Food Packaging Technology and Equipment Market Size, Key Players, and Growth Prospects

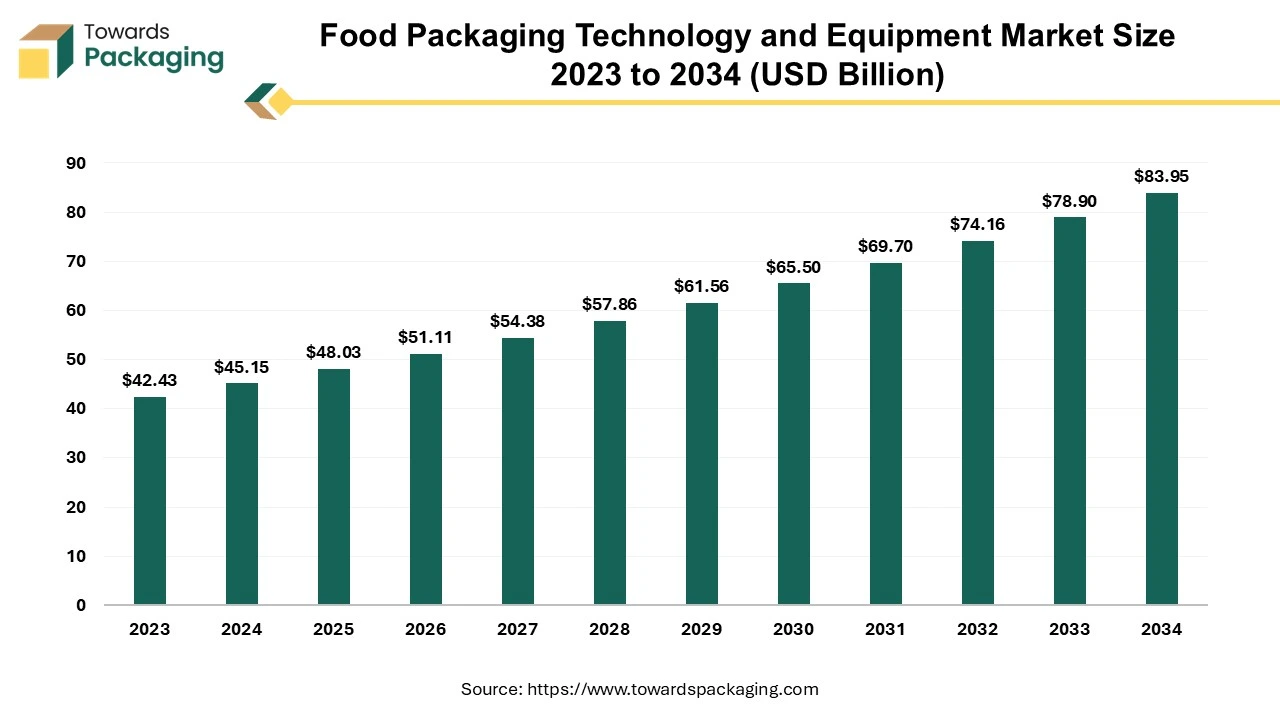

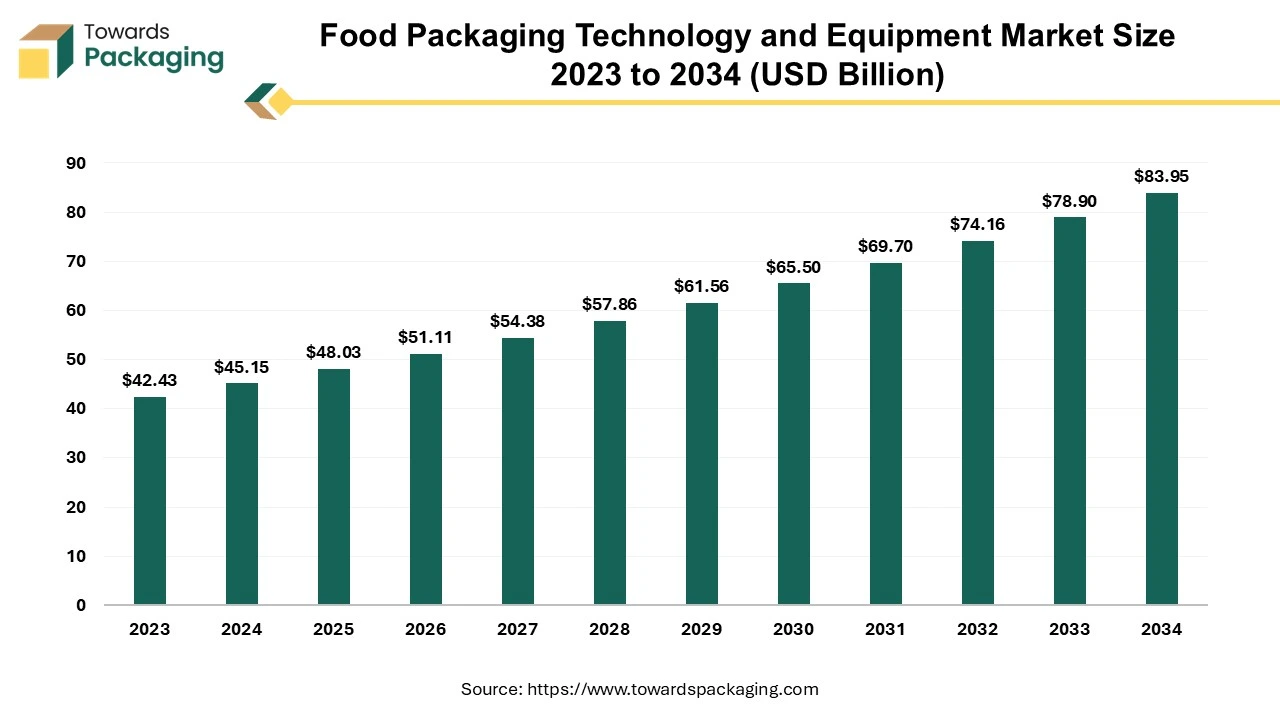

The food packaging technology and equipment market is forecasted to expand from USD 51.11 billion in 2026 to USD 89.33 billion by 2035, growing at a CAGR of 6.4% from 2026 to 2035. This market encompasses various segments, including paper, plastic, glass, and metal packaging materials, and includes technologies like vacuum packaging, modified atmosphere packaging, and active packaging.

