AI in the Packaging Market Size, Growth Trends, and Future Outlook

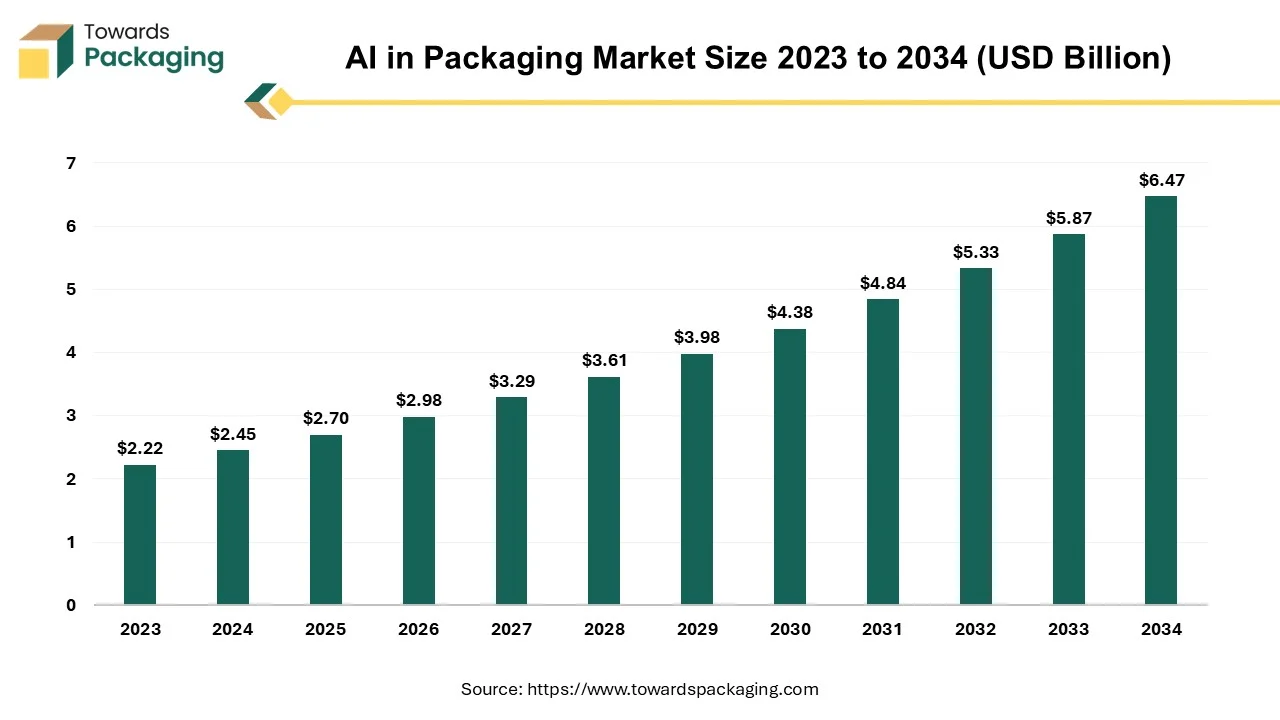

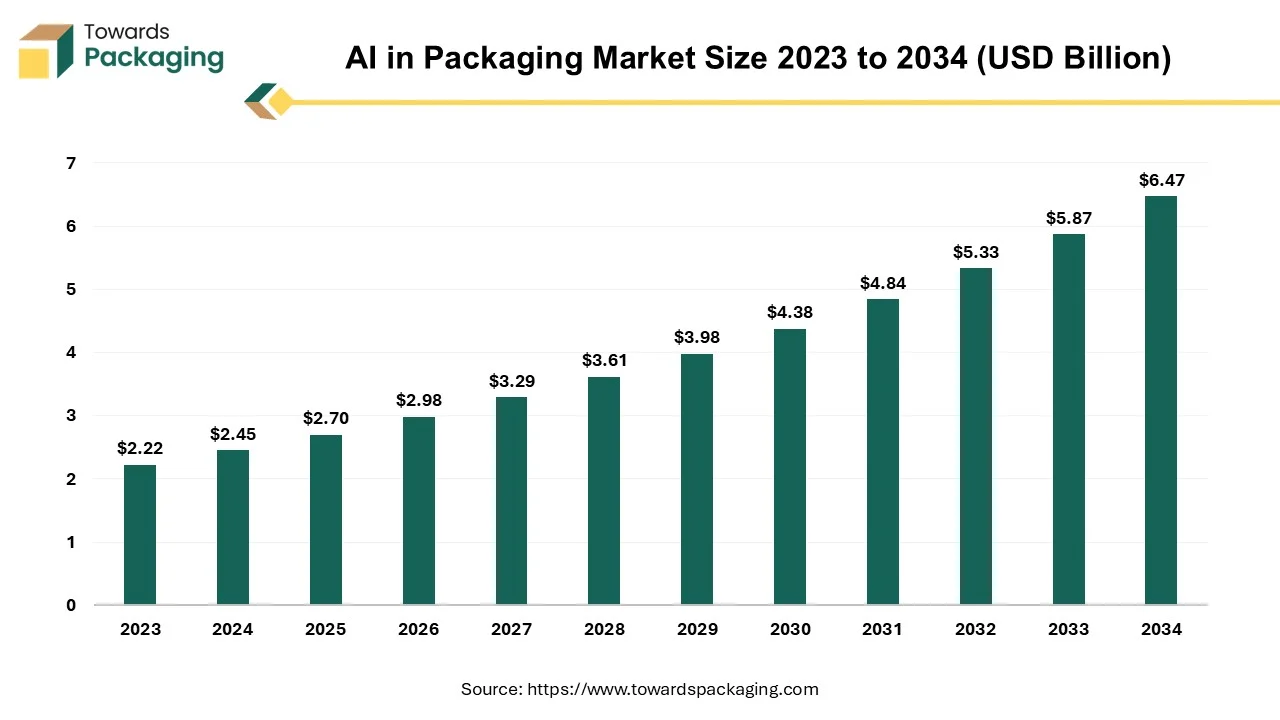

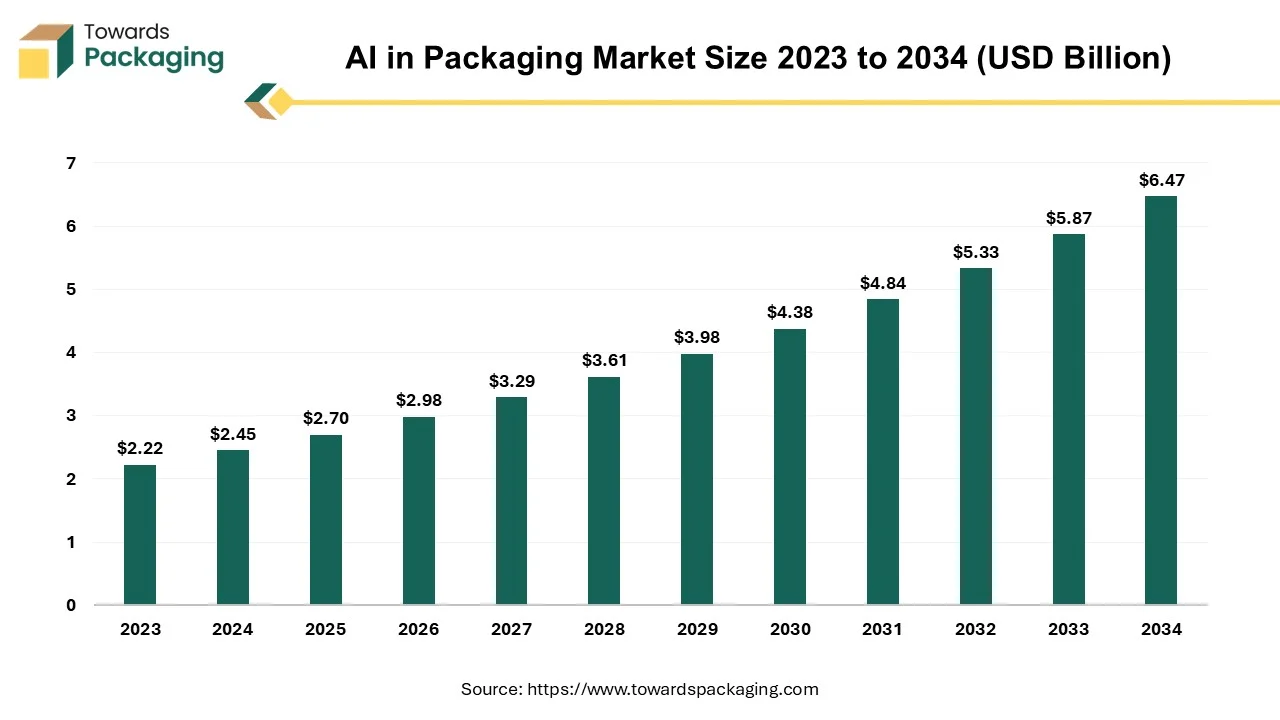

The AI in the packaging market is forecasted to expand from USD 2.98 billion in 2026 to USD 7.19 billion by 2035, growing at a CAGR of 10.28% from 2026 to 2035. The report covers an in-depth segmentation by technology (machine learning, machine vision, and others), application (smart warehousing, data labeling, quality inspection, and AI-based recycling systems), and end users (food & beverage, cosmetics, pharmaceuticals, and electronics). It presents detailed regional data for North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, highlighting North America’s dominance and APAC’s fastest growth.

The study includes a comprehensive competitive analysis featuring key players like SIG Combibloc, Tetra Pak, Sealed Air, Mondi, and Berry Global, along with value chain analysis, trade statistics, and supplier/manufacturer insights shaping the global packaging automation landscape.

