Advanced Coating for Healthcare Packaging Market Size and Regional Production Analysis

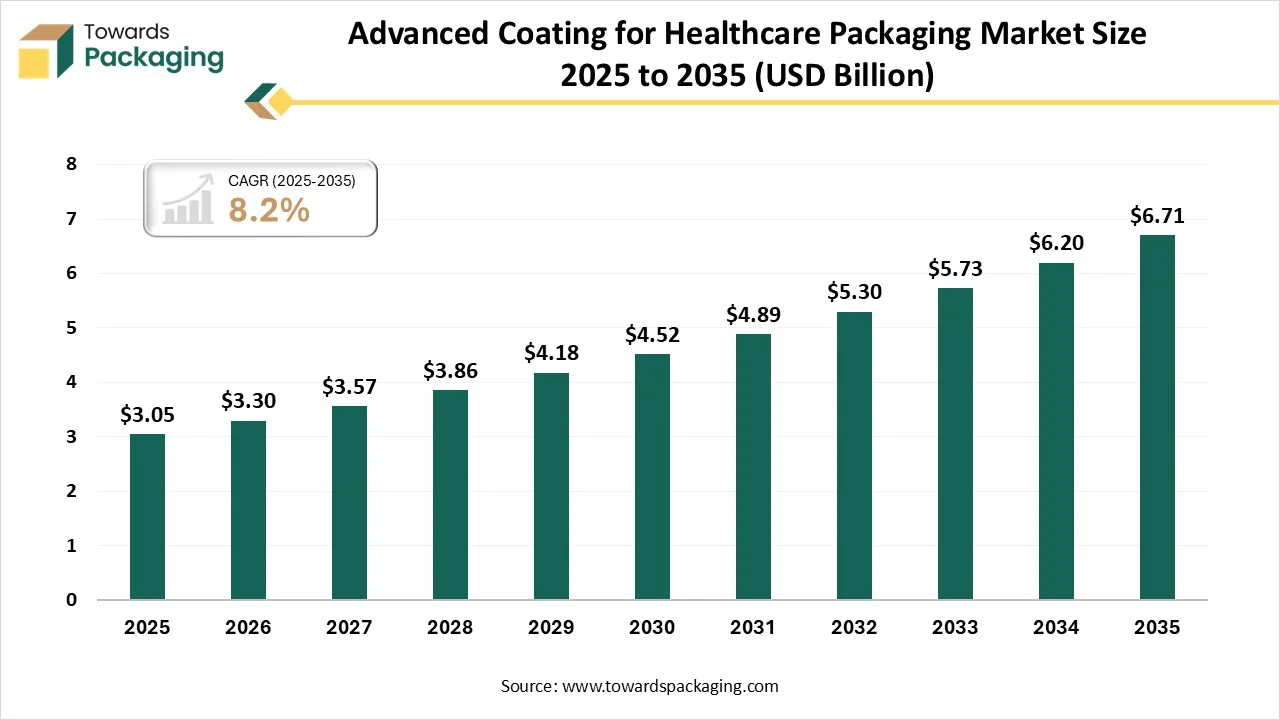

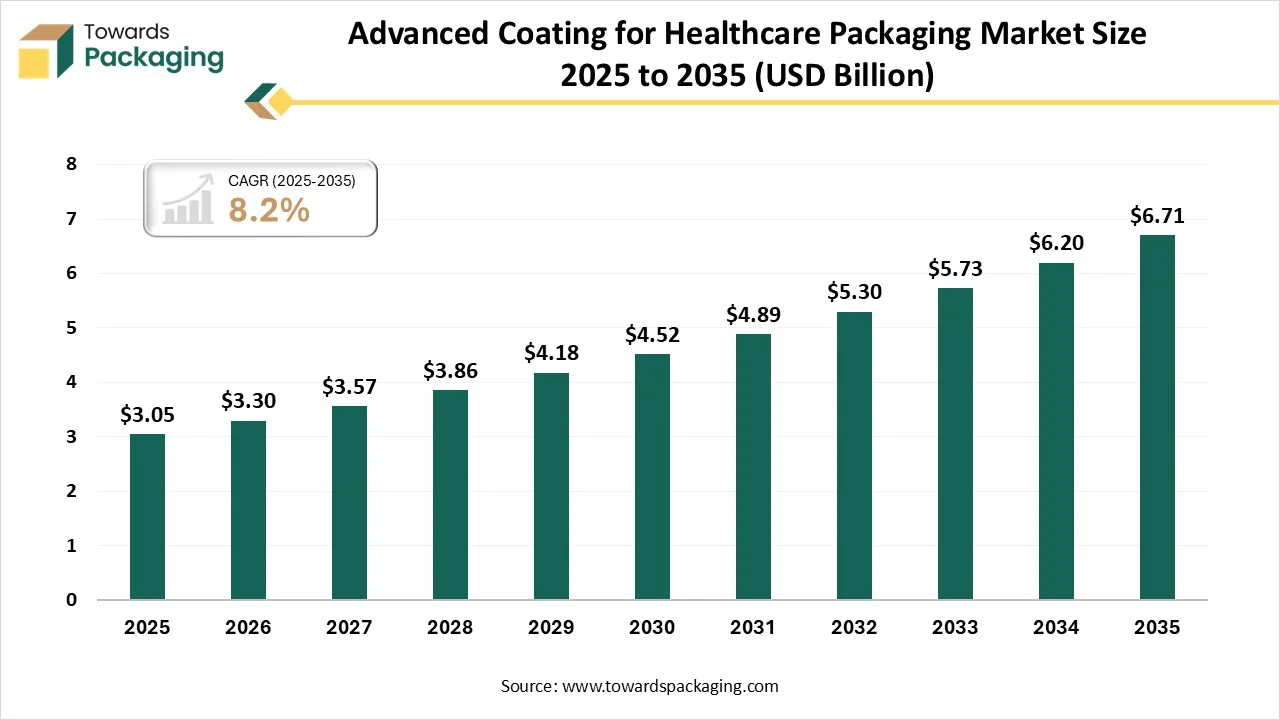

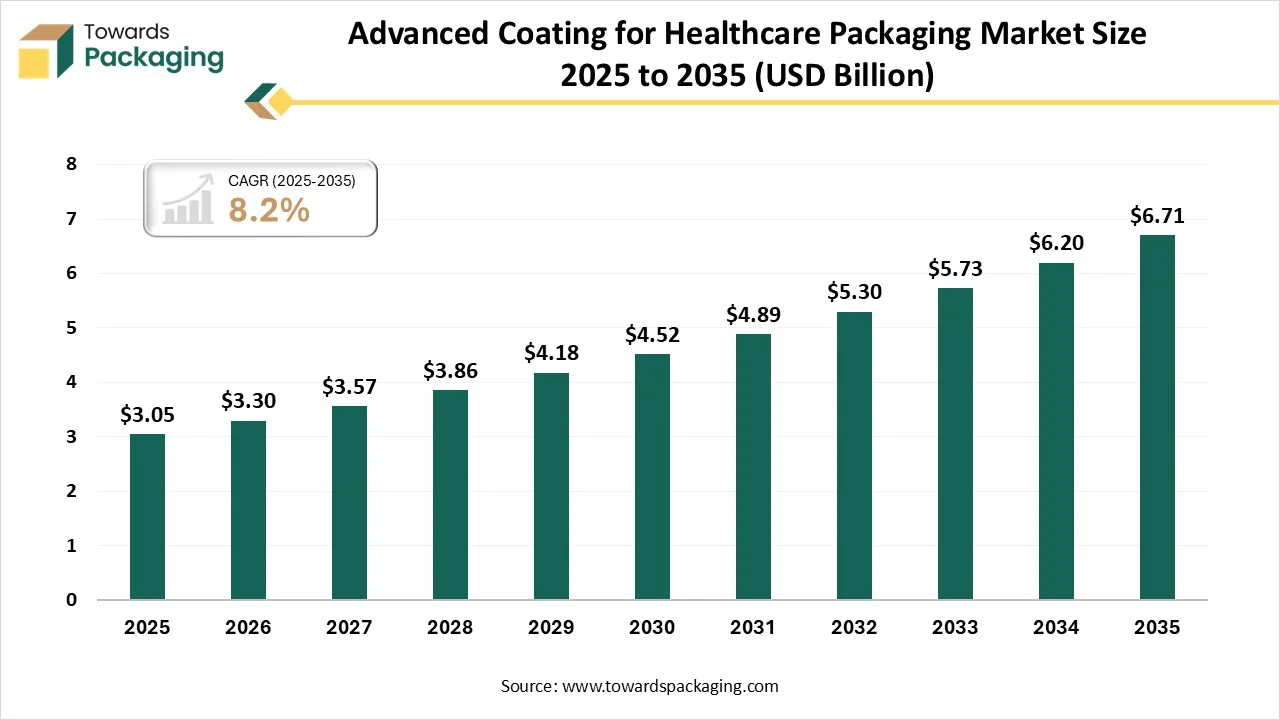

The advanced coating for healthcare packaging market is forecasted to expand from USD 3.3 billion in 2026 to USD 6.71 billion by 2035, growing at a CAGR of 8.2% from 2026 to 2035. Increasing demand for high-performance, sterile, and safe packaging has raised the development of the market. This packaging comprises bio-based, nano-technology based, antimicrobial, and smart coating which enhance the adoption of these packaging significantly.

Major Key Insights of the Advanced Coating for Healthcare Packaging Market

- In terms of revenue, the market is valued at USD 3.05 billion in 2025.

- The market is projected to reach USD 6.71 billion by 2035.

- Rapid growth at a CAGR of 8.2% will be observed in the period between 2026 and 2035.

- By region, North America dominated the global market by holding highest market share in 2025.

- By region, Asia Pacific is expected to grow at a fastest CAGR from 2026 to 2035.