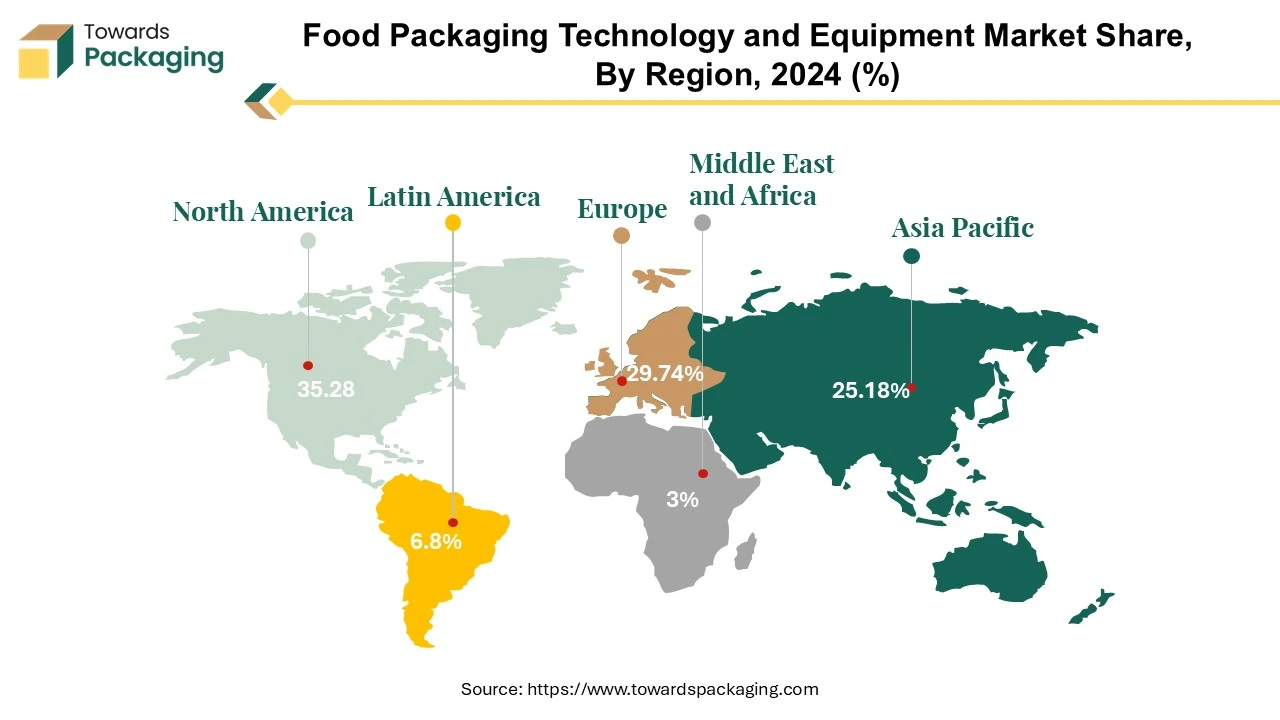

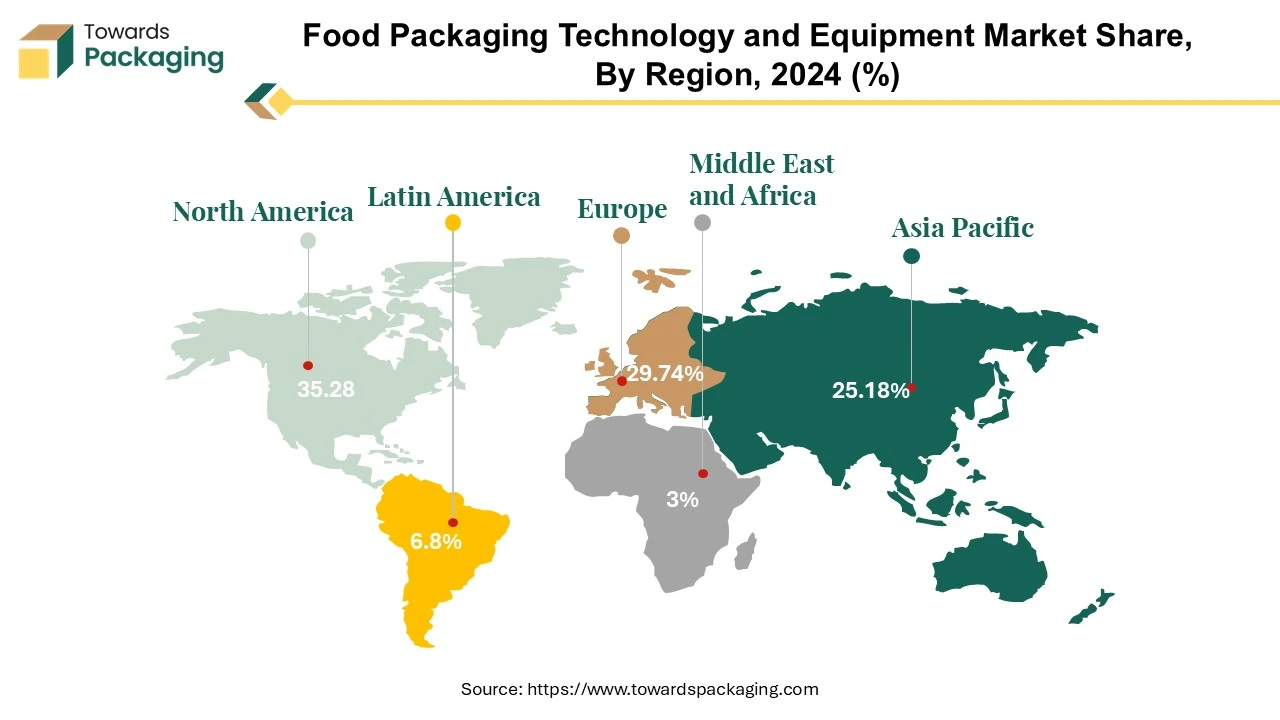

The market is segmented by regions, with North America leading the way due to its mature food industry and technological advancements. Key players include Arpac LLC, GEA Group, Bosch Packaging Technology, and Coesia Group.

