North America Yogurt, Cheese & Meat FFS Packaging Market Size, Demand and Trends Analysis

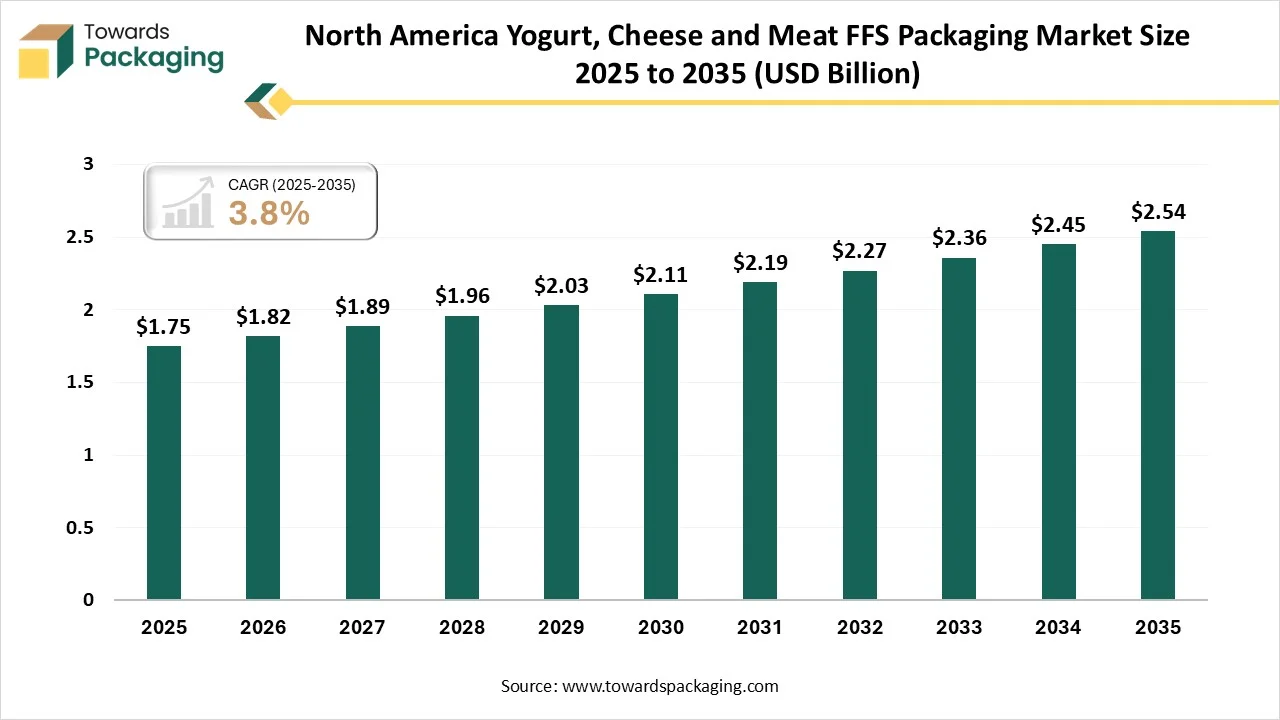

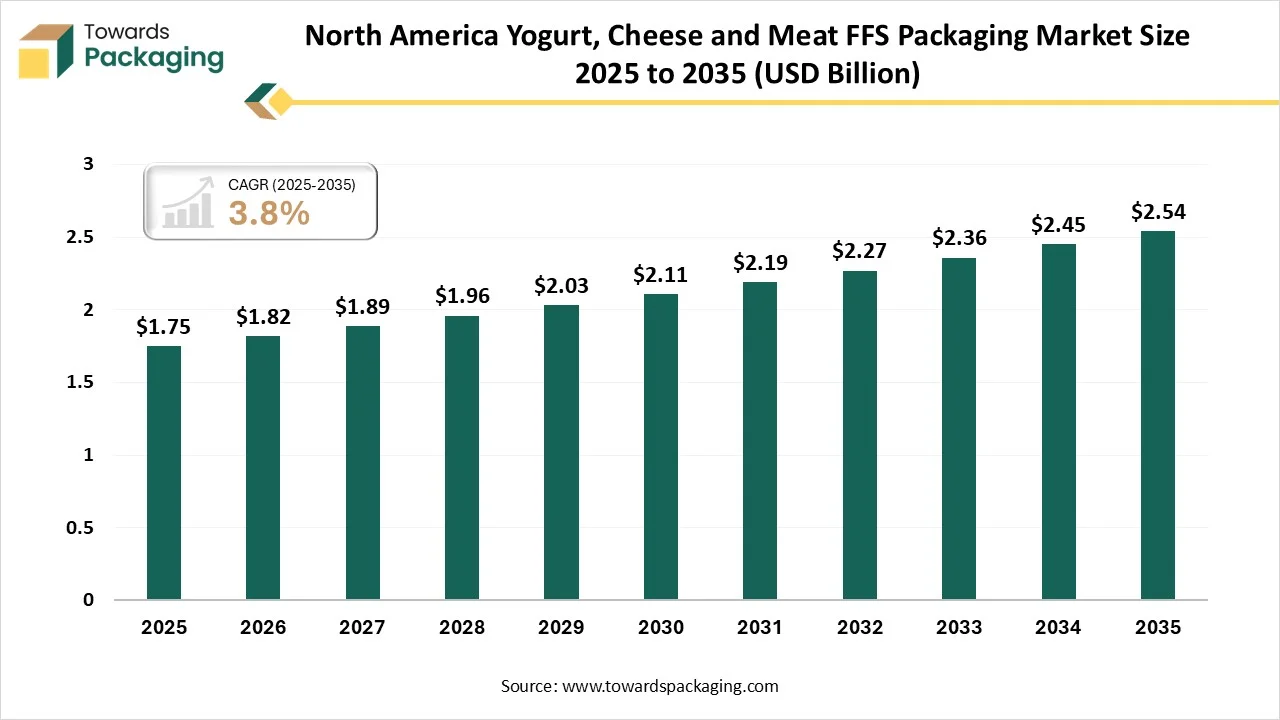

The North America yogurt, cheese & meat FFS packaging market is forecasted to expand from USD 1.82 billion in 2026 to USD 2.54 billion by 2035, growing at a CAGR of 3.8% from 2026 to 2035. This region carries a main share in the form -fill-seal machines industry because of its high-level industrial scenario and early acceptance of packaging automation.

Major Key Insights of the North America Yogurt, Cheese, and Meat FFS Packaging Market

- In terms of revenue, the market is valued at USD 1.75 billion in 2025.

- The market is projected to reach USD 2.54 billion by 2035.

- Rapid growth at a CAGR of 3.8% will be observed in the period between 2026 and 2035.

- By material, the polyethylene terephthalate (PET) segment has dominated the market with approximately 34% share in 2025.

- By material, the polypropylene (PP) segment will be growing at a significant CAGR between 2026 and 2035.

- By packaging type, the flexible FFS segment has dominated the market with approximately 63% share in 2025.

- By packaging type, the rigid FFS segment will be developing at a main CAGR share between 2026 and 2035.

- By product format, the films & wraps segment has dominated the market with approximately 43% share in 2025.

- By product format, the pouches segment will be growing at a significant CAGR between 2026 and 2035.

- By application, the meat segment has dominated the market with approximately 69% share in 2025.

- By application, the yogurt segment will be developing at a main CAGR between 2026 and 2035.

Market Overview

The North America Yogurt, Cheese & Meat Form-Fill-Seal (FFS) Packaging Market involves combined machinery and materials used to fill, form, and seal containers in a continuous process. These systems are essential for providing high-speed, hygienic, and airtight solutions such as cups for yogurt, vacuum-sealed bags for meat, and thermoformed trays for cheese.

