Plastic Corrugated Sheets Market Size, Trends, Share and Innovations

The plastic corrugated sheets market is valued at USD 1.092 million in 2025 and projected to reach USD 1.737 million by 2034, growing at a CAGR of 5.34%. The market assessment includes detailed statistical tables such as the global production trend rising from 3,120 kt in 2018 to 4,460 kt in 2025, PP-based share increasing from 78% to 84%, and PE-based share decreasing from 22% to 16%.

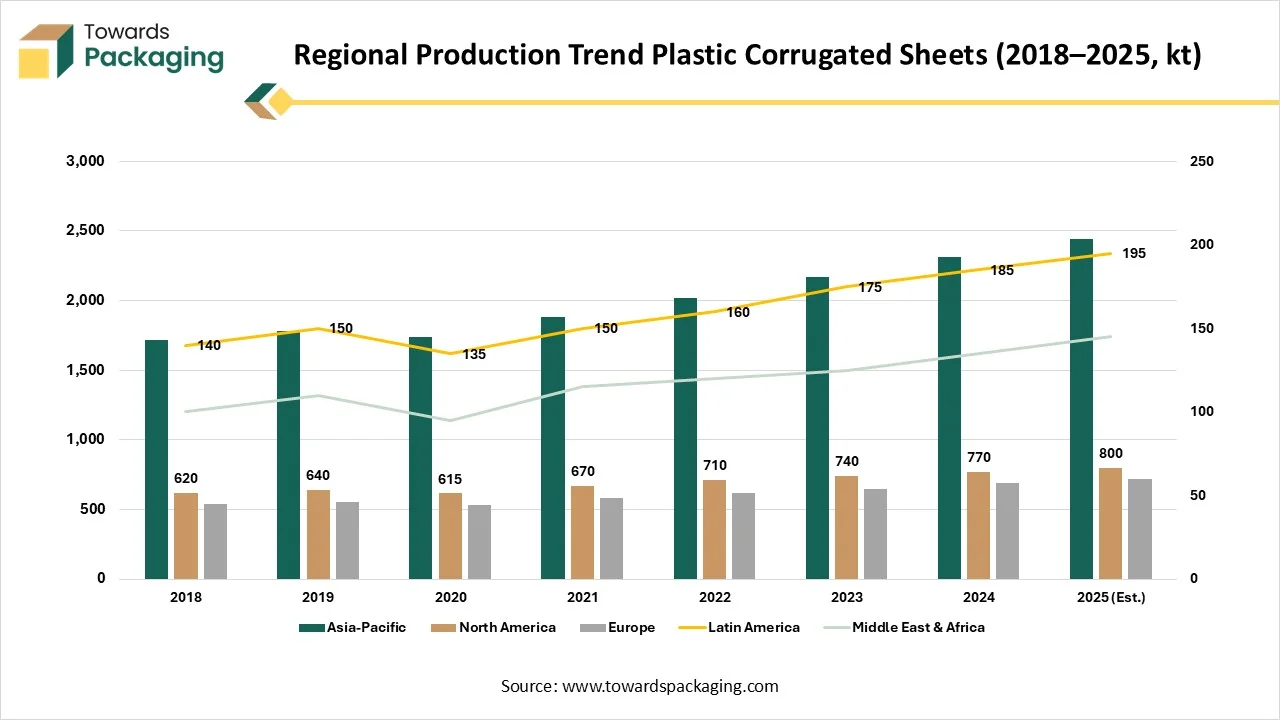

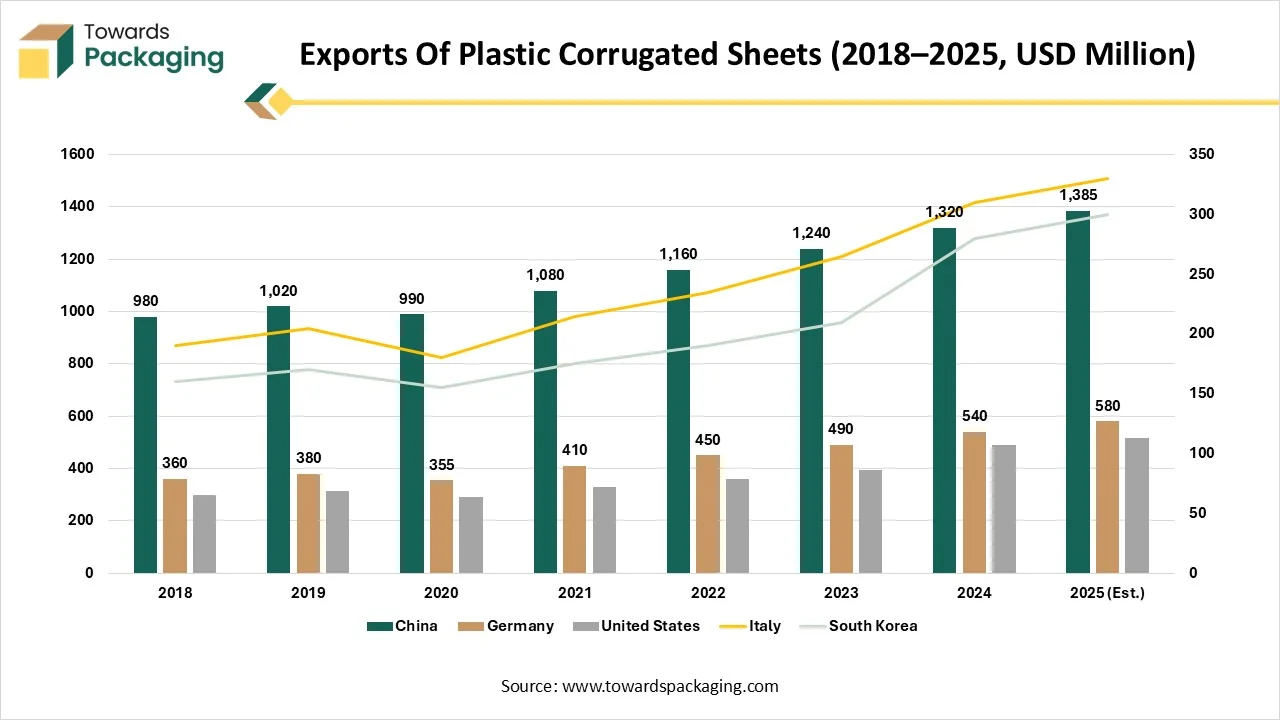

Regional data highlights Asia Pacific's leadership with production rising from 1,720 kt in 2018 to 2,440 kt in 2025, while North America grows fastest at 800 kt in 2025. Trade insights include export values where China leads, rising from USD 980 million in 2018 to USD 1,385 million in 2025, supported by recycling trends showing improvement from 21% in 2018 to 33% in 2025. The report also evaluates major players such as Coroplast, DS Smith, Corex Plastics, and Shish Industries, along with value chain elements like raw material sourcing, fabrication, distribution, and end-user applications.

Key Takeaways

- In terms of revenue, the market is valued at USD 1.092 million in 2025.

- The market is projected to reach USD 1.737 million by 2034.

- Rapid growth at a CAGR of 5.34% will be observed in the period between 2025 and 2034.

- Asia Pacific dominated the global plastic corrugated sheets market in 2024.

- North America is expected to grow at the fastest CAGR over the forecast period.

- By material type, the polypropylene (PP) segment dominated the market with the largest revenue share.

- By material type, the polyethylene (PE) segment will grow a the fastest CAGR in the coming years.

- By thickness, the 3 to 18 mm segment held the highest revenue share in 2024.

- By thickness, the 8 mm segment is expected to grow at the fastest CAGR over the forecast period.

- By end-use, in 2024, the packaging segment dominated the market with the largest revenue share.