Report Highlights: Key Insights and Revelations

- Market Growth: The food packaging technology and equipment market is projected to grow from USD 48.03 billion in 2025 to USD 83.95 billion by 2034, at a CAGR of 6.4%.

- Key Players: North America is the leading region in this market due to its mature food industry, stringent regulations, technological advancements, and commitment to sustainability.

- Sustainability Trends: Increasing demand for sustainable packaging solutions like biodegradable materials, recyclable packaging, and eco-friendly practices is shaping the market.

- Smart Packaging: The integration of sensors, RFID tags, and technology in packaging is enhancing traceability and communication between consumers and producers.

- E-Commerce Packaging: Innovations in packaging to suit online shopping and food delivery services are improving product protection and enhancing consumer experience.

- Shelf Life Extension: Advanced packaging technologies like modified atmosphere and active packaging are extending food shelf life, reducing food waste.

- Technological Advancements: Innovations in intelligent packaging, such as QR codes, NFC, and sensors, are providing real-time monitoring and improving transparency in the food supply chain.

Key Metrics and Overview

| Metric |

Details |

| Market Size in 2025 |

USD 48.04 Billion |

| Projected Market Size in 2035 |

USD 89.33 Billion |

| CAGR (2026 - 2035) |

6.4% |

| Leading Region |

North America |

| Market Segmentation |

By Material, By Technology, By Equipment's, and By Region |

| Top Key Players |

Arpac LLC, Oyster Holding GmbH, GEA Group, Bosch Packaging Technology, Coesia Group, Innovia Film, Kner Pentaplas |

The food packaging technology and equipment market refers to the industry that involves developing, producing, and distributing technology and machinery used in packaging food products. This market plays a crucial role in ensuring food items' safety, quality, and preservation from the point of production to the end of consumption.

The food packaging technology and equipment market constitutes a diverse spectrum of industries engaged in developing, manufacturing, and distributing technologies and machinery dedicated to packaging food products. The food industry will continue to be the largest purchaser of packaging machinery, accounting for slightly under 32% of the global market, which is followed by the beverage industry, which holds 31.5%.

Operating at the core of the food industry, this market plays a pivotal role in guaranteeing food items' safety, quality, and longevity across the entire supply chain. It encapsulates a multifaceted landscape that includes various facets such as packaging technologies, cutting-edge equipment, stringent regulatory compliance measures, ongoing innovations in packaging materials and practices, a growing emphasis on sustainability, and the ever-evolving dynamics of the global market. The global packaging sector has experienced consistent expansion, driven by an annual average growth of 25% in cross-border e-commerce transactions. This surge is attributed to exploring new markets and the increasing prosperity of the global middle-income demographic. This intricate interplay of elements underscores the critical importance of the food packaging technology and equipment market in facilitating food products' seamless and secure movement from production facilities to consumers, ultimately ensuring that these items meet the highest safety standards, quality, and environmental responsibility.

For Instance,

- In May 2023, Syntegon unveils four devices for the most popular vertical form, fill, and seal applications across different food industries with its newly created SVX series.

Key Trends in Food Packaging Technology and Equipment Market

- Eco-friendly packaging: Utilizing biodegradable, recyclable material, and industrially compostable in packaging manufacturing is the top trend in food packaging in 2025. This direction has gained attention over the past few years and displays no signs of display.

- Personalization and customization: Businesses are growing by using custom packaging with logo printing to grow brand recognition and turn containers into mobile advertisements. Personalizing packaging for particular products -such as burgers, sushi, and salads -also assists in protecting food during transport and protects its quality too.

- Minimalist design: Clean and simple packaging design continues to gain popularity. By ignoring over-bold graphics and concentrating on functionality, organizations enable the product itself to take center stage. Minimalist packaging also reduces production costs, which makes it a cost-effective solution.

- Clear and informative labeling: While purchasing food, current users expect transparency. Labels must precisely present ingredients, safety certifications, and nutritional values and encourage customers to make more informed decisions.

- Customer-focussed information: Printed labels serve way to QR Codes which serve customers fast access to detailed product information, marketing, brand stories, or ingredient sourcing. This technology grows engagement, allows direct communication via social media or websites, and serves business valuable data for developing customer retention.