A form-fill-seal machine makes bags from plastic films, then fills them with materials by using a weighing scale or volumetric feeder, and packs and fills them too. Such continuous operation ensures smooth packaging, which makes crisp bags ready for palletization.

Trends in North America Yogurt, Cheese & Meat FFS Packaging Market

- Shelf life and Microencapsulation: Microencapsulation prevents crucial parts in the dairy products. Such technology keeps enzymes, probiotics, and nutrients in small capsules. The capsules store these parts safely until we eat them. Probiotics last for a long period in fermented milk because of this.

- Smart Manufacturing and Automation: Automation creates a safer and quicker process. Auto bagger systems fill and seal packages without people connecting them. This stores any food safely and keeps it clean. Such systems assist in keeping dairy products fresh.

- Aseptic Packaging Advances: Aseptic packaging stores dairy products secured from germs. Packages are filled in clear space. We can store milk and yogurt at room temperature for a long period of time. One can store dairy products for trips and emergencies as special machines load the packages to prevent spoilage.

- Nutri-Score and Worldwide Standards: Nutri-score utilises colors to assist in the choice of healthy foods. Green points to a healthy product, and red means less healthy. Several people use Nutri-Score to select dairy products. The color is convenient to watch, and the letter grade helps more.

Technological Developments in the North America Yogurt, Cheese & Meat FFS Packaging Market

The automation is developing as a main solution for organizations that find higher productivity, accuracy, cost reduction, and sustainability. The technological progression is specifically important in fields with high demand and rigid quality needs, such as pharmaceuticals, food and beverage production, personal care, cosmetics, and fast-moving consumer goods. It even assists sustainable practices for accurate management of dosing, sealing, and cutting, which lowers the material waste. Several modern lines are agreeable with compostable, recyclable, and biodegradable films, which help companies align with strict regulations and surrounding needs.

