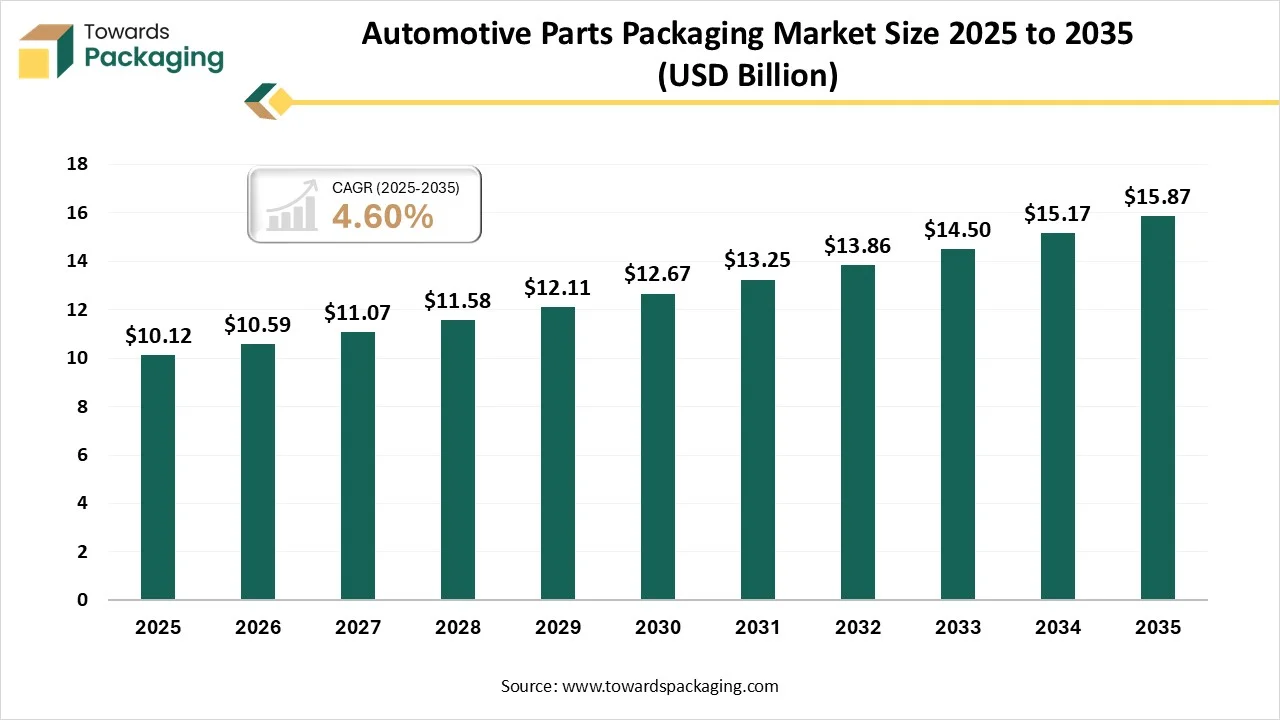

The automotive parts packaging market is forecasted to expand from USD 10.59 billion in 2026 to USD 15.87 billion by 2035, growing at a CAGR of 4.60% from 2026 to 2035. With the rising usage of vehicles and its protective as well as sustainable packaging demand has fuelled the demand for market. Rising concern towards ecological issues has also fuelled the demand to develop such packages.

Automotive parts packaging refers to specialized materials and methods such as corrugated boxes, pallets, and reusable containers used to protect vehicle components during storage and transit. These solutions are engineered to safeguard everything from delicate electronic chips to heavy engine parts against corrosion, moisture, and mechanical damage across the OEM and aftermarket supply chains.

Technological transformation in the automotive parts packaging market plays a significant role by integrating automation in packaging industry. This advancement in production technology has enhance speed, accuracy, and efficiency of the packaging. Incorporation of sensor and RFID tags has encouraged real-time tracking, enhanced supply chain transparency, and condition monitoring. It supports in customization and protective solution for packaging of heavy automotive parts.

The major raw materials utilized in this market are metals, corrugated cardboard, foam, and plastics (PE, PP). Rising demand for biodegradable and eco-friendly packaging has pushed utilization of these materials.