The packaging industry is not an exception to how artificial intelligence (AI) is changing various industries. AI has emerged as a game-changer in the packaging industry due to the growth of e-commerce, shifting consumer demands, and the need for effective and sustainable packaging solutions. Numerous aspects of packaging, including design, production, quality assurance, and supply chain optimization, are being revolutionized by this technology.

Packaging design is one of the leading industries where AI is having a significant impact. Packaging design has typically relied on the imagination and intuition of humans. To create unique and alluring packaging designs, AI algorithms are now being used to analyze vast amounts of data, including customer preferences, market trends, and brand guidelines. Designers can make better choices using AI-powered tools that simulate and visualize how the packaging will appear in various environments. This helps businesses create packaging that appeals to their target market while saving time and resources.

AI is greatly enhancing the packaging industry's manufacturing procedures. Intelligent systems with computer vision capabilities can quickly and accurately find flaws or inconsistencies in packaging materials. This prevents waste and lowers the possibility of product recalls by guaranteeing that only high-quality packaging reaches the market. AI algorithms can also optimize packaging arrangements, maximizing material use and reducing excess packaging, which results in cost savings and improved sustainability.

AI is also advancing the packaging industry's efforts to be environmentally friendly. Companies are increasingly looking for eco-friendly packaging solutions as environmental concerns rise. AI algorithms can evaluate the ecological effects of various packaging materials, assisting businesses in selecting environmentally friendly packaging options. AI can help packaging designs be optimized to use the least amount of material while maintaining product integrity, resulting in less waste and a smaller carbon footprint.

Key Insights from the Latest Industry Trends and Developments

- Innovative Packaging Technologies are rapidly transforming the industry, emphasizing automation and sustainability to meet evolving consumer and environmental demands.

- Rising Demand for Personalized Medicine is reshaping healthcare, with more focus on tailored treatments for genetic disorders and cancer therapies.