Trade Analysis: Import and Export Data of North America Yogurt, Cheese & Meat FFS Packaging Market

- According to global data, the U.S. cheese packaging has imported data between the period June 2024 to May 2025, as buyers have globally imported 284 shipments of U.S. cheese packaging.

- Such shipments were being spearheaded by 284 exporters and bought by 240 official worldwide buyers, which showcases a 18% development as compared to the last twelve months.

- Vietnam, Colombia, and Uzbekistan have come up as the leading three U.S. cheese packaging importers, and the United States, France, and Russia are the three leading exporting countries.

- As per the global data, Mexico Meat Packaging import data between the period December 2023 to November 2024, buyers have globally imported 3 shipments of North American Meat Packaging.

North America Yogurt, Cheese & Meat FFS Packaging Market - Value Chain Analysis

- Package Design and Prototyping: FFS films are particularly crafted plastic materials utilized to create the package directly on the FFS machine. Such films demand particular qualities, such as flexibility, strength, and barrier characteristics against air and moisture, which ensure they can firmly stand up to the forces included in the packaging procedure without puncturing or tearing.

- Recycling and Waste Management: FF's packaging uses biodegradable and recyclable films that serve as more sustainable material options. Multi-layer covers have complicated recycling but serve perfect product prevention with less material. The lower processing temperatures completely save energy. Film waste is less with proper arrangement.

- Logistics and Distribution: Flexible plastic packaging plays a crucial role in logistics and e-commerce sectors, where protection, efficiency, and presentation are crucial. Some of the prevalent uses count polybags and mailers, which are lightweight in nature yet reliable, and are used to transport accessories, clothing, small goods, and electronics. They support in protecting the movement during transportation and protect the goods from dirt, dust, and moisture in storage or transport.

Segmental Insights

Material Insights

How PET Segment Dominated the North America Yogurt, Cheese & Meat FFS Packaging Market in 2025?

The polyethylene terephthalate (PET) segment has dominated the market with approximately 34% share as it has latest thermoplastic material which is leading one in the thermoforming synthetic packaging field. Its exceptional elements are its perfect transparency, similar to that of glass, and its brilliancy, and further benefit is its high mechanical power that enables the manufacturing of dimensionally constant rigid packaging with moderately small wall thickness, and its superior oxygen barrier qualities, which make it ideal for fresh food products.

The polypropylene (PP) segment is expected to witness the fastest CAGR during the forecast period. They are thermoplastic polymers that generate lightweight, flexible sheets, which generate high durability due to their resistance to moisture, as well as chemical resistance. These sheets cross PVC and cardboard packaging while also serving perfect reusability, durability, and overall recyclability, which makes them perfect for eco-friendly uses.

Packaging Type Insights

How Flexible FFS Segment Dominated the North America Yogurt, Cheese & Meat FFS Packaging Market in 2025?

The flexible FFS segment dominated the market with approximately 63% share in 2025, as form, fill, and seal (FFS) machinery showcases one of the most important advances in current packaging technology. Such automated systems have changed manufacturing lines in the pharmaceutical, food, and consumer goods sectors by combining three complicated packaging steps into one common seamless operation. FFS machines make packages from flexible materials, fill them with accurate amounts of product, and pack them with less human involvement and maximum efficiency.

The rigid FFS segment is expected to experience the fastest CAGR during the forecast period. Rigid containers such as cups and trays will have filling, sealing, and labelling processes on the manufacturing line. These systems play a crucial role in liquids, semi-liquids, and semi-solid products. The filler is the main part of any bottling line. Relying on the product factors, the technology is chosen as the gravity fillers are used to thin and free-flowing liquids, as piston fillers make sure precise volumetric fills of sensitive products (yogurt, cheese, etc), and auger fillers are applied to fill granules and powders.

How Films& Wraps Segment Dominated the North America Yogurt, Cheese & Meat FFS Packaging Market in 2025?

The films & wraps segment dominated the market with approximately 43% share in 2025, as flow wrap, machines are initially used for covering products in sealed plastic films. They are skilled in carrying a variety of product sizes, shapes, and materials, which makes them perfect for products like medical devices, snacks, and cosmetics. Flow wrap packing machines generally wrap products horizontally, which means they need a smaller footprint and can cover several items at the same time at high speeds.

The pouches segment is predicted to experience the fastest CAGR during the forecast period. Premade pouch machines apply pre-formed pouches for advanced aesthetics and various designs, which are suitable for luxury products. They are costly for materials and machines, and moderate speeds. Form-fill-seal (FFS) systems, which make pouches from roll stock on -site, deliver lower costs and higher speeds for big-volume and simpler designs. The perfect selection balances speed, cost, desired quality, and packaging quality, too.

Application Insights

How Meat Segment Dominated the North America Yogurt, Cheese & Meat FFS Packaging Market in 2025?

The meat segment dominated the market with approximately 69% share, as tray and film packaging is a prevalent selection for retail customers, such as chicken breasts, steaks, and other portioned meats. In this procedure, the meat is kept in a reliable, moisture-opposing, and sealed with a transparent film. Such packaging style is not only online promising but also user-friendly, which serves users a clear visual of the product that ensures freshness. Furthermore, laminated and foil materials are frequently used for long-term meat storage, particularly in the wholesale industry.

The yogurt segment is projected to witness the fastest CAGR during the forecast period. Yoghurt cup filling machines are necessary in the dairy processing sector, which solves the developing demand for easy yoghurt packaging. There are different yoghurt types- from regular set and stirred varieties to creamy Greek-style and fruit-filled options- automated filling machines match various manufacturing needs. Semi-automatic cup filler machines match smaller production ranges and are a perfect choice for artisan dairy producers and start-ups.

Country Insights

How has the United States dominated the North America Yogurt, Cheese & Meat FFS Packaging Market?

- The United States dominated the market with 74.8% share because flexible packaging has topped the U.S. cheese packaging industry due to its lightweight profile, affordability, and potential to track cheese freshness. Vacuum packaging and modified atmosphere packaging are quickly gaining market share for their role in expanding the shelf life and protecting the product's integrity.

- On the other hand, as sustainability becomes a focus, yogurt brands in the U.S are shifting towards post-consumer recycled (PCR) plastics to lower their eco-friendly practice. PCR materials are extracted from used plastic packaging, which is processed, collected, and reused, which helps to cut down the waste and protect the resources.

- The Yogurt, Cheese & Meat FFS Packaging Market is growing in Mexico as regional cheese production in Mexico is growing to align with both internal and export demands. Rising urbanization and a growing middle class have created easy designs like single-serve sticks and cubes, which are highly popular. The hotels, restaurants, and institutional food delivery sector are initially drivers for big and smooth packaging solutions. Mexican food processing organizations like Tyson and Bachoo are heavily investing in automated FFS solutions to lower the labor dependency and match with high food safety standards.

Government Regulations of North America Yogurt, Cheese & Meat FFS Packaging Market

- Cream, milk, butter, and ice cream, as well as several cheeses, are subject to limitations imposed by both U.S. Customs and Border Protection and the USDA (Department of Agriculture). Every dairy product is contingent on the Animal and Plant Health Inspection Service (APHIS) needs. They are also dependent on the Food and Drug Administration (FDA) needs.

- Cream and milk cannot be officially imported without permission from the FDA. The cartons or wrappers for such products should be printed with the country of origin.

Recent Developments

- In January 2025, Harpak-ULMA revealed a new use of the Mondini Trave Sinfino tray sealing stage, which is crafted to uniformly bulk ground meat manufacturing.

- In October 2025, Frigo Cheese Heads, which is a Saputo USA brand, developed its cheese stick snack series by making a pair of the latest varieties, as well as the packaging, which serves more snacks with every pack.

- In October 2025, one of America’s most cherished cheese brands, named Jarlsberg, relaunched with a highlighted latest campaign, latest appearance, and a changed loyalty to assist more people in discovering or rediscovering its versatile and flavorful cheese.

- In January 2025, Cirkla, a global leader in sustainable packaging, disclosed the launch of its innovative molded fiber Modified Atmosphere Packaging (MAP) trays.

Top Companies in the North America Yogurt, Cheese & Meat FFS Packaging Market

- ProMach, Inc.

- Winpak Ltd.

- Berry Global, Inc.

- Amcor plc

- Sealed Air Corporation

- Syntegon Technology (formerly Bosch)

- IMA Group (IMA Dairy & Food)

- Viking Masek Packaging Technologies

- Matrix Packaging Machinery

- Serac Group

North America Yogurt, Cheese & Meat FFS Packaging Market Segmentation

By Material

- Polyethylene Terephthalate (PET)

- Polyethylene (PE)

- Polypropylene (PP)

- Others (Laminates, Bioplastics)

By Packaging Type

- Flexible FFS (Pouches, Sachets)

- Rigid FFS (Cups, Trays, Tubs)

By Product Format

- Films & Wraps

- Pouches

- Cups

- Trays & Containers

By Application

- Meat (Fresh, Frozen, Processed)

- Cheese (Shredded, Sliced, Blocks)

- Yogurt (Cups, Drinks, Tubs)