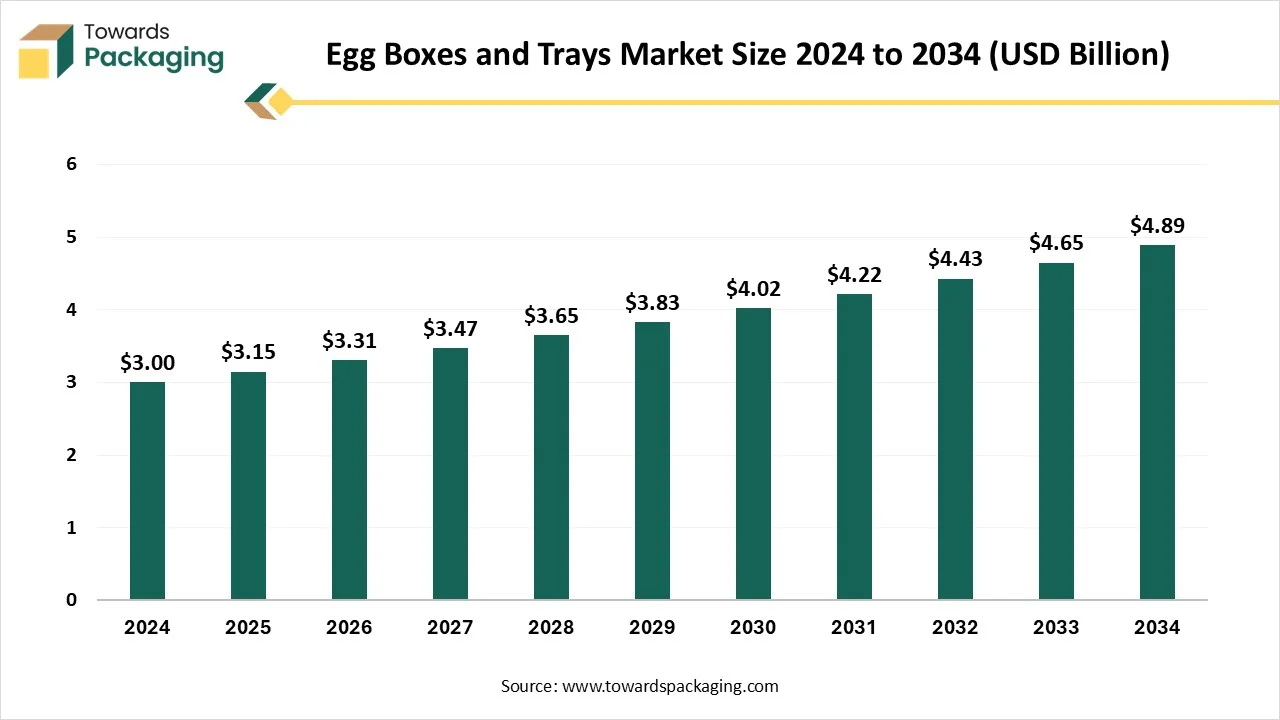

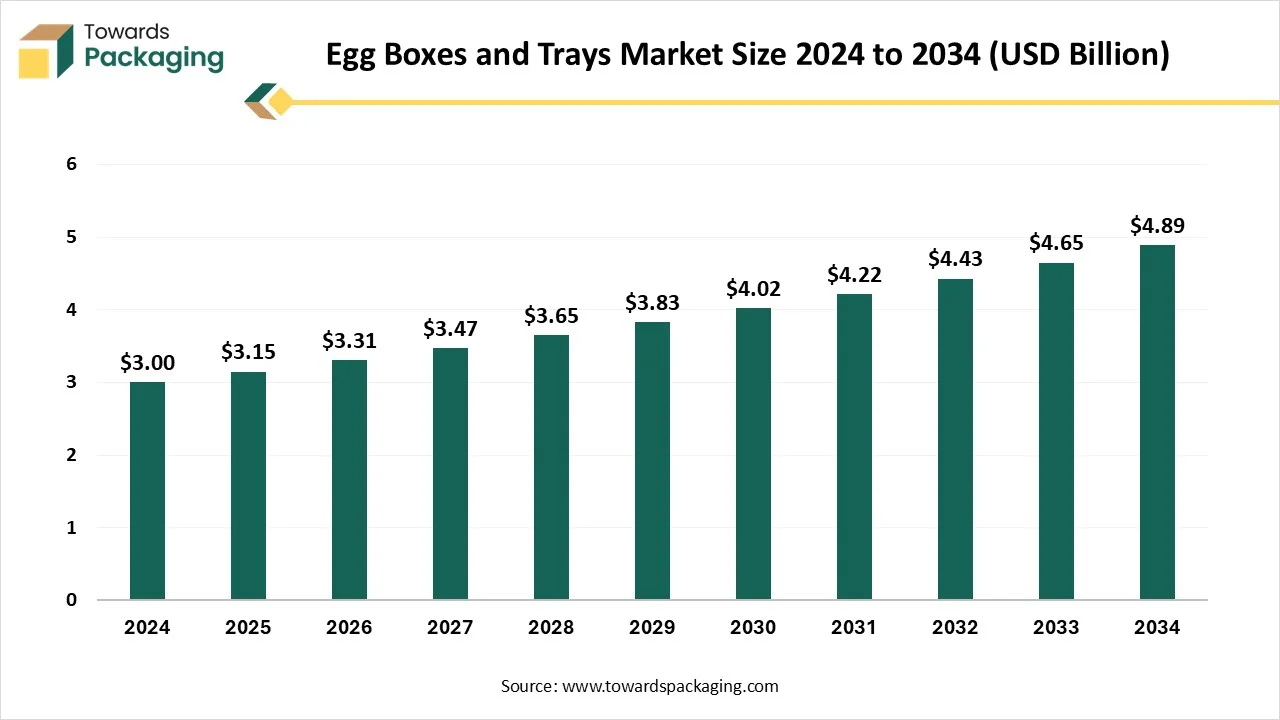

The egg boxes and trays market provides a comprehensive view of global industry performance, covering market size growth from USD 3.15 billion in 2025 to USD 4.89 billion by 2034, at a 5% CAGR. The report covers in-depth trends such as sustainable packaging, molded pulp dominance, the rise of biodegradable composites, and rapid e-commerce adoption. It includes detailed segmentation by product type, material, application, and distribution channels, along with regional insights across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

Competitive profiling of key players like Huhtamaki, Hartmann, Cascades, and Ovotherm is included, with a full value chain breakdown, trade data, raw material sourcing, and supplier/manufacturer mapping.

Key Takeaways

- In terms of revenue, the market is valued at USD 3.15 billion in 2025.

- The market is projected to reach USD 4.89 billion by 2034.

- Rapid growth at a CAGR of 5% will be observed in the period between 2025 and 2034.

- Asia Pacific dominated the global market with the largest revenue share in 2024.

- North America is expected to grow at a notable CAGR from 2025 to 2034.

- By product type, the egg boxes segment contributed the biggest revenue share of 60% in 2024.

- By product type, the egg trays materials segment will expand at a significant CAGR between 2025 and 2034.

- By material type, the molded pulp/paperboard segment contributed 65% revenue share in 2024.

- By material type, the biodegradable composites segment is expected to grow rapidly in the coming years.

- By application, the retail packaging segment dominated the market in 2024.