- By end-use, the logistics and transportation segment will grow a the fastest CAGR in the coming years.

Plastic Corrugated Sheets Market Overview

Plastic corrugated sheets are created using polypropylene or polyethylene and elements like a honeycomb pattern-like structure. This design not only reduces the weight but also increases rigidity and affects resistance. As compared to regular materials, corrugated plastic sheets serve many advantages as it is easy to carry, resist abrasion and impact, and have the potential to withstand major pressure. Plastic corrugated sheets market solutions are perfect for humid surroundings or packaging that needs moisture protection. It can be recycled several times, which reduces packaging costs and environmental effects. It also efficiently assigns weight and force, which makes it stronger and more lightweight, just like a regular plastic sheet. The corrugated plastic sheet perfectly shares force and required pressure. Specifically improves the overall durability of the material without significantly increasing weight.

Key Metrics and Overview

| Metric |

Details |

| AI Integration Impacts |

Predictive maintenance, energy optimization, improved quality control |

| Leading Region |

Asia Pacific |

| Market Segmentation |

By Material type, By Thickness, By End-use and By Region |

| Top Key Players |

Twinplast Ltd, Coroplast, DS Smith, Corex Plastics, Shish Industries, etc. |

Major Applications of Plastic Sheets

Polypropylene Sheets are universally utilized in custom packaging in different sectors due to their permanent and versatile characteristics.

- Office Supplies and Stationery: They are the perfect material for making professional packaging for office products such as binders, folders, and document holders. Their toughness makes sure that items are protected during storage and transport, while the fragile nature of PP Sheets makes them simple to handle and cost-efficient for bulk packaging.