The component manufacturing in this market comprises thermoformed trays, corrugated packaging, plastic interlayers, pallets, anti-corrosive packaging. It helps in secure, store, and transport delicate automotive parts.

This segment comprises customized protective packaging, specialized services, and returnable containers.

The corrugated products segment dominated the market with highest share of 38% in 2025 due to its lightweight nature, high recyclability, and cost-effectiveness. Increasing demand for recyclable, reusable, and eco-friendly packaging has boosted the utilization of these products. It offers excellent protection against damage, vibrations, and scratches. Increasing demand for easy-to-handle, stackable, and standardize packaging has fuelled the demand for corrugated products.

The protective packaging segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to huge complexity in vehicle components. Rapid shift towards electric vehicles has enhanced the incorporation of batteries and sensors that require protective packages. Advancement in biodegradable foams and molded pulp has pushed the demand for this segment. Presence of strict international guidelines to decrease the wastage of materials and enhance safety has raised the demand for protective packaging.

The disposable segment dominated the market with highest share of 63% in 2025 due to its lightweight and cost-effectiveness. It supports in decreasing the shipping charges and boost the consumption of materials. These can be easily customized into required shape and size which raise the adoption of such segments for packaging purpose. Increasing focus towards hygienic packaging has fuelled the demand for disposable packaging.

The reusable segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to long-term cost optimization and rapid shift towards circular economy models. Rising concern for eco-friendly packaging has promoted the usage of reusable packaging. Such packaging attracts a huge number of consumers as these can be utilized for numerous times. Integration of IoT sensors and RFID tags has further promoted the utilization of this segment.

The electrical & electronics segment dominated the market with highest share of 34% in 2025 due to rapid shift towards electronics vehicles. Rising proliferation towards electronic vehicles enhanced the demand for several components such as power modules and batteries. Rising incorporation of advanced technology such as sensor has pushed the demand for protective packaging for electrical and electronics products. Rising focus for safety and maintaining the quality of the products encouraged the utilization of automotive parts packaging industry.

The underbody components segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to rapid growth in EV infrastructures. It provides multiple-layers to protect products from moisture, deformation, corrosion, and scratches which raise the demand for these packaging in this sector. It supports in protecting sensitive battery components from ecological hazards and road debris. Heavy-duty plastics and metal crates assure damage-free packaging of the products.

