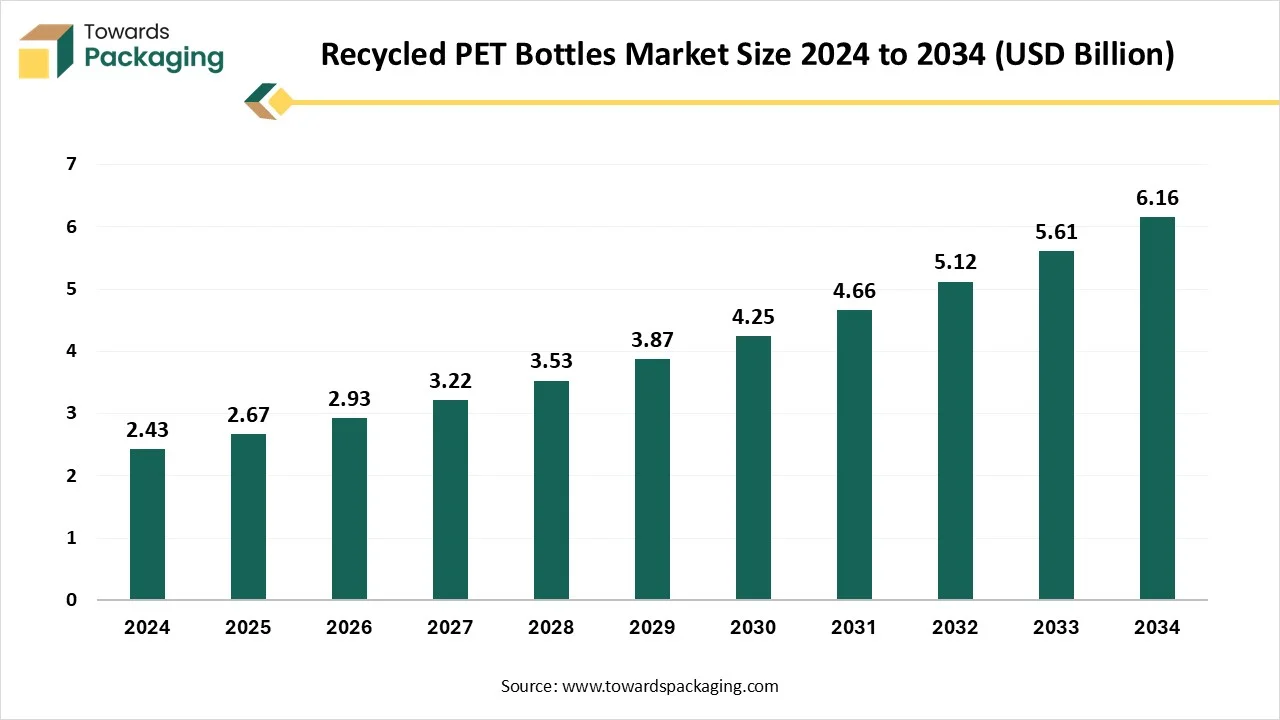

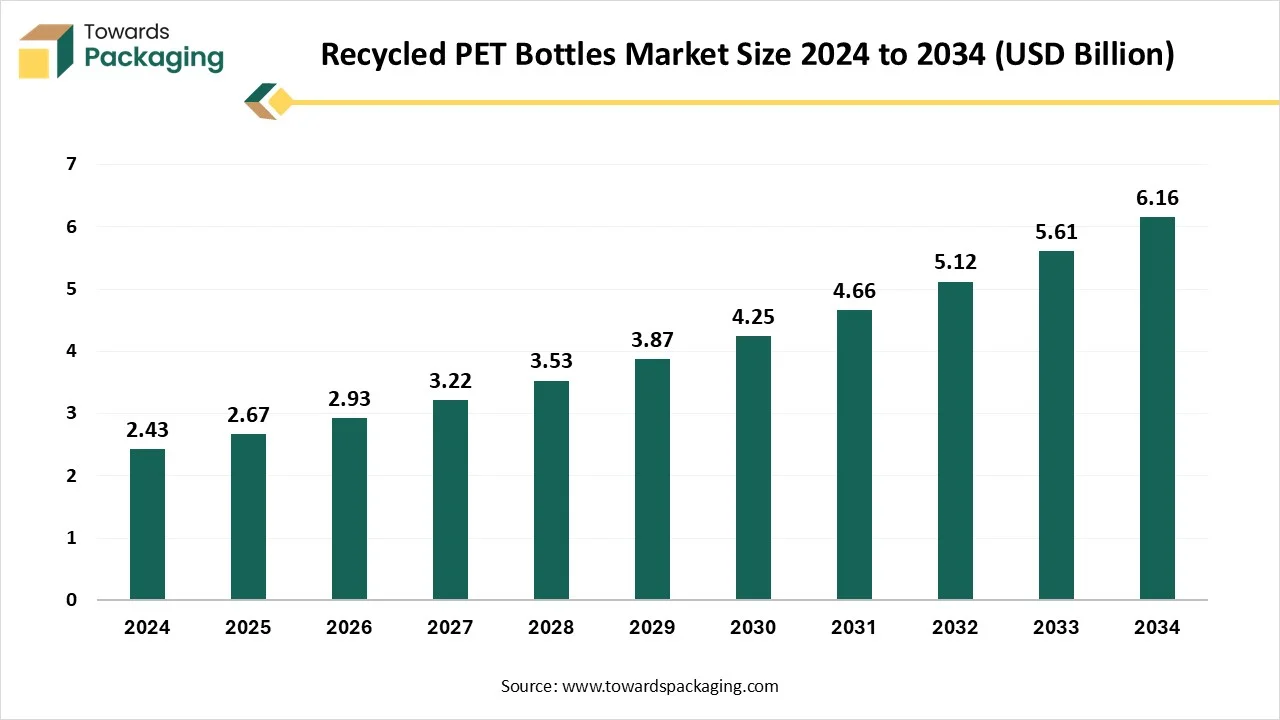

Recycled PET Bottles Market Outlook USD 2.67 Billion Size in 2025, Forecast to Reach USD 6.16 Billion by 2034, Regional Share, Segments

The recycled PET bottles market is projected to grow from USD 2.67 billion in 2025 to USD 6.16 billion by 2034, registering a CAGR of 9.74 percent. This comprehensive report covers market size, multi-level trends, grade-wise and type-wise segmentation, and end-use industry insights including food and beverage, personal care, pharmaceuticals, and other sectors. It also provides deep regional data across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, highlighting Europe’s 2024 dominance and North America’s fastest forecasted growth.

The study includes competitive profiling of major companies such as Indorama Ventures, Berry Global, Plastipak, Biffa, Loop Industries, and others, along with value chain mapping, trade flow analysis, and production supply data supported by global recycling expansions and investments.

Key Takeaways

- In terms of revenue, the market is valued at USD 2.67 billion in 2025.

- The market is projected to reach USD 6.16 billion by 2034.

- Rapid growth at a CAGR of 9.74% will be observed in the period between 2025 and 2034.

- Europe dominated the global market in 2024.

- North America is expected to host the fastest-growing market in the forecasted period.

- Asia Pacific is experiencing notable growth in the recycled PET bottles market.

- By grade, the food-grade rPET segment dominated the market in 2024.

- By grade, the non-food-grade rPET segment is expected to grow at the fastest CAGR in he coming years.

- By type, the clear segment dominated the market in 2024.

- By type, the coloured type segment is expected to grow at the fastest CAGR in he coming years.