- By coating type, the barrier coatings (moisture, oxygen, light protection) segment contributed the biggest market share in 2025.

- By coating type, the antimicrobial / anti-contamination coatings segment will be expanding at a significant CAGR in between 2026 and 2035.

- By end-use industry, the pharmaceutical packaging segment contributed the biggest market share in 2025.

- By end-use industry, the medical device packaging segment will be expanding at a significant CAGR in between 2026 and 2035.

- By distribution channel type, the direct supply to packaging converters & OEMs segment contributed the biggest market share in 2025.

- By distribution channel type, the specialty & regional distributors segment will be expanding at a significant CAGR in between 2026 and 2035.

What is Advanced Coating for Healthcare Packaging?

Advanced coating for healthcare packaging utilizes post-consumer plastic waste to generate new, high-presentation flexible packaging, like overwrap, cereal bags, and stand-up pouches, providing a lower-release substitute to virgin plastic while preserving recyclability and barrier properties, helping circular economy aim in packaging industry.

Advanced Coating for Healthcare Packaging Market Trends

- Market Growth Overview: The market is experiencing strong increase in chronic diseases, increasing number of surgeries, sustainable and smart packaging.

- Major Market Players: The market comprises Arkema, Surmodics, Biocoat, Harland Medical Systems, Berry Global, Amcor and many other.

- Startup Ecosystem: The startup industries are majorly focusing on antimicrobial, nano-coating, biocompatible, smart, and active packaging. These startup companies are highly focused on developing recyclable healthcare packaging to decrease landfill wastes.

Technological evaluation plays a vital role in the growth of the market. It is widely utilized for the development of water-based and biopolymer coating. Smart and intelligent packaging with traceability facility, sensors, and indicators has influenced the demand for this packaging sector. Advancement in application technique and automation in this industry has raised the development of the market.