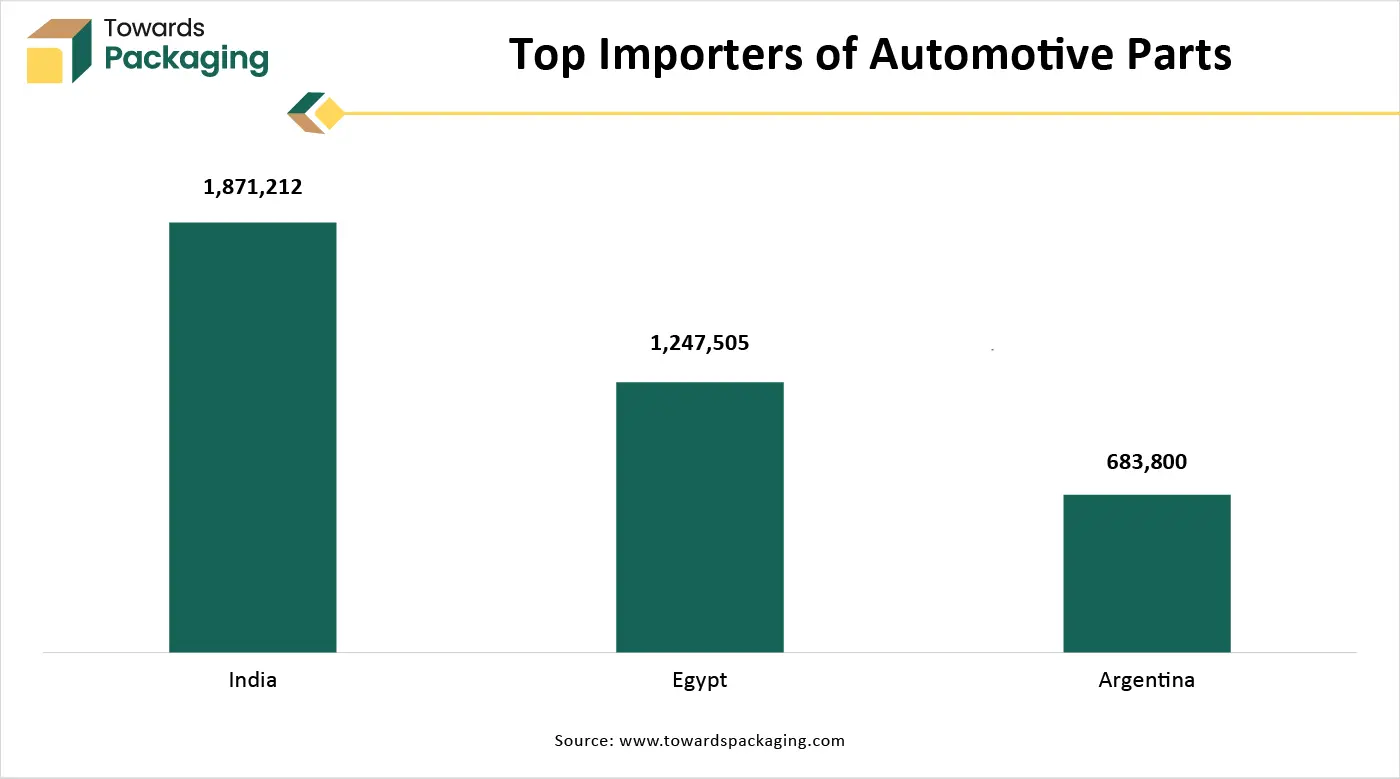

Asia Pacific held the largest share in the market share of 46.4% in 2025, due to its huge manufacturing capacity. Increasing adoption of electric vehicles has pushed the market to develop rapidly. There is a huge demand for cost-effective packaging due to reduction of charges during delivery. Rising sustainability trend has fuelled the demand for this market which is also safe for the packaging of fragile automotive parts. Safe packaging of batteries and other components has promoted this market to grow rapidly.

China Automotive Parts Packaging Market Trends

Strong manufacturing potential and export hub has raised the demand for market in China. Rapid technological advancement in this market has promoted the adoption of this sector. Such advanced packaging help in monitoring the components which help in safe delivery of the products. Strict guidelines for eco-friendly and biodegradable packaging have promoted the demand for this market.

North America expects the fastest growth in the market during the forecast period. Reusable and sustainable packaging have influenced the demand for the market in the North America. The rising concern about ecological issues has pushed this automotive parts packaging sector to manufacture such packaging with high biodegradability. Increasing customization demand with durable designs has promoted the growth of this market. Some electronic components and underbody components need specialized packaging which encouraged this sector.

The U.S. Automotive Parts Packaging Market Trends

Increasing demand for eco-friendly and smart packaging have driven the demand of the market in the U.S. Integration of tracking technology with smart labelling process has fuelled the demand for automotive parts packaging industry. Increasing adoption of electric vehicles has raised the demand for specialized packaging. Rising adoption for custom-fit packaging has enhanced the demand of this industry to evolve rapidly.

The major factors influencing the growth of market are strong preference of durable packaging, smart packaging adoption, logistics efficiency, reusable and returnable packaging. Huge requirement for specialized protection and recyclable materials has pushed the adoption of this packaging in automotive sector. These packaging are well-known for intricate and high-value components protection with specialized packaging. Presence of closed-loop system and cost-effective packaging has pushed this market to grow rapidly.

Germany Automotive Parts Packaging Market Trends

Strong demand returnable and recyclable packaging has influenced the development of the automotive parts packaging market. Presence of major market player have felled innovation process in this market. There is a huge requirement for anti-electrostatic protection and thermal insulation of heavy automotive parts which promote the need of specialized packaging. Rising innovation of shock-resistance and smart packaging has pushed this market to grow exponentially.

By Product Type

By Packaging Type

By Component Type

By Region

February 2026

February 2026

February 2026

January 2026