- By application, bulk /industrial transport is expected to grow significantly over the studied period.

- By distribution channel, the supermarkets and hypermarkets segment dominated the market in 2024.

- By distribution channel, the online retail segment is expected to grow significantly over the studied period.

Market Overview

The egg boxes & trays market encompasses packaging solutions designed to safely store, transport, and display eggs. These packaging types include cartons (boxes) and trays made from materials like moulded pulp, paperboard, plastic (PET, polystyrene), foam, and biodegradable composites. With rising focus on food safety, egg packaging must comply with stringent regulations that mandate the use of non-toxic, hygienic materials and clear labelling for hygienic materials and clear labelling for traceability, expiration dates, and storage conditions.

In terms of sustainability, there is a growing move towards eco-friendly options like compostable or recyclable paper-based trays, as the industry moves away from plastic and polyethylene due to environmental concerns. Lightweight and stackable designs are also being prioritized to reduce material use and carbon emissions in transportation. The growth of online grocery shopping has further influenced egg packaging, demanding more durable,tamper-proof, and space-effective solutions that can protect the product through complex supply chains while ensuring a positive customer experience. Overall, egg packaging is evolving to balance food safety, sustainability, and e-commerce demands.

Egg Boxes and Trays Market Trends

- Sustainable Materials: Increased use of biodegradable, recyclable, and compostable materials to replace plastic.