- By end-use industry, the food and beverage segment dominated the market in 2024.

- By end-use industry, the personal use and cosmetics segment is expected to grow at the fastest CAGR in the coming years.

Recycled PET Bottles Market Overview

The history of PET starts way back to its discovery in the mid-20th century when it was primarily utilized for synthetic fibers. Over the years, it became famous for bottling drinks due to its rigid, lightweight, and shatter-proof characteristics. As the revenue of PET bottles increases, the demand for recycling becomes important. This leads to growth in recycling technologies, which enables the plastic industry to transform used PET into the latest and utilized products. Recycling PET is not just and technological achievement but also an environmental necessity that solves waste management problems and vanishes the demand for virgin plastic manufacturing.

The life span of PET plastic starts with its manufacturing, where it is decomposed into products like bottles and containers. Once these products are utilized, they penetrate the waste line. Collection systems then collect these items, which are moved to recycling facilities. Here, they transform the rigorous procedure to become recycled PET. The rPET can then be reestablished in the market as the newest product. , thus repeating the cycle. This constant loop of production, usage, and recycling assists in minimizing waste and environmental effects.

Recycled PET Bottles Market Trends

- Sustainable Materials: The industry is shifting towards utilizing more sustainable materials such as bio-based PET or recycled PET that comes from recycled plastic bottles and serves as a more environmentally friendly alternative to virgin plastic.