Trade Analysis of Advanced Coating for Healthcare Packaging Market: Import & Export Statistics

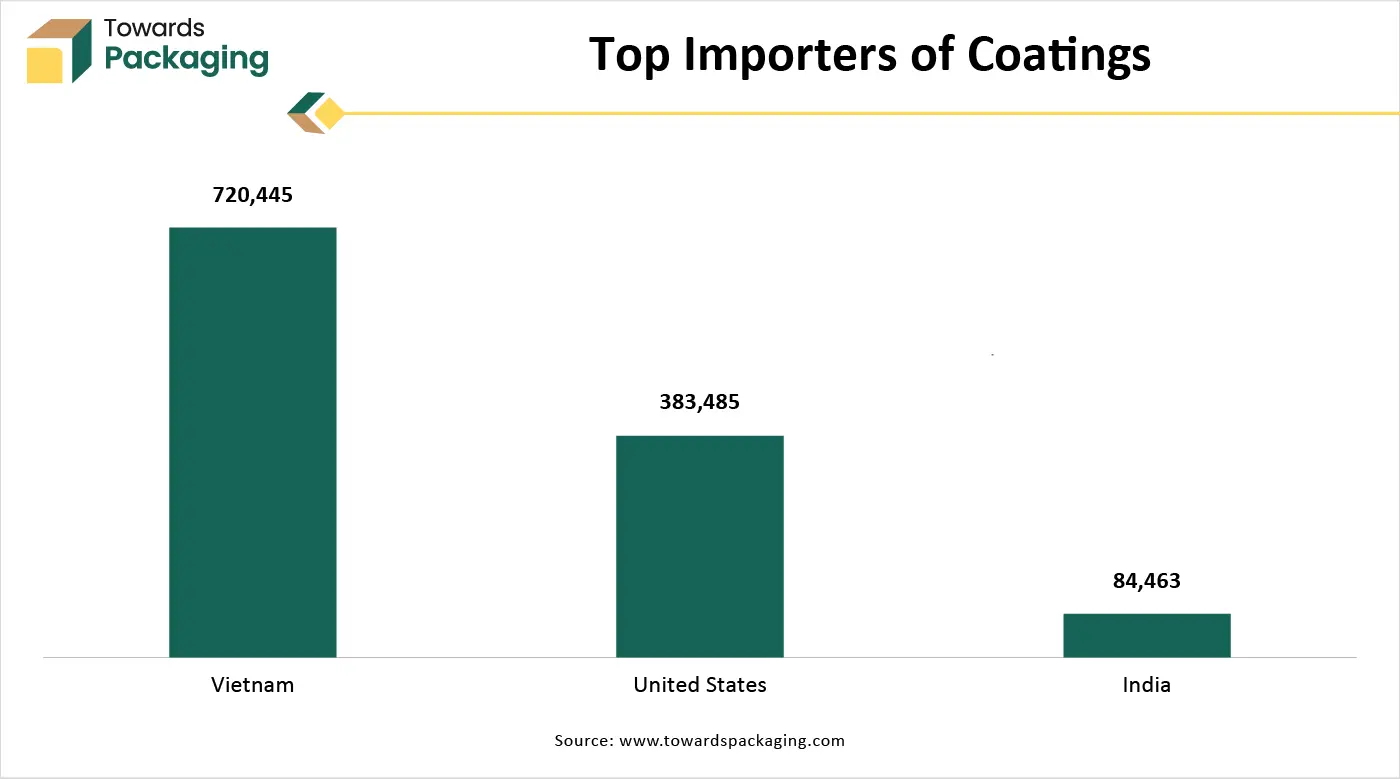

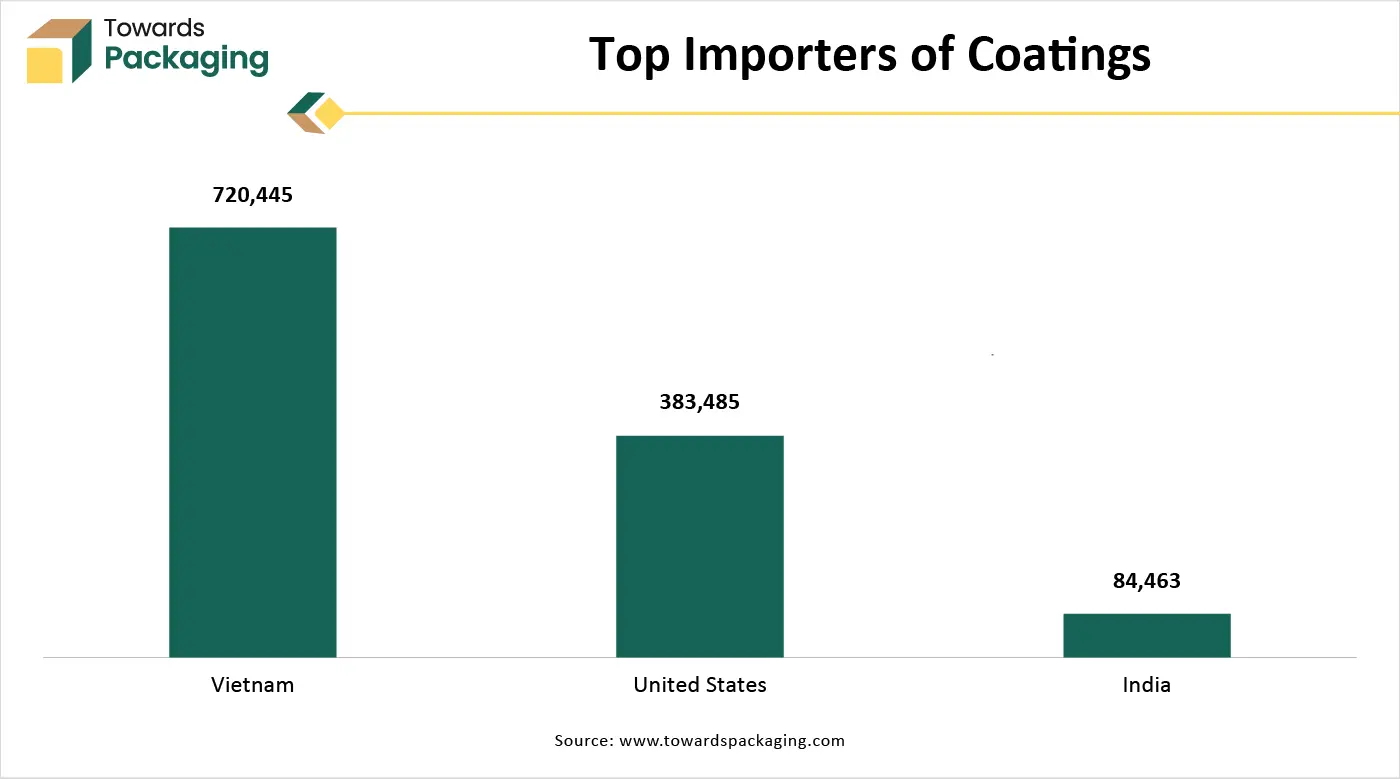

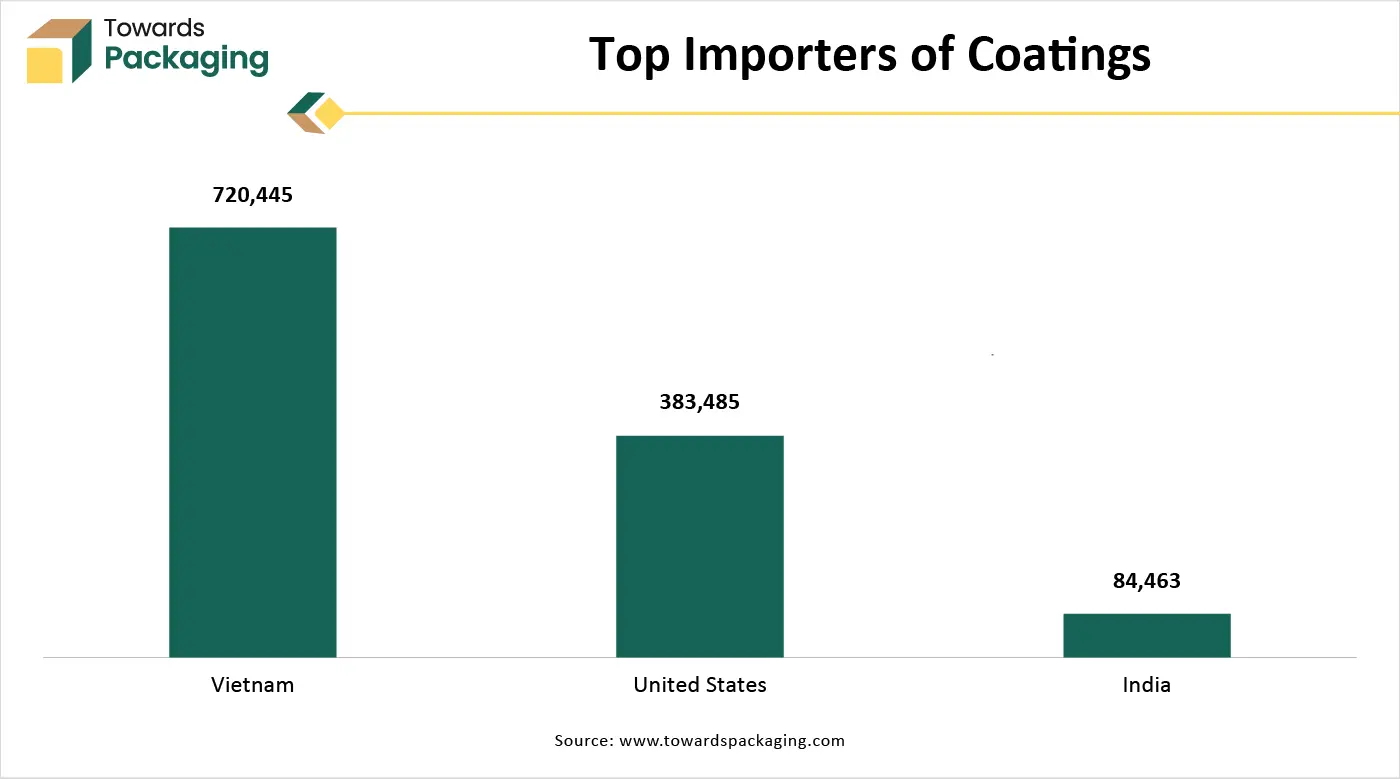

- China is considered as the top-most exporter of the coatings with 591,146 shipments worldwide.

- Vietnam is considered as the second leading exporter of the coatings with 414,524 shipments globally.

- South Korea stands in third-position as coating exporter worldwide with 167,156 shipments.

Advanced Coating for Healthcare Packaging Market - Value Chain Analysis

Raw Material Sourcing

The major raw materials utilized in this market are polymers, resins, aluminum and silicon oxide, and parylene.

- Key Players: ACG, PPG Industries

Component Manufacturing

The component manufacturing in this market comprises hydrophilic, antimicrobial, biocompatible, wear-resistance, and barrier coatings.

- Key Players: DuPont Tyvek®, Technipaq

Logistics and Distribution

This segment ensures supply for high-performance barrier and enhances supply chain security.

- Key Players: TruTag Technologies, BASF SE

Segmental Insights

Coating Type Insights

Why Barrier Coatings (moisture, oxygen, light protection) Segment Dominated the Advanced Coating for Healthcare Packaging Market In 2025?

The barrier coatings (moisture, oxygen, light protection) segment dominated the market with highest share in 2025 due to huge requirement for drug stability, enhance shelf-life, and sterility. It is important to protect pharmaceutical products from external factors such as moisture, air, and contamination which increase the demand for such coatings. Rising focus for development of eco-friendly packaging for healthcare sector has pushed the adoption of these coating types. It is highly accepted due to consumers’ convenience which increase its production rate.

The antimicrobial / anti-contamination coatings segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to huge awareness for infection control and hygiene. The major reason is enhanced requirement to decrease the spread of pathogens in medical facilities and hospitals. Increasing chronic diseases has enhanced the demand for this segment.

End-Use Industry Insights

Why Pharmaceutical Packaging Segment Dominated the Advanced Coating for Healthcare Packaging Market In 2025?

The pharmaceutical packaging segment dominated the market with highest share in 2025 due to increasing patient safety and drug efficacy. Aging worldwide population has raised the diseases which fuel the pharmaceutical and medical packaging industries development. To maintain the sterility and enhance protection of sensitive drugs in the pharmaceutical sector these packages play an important role. These packages are highly customizable which increase its adoption rapidly.

The medical device packaging segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to material versatility and high-barrier coatings requirement. Increasing demand for enhanced protection with rising risk for infectious disease has influenced the growth of this segment. Advancement of intricate developed devices in healthcare sector pushed improved packaging for protection. Development of recyclable and eco-friendly films to wrap medical devices has boost the adoption of these packaging.

Distribution Channel Insights

Why Direct Supply to Packaging Converters & OEMs Segment Dominated the Advanced Coating for Healthcare Packaging Market In 2025?

The direct supply to packaging converters & OEMs segment dominated the market with highest share in 2025 due to enhanced quality control process and traceability facility. Integration of advance facilities to the packaging help to improve the supply chain of the product. This distribution supply channel supports the expansion of the industry. It also enhances affordability by direct supply to the consumers which remove additional shipping charges.

The specialty & regional distributors segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to huge requirement to bridge the gap between complex manufacturers and specific region healthcare sectors. It offers tailored logistics and compliance expertise increase the demand for this segment. This is widely driven by customization and regulation which enhance the adoption of this packaging.

Regional Insights

Why Advanced Coating for Healthcare Packaging Market is Dominating in North America?

North America dominated the market in 2025. Increasing concern for patient safety have influenced the demand for the market. Strict regulations for packaging in healthcare sector has pushed the innovation of high-quality packaging. Advancement in the suppliers of these packaging fuel the expansion of this market in this region. For Instance, Datwyler declared the development of UltraShield™ that is a coating solution for the storage of innovative drugs. It has its own film coating technology, and it is the first and sole supplier that is capable for providing both spray and film fluoropolymer coating technologies used for elastomeric closures in injectable drugs.

How Advanced Coating for Healthcare Packaging Market is Expanding in the U.S.?

Rapid growth of biopharma and increasing chronic diseases has driven the demand of the market in the U.S. Rising biopharmaceutical products usage in the healthcare industry has raised the demand for tamper-evident, sterile, and high-quality packaging which raise the demand for this industry. Advancement in the coating manufacturing process has raised the demand for this market. For instance, Colorcon which is a leading film coating system company introduced Opadry® titanium dioxide (TiO2)-free film coating system, it is to utilize for pharmaceutical tablets packaging.

How is Asia Pacific growing rapidly in the Advanced Coating for Healthcare Packaging Market?

Asia Pacific expects the fastest growth in the market during the forecast period, due to its presence of huge pharmaceutical base. Such high-volume production of medical devices and drugs has fuelled the demand for these packaging. The major market players are continuously developing advanced structures for the production of these packaging.

In April 2025, Amcor has declared about the completion of advanced coating facility construction for healthcare packaging based in Selangor, Malaysia. It is considered as first cutting-edge air knife coating technology in Asia Pacific.

Why Advanced Coating for Healthcare Packaging Market is Dominating in China?

Expansion of healthcare sector has raised the demand for market in China. It boosts the functionality, stability, and safety of the products for prolonged period in adverse ecological condition enhance the demand for such packaging. Rapid advancement by major market players has pushed consumers towards this packaging sector. For instance, AkzoNobel Packaging Coatings announced the development of Bisphenol-A Non-Intent (BPAni) which is first ever coating line for exterior and interior coating products for metal cans.

Which Factor is Responsible for Notable Growth of Advanced Coating for Healthcare Packaging Market in Europe?

Europe expects the substantial growth in the market. The primary factors influencing the growth of market are strong regulatory guidelines, sustainable packaging demand, rising patient safety concern, and rapid technological advancement. Increasing demand for product safety and traceability has raised the adoption of this market. Rising adoption of water-based, bio-based, recyclable, and low-VOC coatings has influenced the development of this market.

- For instance, Siegwerk Druckfarben AG & Co. KGaA declared its participation in Specialty Papers Europe 2025 to show sustainable water-based coating. It is an alternative of perfluoroalkyl and polyfluoroalkyl substances (PFAS) packaging.

Why the Germany is Utilizing Advanced Coating for Healthcare Packaging Market Significantly?

Rapid technological advancement has fuelled the development of the market. Rising demand for high-performance and sterile packaging has enhanced the production of this market. Requirement for smart packaging that help to deliver products to longer distance by maintaining its integrity has raised the demand for innovation in this market. Expanding healthcare sector influence huge production of sterile packaging and boost the manufacturing process of such packaging.

Recent Development

- In January 2026, Terumo Medical Corporation announced the launch of SurTract™ Safety Syringe that is powered by SafeR® which is a passive safety technology.

- In October 2025, DuPont de Nemours and Olympus collaborated to develop ecologically responsible packaging solution for more than 100 categories of single-use devices.

Top Companies in the Advanced Coating for Healthcare Packaging Market

- Amcor: It provides innovative heat seal coatings and advanced manufacturing capabilities for medical packaging.

- Berry Global: It focuses on specialized films and sealant technologies that ensure sterility and protection for medical products.

- DuPont: It is known primarily for its base material, Tyvek®, which serves as a critical substrate.

- Covestro: It focuses on high-performance polymer materials, such as polycarbonates and thermoplastic polyurethanes (TPUs).

- Klöckner Pentaplast: It specializes in rigid barrier films for pharmaceutical and medical device packaging.

- Others: Winpak, Honeywell, Polycine, American Polyfilm, and many others.

Advanced Coating for Healthcare Packaging Market Segments Covered

By Coating Type

- Barrier Coatings

- Moisture

- Oxygen

- Light

- UV

- EVOH

- PVdC

- Parylene

- Acrylic

- Polyurethane

- SiOx

- AlOx

- Metallized

- Lamination

- Extrusion

- Plasma

- Antimicrobial / Anti-contamination Coatings

- Silver

- Copper

- Chitosan

- QAC

- Polymer

- Nanoparticle

- Biocidal

- Nonleaching

- Sterilizable

- Biocompatible

- Anti-static / Anti-fog / Other Functional Coatings

- Antistatic

- Antifog

- Conductive

- Hydrophilic

- Slip

- Release

- Antiblock

- Printable

- Tamperproof

- Smart

By End-Use Industry

- Pharmaceutical Packaging

- Blister

- Vials

- Ampoules

- Bottles

- Sachets

- Pouches

- Syringes

- Coldchain

- Medical Device Packaging

- Implants

- Catheters

- Disposables

- Trays

- Pouches

- Sterile

- Peelable

- Laminates

- Diagnostic & Laboratory Packaging

- Tubes

- Vials

- Microplates

- Reagents

- Assays

- Cassettes

- Cryogenic

- Consumables

By Distribution Channel

- Direct Supply

- OEMs

- Converters

- Manufacturers

- Contracting

- Partnerships

- Specialty & Regional Distributors

- Specialty

- Regional

- Wholesalers

- Distributors

- Suppliers

- Other Channels

- Ecommerce

- Integrators

- Formulators

- PrivateLabel

- Consultants

By Region

- North America

- U.S.

- Canada

- Mexico

- Rest of North America

- South America

- Brazil

- Argentina

- Rest of South America

- Europe

- Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

- Eastern Europe

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

- Asia Pacific

- China

- Taiwan

- India

- Japan

- Australia and New Zealand

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

- MEA

- GCC Countries

-

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

- Rest of MEA