- Sustainability Efforts in manufacturing are pushing for biodegradable and eco-friendly materials, encouraging companies to adopt greener production practices.

- AI and Robotics Integration are becoming increasingly vital across sectors, enhancing efficiency in production lines and decision-making processes.

- Key Players' Market Movements in sectors such as pharmaceuticals and healthcare are focusing on acquisitions, mergers, and strategic partnerships to expand their reach and capabilities.

- Growth of Emerging Markets in regions like Asia-Pacific is significantly contributing to the overall growth in sectors such as packaging, healthcare, and biotechnology.

- Increased Investment in R&D is driving the creation of next-generation therapies and advanced packaging solutions, pushing companies to stay ahead of the curve.

Exploring the Future of Packaging Inspection: Unlocking the Potential of AI-Powered Vision Systems

Artificial Intelligence (AI) has been playing a significant role in driving sustainable packaging practices. One notable example is the application of AI by Amazon to optimize packaging and reduce product damage. Leveraging a machine learning model, Amazon analyses real-world customer complaint data to identify patterns and improve packaging materials for various products purchased through their online platform.

By utilizing this AI-driven model, Amazon has achieved remarkable results in terms of waste reduction and product preservation. The implementation of AI technology has led to a significant 24% reduction in shipment damage across hundreds of thousands of Amazon packages. Additionally, the optimized packaging materials chosen by the AI model have contributed to a 5% decrease in shipping costs.

This successful integration of AI in sustainable packaging demonstrates the power of machine learning algorithms to learn from real-time data and make informed decisions that benefit both the environment and business operations. By continuously improving packaging materials and reducing damage, companies like Amazon can enhance customer satisfaction, minimize waste generation, and drive cost savings in their supply chain and logistics processes.

The algorithms employed in this AI model can determine the appropriate packaging materials for different items or deliveries, including plastic packaging, flexible packaging, corrugated cardboard, or padded mailers. By intelligently selecting the most suitable packaging option, the model ensures that packages are lighter while maintaining the necessary level of protection for safe delivery.

This optimized packaging approach offers several benefits, including increased efficiency in logistics operations. With lighter packages, more items can be accommodated on each delivery truck, improving load capacity utilization. Consequently, this reduces the overall amount of packaging material required and lowers the volume of packaging waste that needs recycling.

This sustainable packaging strategy contributes to environmental conservation by reducing the carbon footprint per item and yields cost savings in the delivery process. Maximizing the capacity of each delivery truck minimizes transportation costs, aligning with the triple bottom line concept - achieving social, environmental, and economic success.

In summary, applying AI algorithms in packaging decisions enables the selection of appropriate materials for different items or deliveries, resulting in lighter packages and safer delivery. This approach optimizes load capacity, reduces packaging waste, lowers the carbon footprint per item, and drives cost efficiencies, showcasing a successful integration of sustainable practices into the business model.

Revolutionizing the Packaging Industry: How Artificial Intelligence is Shaping the Future

The packaging industry is changing due to artificial intelligence (AI), fuelled by several important factors. The adoption of AI technologies is a result of the increased demand for effective packaging solutions caused by the growth of e-commerce. Intelligent algorithms improve order fulfilment accuracy and waste reduction in e-commerce fulfilment centers' packaging processes. Incorporating AI in packaging is also influenced by shifting consumer demands and preferences. AI algorithms analyze consumer data to create personalized packaging experiences and increase brand loyalty. Concerns about sustainability are pushing businesses to use AI to improve packaging designs, use less material, and have a more negligible environmental impact.

For Instance,

- On February 2, 2023, Recycleye secured an additional USD 17 million Series A investment from DCVC to enhance its AI-driven waste-picking robotic system. This advanced technology, implemented at the final stage of the recycling process, integrates computer vision and robotics to achieve a scanning and identification rate of 60 frames per second, surpassing the industry standard by twofold. Each item passing through the conveyor belt is observed by the robot an average of 30 times, significantly increasing the identification accuracy prior to picking.

