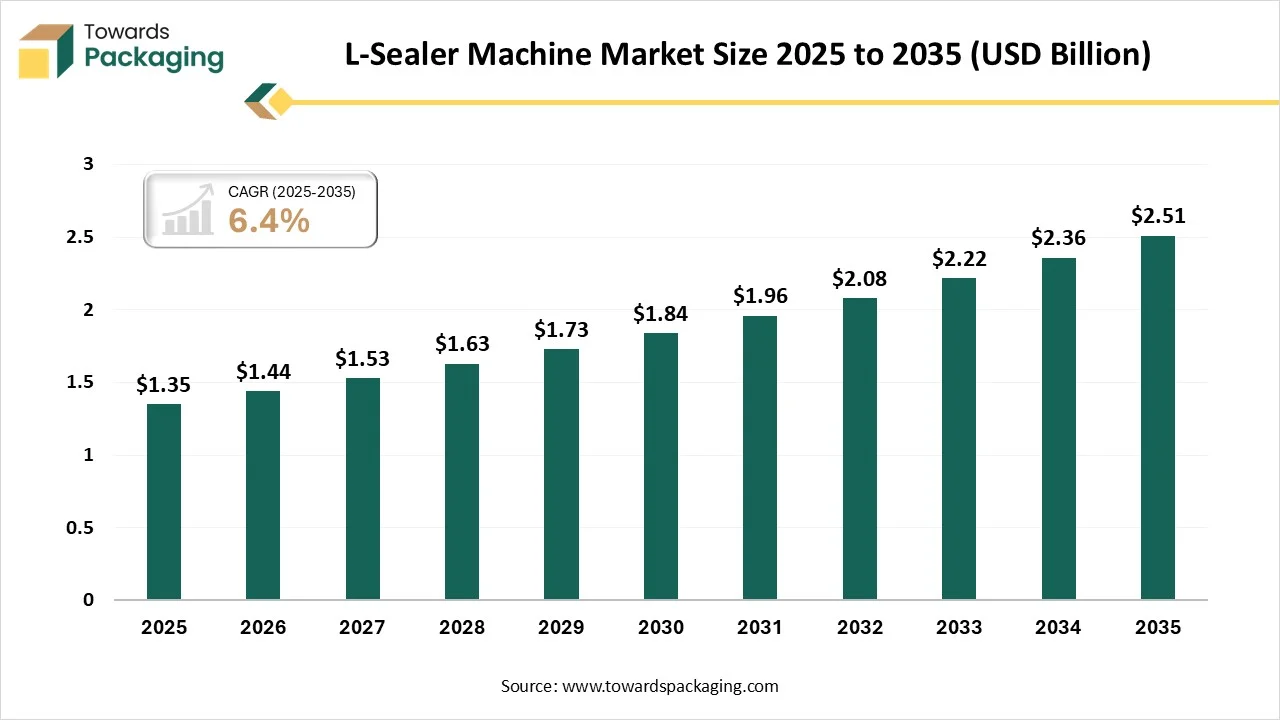

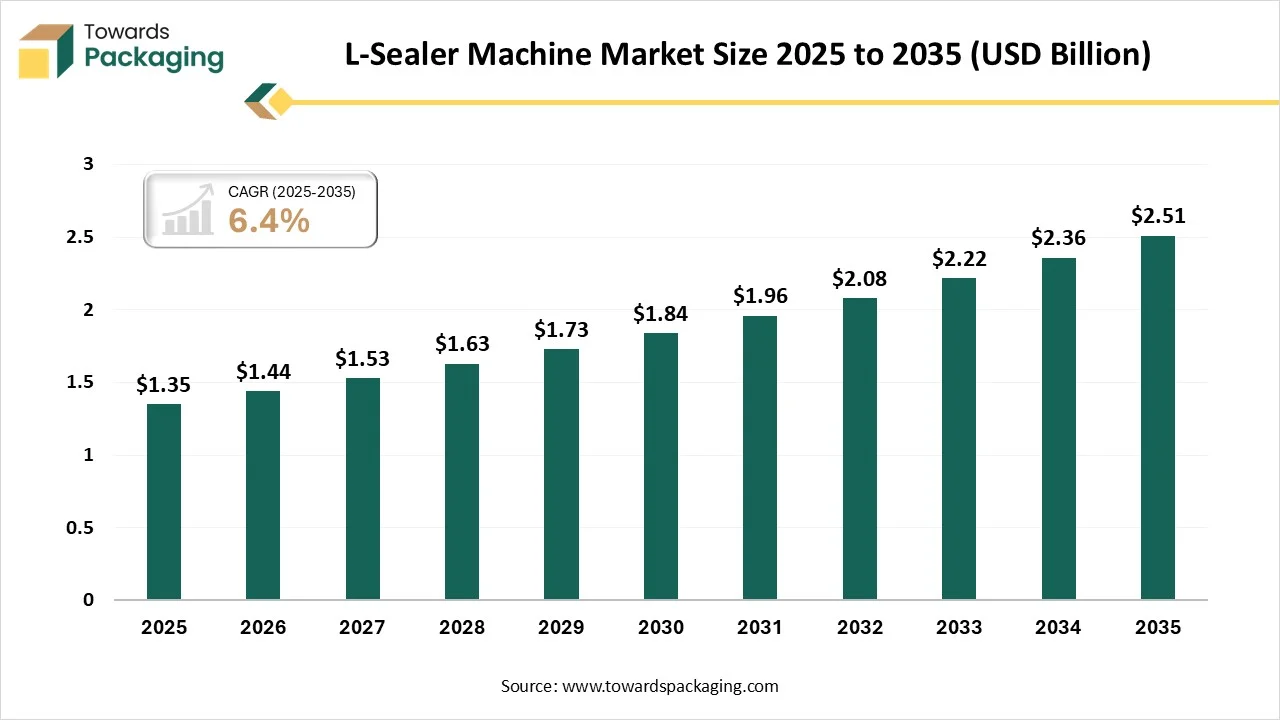

The l-sealer machine market is forecasted to expand from USD 1.44 billion in 2026 to USD 2.51 billion by 2035, growing at a CAGR of 6.4% from 2026 to 2035. The growth is due to ensure product safety and expand the shelf life. Also, it facilitates effective packaging for a huge series of products.

An L-sealer machine is a kind of shrink wrap machine that is crafted to smoothly enclose the products in shrink film. It gets its name from the L-shaped sealing bar that packs two sides and the front, making a neat and sealed package. After packing, the product is shifted through a heat tunnel, in which the film tightly shrinks around the product, which serves to give a secure and professional appearance.

| Packaging Machine Range | Machine Type | Applications |

| Industries Served | Shrink Tunnels | Heat-shrinking film around products |

| Food, Beverages, Retail | Pallet Wrapping Machine | Protecting pallet loads for transport |

| Logistics, Manufacturing, Warehousing | Shrink Wrapping Machines | Using shrink film to products |

| FMCG, Pharmaceutical, Cosmetics | Round Bottle Labeling Machines | Accessing labels to cylindrical containers |

| Beverages, Cosmetics, Chemicals | L Sealer Machines | Sealing products in shrink film |

| Manufacturing, E-commerce, Food | Square Bottle Labeling Machines | Labeling flat-sided containers |

| Food, Lubricants, Household Products | Pedal Sealers | Small Businesses, Bakeries, Retail |

| Band Sealers | Constant bag sealing operations | Food Processing, Packaging Factories |

Automation is one of the largest developments in sealing machine technology. Automated sealing machines are highlighted in self-diagnostic systems, smart sensors, and programmable control panels to ensure smooth operation. Such technologies lower manual labor while maximizing accuracy and throughput, too. Sealing machines with automatic adjustments are amenable to fast transformations between various packaging sizes and types. The automation not only develops productivity but also ensures constant sela quality, lowering the rework and waste over a long period of time.

According to the global data, the globe has imported 3 shipments of the Lsealer machine during the period March 2023 to February 2024. Such imports were being supplied by 1 exporter to 1 global buyer.

Worldwide, the leading three importers of the L-sealer machine are India, Brazil, and Pakistan. Brazil has topped the globe in terms of l-sealer machine imports with 3 shipments, followed by India with 2 shipments, and Pakistan which has taken the third position with 2 shipments.

L-sealer machines are a regular industrial solution for making protective, shrink-covered packaging. The “L” design points to the shape of the selling patch, which packs and cuts both sides of the plastic film at the same time, generally it is used with center-folded film to completely enclose a product.

The move towards a sustainable shrink wrap also includes responsible end-of-life analysis. Organizations are marketing the usage of shrink-wrap materials, which are conveniently compostable or recyclable. This makes sure that even after its starting usage, the material can be mixed again into the production cycle, which lowers waste and maximizes resource efficiency.

Logistics and Distribution: Sealing machines are usually shipped in heavy-duty wooden crates or tailored reinforced crates in order to prevent sensitive elements like sensors, heating factors, and the PLC controls, too. Suppliers use the rigid logistics links to serve machines globally.

The manual l-sealer machine segment has dominated the l-sealer machine market in 2025 as it is a kind of packaging machine crafted to cut and seal shrink film around a product. It is prevalently used for wrapping products in the shrink films, which makes a sealed package that can be further shrunk by using the heat tunnel or heat gun too. Manual L-sealers are perfect for low to moderate manufacturing volumes in which complete automation is not compulsory.

The automatic l-sealer segment is predicted to witness the fastest CAGR during the forecast period. An automatic L-bar sealer is a packaging machine that packs and wraps the products in a variety of materials, which include shrink film, by using a heated sealing bar that makes a seal around the product. The machine automatically seals and cuts the film, which makes it a quick and smooth way to package items. It is known as the L-bar sealer due to the heated sealing bar, as it has an ‘L-shaped ’ design, which enables it to wrap around the product’s ends, making the protective seal.

The food and beverages segment has dominated the market in 2025 as sealing food packaging is a complicated procedure that ensures food safety, tracks freshness, and expands the shelf life. It also delivers tamper resistance. Accurate sealing protects the food products by blocking external factors from penetrating the package, hence protecting the safety and quality of food products during transportation and storage. Furthermore, effective sealing serves tamper-proof characteristics that prevent users from compromising product integrity.

The consumer goods and electronics segment is expected to witness the fastest CAGR during the forecast period. Vacuum sealing is also necessary in preventing electronic products from dust, moisture, and pollutants. Fragile electronic components, such as microchips and circuit boards, are frequently packed by using vacuum sealing machines to track their reliability during storage and shipping. By making a sealed, moisture-free surrounding, vacuum sealing assists in protecting the results of electronic devices and functionality, it protects the toxic from environmental factors during storage and transportation.

The large enterprises segment has dominated the market in 2025 as they need sealing machines to track huge manufacturing scales while making sure brand consistency, product safety, and operational efficiency. In the year 2026, as the supply chains urge bigger speed and sustainability, automated sealing has transformed from a competitive benefit to a baseline need and demand. Machines make leak-proof, airtight, and dust-proof seals that protect products from external pollutants and moisture during logistics. Also, sealing serves as a precise indicator that a product has been opened, which constructs user trust and aligns with strong safety regulations.

The small and medium enterprise segment is predicted to experience the fastest CAGR during the forecast period. It is an accurate seal that keeps air, moisture, and bacteria out, which is necessary for spices, snacks, and powders, too. It is a clean, uniform seal that looks very professional and constructs trust among users. It is particularly crucial for oil products or powdered ones. Also, retailers may urge tamper-proof packaging as the FSSAI registration also favors the hygienic sealing.

North America has dominated the market in 2025 as it stands as a crucial segment in the huge packaging machinery sector, which is being driven by the region’s strong production of pharmaceuticals, food and beverages, and consumer goods. As consumer demands for packaged items are developing, the demand for reliable, smooth, and technologically developed sealing solutions grows. Currently, North America has a main market size, which is expected to sustain growth fueled by the development of strict regulatory standards, automation, and inventions in sector technologies.

How is the L-Sealer Machine Market Growing in Canada?

The Canadian l-sealer machine market carries main overall importance as it plays a complicated role in developing packaging efficiency and product safety across different sectors. With rising demand for quick, relevant, and hygienic sealing solutions, this field is becoming a central point to industries such as food and beverages, consumer goods, and pharmaceuticals. The automated sealing machines assist in lowering human error, also increase the manufacturing speed, and ensure constant quality, making them indispensable in the current production environment globally.

Asia Pacific expects the fastest growth in the market during the forecast period, as it is important in terms of an inflection point, which is driven by the fast development in diagnostics, pathology, and laboratory automation. As the healthcare machines in the region grow their concentration on diagnostic precision, medicine, and operational effectiveness, the urge for automated sealing solutions is developing exceptionally.

Why Is India Using The L-Sealer Machine Market Importantly?

Manual procedures are quickly being substituted by fully automatic systems to develop productivity and hygiene. Fully automatic sealing machines are expected to carry the biggest share in the market, particularly in segments like tray sealing and tube sealing. Current machines can now highlight IoT integration for real-time performance tracking and the predictive maintenance that mainly lowers the operational downtime.

The L-Sealer Machine Market in the region is growing as in Europe. It is quickly developing as sectors across different industries urge more smooth and protective packaging solutions. This urge is highly driven by the demand for developed tamper opposition, product safety, and product checking too. The application of–selaer machines that have been excessively included in sectors such as food and beverages, electronics, pharmaceuticals, and cosmetics to ensure that products reach users without any alternatives.

Germany L-Sealer Machine Market

The German l-sealer machine market is experiencing significant development, driven by many main drivers and rising trends. The market drivers count strict packaging regulations, which are enforced by Europe, linked with the government funding that promotes sustainability and automation. There are growing user choices for faster and more protective packaging methods, which is urging the demand for high-level sealing technologies.

In South America, the L-Sealer Machine Market is growing constantly as current machines are being filled with IoT connectivity, PLC-based touchdowns, and AI-driven sensors. Such characteristics enable real-time tracking, which analyzes the maintenance and smooths the data exchange with the enterprise systems to lower the run time. Additionally, there is a developing importance on “green” sealing technologies as producers are accepting l-sealers to carry recyclable and biodegradable films to match with strict regional eco-friendly regulations.

Brazil L-Sealer Machine Market

Across Brazil, regulatory pressure is changing as governments meet with overall sustainability goals. For example, national plastic packaging limitations in countries such as Colombia, Chile, and Mexico are constantly producing eco-friendly materials. As an outcome, l-sealer machines should now have recyclable, biodegradable, and thinner gauge films without adjusting for seal integrity. This has grown the demand for high-level machines filled with precision control systems and the heat calibration.

In the Middle East and Africa, the L-Sealer Machine Market is Growing Steadily as the initial element for completing the development of this region counts growing demand for hygienic and smooth packaging solutions across industries such as pharmaceuticals, food and beverage, and cosmetics too. With the assistance of growing disposable income, urbanization, and the choice for ready-to-eat and packaged food, there is a compulsion for the application of pollutant-free packaging and enhanced shelf life.

UAE L-Sealer Machine Market

The industry for L-sealer machines in the UAE is being classified by the main move towards high-speed automation and smart technology integration. It is driven by the development of food processing, e-commerce, and pharmaceuticals, as these machines are growing to align with the demands of current and high-volume manufacturing lines. There is a rigid trend towards a completely automatic system that has Programmable Logic Controllers (PLCs) and touchscreen HMIs. There are high-level designs that count IoT potential for real-time performance that tracks monitoring and predictive maintenance, too.

By Type

By Application

By End-User

By Region

March 2026

March 2026

February 2026

February 2026