- Signage and Display Solutions: PP sheets are repeatedly utilized for generating a customizable and lightweight product. Their sophisticated surface allows for high-quality printing, making them ideal for marketing displays, retail signage, and trade show materials. Whether it's a permanent or temporary sign, PP Sheets offer long-term flexibility and are resistant to cracking, fading, and other damage from environmental exposure.

- Consumer Product Packaging: Several consumer products, ranging from cosmetics to electronics, take advantage of the usage of PP Sheets in their packaging. The material is perfectly suited for making custom, protective packaging which the product, while making sure it for continuous safety during handling and shipping. PP Sheets can be easily shaped and locked to make functional and attractive packaging that meets brand attractiveness and provides optimal protection.

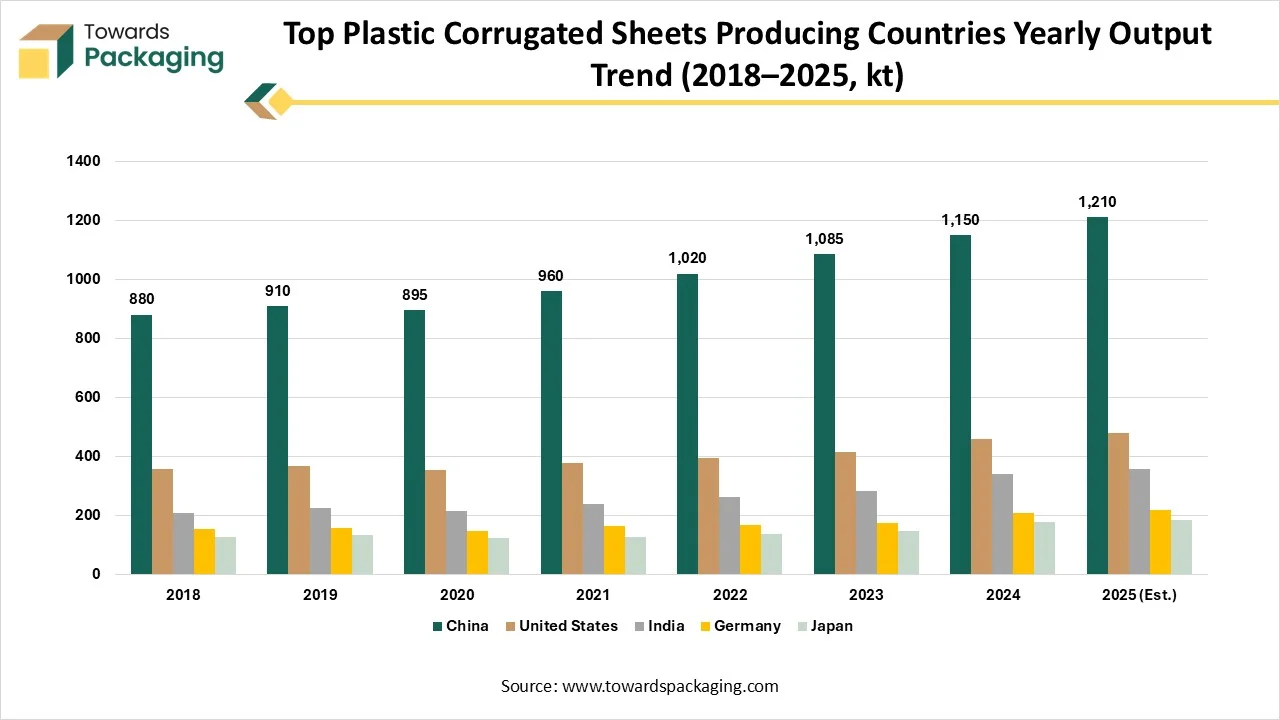

Top Plastic Corrugated Sheets Producing Countries Yearly Output Trend (2018-2025, kt)

| Year |

China |

United States |

India |

Germany |

Japan |

| 2018 |

880 |

360 |

210 |

155 |

130 |

| 2019 |

910 |

370 |

225 |

160 |

135 |

| 2020 |

895 |

355 |

215 |

150 |

125 |

| 2021 |

960 |

380 |

240 |

165 |

130 |

| 2022 |

1,020 |

395 |

265 |

170 |

140 |

| 2023 |

1,085 |

415 |

285 |

175 |

150 |

| 2024 |

1,150 |

460 |

340 |

210 |

180 |

| 2025 |

1,210 |

480 |

360 |

220 |

185 |

The data indicates steady growth across all major countries between 2018 and 2025, with a brief slowdown in 2020. China remains the clear leader, increasing from 880 in 2018 to 1,210 by 2025, driven by strong industrial output. The United States shows consistent expansion, especially after 2021, reflecting recovering demand and investments. India records the fastest growth rate, rising sharply from 210 to 360 over the period, highlighting its expanding manufacturing base. Germany and Japan grow more gradually, indicating mature but stable market conditions.