Additional motivating factors include increased operational effectiveness and cost savings. Automation powered by AI improves productivity and profitability by streamlining processes, identifying packaging flaws, and optimizing packaging configurations. AI adoption has accelerated due to technological advancements and increased accessibility, making implementation more practical. The packaging industry is embracing AI to deliver personalized experiences, minimize environmental impact, and improve operational efficiency.

How Artificial Intelligence is Shaping the Future of Packaging Design

AI is going to influence how packaging is designed in the future. The technology will assist designers in producing better packaging, more effective packaging, and even packaging that is economical, sustainable, and environmentally friendly. Designers use AI to help them in their work in different ways which are:

Creating New Products

Developing new products is a complex endeavour, yet it is essential for companies aiming to maintain relevance in today's dynamic marketplace. Regular updates are imperative to ensure a company's product portfolio remains vibrant and forward-thinking. This entails introducing fresh items to sustain ongoing consumer interest and purchasing while periodically unveiling new offerings that captivate consumers with constant discovery and novelty. By adopting this approach, businesses can foster a perception that there is a continuous stream of compelling products worth exploring, thereby stimulating consumer engagement and sustaining market competitiveness.

Creating Better Designs for Existing Products

Amidst discussions surrounding the creation of novel products, I emphasize a crucial aspect before we proceed. There are instances where we possess pre-existing offerings that we do not intend to alter substantially in the immediate future or indefinitely. However, these products could still derive advantages from minor adjustments based on their current positioning relative to the criteria for overall improvement.

The Food and Beverage Industry's Role in Driving Future Innovations

The food and beverage industry represents a significant artificial intelligence (AI) adoption market. This sector is fuelled by robust expansion in emerging markets like Asia Pacific, Africa, and Latin America.

Within this rapidly evolving market landscape, AI technologies offer valuable opportunities for optimizing supply chain management. By enhancing tracking capabilities throughout the supply chain, AI enables companies to elevate product quality control measures before reaching customers. This facilitates improved monitoring, traceability, and overall visibility, enhancing efficiency and customer satisfaction.

In addition, AI can play a pivotal role in optimizing customer relationships by leveraging sales data gathered from online and physical stores. Through comprehensive analysis, AI enables a deep understanding of individual customer purchasing behaviors, allowing for tailored promotions and personalized experiences at various customer journey stages, ranging from pre-purchase to post-purchase interactions, such as providing customized coupons.

Moreover, AI-driven insights can contribute to optimizing product packaging design. AI can utilize consumer preferences to inform packaging decisions rather than solely adhering to trends or marketing campaigns that may not align with all consumer needs. This data-driven approach ensures that packaging designs resonate with target consumers, leading to increased appeal, customer satisfaction, and brand loyalty.

North America's Continued Dominance in the Global Market: Key Projections and Future Outlook

Between 2023 and 2032, North America is projected to maintain its dominance in the global market. The region's growth is propelled by the rising adoption of AI technologies within the packaging industry and the establishment of collaborative efforts between public and private entities to introduce cutting-edge machinery. The convergence of high-end technologies like artificial intelligence (AI) and the Internet of Things (IoT) has garnered significant interest across various industrial sectors, driving increased demand for advanced packaging solutions among integrated device manufacturers (IDMs) and foundry suppliers. The presence of well-established market players such as Broadcom, Skyworks, and Qualcomm in the region will have a favourable impact on market growth and development.

Additionally, the Asia-Pacific (APAC) region is poised to experience the highest growth rate in the market during the projected period. The APAC market's rapid expansion can be attributed to the increasing sales of packaged food products, a thriving pharmaceutical packaging sector, and industry players' implementation of growth strategies in the region.