- Smart Packaging Integration: Use of QR codes and RFID for safety, traceability, and consumer interaction.

- Durable Designs for E-Commerce: Shock-resistant and tamper-proof packaging for safe last-mile delivery.

- Stackable and Space-Saving Formats: Lightweight and compact designs to enhance storage and reduce logistics costs.

- Standardized Taurus for Automation: Compatibility with automated grading and packaging systems in huge-scale operations.

- Minimalist and Branded Packaging: Eco-conscious designs, clean to appeal to current, environmentally conscious users.

- Circular Economy Practices: Focus on recyclability, reusability, and lower environmental impact throughout the product life cycle.

- Global Regulatory Alignment: Future packaging designs will conform to rigid food safety and environmental standards.

- Innovations in Material Science: Development of fibre-based and plate-derived materials to develop strength and sustainability.

- Increased Customization: Brands may offer tailored packaging options for niche markets, premium eggs, or organic product lines.

AI Integration in Egg Boxes and Trays Market

Artificial intelligence (AI), robotics, and the Internet of Things (IoT) and other technological advancements are increasingly being integrated into the egg packaging industry. To develop efficiency, safety, and traceability during handling, transportation, and storage of egg boxes and trays in production and packaging facilities, robotic arms and automated conveyors are used to handle delicate eggs and stack trays with accuracy, reducing breakage and human error. AI-driven systems analyze data in real time to prioritize sorting, grading, and packaging procedures based on weight, size, and shell quality.

In terms of logistics and transportation, IoT-enabled sensors are embedded in packaging or transport crates to track humidity, temperature, and shock levels, making sure that eggs are transported under perfect conditions. These smart systems can alert logistics managers in case of deviations, lowering spoilage, and developing supply chain reliability. In retail and distribution centers, automated storage and retrieval systems efficiently manage inventory by tracking the movement and freshness of egg crayons using an AI algorithm. Additionally, digital labels and QR Codes on egg boxes allow customers and retailers to manage the origin, handling history, and shelf life of the eggs, enhancing transparency and trust.

Market Dynamics

Driver

The egg boxes and trays market is driven by many main factors, primarily the growing global demand for eggs due to their affordability and nutritional value. Growing awareness of food safety and hygiene has led to increased adoption of protective packaging solutions that minimize breakage and contamination during transport and storage. The expansion of organized retail, supermarkets, and online grocery platforms has further boosted the demand for stackable, durable, and tamper-evident packaging.

Environmental concerns and regulatory pressures are also driving the move towards sustainable packaging materials like molded pulp and biodegradable trays. Additionally, technological growth in automation and logistics is influencing the design and production of standardized,machine-compatible trays. Overall, consumer demand, food safety standards, e-commerce growth, and sustainability trends are the main forces shaping the evolution of the egg boxes and taurus industry.

Restraint

This market faces challenges such as high vulnerability to damage during transit, especially in low-quality packaging. Rising raw material costs and limited availability of sustainable materials can impact production. Adapting to strict food safety and environmental regulations needs continuous investment. Inconsistencies in packaging standards across regions hinder automation and overall trade. Furthermore, balancing eco-friendliness and durability remains a limitation. Logistics complexities in e-commerce and the need for tamper-proof,shock-resistant designs add further pressure on innovation and cost-efficiency in the industry.

Opportunity

The future of the egg boxes and taurus industry is expected to move beyond just protection and transportation. There is rising potential for foldable, lightweight, and space-saving designs to improve storage and reduce transportation costs. Water-resistant and grease-resistant coatings derived from natural sources may be used to enhance durability without compromising recyclability. The field could also see the rise of modular packaging sheets that allow retailers to adjust tray sizes based on varying quantities. With the growth of organic and premium eggs, aesthetic and branding elements like printing, embossing, and color variations are becoming more prominent. Additionally, integration with digital inventory and supply chain systems may allow real-time stock tracking, developing efficiency for retailers and suppliers alike.

Segmental Insights

How did the Egg Boxes Dominate the Product type in the Egg Boxes and Trays Market?

Egg boxes have dominated the market due to their effectiveness, simplicity, and adaptability. Originally crafted to protect fragile eggs during transport, these boxes-especially those made from molded pulp- proved to be cost-efficient, recyclable, and highly protective against breakage. Their stackable design and ease of use make them perfect for consumers and retailers alike. Over time, manufacturers introduced variations in sizes, shapes, and materials, including plastic and foam, to meet particular market needs as demand for hygiene, convenience, and sustainable food packaging grew. Egg boxes became a staple in both traditional retail and modern e-commerce grocery sectors, solidifying their market presence.