What are the New Trends in the Plastic Corrugated Sheets Market?

- Incorporating automation and robotics into corrugated production procedures grows productivity and cuts labor expenses. Robots now serve many purposes, from accurately stacking complete items to conducting quality control checks. Also, automation modernizes the design and paradigm development procedure, which makes it quicker and more effective.

- Packaging companies give importance to waste reduction by reducing the recyclability of corrugated materials and marketing practices among consumers. Several are discovering materials, such as offering reusable materials or reshaping products for other purposes.

- The growth in digital printing technology allows cost-effective short-run and tailored packaging solutions. This is an important benefit for small businesses and brands looking to differentiate themselves. It also excludes the urge for regular printing plates, which makes it more economical for smaller print quantities.

- Smart packaging is a rising trend in the corrugated plastic sector because of the demand for improved customer engagement and supply chain efficiency. RFID Tags and QR Codes are the main components of this technology, which allows for smooth product tracking throughout their supply chain journey.

- Due to deepening environmental awareness, sustainable materials have become a central point in the packaging industry. Corrugated plastic producers are taking steps toward sustainability by accepting eco-friendly practices. This includes the help of board-made post-consumer and post-industrial recycled content to lessen the urge for the latest raw materials and lessen the environmental impact of production.

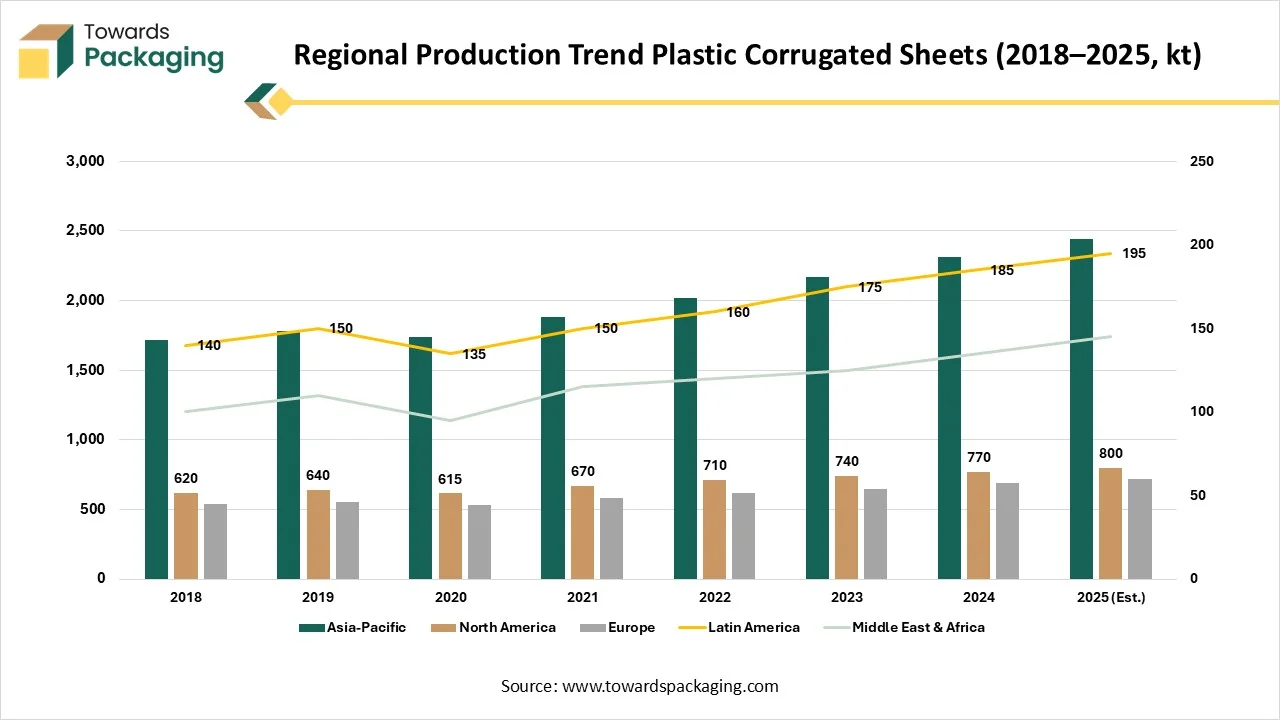

Regional Production Trend Plastic Corrugated Sheets (2018–2025, kt)