Overcoming the Cost Barrier: Addressing High Implementation Expenses in the AI Packaging Market

One significant restraint observed in the AI in packaging market pertains to the high costs associated with implementation. The integration of AI technologies into packaging processes necessitates substantial investments in infrastructure, software, and skilled personnel. The expenses incurred in acquiring AI systems, providing employee training, and ensuring the ongoing maintenance of the technology can pose a significant barrier, especially for small and medium-sized enterprises (SMEs) with limited financial resources. Consequently, this cost factor may impede the widespread adoption of AI in packaging, particularly among smaller players within the industry.

- On April 14, 2022, DHL Supply Chain, a leader in global logistics, announced the launch of an innovative demand-based packaging option for its business customers. Enhancing shipments' cost-effectiveness and environmental sustainability is the goal of introducing the AI-powered OptiCarton system.

The OptiCarton system uses artificial intelligence to choose the best carton from a pre-configured set to maximize box filling. This intelligent system goes beyond conventional packaging techniques by offering the option to suggest dividing an order into multiple consignments. Individual shipments can be made more cost-effective and have a smaller carbon footprint.

The integration of AI technologies into packaging operations necessitates a comprehensive financial commitment. Procuring the required infrastructure and software solutions and acquiring AI systems tailored to specific packaging needs can impose a substantial upfront investment. Additionally, providing comprehensive training programs to employees to ensure their proficiency in utilizing AI tools and effectively managing the technology's implementation entails additional costs. Moreover, the ongoing maintenance and technical support required to ensure optimal functionality and performance of AI systems require dedicated personnel and financial allocations.

These costs can be a significant hurdle for SMEs with limited financial resources. The budget constraints faced by smaller players in the industry may impede their ability to invest in AI technologies, thereby limiting their access to the potential benefits that AI can offer in enhancing packaging operations. As a result, these organizations may face challenges competing with larger counterparts with greater financial capabilities to adopt and leverage AI in their packaging processes.

To overcome this restraint, businesses must explore cost-effective options and strategies for AI implementation in packaging. This may involve considering scalable solutions or partnering with AI technology providers that offer flexible pricing models or leasing options to reduce the upfront investment. Additionally, seeking government grants or funding programs to support AI adoption in industries can help alleviate the financial burden.

Machine Learning Leads the Way in Identifying the Fastest-Growing Market Segment in the AI Landscape

The market for artificial intelligence (AI) in packaging is segmented into machine learning (ML), machine vision, and other categories. Among these segments, ML is projected to experience the highest growth from 2023 to 2032. This growth is primarily driven by the increasing demand for ML in various areas such as data labelling, process automation, and content inspection within product quality assurance and quality control (QA/QC) processes. Ensuring accurate labelling of products is crucial to avoid inspection failures, customer dissatisfaction, and potential profit loss.

ML has played a significant role in standardizing date labelling processes by reducing manual errors and enhancing overall process efficiencies. It is extensively utilized across the packaging supply chain to support businesses with preventive analytics and cybersecurity measures. A recent survey conducted by Anchore revealed that in 2021, three out of every five companies experienced targeted attacks on their software supply chain, highlighting the critical need for robust cybersecurity measures.

The adoption of ML in packaging processes offers substantial benefits, including improved accuracy, enhanced productivity, and heightened security. By leveraging ML algorithms, companies can automate data labelling tasks, optimize production workflows, and strengthen their defences against cybersecurity threats in the supply chain. This underscores the growing significance of ML in the packaging industry as organizations seek to mitigate risks, streamline operations, and safeguard their brand reputation.

The projected growth of the ML segment within the AI in packaging market underscores the increasing recognition of its value across various applications. As businesses continue to prioritize efficiency, quality control, and security, the demand for ML-driven solutions in packaging is expected to surge. Embracing ML technologies presents a significant opportunity for companies to elevate their competitiveness, protect their supply chains, and deliver products that meet the highest quality standards, ultimately driving sustainable growth and customer satisfaction.