- Convenience and Functionality: Both organizations and users give importance to packaging which is easy to close, open, dispose of, and carry, Packaging perfect for microwave heating and freezing is also in heavy demand, specifically for ready-to-eat and takeaway products.

North America's Leading Role in Food Packaging Technology and Equipment

Within the intricate tapestry of the food packaging technology and equipment market, regional dynamics emerge as a defining factor, shaped by a confluence of economic, technological, and consumer-centric considerations. As of the current landscape, North America stands prominently as a leading region in this dynamic market, its pre-eminence underpinned by a combination of factors that collectively contribute to its robust market position.

At the forefront of North America's ascendancy is the maturity of its food industry, a hallmark of economic development that propels the demand for advanced packaging technologies and equipment. The region boasts a well-established and sophisticated food production ecosystem with diverse products that necessitate innovative packaging solutions. This mature industry landscape, marked by a continuous pursuit of efficiency and quality, acts as a catalyst for adopting cutting-edge packaging technologies and equipment to meet the evolving needs of producers and consumers.

Stringent regulatory frameworks further elevate North America's status within the food packaging technology and equipment market. Regulatory measures designed to ensure the safety and integrity of packaged food products foster an environment where adherence to high-quality standards is imperative. The rigorous regulatory landscape compels industry players to invest in state-of-the-art packaging technologies and equipment that comply with existing standards and position North American products as exemplars of safety and quality on the global stage.

A defining feature of North America's leadership is its unwavering commitment to technological advancements. The region serves as a crucible for innovation, with a dynamic landscape that continually pushes the boundaries of what is possible in food packaging. Investments in research and development, coupled with a culture that embraces technological progress, contribute to the rapid integration of cutting-edge packaging solutions. This relentless pursuit of innovation positions North America as a trendsetter, with new technologies often setting global industry standards benchmarks. Online grocery buying has evolved into a significant competitive battleground. Millennials are the group most likely to purchase groceries online, accounting for nearly half of all buyers in the US. By 2025, twenty per cent of US food spending is expected to occur online, generating a $100 billion business, effectively fuelling the growth of the food packaging and equipment market.

Sustainability is a cornerstone of North America's influence in the food packaging technology and equipment market. A growing societal consciousness and an environmentally aware consumer base have catalyzed eco-friendly practices and materials. Cognizant of this paradigm shift, North American businesses are increasingly investing in and adopting sustainable packaging solutions. This commitment to sustainability aligns with broader environmental goals and resonates with consumers who prioritize products that demonstrate a genuine dedication to reducing their ecological footprint.

In essence, North America's pre-eminence in the food packaging technology and equipment market is a convergence of a mature food industry, stringent regulatory oversight, a relentless pursuit of technological progress, and a steadfast commitment to sustainability. As the region continues to set benchmarks and redefine industry norms, its influence reverberates globally, shaping the trajectory of the broader food packaging landscape.

United States Food Packaging Technology and Equipment Market Trends

The United States holds a dominant place in the North American market due to its advanced infrastructure, which supports innovation in packaging solutions. The established food industry in the country is also a major factor that is led by leading companies like Nestle, PepsiCo and many others. The technological advancements also include automation and various sensors that are boosting the manufacturing capabilities. The presence of regulatory bodies like the FDA and the USDA is also pushing the companies to maintain high-quality packaging.

- In October 2021, ATS Packaging Machinery launched a new line of capping machines for food and beverage applications.

Within the expansive landscape of the food packaging technology and equipment market, Europe stands out prominently as the second leading region, leveraging a unique blend of factors delineating its commanding position in this dynamic industry. A key hallmark of the European market's ascendancy is its unwavering commitment to sustainability, which resonates across the continent. Many European countries have taken proactive measures by implementing stringent regulations to curb plastic waste, reflecting a conscientious effort to address environmental concerns associated with conventional packaging materials. This sustainability-centric approach underscores a broader societal shift towards eco-friendly practices, creating a distinctive identity for the European food packaging landscape.

The robust emphasis on sustainability within the European market is not merely a regulatory obligation but is deeply ingrained in the ethos of the region's business practices. Companies operating within the European food packaging sector increasingly embrace sustainable packaging solutions, responding to consumer demand for environmentally conscious products and the imperative to align with overarching global sustainability goals. This commitment has fuelled innovation in materials and practices, driving the adoption of alternative packaging solutions that minimize environmental impact.