Furthermore, with the growth of urbanization, food delivery services and online grocery platforms, demand for lightweight, compact, and protective packaging surged, further reinforcing the role of egg boxes. Branding and customization options added marketing value, making them not just functional, but a main part of product presentation and consumer appeal.

Egg Trays are the Fastest-growing Product type in the Egg Boxes and Trays Market

Egg trays are the fastest-growing product type, caused by mass handling, storage, and distribution of eggs, especially in wholesale and commercial settings. Their open, stackable design allows for ventilation and visibility, which assists in maintaining egg freshness and enabling quick inspection. Typically, made from molded pulp, recycled paper, or plastic, egg trays are both cost-effective and reusable in many cases, making them ideal for large-scale operations such as farms, supermarkets, and food processing industries.

Additionally, their compatibility with sanitation standards and easy disposal or recycling has aligned with growing environmental and hygiene demands. As the egg sector grows to meet increasing global consumption, egg trays become indispensable, allowing efficient supply chain movement from farm to shelf.

How did Molded Pulp dominate the Material Type in the Egg Boxes and Trays Market?

Molded pulp has emerged as the dominant material in the egg boxes and taurus industry due to its perfect protective qualities, cost-effectiveness, and eco-friendly nature. Made from recycled paper and cardboard, molded pulp serves as a strong cushioning and shock absorption, ensuring minimal egg breakage during handling and transport.

Its biodegradable and compostable properties align perfectly with the growing global demand for sustainable and plastic-free packaging solutions. It is highly adaptable to automation, further streamlining packaging and logistics procedures in high-volume operations. With growing regulations against single-use plastics and increased consumer awareness about environmental impact, molded pulp continues to lead as the most reliable and sustainable solution in the egg packaging market.

Biodegradable Composites are the Fastest-growing Material Type in the Egg Boxes and Trays Market

Biodegradable composites are rapidly emerging as the fastest growing segment in the egg boxes and taurus industry due to the global push for sustainable and environmentally friendly alternatives to regular plastics and foam packaging. Made from materials like agricultural waste, bamboo fiber, starch blends, and bagasse, these composites offer power, durability, and biodegradability, meeting both ecological and functional demands.

Governments and regulatory bodies are increasingly enforcing bans on using plastics and marketing green packaging, creating strong market incentives for biodegradable options. These composites are not only compostable and recyclable, but they not only compostable and recyclable, but they also serve excellent protection and insulation for eggs during transport. As consumers shift toward eco-conscious brands and products, producers are accepting biodegradable composites to meet environmental goals and gain a competitive edge.

How did the Supermarkets and Hypermarkets Dominate the Egg Boxes and Trays Market Distribution Channel?

Supermarkets and hypermarkets have become dominant players in the egg boxes and trays sector, caused by large-scale retail operations, high consumer footfall, and constant demand for fresh food products. These retail giants offer a centralized platform where a variety of egg types - free-range, range-organic, and conventional -are sold in secure, neatly packaged trays and boxes.

Their preference for standardised, attractive, and durable packaging has significantly influenced the design and material selection in egg packaging. Moreover, these supermarkets depend on effective supply chains and need packaging that assists in easy stacking, space optimization, and protection during long transit times. This has driven the demand for high-quality molded pulp and biodegradable packaging solutions.

Online Retail is the Fastest-growing Distribution Channel in the Egg Boxes and Trays Market

Online retail is fastly changing the egg boxes and taurus market by moving consumer buying attitudes toward convenience, doorstep delivery, and contactless shopping. With the expansion of grocery e-commerce platforms, there is a growing demand for protective, robust, and tamper-evident packaging to make sure that eggs remain intact during last-mile delivery.

This has led to the invention of packaging design, concentrating on cushioning, secure closures, and durability. Online retailers also demand compact, lightweight, and eco-friendly materials to lower shipping costs and align with sustainable practices. As a result, there's increased adoption of molded pulp and biodegradable composite trays that integrate environmental advantages with functional performance.

How did Retail Packaging dominate the Egg Boxes and Trays Market?