- Circular Economy: The focus is being put on making a circular economy for plastic bottles, where they are sorted, collected, and recycled back into new bottles. This strategy reduces waste and saves resources.

- Biodegradability and Compostability: Research and development attempts are concentrating on making PET Plastic bottles that are biodegradable or compostable under certain conditions. Biodegradable plastics are classified into natural elements, and compostable plastics can be transformed into nutrient-rich compost.

- Technological Advancements: Technologies like high-level recycling (chemical recycling) that distinguish plastics into their basic component for reuse, have kept the promise for developing the sustainability of PET Plastic bottles.

- Regulatory Changes: Stringent regulations on single-use plastics and expanded producer responsibility are encouraging the production, design, and recycling of PET bottles. This has led to a growing concentration on eco-friendly alterations and effective recycling processes.

- Consumer Awareness and Preferences: Rising consumer awareness about environmental problems is driving the urge for sustainable packaging solutions. Brands are giving feedback by serving eco-friendly packaging options that include PET bottles made from recycled materials.

- Collaboration and Partnership: Government assistance, industry acquisition, and partnerships across the value chain are important for achieving a more sustainable future for PET Plastic bottles. This includes initiatives to develop recycling infrastructure, end-of-life management, and collection systems.

AI Integration in Recycled PET Bottles Market

Optical sorting utilizes high-level sensors and artificial intelligence to accurately identify and separate PET from other materials. This procedure receives high purity rates and specifically reduces contamination, and it is a better option for effective and quality recycling of PET. Optical sorting technology is creating a big difference in bottles and cans. Bottle color sorters assist recycling centers in analyzing and distinguishing materials like aluminum, plastic, and glass. By automating the sorting procedure, these machines enable recycling facilities to handle huge amounts of waste quickly, which means less manual work is needed and the quality of recycled materials is improved. They are very adjustable and can be updated to distinguish new kinds of materials, which is crucial as various kinds of packaging are formulated. This limberness means that these machines are the best long-term solution for recycling availability.

Market Dynamics

Driver

PET Bottle Recycling: Paving the Way for a Circular Economy and Sustainable Profitability

PET bottle recycling is fundamental to a circular economy system in which wastes are changed into valuable resources. This difference with the conventional linear economy, in which products and components, such as PET bottles, vanish after usage, wastes are maximized, recycling costs money, and ecological footprints are maximized. With the assistance of PET bottle recycling, the main consideration created is the revenue returns, and environmental impact, which also, therefore, grows financial gains. Hence, recycling PET bottles paved the way for the disposal of products, rational use of natural resources, and lesser greenhouse gas emissions. Organizations practicing sustainable operations also earn customer confidence and satisfaction, which makes sustainable practices similar to long-term revenue.

Restraint

Discoloration Challenges in Recycled PET

One of the main challenges and limitations is preserving the appeal of recycled PET, which lies in the problem of discoloration post-recycling procedure. Once recycled rPET periodically exhibits a shade or other minor color differentiation that can be observed. This transformation, in coloration specifically, stems from the following factors. Tiny remains of potential like colored substances, different plastics, and pastes from tags, covers, and lids. These dwelling effects may not affect the safety of food contact. It can affect the color negatively and is usually seen as unwanted. Several people associate a tint with poor cleanliness and view it as unpleasant in products they use on a daily basis.

Opportunity

Advancing Plastic Recycling from Collection to Chemical Transformation

Basically, there are two stages for plastic recycling. The primary one includes collecting plastic waste and sorting it by type. This is usually completed by municipal governments, informal workers, and private companies who move through landfills seeking recyclable products. The secondary term, performed by plastic producers and recyclers, takes the different plastic waste and uses it to generate new plastic products. The latest group of rising technologies, collectively known as the chemical recycling procedure, creates more types of plastic recyclable.

Different from regular mechanical recycling, which splashes and melts products like plastic bottles to generate the latest ones, chemical recycling separates plastic waste into its component chemicals that are transformed into new products. It means hard-to-recycle products such as car parts, take-out containers, or household appliances, which could be more easily recyclable. Investors are heavily contributing to research and development and commercial-scale chemical recycling projects.

Segmental Insights

Why does the Food-grade rPET Bottles Segment Dominate the Recycled PET Bottles Market?