- European company Ahlstrom and The Paper People, a sustainable packaging manufacturer, collaborate to produce fibre-based frozen food packaging.

Its unwavering dedication to technological innovation further fortifies the European market's influence. A hotbed of research and development, Europe continually pushes the boundaries of food packaging technology, setting benchmarks for the global industry. Investments in cutting-edge technologies, including advancements in intelligent packaging, active packaging, and materials science, position European companies at the forefront of innovation. This proactive pursuit of technological excellence enhances the efficiency of food packaging processes and ensures that European products meet the highest safety, quality, and traceability standards.

Its well-established and sophisticated food and beverage industry is crucial to Europe's standing, which forms a robust foundation for the food packaging technology and equipment market. The diversity and complexity of products within the European food industry necessitate advanced and adaptable packaging solutions. Recognizing the need for precision and efficiency, European manufacturers invest significantly in state-of-the-art packaging equipment to meet the evolving demands of a discerning consumer base. This well-oiled machinery of production and distribution contributes to the overall resilience and competitiveness of the European market on the global stage.

The European market's journey to the forefront of the food packaging technology and equipment arena is marked by a convergence of sustainability-driven policies, a relentless pursuit of technological prowess, and a well-established food and beverage industry. As the region continues to navigate the evolving landscape of consumer preferences, regulatory frameworks, and technological advancements, its influence remains pivotal, shaping the trajectory of the global food packaging market. Europe's position as the second leading region reflects more than just its regulatory landscape. Still, it is a testament to its holistic approach that seamlessly integrates sustainability, innovation, and industry expertise.

Asia Pacific is anticipated to be an opportunistic region during the forecast period of 2025 to 2034. The rising urban lifestyles in countries like Japan, China and India are the major factors promoting the growth of packaged foods and beverages. The food packaging technology and equipment market is expanding rapidly due to growth in local production, which is generating significant revenue for the company. The investments are also shifting the manufacturing capabilities by the adoption of automation, which helps in reducing time and labor costs.

The established food processing industry in China has maintained significant demand due to its strength in machinery and packaging solutions. The manufacturing sector is also a major contributor to the country’s economy as it has widely adopted robotics and IoT in its technologies. Other countries are anticipated to rely on China due to affordable packaging pricing and product costs.

Key Advancements in Materials for Food Packaging

In the food packaging technology and equipment market, the choice of materials stands out as a pivotal determinant, wielding significant influence over industry dynamics. Plastic asserts its dominance as a prevailing material due to its unparalleled versatility, cost-effectiveness, and lightweight attributes. This preference for plastic has historically been driven by its ability to provide diverse packaging solutions that cater to various food product requirements. The cost-effectiveness of plastic, combined with its adaptability to different shapes and sizes, has made it a staple choice for packaging across the food industry.

However, the tides of industry preference are undergoing a noteworthy shift, fueled by an escalating global consciousness towards environmental sustainability. In response to mounting environmental concerns, there is a discernible surge in the exploration and adoption of sustainable alternatives, marking a departure from the conventional reliance on plastic. Biodegradable plastics, heralded for their capacity to disintegrate naturally and reduce environmental impact, have gained traction as a promising substitute. This shift reflects a conscientious effort within the industry to mitigate the ecological footprint associated with traditional plastic packaging.

- In May 2022, Trioworld introduced the first plastic film approved for frozen food packaging—post-consumer recycled (PCR) film.

Furthermore, a rising momentum favours paper-based packaging, gaining prominence for its biodegradability and recyclability. Paper, a renewable resource, aligns with the growing consumer preference for eco-friendly packaging solutions, providing a viable alternative to mitigate concerns associated with non-biodegradable materials. The versatility of paper in accommodating various printing techniques for branding and information purposes adds an extra layer of appeal for manufacturers and consumers alike.

Compostable materials represent another facet of this eco-conscious transition, offering packaging solutions designed to break down into natural elements under specific conditions. Compostable packaging aligns with the circular economy concept, contributing to waste reduction and environmental impact. The emphasis on compostable materials underscores an industry-wide commitment to rethinking the entire packaging lifecycle, from production to disposal.