| Year |

Asia-Pacific |

North America |

Europe |

Latin America |

Middle East & Africa |

| 2018 |

1,720 |

620 |

540 |

140 |

100 |

| 2019 |

1,780 |

640 |

550 |

150 |

110 |

| 2020 |

1,740 |

615 |

530 |

135 |

95 |

| 2021 |

1,880 |

670 |

580 |

150 |

115 |

| 2022 |

2,020 |

710 |

620 |

160 |

120 |

| 2023 |

2,170 |

740 |

650 |

175 |

125 |

| 2024 |

2,310 |

770 |

690 |

185 |

135 |

| 2025 |

2,440 |

800 |

720 |

195 |

145 |

The regional data shows consistent growth across most markets from 2018 to 2025, with Asia-Pacific leading by a wide margin. Asia-Pacific rises from 1,720 in 2018 to 2,440 in 2025, driven by strong manufacturing and consumption growth. North America and Europe also show steady expansion, reflecting stable demand and technological advancements. Latin America and the Middle East & Africa grow at a slower but consistent pace, indicating emerging market potential. Overall, the upward trend highlights increasing global adoption and regional diversification over time

Germany Plastic Corrugated Sheets Market Trends

Germany’s market will grow as plastic corrugated sheets are still used by the engineering, construction, and automotive sectors for site signage prototypes and apart protection. Customers will, however, favor sheets with better strength-to-weight ratios, easy recycling, and compliance with environmental regulations. Advanced corrugated plastics will become more in demand as lightweight industrial materials continue to innovate.

MEA market will see rising demand because of ongoing infrastructure projects, a rise in commercial building, and an increasing demand for protective sheets and long-lasting signage. The region's preference for durable weather-resistant materials that function well in challenging climates will propel adoption. Megaprojects supported by governments throughout the Gulf Cooperation Council and Africa will continue to drive steady material requirements.

UAE Plastic Corrugated Sheets Market Trends

The UEA demand will increase due to high-volume trade, retail growth, and ongoing event activity. With a gradual transition to more recyclable and sustainable product options, plastic corrugated sheets will be widely used in construction protection, exhibitions, and reusable packaging. Future demand will also be influenced by the growing interest in premium visual display materials.

Latin America Plastic Corrugated Sheets Market Trends:

Latin America will show steady future demand, supported by the local packaging, retail marketing, and agricultural sectors. Growth will support the region's transition to a more robust packaging solution by favoring affordable lightweight sheets that can endure a variety of environmental conditions. The use of plastic corrugated materials will be further stimulated by increasing local manufacturing capacity.

Brazil Plastic Corrugated Sheets Market Trends:

Brazil’s market will see increasing demand from agriculture, retail displays, and industrial packaging as local manufacturers seek durable and weather-resistant materials. As companies search for long-term economical substitutes for conventional packaging, interest in UV-stable and recyclable corrugated sheets will increase. The use of protective corrugated plastic sheets will increase due to the nation's expanding export activities.

How Does AI Integration Affect the Plastic Corrugated Sheets Market?

Artificial intelligence (AI) in the plastic corrugated sheets market is transforming quality control procedures through high-level defect detection systems. These AI-driven systems engage high-resolution cameras and machine learning algorithms to constantly analyze products on the manufacturing line. They are important in implementing prophylactic maintenance in plastic production. By executing AI with Internet of Things (IoT), machines can constantly convey operational data to AI Systems that examine patterns and predict future events before they occur.

AI growth simplifies the overall supply chain in the plastic corrugated sheets market, from the primary raw material acquisition to the allocation of goods. Its application concentrates on growing energy efficiency .AI Systems track and manage energy usage across different stages of production, identify patterns, and suggest optimal operational modifications. Lately, it has also played an important role in growing recycling procedures in the plastic industry. High-level AI-enabled sorting systems smoothly and accurately examine different plastic materials and grow the speed and accuracy of recycling operations.

Future Demands

- Rising demand for lightweight, reusable, and durable packaging solutions across logistics, warehousing, and e-commerce.

- Growing use in construction for protection boards, floor guards, and signage due to weather resistance and strength.

- Increasing adoption in retail for point-of-sale displays, advertising boards, and temporary partitions.

- Higher preference for recyclable and eco-friendly polypropylene sheets as sustainability requirements tighten.

- Expanding usage in agriculture for greenhouse panels, crop protection, and transport trays.

- Strong demand from automotive and industrial sectors for part protection, material handling, and prototype applications.

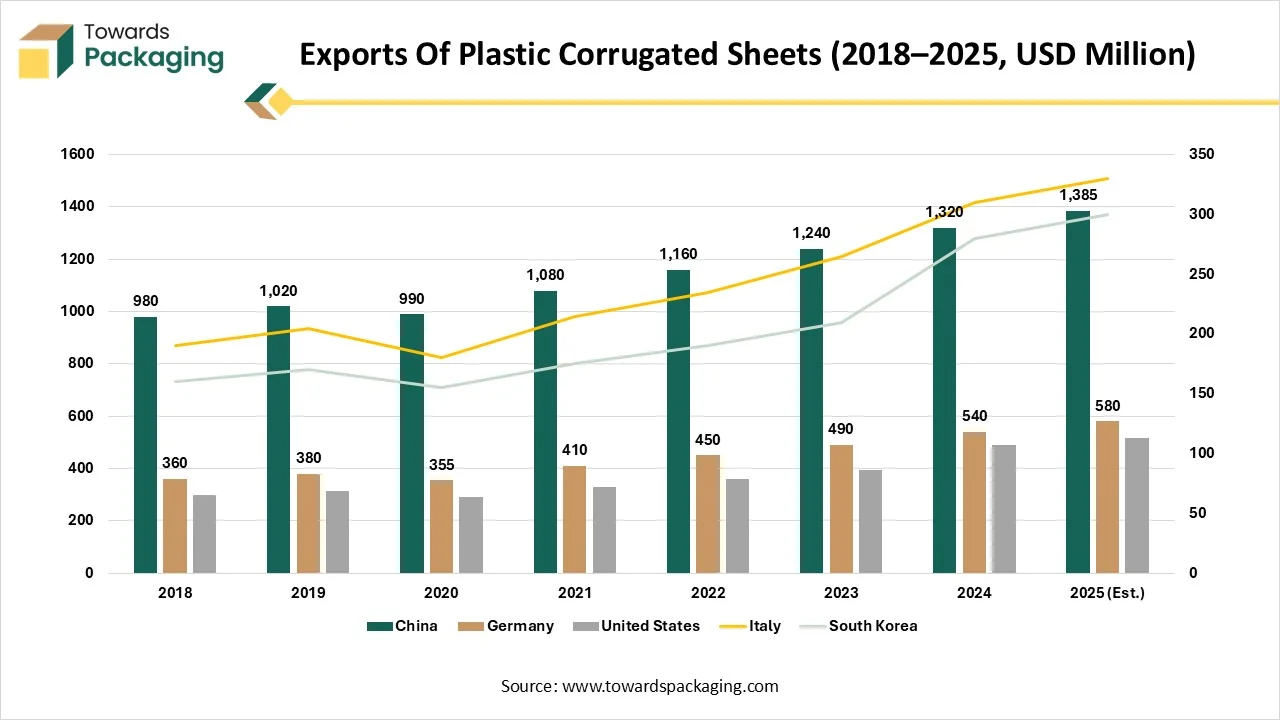

Exports Of Plastic Corrugated Sheets (2018-2025, USD Million)

| Year |

China |

Germany |

United States |

Italy |

South Korea |

| 2018 |

980 |

360 |

300 |

190 |

160 |

| 2019 |

1,020 |

380 |

315 |

205 |

170 |

| 2020 |

990 |

355 |

290 |

180 |

155 |

| 2021 |

1,080 |

410 |

330 |

215 |

175 |

| 2022 |

1,160 |

450 |

360 |

235 |

190 |

| 2023 |

1,240 |

490 |

395 |

265 |

210 |

| 2024 |

1,320 |

540 |

490 |

310 |

280 |

| 2025 (Est.) |

1,385 |

580 |

515 |

330 |

300 |

The data shows a steady long-term growth trend across all listed countries from 2018 to 2025. China consistently leads, rising from 980 in 2018 to an estimated 1,385 by 2025, reflecting strong industrial expansion. Germany and the United States also demonstrate stable growth, with notable acceleration after 2021. Italy and South Korea show sharper increases in recent years, particularly from 2023 onward, indicating improving market momentum. Overall, the estimates for 2025 suggest continued expansion driven by recovery, investment, and rising demand across major economies.

Market Dynamics

Driver

Quality Requirements

Plastic corrugated sheets, which are also known as twin-wall plastic sheets or coroplast, have trailblazers across industries. They are 100% recyclable and reusable, which offers businesses the best alternative without compromising performance. Their lifelong means less use, which saves both material costs and labor in the long run. Plastic corrugated sheets are easily folded, cut, printed, and die-cut into tailored designs. Whether we need protective packaging for automotive parts, attention-grabbing promotional displays, or lightweight partitions for warehouses, these sheets accept projects flawlessly.

Restraint

Challenges in Lighting Inefficiencies and Durability Problems

Industrial sheds frequently struggle with insufficient lighting, which leads to high energy costs and an unproductive work atmosphere. Regular metal roofing, while long-lasting, lacks transparency, which requires continuous artificial lighting, even during the highest hours. This dependency on artificial light not only increases operating costs but also increases the facility’s carbon footprint.

Plastic corrugated sheet cracks often occur due to their durability, UV radiation, or the effect of detritus from falling branches or hail. Even a minimal crack can strengthen over time, specifically if moisture gets inside and freezes, which causes the crack to grow. Warping is an issue, specifically if the plastic is exposed to high temperatures or is stored inappropriately before installation. Over a long period, fastening may be lost due to thermal growth or wind pressure.