The packaging market for artificial intelligence (AI) is segmented into machine learning (ML), machine vision, and other categories. Among these segments, ML is projected to experience the highest growth from 2023 to 2032. This growth is primarily driven by the increasing demand for ML in various areas, such as data labelling, process automation, and content inspection within product quality assurance and quality control (QA/QC) processes. Ensuring accurate labelling of products is crucial to avoid inspection failures, customer dissatisfaction, and potential profit loss.

ML has significantly standardized date labelling processes by reducing manual errors and enhancing overall process efficiencies. It is extensively utilized across the packaging supply chain to support businesses with preventive analytics and cybersecurity measures. A recent survey conducted by Anchor revealed that in 2021, three out of every five companies experienced targeted attacks on their software supply chain, highlighting the critical need for robust cybersecurity measures.

Integrating DL algorithms into MV systems allows for advanced inspection techniques, surpassing traditional methods and enabling the detection of intricate defects and anomalies. By harnessing the power of DL, MV systems can enhance the efficiency and effectiveness of quality control processes, ensuring that products meet the highest standards of accuracy and reliability.

The utilization of MV in packaging operations enables companies to achieve superior quality assurance, minimize production errors, and optimize resource utilization. The ability to conduct fast and precise inspections enhances overall operational efficiency while reducing the risk of defective products reaching the market. Furthermore, MV systems contribute to sustainable packaging practices by supporting recycling efforts by identifying and sorting recyclable materials.

Both consumers and manufacturers have become increasingly aware of the ecological consequences of improper material recycling practices. With the world producing over 2.1 billion tons of garbage annually, only about 16% is being recycled. This alarming statistic highlights the urgent need for concerted efforts to improve recycling rates and reduce the environmental impact of waste accumulation.

As sustainability becomes a key focus for businesses and individuals alike, proper material recycling is gaining prominence. Recognizing the ecological cost of neglecting responsible recycling practices, stakeholders are actively seeking innovative solutions to tackle this global challenge. From a business perspective, embracing efficient and effective recycling strategies aligns with environmental goals and enhances brand reputation and consumer trust.

Manufacturers, in particular, have a vital role in driving positive change. By implementing advanced recycling technologies, optimizing material recovery processes, and prioritizing sustainable packaging solutions, companies can reduce their ecological footprint and contribute to a more circular economy. Additionally, proactive consumer education and engagement initiatives can empower individuals to make informed choices and actively participate in recycling efforts.

Comparative Landscape Analysis: Key Trends and Competitors in the Industry

The comparative landscape of Artificial Intelligence (AI) in the packaging market comprises various players that contribute to developing and adopting AI technologies in the packaging industry. Market leaders in this landscape are established companies with a strong market presence, advanced AI technologies, and a wide range of AI-enabled packaging solutions. These companies set industry standards and drive innovation in the market. On the other hand, emerging startups bring fresh ideas and unique approaches to packaging automation, optimization, and customization, focusing on niche markets or specific packaging applications.

Technology providers specialize in developing and providing AI tools, platforms, and software solutions for the packaging industry, offering AI algorithms, machine learning models, computer vision systems, and data analytics tools. Packaging equipment manufacturers integrate AI capabilities into their machinery to enhance performance, reliability, and automation. Research and consulting firms provide market analysis, strategic insights, and advisory services related to AI adoption in packaging. Collaborative partnerships between packaging companies and AI technology providers aim to combine packaging expertise with AI capabilities, fostering knowledge exchange and mutual innovation.

Key Players Driving Artificial Intelligence in the Packaging Market

Market Segments Covered in the Insight

By Technology

- Machine Vision

- Machine Learning

- Others

By Application

- AIE of Packaging

- Smart Warehousing

- Data Labeling

- Quality Inspection

- AI-based Recycling Systems

- Others

By End-User

- Food & Beverage Industry

- Cosmetic Industry

- Medical and Pharmaceutical Industries

- Consumer Electronics Industry

- Others

By Region

- North America

- Europe

- U.K.

- France

- Germany

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-East Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of Middle East & Africa