Regulatory pressures do not solely drive the rationale behind this transformative shift in material preferences but are increasingly moulded by consumers' evolving expectations. Modern consumers exhibit a heightened awareness of environmental issues and are inclined towards brands and products that align with their values. As sustainability becomes a central tenet of consumer choice, the food packaging technology and equipment market are compelled to adapt and innovate.

While plastic remains a stalwart in the industry, the ascent of sustainable alternatives such as biodegradable plastics, paper-based packaging, and compostable materials reflects a conscientious pivot towards environmental responsibility. This shift not only echoes regulatory imperatives but, more importantly, mirrors a collective industry commitment to meeting consumer demands for eco-friendly packaging solutions. The evolving material landscape underscores the dynamic nature of the food packaging technology and equipment market, where innovation harmonizes to redefine industry norms.

Revolutionizing Food Packaging: Advancements in Active and Smart Technologies

Simultaneously, the emergence of intelligent packaging technologies represents a paradigm shift in how food products are monitored and managed throughout the supply chain. Notable components of innovative packaging include QR codes, Near Field Communication (NFC), and sensors. Ubiquitous in retail, QR codes now find application in food packaging by providing consumers instant access to comprehensive product information.

This includes details about the product's origin, ingredients, nutritional facts, and interactive content. NFC technology, facilitating communication between devices in proximity, enhances traceability by allowing consumers to engage with products through their smartphones. These technologies contribute to greater transparency in the supply chain, enabling consumers to make informed choices about the products they purchase. Retailers of food estimate that 31 per cent of food products are thrown out because they decay, resulting in losses of US$146 billion. In the case of counterfeit products, innovative packaging might help prevent losses exceeding US$460 billion.

Sensors embedded in intelligent packaging play a critical role in real-time monitoring, offering a proactive approach to quality and safety assurance. These sensors can measure and transmit data on various parameters such as temperature, humidity, and freshness. For example, in the perishable goods sector, temperature sensors ensure that the cold chain is maintained, preventing spoilage and preserving the integrity of the products from production to consumption. Real-time monitoring facilitated by these sensors enhances supply chain efficiency and enables swift responses to deviations from optimal storage conditions, minimizing compromised products reaching consumers.

- In October 2021, the technology company GEA launched a new food and dairy powder or granule packing range. The new GEA SmartFil M1 has been designed to accommodate various filling configurations for low-capacity applications, catering to the different needs of the food, dairy, and pet food industries.

The advancements in food packaging technology, particularly in active and intelligent packaging technologies, signify a transformative era for the industry. These innovations address critical product shelf life and quality challenges and pave the way for a more transparent and consumer-centric food supply chain. As technology continues to evolve, integrating these solutions is poised to become increasingly sophisticated, further elevating the standards of safety, quality, and efficiency in the food packaging sector.

Vertical Form Fill and Seal (VFFS) packaging machines have become indispensable across diverse industries, and their widespread adoption is rooted in their efficiency and cost-effectiveness. These machines prove to be optimal packaging solutions, maximizing the utilization of limited factory floor space.

The core structure and operation of vertical packing machines follow a consistent pattern. They use a substantial roll of film, shape it into a bag, fill it with goods, and then seamlessly seal it—all while moving vertically at impressive speeds of up to 100 bags per minute. This standardized process ensures a swift and reliable packaging mechanism.

VFFS machines exhibit remarkable versatility in handling various materials. They are adept at packaging Paper, Polystyrene, Polyethylene, Plastic laminate, Cellophane, Aluminum foil, Metalized film, and Composite film (laminated). This adaptability makes them suitable for a wide array of products, ranging from candies to crisps, detergent powder, juices, beverages like milk, snacks like nuts, and other food items such as oats. These machines find application across a broad spectrum of sectors, seamlessly meeting diverse production and packaging requirements imposed by specific businesses. Their efficiency not only reduces the labor required but also cuts down on associated expenses, particularly for the production of large quantities of items.

One of the standout features of VFFS machines is their ability to output between 30 to 200 bagged items every minute. This high-speed production capability not only saves money but also enhances market competitiveness. The increased output provides customers with a broader range of choices, thereby contributing to expanded market reach. The integration of vertical packaging equipment proves to be a strategic and effective method for businesses looking to optimize their production processes, reduce costs, and stay competitive in today's fast-paced market landscape.

- In November 2023, SEE has unveiled the introduction of the CRYOVAC CE Vertical Form-Fill-Seal System. It is cutting-edge automated packaging solution is meticulously crafted to address the distinctive needs of liquid products.

Analysis of the Competitive Landscape in the Market

The food packaging technology and equipment market is characterizing characterized competition among key industry players, including Arpac LLC, Oyster Holding GmbH, Bosch Packaging Technology, GEA Group, Coesia Group, Innovia Filmckner Pentaplas, Ishida Co. Ltd, MULTIVAC Group, Omori Machinery Co. Ltd., Nichrome India Ltd., Robert Bosch GmbH, Lindquist Machine Corporation, and IMA Group. These entities are making significant investments in manufacturing Food Packaging Technology and Equipment solutions. Notably, industry leaders are adopting inorganic growth strategies such as acquisitions, mergers, partnerships, and collaborations to augment their product portfolios, thereby contributing to the global expansion of the Food Packaging Technology and Equipment market.

- In December 2023, Global packaging machinery maker Serac claimed that its newly established cup sector brought in $31.6 million in revenue, installing more than 1,000 machines and dosing systems for significant clients. Serac, the global leader in producing food product cup packaging equipment, aims to increase its production by thirty per cent in the next three years.

Recent Developments

- In May 2025, Foopak partnered with Paper Force to highlight the use of recyclable and compostable paperboard solutions. The initiative is anticipated to highly boost sustainable food packaging practices in Australia.

- In December 2024, Bpacks raised 1 million euros in seed funding to scale its bark-based packaging technology. It helps in extending the food shelf life by up to 7 days and reduces waste by over 42% by using pulp moulding equipment.

Major Key Players in the Food Packaging Technology Market

Latest Developments and Innovations in the Market

- On 19 May 2025, Cuica, a Brazilian food company that develops plant-based food and beverages from Brazilian Biomes, selected Tetra Pak, a top leader in food processing and packaging solutions, to reveal its first Amazon nut milk. (Source: Food Tech Biz)

- On 17 February 2025, under its campaign and goal #Sealingthefuture, SEALPAC will be launching different types of innovative technology, all created in Germany, during IFFA 2025 from May 3rd to 8th. (Source: Asia Food Journal)

- Ahlstrom, who is a leading server of fiber-based specialty material has revealed Lambipack, Flex, the newest addition to its LambiPak profile of high-performance base papers. Crafted especially for flexible packaging, LambiPak flex constructs on the proven success of the Original Lambipak. (Source: Packaging Strategies)

- Sidel has revealed CoboREEL, an automatic reel-loading solution for beverage packaging labels with three times the reel capacity of any other solution for the market. (Source: Packaging Strategies)

- Constantia Flexibles, who leads in flexible packaging has auspiciously implemented EcoVerHighPlus, an inventive mono PP Laminate now changing coffee packaging. (Source: Foodtechbiz)

- In March 2023, Cepac, the UK's most inventive and active corrugated packaging company, purchased EW Cartons, a sustainable corrugated tray manufacturer.

- In May 2023, Amcor, a leader in developing and producing sustainable packaging solutions globally, said that it had finalized a deal to purchase Moda Systems, a top producer of automated, cutting-edge protein packaging equipment.

- In August 2023, The Oregon-based GEM Equipment, which produces fryers and blanchers, was acquired by the international freezing and cooling equipment manufacturer FPS Food Process Solutions.

- In August 2023, The UK-based food company Regal Food Products Group announced that it acquired Packaging 'R' Us, a supplier of disposable food packaging solutions.

- In December 2023, The Packaging Development Centre, worth US$10.8 million, was officially opened by SIG on the location of the company's packaging facilities in Linnich, Germany.

Market Segmentation and Analysis in Food Packaging Technology and Equipment

By Material

- Paper and Cardboard

- Plastic

- Glass

- Metal

By Technology

- Vacuum Packaging

- Modified Atmosphere Packaging (MAP)

- Active Packaging

By Equipment's

- Coding and Marking Equipment

- Labeling Machines

- Filling and Sealing Machines

- Inspection and Quality Control Systems

By Region

- North America

- Europe

- Asia Pacific

- LA

- MEA