Food-grade recycled PET bottles are gaining popularity as they are highly flexible and versatile and can be utilized across various sectors of applications. This sustainability advocate is predominantly found in consumer goods such as food packaging, beverage bottles, textiles, and clothing. Industrial uses also benefit from the usage of recycled PET, which can be used for construction materials, automotive parts, and more. The elasticity of recycled PET allows industries to incorporate sustainable practices without compromising the quality or functionality. This variability makes sure that recycled PET is able to match various demands across different sectors, driving its extensive acceptance.

Non-food-grade recycled PET bottles play an important role in the recycled PET bottles industry, specifically for uses that do not require direct food contact. These kinds of bottles are specifically sourced from post-consumer or post-industrial PET waste and experience mechanical recycling procedures that may not align with the strict purity standards necessary for food-grade uses. As a result, non-food grade rPET is extensively used in manufacturing textiles (such as polyester fibers, strapping materials, automotive parts, and packaging for non-edible products like cosmetics, detergents, and household cleaners. Additionally, it eases the pressure on landfills and lessens the carbon footprint linked with virgin plastic manufacturing.

Why did the Clear Type Segment Dominate the Recycled PET Bottles Market in 2024?

The dominance of the clear recycled PET (rPET) bottles segment is due to their high purity, versatility, and superior market demand. These bottles are specifically collected through post-consumer recycling programs and are differentiated for cleanness and cleanliness. Clear PET is selected because it can be more easily reprocessed into a huge range of products, including new beverage bottles, fiber for textiles, and food containers. In the production cycle, clear rPET experiences cleaning, grinding, and decontamination procedures -especially when intended for food-grade usage -following rigid safety and quality standards. Brands and manufacturers favor clear rPET as it serves as a sustainable alternative to virgin plastic while aligning both aesthetic and functional demand.

Colored recycled PET (rPET) bottles are derived from post-consumer plastic containers that have been tinted predominantly in shades like blue, green, or amber. While they carry value in the recycling chain, colored rPET presents more challenges than clear rPET. The colorant used in these bottles limits their reusability, as they cannot be easily transformed back into clear or neutral-colored products. Due to this, colored rPET is specifically downcycled into non-food-grade products such as textile fibers, strapping bands, construction materials, and automotive parts.

Food and Beverage Industry Dominates the Recycled PET Bottles Market

Recycled PET bottles have completely transformed the approach we use to package food and drinks. They propose secure food packaging that keeps products safe. This type of bottle keeps drinks perfect and fizzy for sodas. They are also utilized for sauces, meals, and condiments, matching our demand for fast options. It’s 100% recyclable, assisting our planet. In reality, 55 % of recycled PET bottles are recycled for the latest uses. This decreases waste and saves energy as compared to using glass. For more than 30 years, PET plastic has been credible for storing our food and drink safely. It’s free from toxic chemicals, which means it's completely safe. Recycled PET bottles' blockage properties aid in storing items of high quality and freshness. Their malleability and the force for eco-friendly options make them a favorite with manufacturers. The industry is shifting toward a more circular economy, in which plastic bottles are reused and repurposed rather than trashed. Organizations are investing in perfect recycling systems and alteration materials to make sure plastic remains a feasible and responsible packaging choice. As users, creating apprise decisions, such as selecting brands that utilize recycled plastic and properly disposing of bottles, can assist in driving more sustainable practices in the sector.

Recycled PET bottles are being heavily accepted in the cosmetic industry as part of a wider push towards sustainability and eco-conscious packaging. It offers a durable, lightweight, and visually appealing alternative to virgin plastics, which makes it perfect for keeping different cosmetic products like lotions, shampoos, face cleansers, conditioners, and body washes. rPET bottles can be molded into a huge range of sizes, shapes, and transparencies, which allows brands to maintain an aesthetic look while using recycled materials. The material is also compatible with most labeling and decoration procedures, making sure that sustainability does not compromise brand identity or shelf effect.

By Region

Europe

The packaging sector generated 40.5 % of plastic demand in Europe in the year 2020, and in packaging, PET is needed everywhere. By not only substituting but also rescuing a specific amount of virgin PET, rPET marks an improvement in solving Europe’s plastic waste issue. The Packaging and Packaging Waste Regulation (PPWR) defined minimum percentages for recycled content in PET Food packaging as at least 30% by year 2030 for all PET food and drink packaging and on the other hand, at least 50% by year 2040 for most PET food and drink packaging for at least 65% of PET bottles. Recycled PET is safe for food contact, and as such, it complies with the relevant regulations. The European Food Safety Authority has set these, and Regulation EC 282/ 2008 establishes the perfect rules.