Opportunity

Sustainable Packaging Solution

Plastic corrugated sheet machines in order to create lightweight and recyclable packaging. These machines generate sheets that are both durable and eco-friendly. That makes them perfect for industries seeking to diminish their environmental impact. The lightweight quality of these sheets assists in lower transportation costs. It also decreases the carbon footprint of shipping.

Recyclability makes sure that the material can be reshaped, which assists a circular economy. It also enables the making of customized designs to particular requirements. Whether one needs packaging for fragile items or uniquely shaped products, this kind of machine can serve. They provide elasticity in thickness, size, and color. This makes sure that the packaging meets exact requirements. Tailored designs also grow branding opportunities, which creates packaging not only operational but also optically appealing.

Recycling Trend in Plastic Corrugated Sheets (2018-2025)

| Year |

Global Recycling Rate (%) |

Recovered PP/PE (kt) |

Share Of Industrial Take-Back (%) |

| 2018 |

21% |

640 |

9% |

| 2019 |

23% |

695 |

10% |

| 2020 |

22% |

670 |

10% |

| 2021 |

25% |

760 |

11% |

| 2022 |

27% |

820 |

12% |

| 2023 |

29% |

880 |

13% |

| 2024 |

31% |

945 |

15% |

| 2025 |

33% |

1,010 |

16% |

Segmental Insights

Why did the Polypropylene Segment Dominate the Plastic Corrugated Sheets Market in 2024?

Polypropylene sheets or PP sheets are lightweight, flat, and have durable layers created from polypropylene, which is an extensible thermoplastic polymer known for its great power, versatility, and chemical resistance properties. PP sheets are produced by using a prominence or molding procedure, which enables them to be manufactured in a variety of sizes, thicknesses, and finishes to align with the particular needs of various sectors. PP Sheets are heat-resistant, non-toxic, and recyclable. It is presently used in packaging, automotive, and medical industries. They are treasured for their adaptability and durability, too, offering solutions for both decorative and functional uses. Different from cardboard or wood, PP Corrugated sheets do not absorb water. This makes them perfect for outdoor uses such as temporary shelter, agricultural coverings, and signage boards.

Polyethylene Multi-Sector Applications Promote Growth

Construction, packaging, agricultural, and sign-creating sectors utilize polypropylene corrugated sheets as one of the most adaptable sheets. Lightweight variable sheets serve both durability and a lower price to become a popular selection for several industrial applications. The expertise of sheet structure integrated with composition enables people to choose the specific product as per their requirements. The market offers enough choices about sheet sizes, broadness, and particular elements from producers and suppliers. PP Corrugated sheet manufacturers maintain high production standards due to the market demand growing constantly. They propose tailored options for large orders from producers who are experts in providing these flexible and durable sheets.

Which Thickness Dominates the Plastic Corrugated Sheets Market?

The 3 to 18mm segment dominated the global market in 2024. These sheets are lightweight, durable, and impact-resistant, created from polypropylene. It gives perfect water resistance, recyclability, and strength, which makes it perfect for commercial, industrial, and packaging uses. Its reusable and eco-friendly nature ensures a cost-effective and sustainable solution for different industries. It is a highly acceptable plastic material made from an integration of polypropylene copolymer, homopolymer resin, and premium fillers. This sheet is classified by its unique construction, which has two flat surfaces linked by vertical ribs, giving durability and power.

8mm Thickness Boasts Enhanced Durability and Impact Resistance

The 8mm thickness sheet is suitable for heavy-duty uses such as industrial packaging, signage, construction, and agricultural usage. As compared to thinner sheets, the 8mm variant serves as perfect structural assistance without particularly increasing weight or cost. Additionally, it is extremely strong and also allows it to maintain form under pressure, which is crucial for packaging and logistics, where repeated handling is needed.

Dominance of the Packaging Sector over the Market

The most crucial benefit of plastic in terms of packaging is its reusability. This kind of material can combat repeated usage without specific degradation and serves long-term cost savings instead of higher primary costs. It is highly available in various colors and can be effortlessly tailored, which offers aesthetic and branding benefits. Its adaptability in design makes it perfect for specialized packaging demands. They are recyclable, and their environmental effect is a central point of dispute. The recycling procedure is more complicated than compared of cardboard, and if not perfectly recycled, it will lead to plastic pollution.

Logistics and Transportation Sector Growing Rapidly

Plastic corrugated sheets assist in reducing waste and lower costs in logistics processes. Their reutilization lessens the demand for disposable materials, cutting down on waste generation. One can recycle sheets at the end of the life process, which supports eco-friendly practices. The lightweight design decreases fuel consumption during transportation, which saves money on shipping. Furthermore, their durability ensures long-term usage, which reduces the frequency of substitution. By transaction in a plastic corrugated sheet machine, you make cost-effective solutions that match with sustainable business habits. Apart from this, it is extensively used in the packaging and shipping industry because of its lightweight and durable nature. These kinds of sheets can be smoothly cut and shaped into required boxes, protective inserts, and containers for different products.

Global Plastic Corrugated Sheets Production Trend (2018-2025, kt)

| Year |

Global Production (kt) |

YoY Growth (%) |

PP-Based Share (%) |

PE-Based Share (%) |

| 2018 |

3,120 |

— |

78% |

22% |

| 2019 |

3,260 |

4.50% |

79% |

21% |

| 2020 |

3,180 |

-2.40% |

80% |

20% |

| 2021 |

3,440 |

8.20% |

81% |

19% |

| 2022 |

3,710 |

7.80% |

82% |

18% |

| 2023 |

3,960 |

6.70% |

82% |

18% |

| 2024 |

4,220 |

6.50% |

83% |

17% |

| 2025 |

4,460 |

5.70% |

84% |

16% |

By Region

Asia Pacific

Asia Pacific dominance in the plastic corrugated sheets can be attributed to the growing population demands. In China, an enormous number of local producers serve highly cost-effective, customizable solutions for domestic usage and export. The semiconductor and electronics industry in South Korea and Japan are the main acceptors for anti-static corrugated plastic packaging boxes, as they need accurate, clear, and favorable-safe containers for delicate elements. Rising exports from this region also encourage the urge for rigid packaging to resist long-distance transport while lowering material wastage.

How is India Booming in the Asia Pacific’ Plastic Corrugated Sheets Market?

In India, the future demand for plastic corrugated sheets market will rise as construction firms, retail chains, and e-commerce warehouses move toward reusable and lightweight packaging and display Stable market growth will be supported by the growing demand for economical logistics, the expansion of infrastructure projects, and the interest in recyclable PP sheets. The use of environmentally friendly corrugated plastics will increase due to the government's growing emphasis on sustainable packaging.

The North American Market Expects the Fastest Growth

Due to rising demand for automotive, packaging, and construction companies, North America is witnessing momentum within the United States and Canada, and has accepted lightweight and durable plastic elements, with a move toward eco-friendly and recyclable options. The rising application of plastic corrugated sheets includes agriculture and industrial end-use, and hence, the market is experiencing a rising demand for these sheets. Furthermore, rigid distribution networks and technological growth in plastic manufacturing further facilitate development within the industry.

What Made the U.S. Grow Fastest in the Plastic Corrugated Sheets Market?

In the U.S., demand will increase with the expansion of fulfillment centers, cold chain distribution, and industrial returnable packaging. To cut waste and boost operational efficiency, businesses are switching to more robust reusable and recyclable corrugated plastic sheets, which will keep the market growing. As companies prioritize material traceability and adherence to sustainability standards, adoption will also increase.

Across Europe, the future market will be shaped by strict sustainability rules that encourage recyclable plastic sheets and cleaner production. Demand will continue to be driven by retail displays, reusable transport packaging, and construction applications, but manufacturers that provide environmentally friendly and compliant materials will benefit from growth. Durable plastic sheets will become more appealing for long-term use as circular packaging systems become more common.

Plastic Corrugated Sheets Market Key Players

- Twinplast Ltd

- DS Smith

- Corlite Packaging Industries Sdn.Bhd

- Coroplast

- Classic Enterprises Pvt Ltd

- Shish Industries Ltd

- Distroplast

- Siddhi Plast

- Creabuild Trading LLC

- Roplast

- Corex Plastics Pty Ltd

- Yamakoh

- FlutePlast

- Karton S.p.A

- Androp Packaging Inc

Latest Announcements by Industry Leaders

- On 10 January 2025, with a goal to a high level of a circular economy for flexible packaging in India, the Confederation of Indian Industry in acquisition with top consumer packaging and the Embassy of Finland revealed a roadmap for managing films and adaptable packaging in India with several stakeholders of the plastic value chain in the country. (Source: Outlook Business)

Recent Developments

- On 17 February 2025, IPG, which is a top company in packaging and protective solutions, revealed the launch of its latest American brand, Plastic Sheeting, available in both Performance and Ultra Films. This kind of tear-resistant, high-performance, and easily running plastic sheet film is crafted to serve superior surface care in a use of applications. (Source: Packaging Strategies)

- On 10 December 2024, Industrial Packaging and Products and Services Giver Grief revealed a new modular packaging solution, ModClan, at the Pack-Expo Conference in the United States. (Source: Packaging Gateway)

Plastic Corrugated Sheet Market Segments

By Material type

- Polyethylene (PE)

- Polypropylene (PP)

By Thickness

By End-use

- Packaging

- Logistics and Transportation

- Building and Construction

- Agriculture and Allied Products

By Region

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait