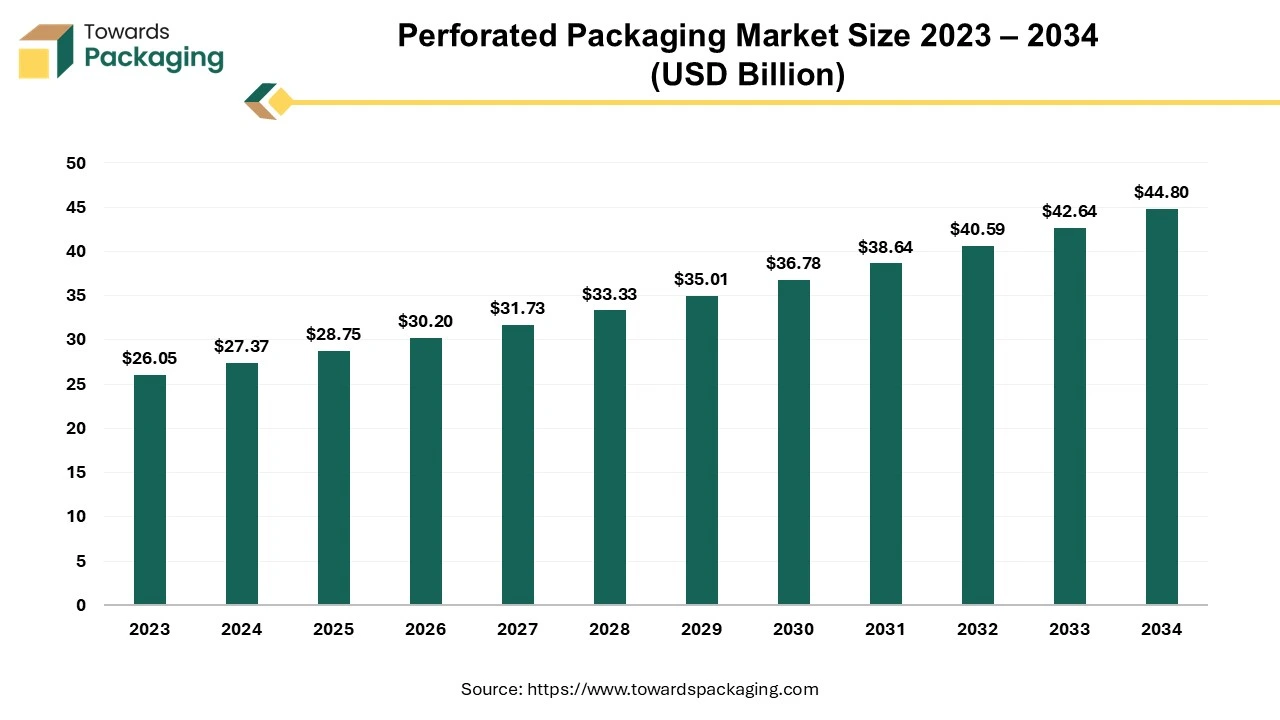

The perforated packaging market is forecasted to expand from USD 30.20 billion in 2026 to USD 47.06 billion by 2035, growing at a CAGR of 5.05% from 2026 to 2035. Industry demand is pushed by rising consumption of ready-to-eat meals, which grew by over 12% globally in the last year. Fresh produce packaging using perforation increased by 8.4% YoY, reflecting strong adoption across supermarkets.

Competitively, firms such as UFlex, Amcor, KM Packaging, OXO Packaging, and Crown Holdings represent major stakeholders. Manufacturers in APAC supply nearly 60% of global perforated film exports, while Europe imports over USD 1.2 billion worth annually. The value chain indicates resin suppliers hold 28–32% cost share, while distributors and converters contribute over 40% of value addition.

It is observed to grow due to the growing food and beverage industry, which has a high demand for safe and preserved packaging. The growing supply chain of the food & beverages sector has influenced this perforated packaging market exponentially.

Perforated packaging is a method of packaging products with the addition of tiny holes in the packaging. These holes are essential for the passage of carbon dioxide and Oxygen in the packaging which enhances the shelf life of the food products packed inside such as meat, vegetables, dried fruits, and many others. Major market players have a significant role in the growth of this market. These are generally of two types mechanical perforation and laser perforation, which are used to make the holes on the packaging purpose. With the capacity to generate identical holes laser perforation is highly preferred by the food packaging industry.

AI has significantly influenced this market as with the incorporation of such technology it becomes easy to understand customer demand and produce such packaging services to improve brand reach. It cuts down labour costs as well which helps to lower down price of the packaging of food products such as baked products, dried fruits, vegetables and many others.

Accuracy in making holes helps to keep products safe and secure increasing the customer reliability on the products. Several market players are introducing AI in the packaging industry due to the growing demand for perfect packaging according to the product that varies in shape, size, and storage capacity. The quick production by the incorporation of AI has helped the market to fulfil the rising demand of the market.

A perforated packaging market uses a particular packaging material including micro-perforations that permit carbon dioxide and oxygen exchange, mainly used to spread the shelf life of fresh food products such as vegetables, bakery goods, and fruits by preserving an ideal atmospheric state inside the packing. The requirement of perforated packaging market ascends from its capability to discourse food waste problems while preserving excellence, freshness, and juiciness. Its applications extend to various sectors comprising food and beverage, healthcare, pharmaceuticals, and agriculture, with the food and beverage sector accounting for the chief share of the demand because of the amplified ingesting of fresh food and ready-to-eat products. End-use segment spreads from superstores and selling to the food service sector and e-commerce services.

The major reasons influencing development aspects comprise growing consumer awareness concerning food quality and protection, growing demand for justifiable packaging methods, and strict government guidelines about food waste administration. The market development is further pushed by technological progressions in construction procedures and materials, resulting in improved product presentation and decreased manufacturing charges. Chances lie in the growing demand for decomposable and ecologically friendly packing methods, as well as the investigation of new sectors in developing countries with increasing expansion and lifestyle variations.

Additionally, perforation permits measured airflow, which allows for the higher squeezability of packaging. The firmness of packaging benefits in the decrease of total delivery charge by allowing easy assembling of the packed product. The aforesaid assistance delivered by the perforated packaging is mainly attracting food producers in the direction of the packaging.

Challenges associated with this market are variations in raw material charges and the competitive market for substitute packaging solutions. Moreover, recyclability problems and ecological guidelines pose potential restrictions. Inventions are expected to prosper in materials science, mainly in the growth of bio-based wrappers and cutting-edge damage technologies to improve functionality. Studying customer behaviour and liking can deliver appreciated visions into modifying products consequently.

| Source | 2020 | 2021 | 2022 | 2023 | 2024 |

| Mayr-Melnhof Board & Paper | 934.50 M | 1.43 B | 2.51 B | 1.73 B | 1.76 B |

| Mayr-Melnhof Premium Packaging | — | — | — | — | 1.70 B |

| Mayr-Melnhof Healthcare Packaging | — | — | — | — | 615.68 M |

| Mayr-Melnhof Packaging | 1.59 B | 1.64 B | 2.17 B | 2.43 B | — |

| Country / Region | 2020 | 2021 | 2022 | 2023 | 2024 |

| Rest of Europe | — | — | 1.44 B | 1.31 B | 1.25 B |

| Germany | 428.20 M | 509.42 M | 802.92 M | 602.54 M | 555.53 M |

| Poland | — | 374.30 M | 684.09 M | 568.72 M | 538.77 M |

| Rest of World | — | — | 690.79 M | 479.37 M | 477.18 M |

| France | 273.94 M | 296.99 M | 419.38 M | 421.79 M | 436.72 M |

| Americas | 123.86 M | 146.81 M | 239.96 M | 386.19 M | 413.11 M |

| United Kingdom | 231.99 M | 232.19 M | 319.50 M | 327.85 M | 325.44 M |

| Austria | 47.39 M | 65.19 M | 85.81 M | 70.77 M | 84.71 M |

| Eastern Europe (including Turkey) | 715.99 M | 619.28 M | — | — | — |

| Other Western European Countries | 415.49 M | 563.23 M | — | — | — |

| Asia, Middle East & North Africa | 256.69 M | 241.80 M | — | — | — |

| Other | 34.86 M | 20.49 M | — | — | — |

| Asia | — | — | — | — | — |

The micro perforation packaging segment is leading in perforation packaging as the process of generating small holes on the surface of the materials. This method of packaging is extensively used by several market players such as printing, food & beverages, and textiles. In the textile sector, it helps to make fabrics comfortable by making them breathable mainly to the activewear segment of the clothing industry. It is growing significantly with the rising usage of technology in this field due to the high production of a variety of products. These incorporations of technology help to produce enhanced quality products without any kind of damage to the clothes.

The low density polyethylene packaging segment is growing rapidly in the perforated packaging market in the predicted period due to its cost-effectiveness, versatility, and durability of the packaging. It is commonly flexible and lightweight plastic packaging which is widely used in manufacturing wraps, films, and bags. These are used mostly in the food industry for the packaging of products such as baked products, meat, and fresh food. The presence of tiny holes allows the airflow to maintain the freshness of the food items. This flow of air is useful in protecting perishable food products. As it is highly flexible it can be produced in a variety of shapes and sizes according to the requirements of the industry which makes it highly preferable.

In the perforated packaging, the woven sack bags segment is highly preferred in the predicted period for bulk packaging majorly in sectors such as chemicals, agriculture, and construction. These sack bags are formed of materials such as polyethylene or polypropylene which make them strong and durable packaging choices. These bags provide high ventilation and structural integrity which make them a reliable choice for packaging. Woven sack bags are extensively used in the agriculture sector for the transportation of vegetables such as onions, grains, potatoes, and other fresh vegetables. These are highly recyclable which makes them eco-friendly and highly preferred by several market players.

This segment of laser perforated films leads the manufacturing technology sector of the perforated packaging market. This type of packaging allows an efficient and precise perforation process for the packaging of a variety of products in the food and consumer industry. The major quality of these types of packaging is they can regulate airflow or exchange of gasses according to the requirement of the packaged food.

This segment of bakery and confectionery products in the perforated packaging market in the predicted period is due to the growing consumption of such products due to their enhanced shelf life. The tiny holes allow the product to store freshly and also maintain its crispiness, this quality intact packaging influences the consumers and enhances the demand for such packaging products in the bakery industry.

North America witnessed the highest revenue share for the year 2024. The rapid growth of this market is due to the high demand for processed meat and packaged food consumption. There are several factors responsible for this such as the large number of working professionals, huge disposable earnings, growing weight, easy-to-eat options, and many more. As some men and women come under the working category they lack time to cook which significantly influences this market. Due to the high protein in meat, many people choose to consume such products as these are sufficient to fulfil the nutritional demand of the consumers.

The growing awareness due to government strict guidelines in the packaging industry also causes growth in the market. With such rules consumers' reliability enhances packaged food and increases the consumption of such ready-to-eat packaged food available in the market. Due to the high preservation duration, it is a convenient option for consumers to store and consume which makes such food materials more preferable and hence boosts the development of this market.

The major market players such as OXO Packaging, ProAmpac Flexible Packaging, Blue Box Packaging, Crown Holdings, Packaging Corporation of America, and many others are playing a significant role by introducing innovation in the field of the packaging industry by incorporating technology into it raising the demand. Such companies provide packaged food with high protection which is preferred by several industries to use them.

Asia Pacific is estimated to grow at the fastest rate over the forecast period. The market is witnessed as rapidly growing due to the changing lifestyle of people in this region. There are several changes such as urbanization, the rising trend of late-night parties, the growing number of working individuals, and many more aspects that are responsible for the growth of this market. The advancement in technology plays a major role as it drastically changes the lifestyle of People. With the incorporation of technology, the labour demand is decreasing and production increases with perfection. Due to the production of defect-free packaging, the market is growing rapidly.

The growing activities of the government to help incorporate technologies in all the Sector has influenced the market drastically. Reduction of Labour requirements in the packaging industry has helped the market to supply products with lower prices which makes them more preferrable by the food and beverages industry.

The Rising trend of consuming dried fruits is responsible for the growth of the market. As these can be stored and used for a longer period and reduce the time of consumption of such food products. The Major market players such as Ultraperf Technologies, UFlex Limited, KM Packaging Services, Amcor Limited, and many others raising this industry significantly by introducing more effective, safe, and convenient packaging.

By Size

By Material Type

By Product Type

By Manufacturing Technology

By Application

By Region Covered

January 2026

January 2026

January 2026

January 2026