North America

The demand for recycled PET bottles in North America has been constantly rising, driven by strong regulatory assistance, corporate sustainability aims, and growing consumer awareness about environmental problems. Several beverage and packaging organizations in the region have committed to using higher percentages of recycled content in their packaging to reduce plastic waste and carbon emissions. This has drastically pushed up the urge for high-quality rPET, especially clear food-grade material. Governments in both the U.S. and Canada have also introduced policies and extended producer responsibility (EPR) programs that market plastic recycling and encourage circular economy practices.

Asia Pacific

The urge for recycled PET (rPET) bottles in Asia Pacific is experiencing specific growth, fueled by growing environmental awareness, strengthening industrial uses, and government regulations. Fast urbanization and increasing plastic consumption across countries like India, China, Japan, and South Korea have led to a pressing demand for sustainable packaging alternatives, positioning rPET as a main solution. Furthermore, the booming food and beverage, personal care, and textile sectors are accepting recycled PET bottles to appeal to eco-conscious consumers. Countries like China and India are also witnessing strong investments in recycling, construction, and technological upgradation to boost rPET production quality and effectiveness.

Latin America

In Mexico, there are recycling plants that process used PET bottles and change them back into food-grade PET Bottles. This points out that the recycled resin created in these plants goes through a purification procedure which transforms it into resin that is perfect for contact with food and beverages again. This bottle-to-bottle cycle shows how PET can be recycled on a repeat mode, without losing its quality, leading to a major reduction in plastic waste and the making of sustainable products.

- On 28 January 2025, Circulate Capital, a top investment management firm developing the circular economy in high-development markets, revealed its expansion into Mexico with an investment in Omnigreen SAPI de CV, a pioneer in flexible plastic recycling.

Recycled PET Bottles Market Key Players

Latest Announcements by Industry Leaders

- On 4 December 2024, a greenfield recycling plant, worth INR 220 crores was set up in Uttar Pradesh’s Gorakhpur, which is a joint venture between SLMG beverages and DPIPL and Coca-Cola India whose goal is to generate 36,000 MT of recycled PET Flakes and 24,000 MT of PET granules yearly which solves India’s plastic waste challenge. (Source: THE NEW INDIAN)

Recent Developments

- On 22 August 2024, Packaging and recycling specialist Alpla has partnered with the German startup Sea Me to reveal a new line of reusable PET bottles crafted for cosmetic uses.

- On 22 July 2025, Avient Corporation disclosed the introduction of the first grade in its latest ColourMatrix Amosorb Oxyloop profile of oxygen scavengers, ColourMatrix Amosorb Oxyloop-1.

- On 10 July 2025, Avient Corporation revealed an oxygen-scavenging addictive crafted particularly to develop the recyclability of polyethylene terephthalate (PET) packaging while expanding the product shelf life.

- On 12 March 2025, Jokey disclosed its latest packaging lines that depend on recycled PET. These transparent containers for the pharmaceutical and food sectors use the injection stretch blow moulding procedure. The plastic is made from recycled material.

- On 1 November 2024, the world’s first-ever bio-PET bottle came from using cooking oil and is believed to lessen the reduction of CO2 emissions, revealed at commercial scale by Suntory, Nestle, Indorama Ventures, and Iwatani too.

- On 15 October 2024, top packaging solutions Berry Global revealed a series of clarified polypropylene (PP) bottles for healthcare uses, which serve superior sustainability and developed product protection as compared to regular coloured PET pill bottles.

- On 22 August 2024, the packaging and recycling specialist Alpha partnered with German Startup Sea Me to reveal a new line of reusable PET bottles crafted specifically for cosmetic applications. This acquisition has outcome in the development of Sea Me’s zero packaging system, whose goal is to improve the sustainability of cosmetic packaging.

- On 16 August 2024, Ganesha Ecosphere Limited, which is an industry leader in terms of India’s PET Plastic recycling industry, surpassed the Nifty Smallcap 250 index by almost 2.5 times (54% vs 22%) over the past six months.

Recycled PET Bottles Market Segments

By Grade

- Food-Grade rPET

- Non-Food-Grade rPET

By Type

By End-Use Industry

- Food and Beverage

- Pharmaceuticals

- Food and Beverage

- Others

By Region

- North America

- Europe

- Latin America

- Asia Pacific

- Middle East and Africa