Retail packaging has dominated the egg boxes and trays market by driving demand for pre-packed, ready-to-purchase egg trays and boxes in standardized sizes and counts. Additionally, growing consumer preference for eco-conscious packaging has shifted the market toward recyclable and biodegradable materials such as molded pulp and fibre-based cartons. With its ability to integrate functionality, branding, and sustainability, retail packaging has become the selected choice across both offline and online sales channels, giving it a dominant position in the egg packaging industry.

Crafted for point-of-sale environments, retail packaging not only protects eggs from breakage but also enhances shelf visibility through attractive branding, labeling, and transparent material. Retailers favor packaging that assists tamper resistance, stackability, and portion control, making it convenient to handle, store, and display in limited shelf space.

Bulk/Industrial Transport is the Fastest-growing Distribution Channel in the Egg Boxes and Trays Market

Bulk and industrial transport packaging plays an important role in the egg boxes and trays market by assisting large-scale distribution from farms to processors, retailers, and foodservice providers. These packaging solutions are crafted to carry high volumes of eggs safely and effectively, often using sturdy molded pulp or plastic trays stacked in crates or pallets.

The initial focus is on shock absorption, durability, and optimal space utilization to minimise breakage during long-distance or high-frequency transportation. Just like retail packaging, bulk transport prioritizes function over branding, with washable, reusable, and nestable taurus being common in industrial supply chains. With the expansion of centralized egg processing and cold chain logistics, bulk packaging is important for maintaining product quality and hygiene standards.

By Region

How did the Asia Pacific dominate the Egg Boxes and Trays Market?

Asia Pacific has emerged as the dominant region in the egg boxes and trays market due to its huge population, growing egg consumption, and expanding poultry industry. Countries like China, India, Indonesia, and Vietnam have experienced major growth in effective, cost-effective, and protective packaging solutions. The region's focus on sustainable materials, such as molded pulp and biodegradable trays, is meeting with growing environmental awareness and government regulations on plastic use.

The growth of organised retail chains, online grocery platforms, and urbanization has boosted the urge for standardised, retail-ready egg packaging. The growth in disposable income and changing consumer preferences for hygienically packed, visually appealing products have further propelled the market. With constant investment in automated packaging solutions and cold chain logistics, Asia-Pacific has solidified its position as a main driver and leader in the global egg boxes and trays industry.

North America is the fastest-growing region in the egg boxes and trays market

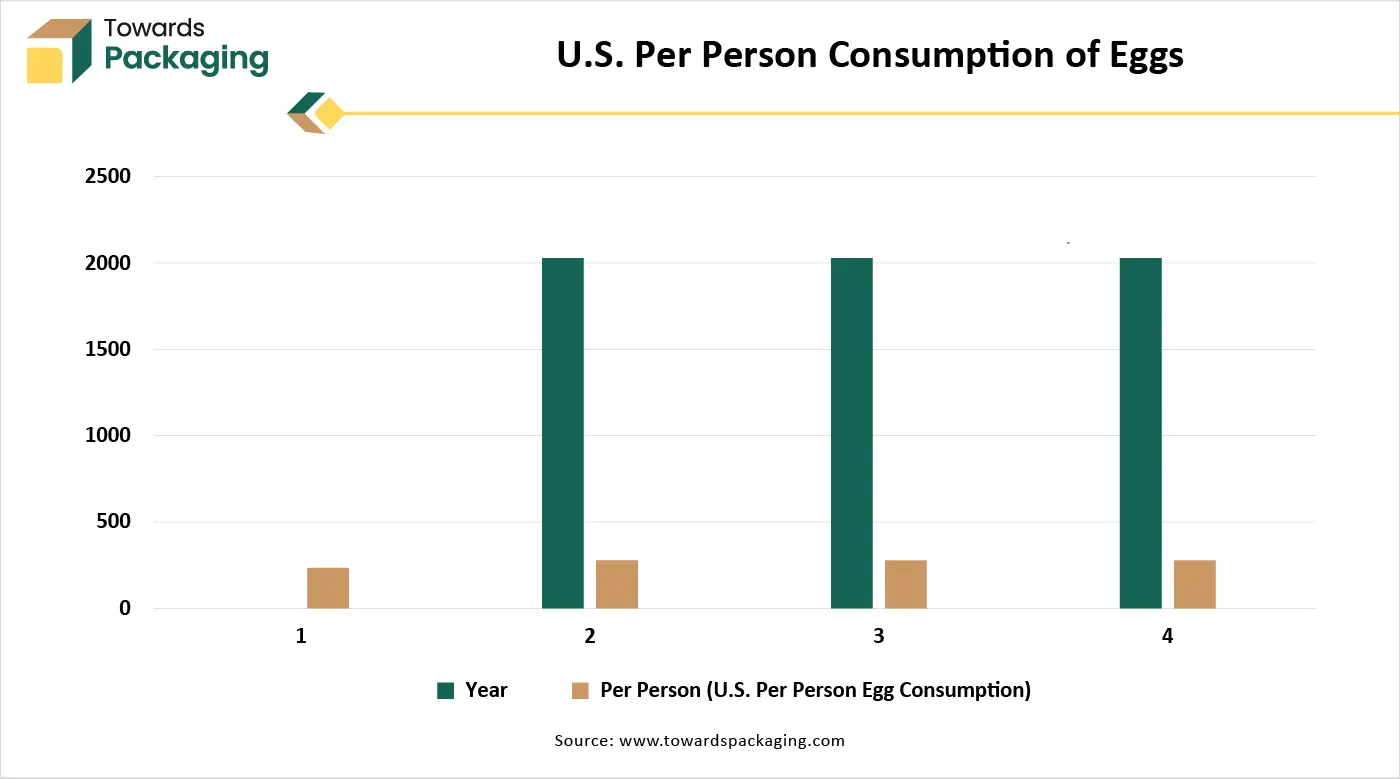

(Source: Federal Reserve Bank of St. Louis)

North America, specifically the United States, has dominated the egg boxes and trays industry due to a well-established poultry industry, advanced logistics infrastructure, and strong focus on food safety. The region's high per capita egg consumption and demand for luxury, branded, and organic eggs have driven the demand for effective and visually attention-grabbing packaging solutions. Retailers and egg producers in the United States give importance to hygiene, durability, and sustainability, which leads to widespread use of molded pulp and biodegradable trays.

Regulatory standards set by organizations like the FDA and USDA ensure the acceptance of high-quality packaging to protect eggs during transport and display. The growth of eco-friendly consumers has accelerated the move toward recyclable and compostable packaging options. Development in online grocery platforms and cold chain systems has also contributed to steady demand for secure and stackable egg packaging. North America's technological inventions, technological advancements, and demand for egg boxes and trays have led to a huge demand for egg boxes and trays.

Top Players in the Egg Boxes and Trays Market

Industry leader Announcement in the Industry

- On 31st March 2025, during its spring 2025 meeting, the American Egg Board ( AEB) welcomed the latest members and alternatives, as designated by the USDA's Agricultural Marketing Service. The Board is composed of 36 egg farmers -18 farmers and 18 alternates -and also collectively accepted its newly elected Executive Committee, as presented by the Nominating Committee. (Source: The American Egg Board)

- On 28 January 2025, the International Egg Commission (IEC) experienced a major transformation, rebranding itself as the World Egg Organisation (WEO). This change has revealed that in January 2025, the organisation's loyalty to growing alongside the global egg sector and leading the way to a successful collective future. (Source: Avinews)

Recent Developments

- On 12 January 2025, Food Company Charoen Pokphand Foods (CP Foods) revealed that egg tray packaging is created from 100% recyclable plastic. The tray is created from 100% recycled Polyethylene terephthalate (PET), which counts 55% post-consumer recycled (PCR) plastic and 45% post-industrial recycled ( PIR) plastic. (Source: WATTPoultry)

- On 8 January 2025, Techniplex consumer products, a globally mixed server of inventive solutions through material science and manufacturing technologies, will have its rising fibre-based packaging solutions prowess on complete display at the International Production and Processing Expo Atlanta. (Source: Food Industry Executive)

Segmentation of the Egg Boxes & Trays Market

By Product Type

By Material Type

- Moulded Pulp / Paperboard

- Recycled Fiber

- Virgin Fiber

- Plastic

- Rigid PET

- Polystyrene Foam

- Biodegradable Composites

- Bioplastics, starch blends

- Others (foam, flex plastic)

By Application

- Retail Egg Packaging

- Bulk/Industrial Transport

- Food Service

- OEM Use (e.g., bakeries using liquid egg)

By Distribution Channel

- Supermarkets & Hypermarkets

- Convenience Stores

- Online Retail / eGrocery

- Food Service / Institutional

- Wholesale / Bulk Suppliers

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa