Cardboard Boxes Market Size, Trends, and Competitive Landscape Report 2025-2035

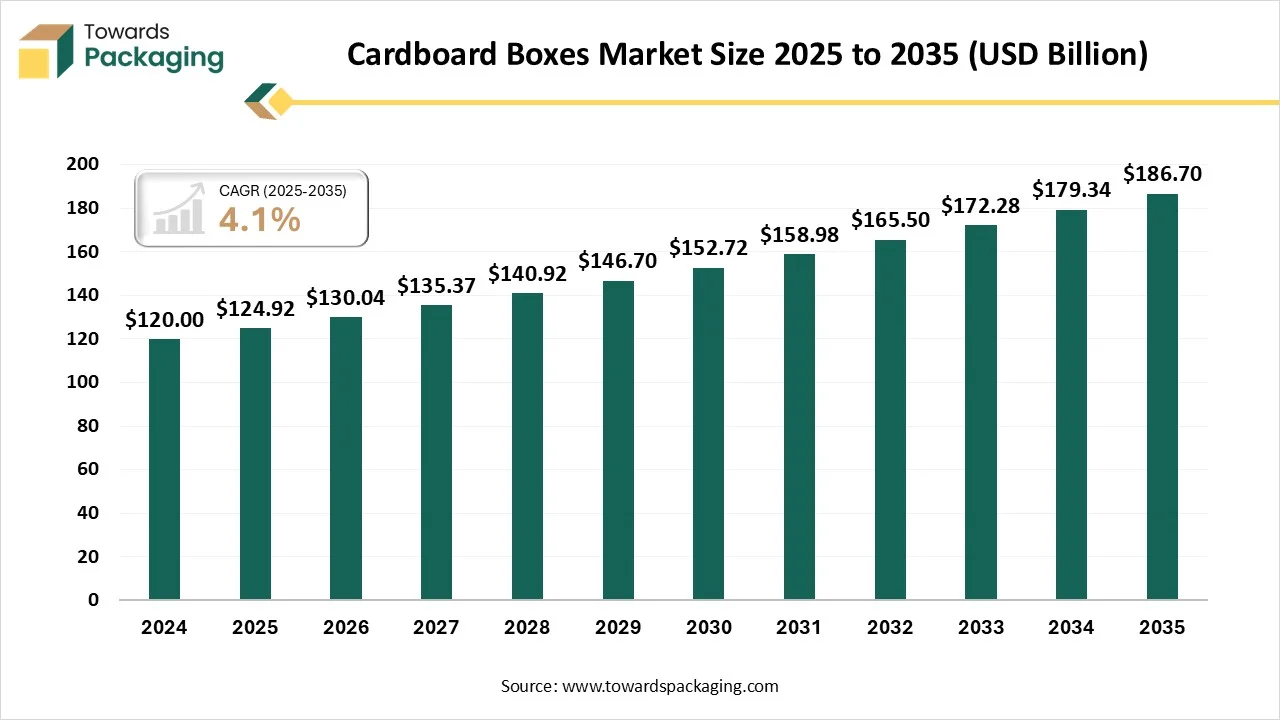

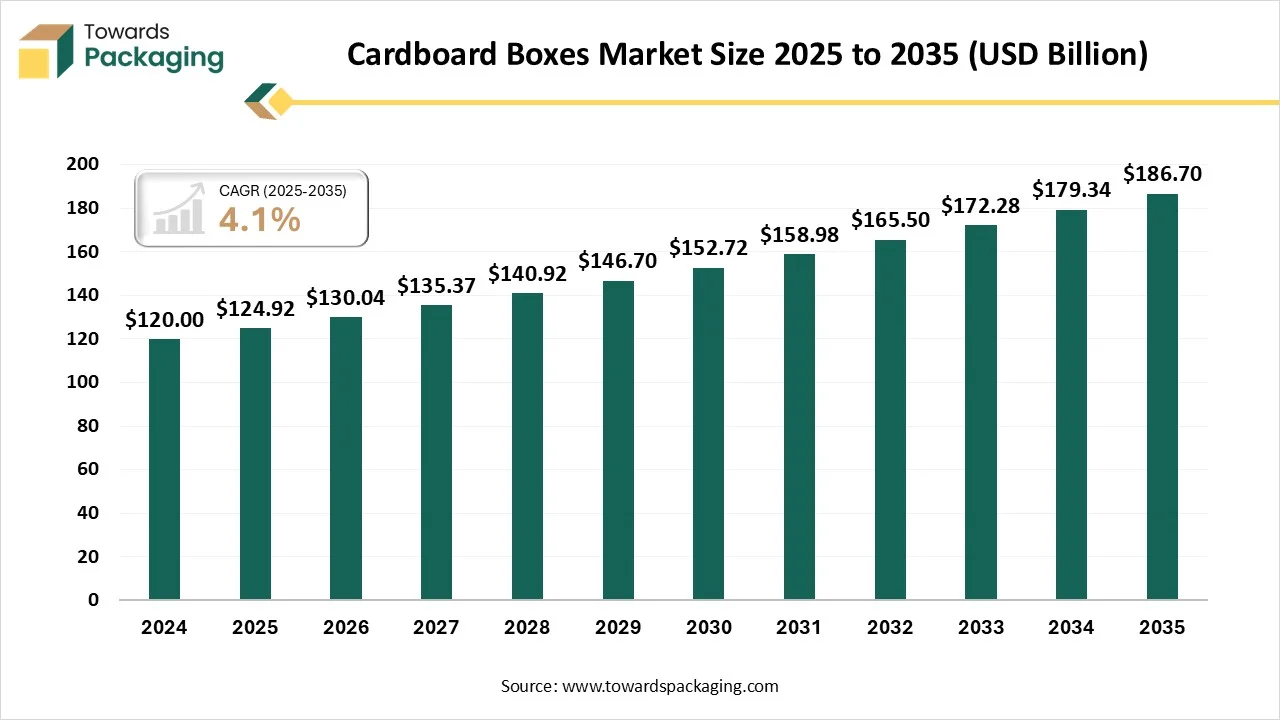

The cardboard boxes market is valued at USD 124.92 billion in 2025 and is projected to reach USD 186.70 billion by 2035, expanding at a CAGR of 4.1%, driven by accelerating e-commerce volumes accounting for over 45% of global box demand and rising sustainability mandates. Asia Pacific dominates with over 42% market share, led by China’s production of 78.5 million metric tons, while North America is the fastest-growing region with e-commerce packaging demand rising at 5% CAGR.

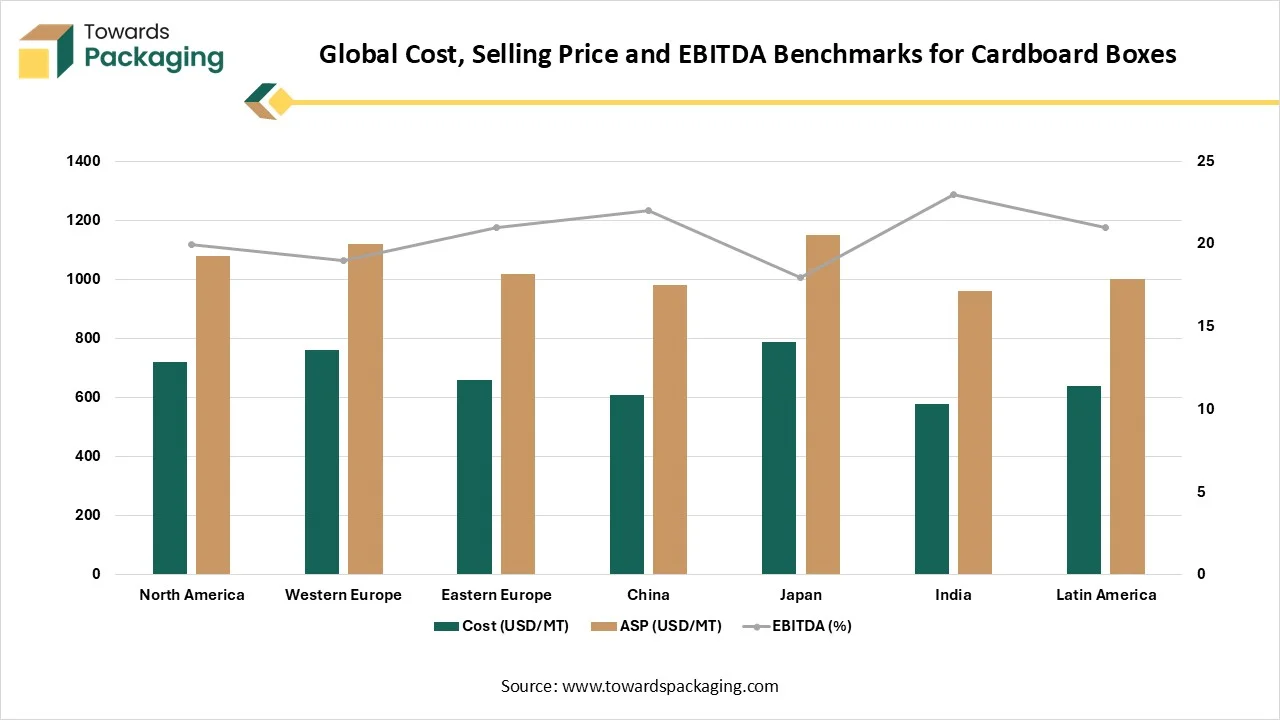

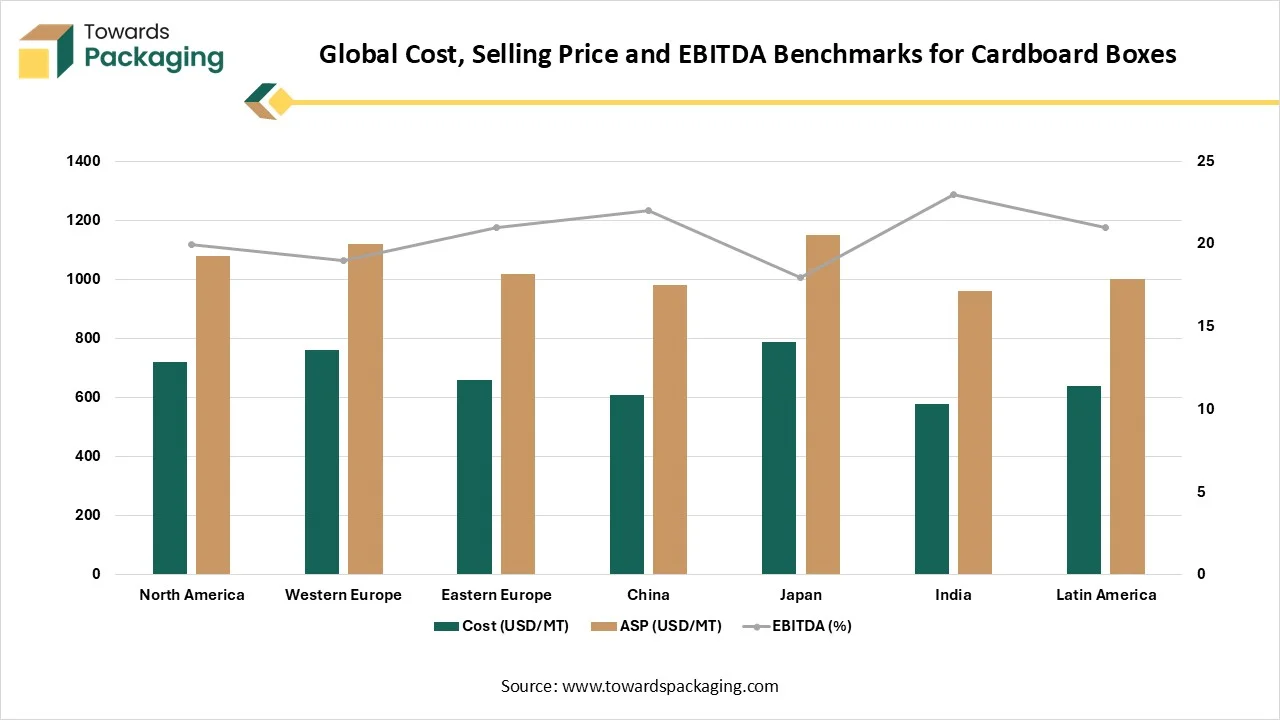

From a printing and design perspective, flexographic printing accounts for 60% of total printed box output, while digital printing is growing above 6% CAGR, fueled by short runs and customization. Regionally, North America ASPs average USD 1,080/MT, Europe USD 1,120/MT, and Asia USD 980/MT, with EBITDA margins peaking at 23% in India.

The report covers key manufacturers including International Paper (32.5 MT capacity), WestRock (30.8 MT), Smurfit Kappa (28.6 MT), and DS Smith (18.9 MT), alongside value chain analysis, trade flows (China exports USD 18.5B), supplier dynamics, and AI-enabled box-on-demand manufacturing trends.

Key Takeaways

- Asia Pacific dominated the cardboard boxes market.

- North America is expected to host the fastest-growing market in the forecast period.

- By type, the corrugated boxes segment dominated the cardboard box market in 2024.

- By type, the rigid boxes segment is expected to grow at the fastest CAGR in the coming years.

- By wall type, the single wall segment dominated the market in 2024.

- By wall type, the double wall is the fastest-growing type in the market as it has two layers of corrugated cardboard that provide extra power as compared to a standard single-wall box.

- By box style, the slotted box style dominated the market in 2024.

- By box style, the folding segment will grow at the fastest CAGR over the forecast period.

- By printing technology, the flexographic segment dominated the market in 2024.

- By printing technology, the digital printing segment is expected to grow at the fastest CAGR in the coming years.

- By end-use industry, the e-commerce and retail segment dominated the market in 2024.

- By end-use industry, the food and beverage segment will grow at the fastest CAGR over the forecast period.

Key Metrics and Overview

| Metric |

Details |

| Key Drivers |

- Expansion of e-commerce

- Demand for sustainable packaging

- Versatility and cost-effectiveness of cardboard |

| Leading Region |

Asia Pacific |

| Market Segmentation |

By Type, By Wall Type, By Box Style, By Printing Technology, By End-Use Industry and By Region |

| Top Key Players |

International Paper, Smurfit Kappa Group, Trident Paper Box Industries, DS Smith, Packaging Corporation of America |

Smart, Sustainable, and Strong: The Power of Cardboard Boxes

A cardboard box is specifically created from a single layer of thick paper stock or paperboard, typically used for lightweight packaging such as cereal boxes or shoe boxes. They are constructed from a single layer of thick paperboard. This material is generated by pushing together most fibers, particularly cellulose pulp gathered from rags, wood, or grasses, and drying them into flexible sheets. The outcome paperboard is then cut and folded into the required shape and size, often secured with staples, glue, or tape. While cardboard is almost stout for its weight, it lacks the structural probity needed for heavy-duty uses.

Cardboard boxes are perfect for shipping goods and packaging because of their lightweight nature, strength, and cost-effectiveness. They serve ultimate protection and are easy to transport and stack. They are widely used in storing items in businesses and homes, storing items too and come in different designs and sizes to suit various storage needs. It is usually considered an environmentally friendly material because of its biodegradability and recyclability. The cardboard grades are classified based on the percentage of recycled fiber they have, as all grades are recyclable.

Global Cost, Selling Price and EBITDA Benchmarks for Cardboard Boxes

Profitability hotspots & investment attractiveness

| Region |

Cost (USD/MT) |

ASP (USD/MT) |

EBITDA (%) |

| North America |

720 |

1,080 |

20 |

| Western Europe |

760 |

1,120 |

19 |

| Eastern Europe |

660 |

1,020 |

21 |

| China |

610 |

980 |

22 |

| Japan |

790 |

1,150 |

18 |

| India |

580 |

960 |

23 |

| Latin America |

640 |

1,000 |

21 |

What are the New Trends in the Cardboard Boxes Market?

- E-commerce driving packaging demand: The growing complicated logistics chain for direct-to-consumer delivery means packages are handled several times, urging durable and cost-effective secondary corrugated packaging. This move has cheered up brands to accept packaging that prevents products and supports their brand image directly in consumers’ homes, raising the demand for good-quality graphic design on shippers.

- Fit-to-product and box-on-demand technology: Inventions like fit-to-product packaging and boxes to the particular size of products, which reduces the demand for excess filler material. This specifically advantages companies like Amazon, which need tailored packaging for different product sizes and shapes. The growth of FtP Technology has paved the way for the growing demand for fanfold board and finishing equipment, which can print and cut boxes on demand.

- Sustainability and lightweight: Sustainability continues to be a rising factor in the packaging industry. With the growth in consumer awareness around environmental problems, cardboard boxes are heavily favored for their eco-friendliness and recyclability. Lightweight includes using thinner yet rigid board grades, which have been specifically successful in Western Europe. Where box weights are particularly about 80% of the U.S. equivalent.

- Retail-ready packaging (RRP): Retail-ready packaging continues to be important, especially in Western Europe, where it has grown into a main cost-saving measure. Retail-ready packaging includes pre-packed products that are easy to display and need less setup time.

- Advancements in digital printing: The rising acceptance of digital printing in the corrugated sector has opened the latest possibilities for customization and personalization. Digital printing offers adaptability in huge lengths, lower strip costs, and the potential to personalize packaging for particular stores, regions, and individual customers.

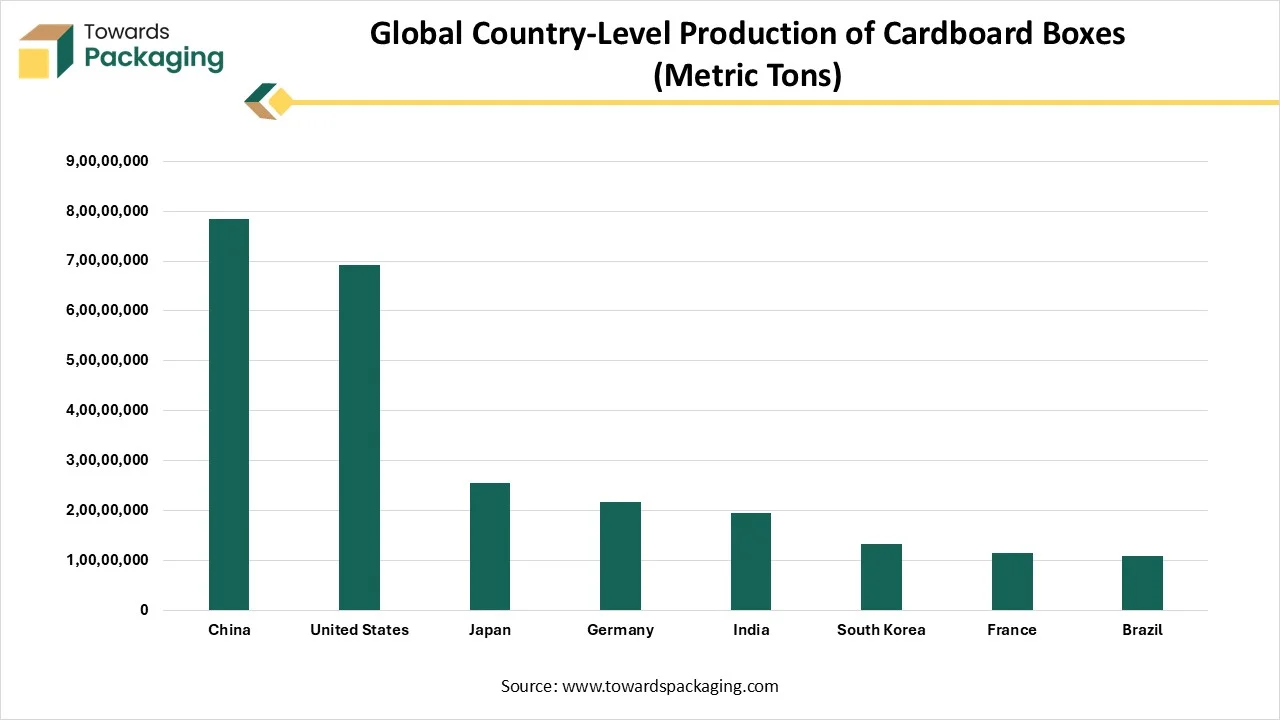

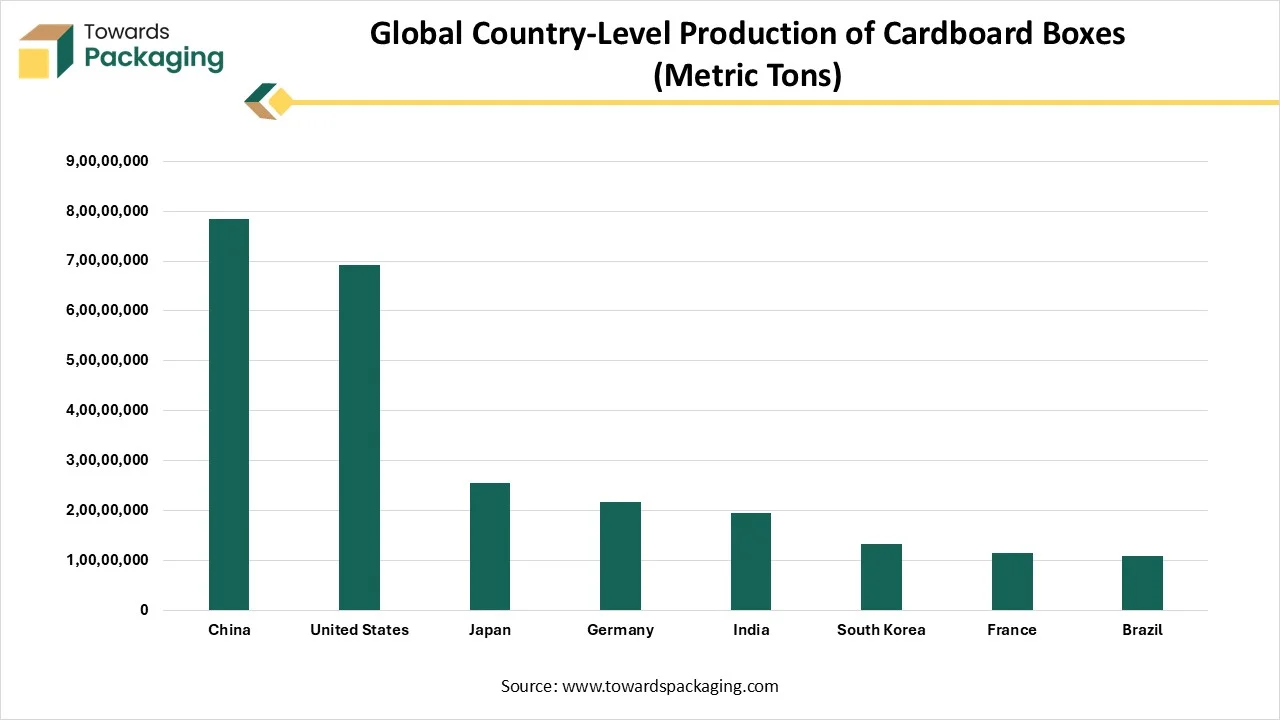

Global Country-Level Production of Cardboard Boxes (Metric Tons)

Where global cardboard box supply is manufactured

| Country |

Production (MT) |

| China |

78,500,000 |

| United States |

69,200,000 |

| Japan |

25,600,000 |

| Germany |

21,800,000 |

| India |

19,500,000 |

| South Korea |

13,200,000 |

| France |

11,400,000 |

| Brazil |

10,900,000 |

The cardboard box market is evolving with the integration of artificial intelligence (AI), which is poised to transform everything from box design to inventory management. It is changing box design, regularly a procedure of trial and error to balance durability, strength, and material effectiveness. Machine learning algorithms can now examine huge datasets to predict the most efficient box materials, structures, and dimensions. This not only lessens the waste but also improves overall performance. AI-driven tools can suggest the optimal materials for particular packaging needs, which ensures companies utilize the least amount of material while maintaining structural integrity. This perfect nature reduces both material costs and environmental effects. One of the most important benefits AI brings in terms of the packaging industry is predictive maintenance. AI models examine data from machinery to forecast potential failures and maintenance demands.

Market Dynamics

Driver

Versatility of Cardboard Boxes

Cardboard boxes are utilized worldwide, forming a main part of supply chains and daily life online every day in the sector. The global demand for cardboard packaging continues to grow, driven by different factors that include the expansion of e-commerce, rising consumerism, and the current shift towards sustainable packaging solutions. Efforts to grow the sustainability of cardboard manufacturing production are returning positive results that make cardboard a cornerstone of environmentally conscious packaging. As more businesses and consumers analyze the benefits linked with using recyclable materials, cardboard continues to gain importance as a feasible alternative to less sustainable packaging options.

Restraint

Challenges in the Cardboard Boxes Industry

Though cardboard boxes are a rigid and versatile material, they can sometimes fall short in terms of continuity, especially under particular conditions. It is vulnerable to moisture and can be affected when exposed to water or high humidity. For products that need a huge level of protection or are shipped in wet conditions, additional care, such as water-resistant coatings, is necessary. It provides an acceptable amount of cushioning. But for heavy, fragile items that may not provide enough protection on their own, businesses can solve this by adding internal padding or inserts, which adds to both the cost and the packaging procedure. For sensitive products alteration, or additional protective packaging material may be necessary, which may affect overall cost-effectiveness.

Opportunity

Sustainability Grows in Cardboard Boxes

Several individual products were sealed in plastic and held together with staples. We have now shifted towards using recyclable paper and protective cardboard to substitute plastic completely. This not only makes our packaging fully recyclable, but it also makes a safer experience for customers, with no staples or sharp edges to care about. The effect of this transformation is considerable. By vanishing plastic in our packaging, we assist in reducing plastic that results in ocean pollution. The move towards paper and cardboard makes our packaging 100% recyclable, and the lighter weight of our packaging means fewer emissions from transport, both minute but meaningful steps towards a healthier planet.

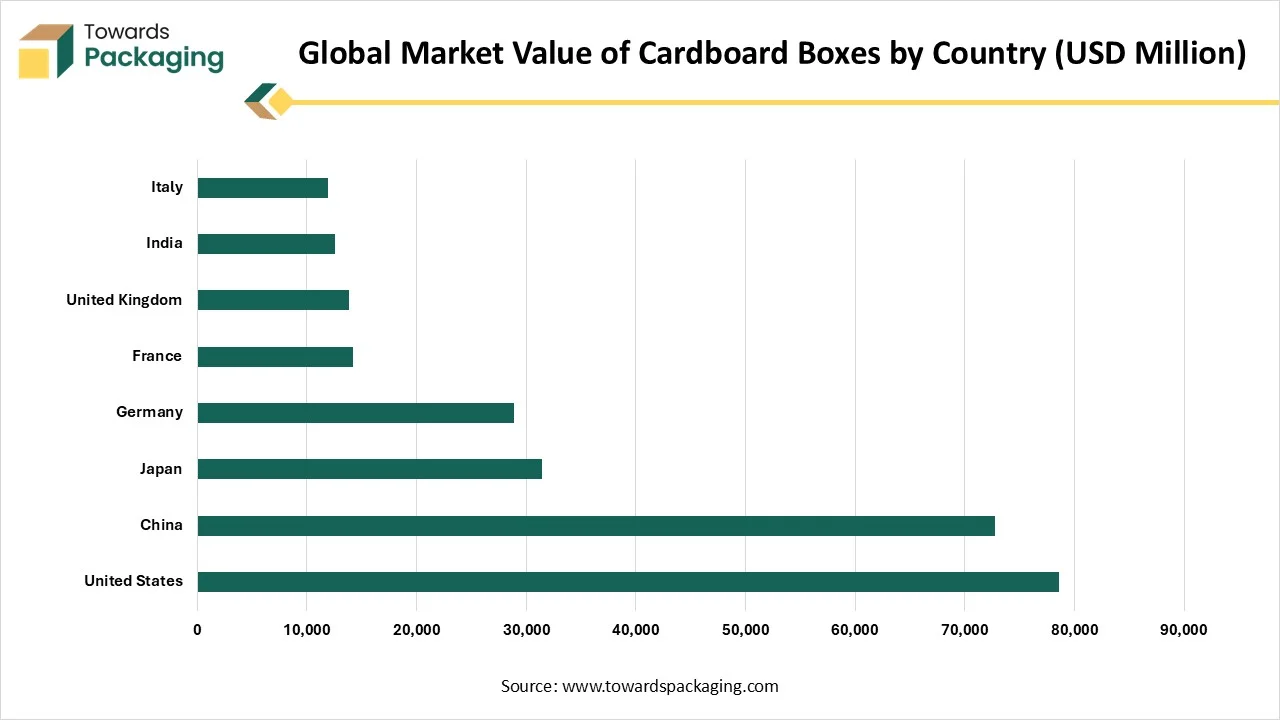

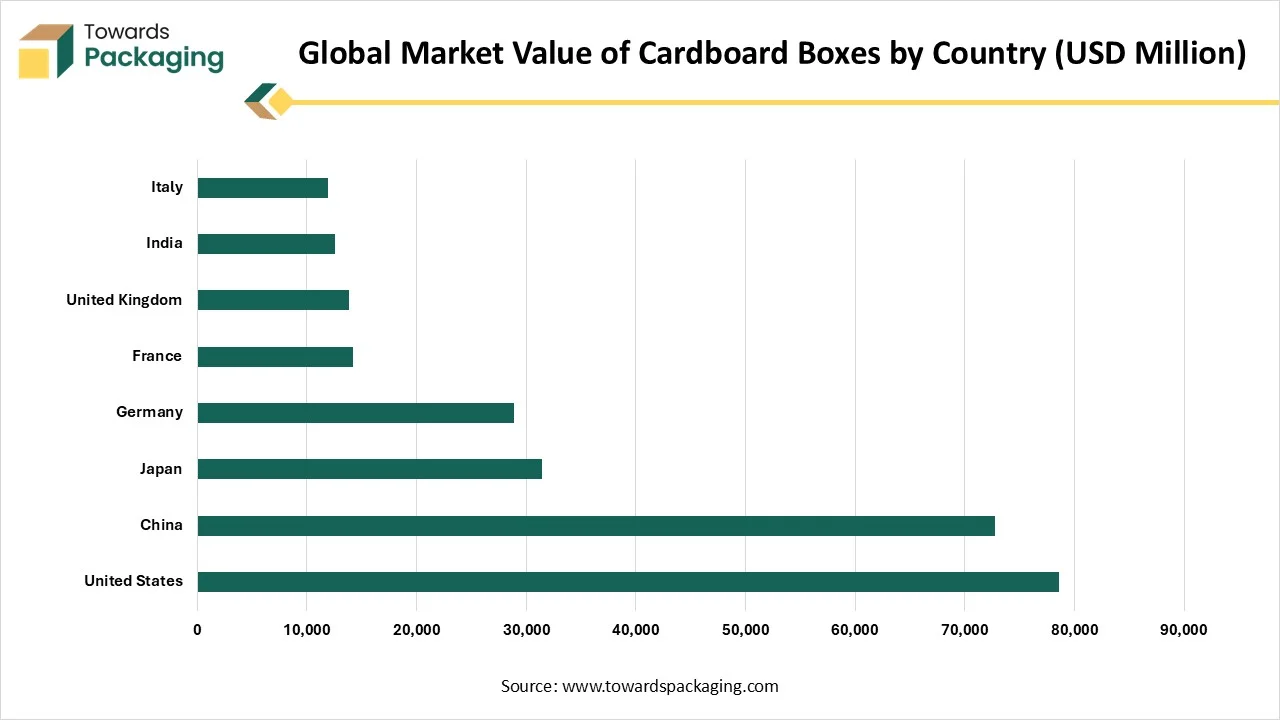

Global Market Value of Cardboard Boxes by Country (USD Million)

Revenue concentration and pricing strength

| Country |

Market Value |

| United States |

78,600 |

| China |

72,800 |

| Japan |

31,400 |

| Germany |

28,900 |

| France |

14,200 |

| United Kingdom |

13,800 |

| India |

12,600 |

| Italy |

11,900 |

Segmental Insights

Corrugated Boxes Dominate the Market

A corrugated box is a kind of container created from a material known as corrugated cardboard. It’s one of the most famous packaging materials utilized worldwide, especially for shipping. The main reason why corrugated boxes are so widely used is that they provide protection, strength, and adaptability. They are particularly made from trees, which are a renewable resource as its most recycled packaging materials overall, containing recycling rates soaring around 90 % in recent years. The main characteristic of corrugated features is their flute, which is a wavy layer between the two flat layers. It serves cushioning, power, and protection in one box.

Rigid boxes are utilized for displaying, packaging, and shipping high-value goods. These boxes are created from paperboard, which can be eco-friendly if sourced properly. They can also be recycled, which reduces environmental waste. The greater thickness and smooth surface of rigid box packaging assist in customization and production. Rigid stock is not a flexible material, which is created from kraft paper and cardboard. Rigid packaging boxes are counted as one of the best among other packaging types because of their versatility, power, and great look. Usually, the thicker the packaging material is, the greater protection it provides to the products.

Which Wall Type Dominated the Cardboard Boxes Market in 2024?

The single-wall segment led the market in 2024. These boxes are being created from a single layer of corrugated cardboard. From a design perspective, these boxes include three layers: an outer recycled cardboard layer, a corrugated inner liner, and another recycled layer. While they are less crowded as compared to double wall boxes, they can still provide huge protection for a huge range of items, but they will not advocate in the same way a double wall box will. They are usually more reliable than double-wall boxes because of their simpler design. This makes them an attention-grabbing option for businesses seeking to reduce packaging costs for lighter-weight products.

A double-wall cardboard box has two layers of corrugated cardboard that provide extra strength as compared to a standard single-wall box. The double wall corrugated includes two fluted cardboard layers squeezed between three flat liner boards. This pattern gives the box more outstanding opposition to crushing and serves as added protection for its contents. It is more sturdy than single-wall boxes and can handle cumbersome loads. The dual layers are perfect for moving, shifting, or storing heavy products, which makes these boxes a perfect choice for anyone who needs extra peace of mind during transformation.

Slotted Boxes Dominated the Market in 2024

Slotted boxes are the best option when it comes to packaging solutions. These boxes serve many benefits over die-cut boxes, such as effectiveness when packaging and stocking. It is most regular slotted cartons are created from corrugated material, which is shipped flat and can be efficiently stacked on each other for storage purposes. They are smooth and fast to manage due to their simple design, which features two equal-length sides attached together by flaps at one end. Furthermore, they provide good protection of the product with their double wall construction that assists in absorbing any impact or effects caused during transportation during handling.

A folding paper box template is an already created outline or pattern for making a paper box. Cutting lines, fold lines, and perhaps a depiction to support box assembly will be given on the template. Templates are crafted so they are easy to cut and fold, which requires little craft skill to generate a professional-looking box. The flexibility of folding boxes is in their simplicity. They are generally made from a single sheet of paper or cardboard, which you fold along dedicated lines to make the structure of the box. The design is useful for every kind of purpose, including packaging, giving gifts, or even for storage. Folder box design templates work great to tailor and create different forms of packaging economically. Be it for organizing or gift-giving, it comes with the latest form of packaging solution for your business.

How will Flexographic Printing Dominate the Cardboard Boxes Market in 2024?

Flexographic printing utilizes flexible photopolymer plates to receive high-quality prints and pictures on different surfaces. These rubber plates have grown images that press ink on the substrates. The flexographic printing plates utilized are positioned around cylinders on a web press and twist quickly in order to produce accurate prints. Flexo printing is consistent with other procedures such as embossing, laminating,die-cutting, and cold foil stamping. Such formation allows the formation of new and top-notch custom packaging. This variability makes flexography the perfect choice in sectors that need tailored solutions.

Digital printing is the current printing method that transforms digital images directly into different materials. It prints from a digital file, like a PDF, or straight to the printer. The procedure enables custom digital printing, which makes it easy to tailor packaging with different colors, designs, and branding, too. This procedure works by planning an image on the surface using small droplets of ink. The outcome is sharp, dark prints with extreme details. Several industries now utilize digital printing technology in packaging due to its efficiency and speed. It's especially of use in businesses that need fast reversal and different design variations.

E-Commerce and Retail Dominates the Cardboard Boxes Market in 2024

As packaging amendments in e-commerce continue to change, the changes and effectiveness of packaging at the end of order-picking operations have become important factors in ensuring customer satisfaction, environmental sustainability, and operational efficiency. With the growth of online shopping, organizations face the limitations of changing their packaging procedure to align with rising demand while solving cost, speed, and environmental issues. Right-sizing uses right-sizing procedures, which are not just reducing costs but also consider responsibility for the environment. Make sure that boxes are accurately sized for their products, which reduces the usage of excess materials. It requires fewer costs, which contributes to a more sustainable e-commerce industry and foretells a sense of environmental management.

Cardboard boxes are an evergreen option. They come in different sizes and shapes, which can be printed with logos or other marketing messages. Cardboard boxes are also recyclable, but they are not as durable as some other options, and moisture can damage them. Paper and paperboard are utilized as primary and secondary packaging materials by food producers. It is a prevalent choice in direct contact material for dry food, but not for wet foods. Paper packaging material is feeble, but paperboard with added fiber characteristics has great strength. Trays, boxes, and cartons can be made using paperboard. There are several types of paperboard suitable for a range of food items.

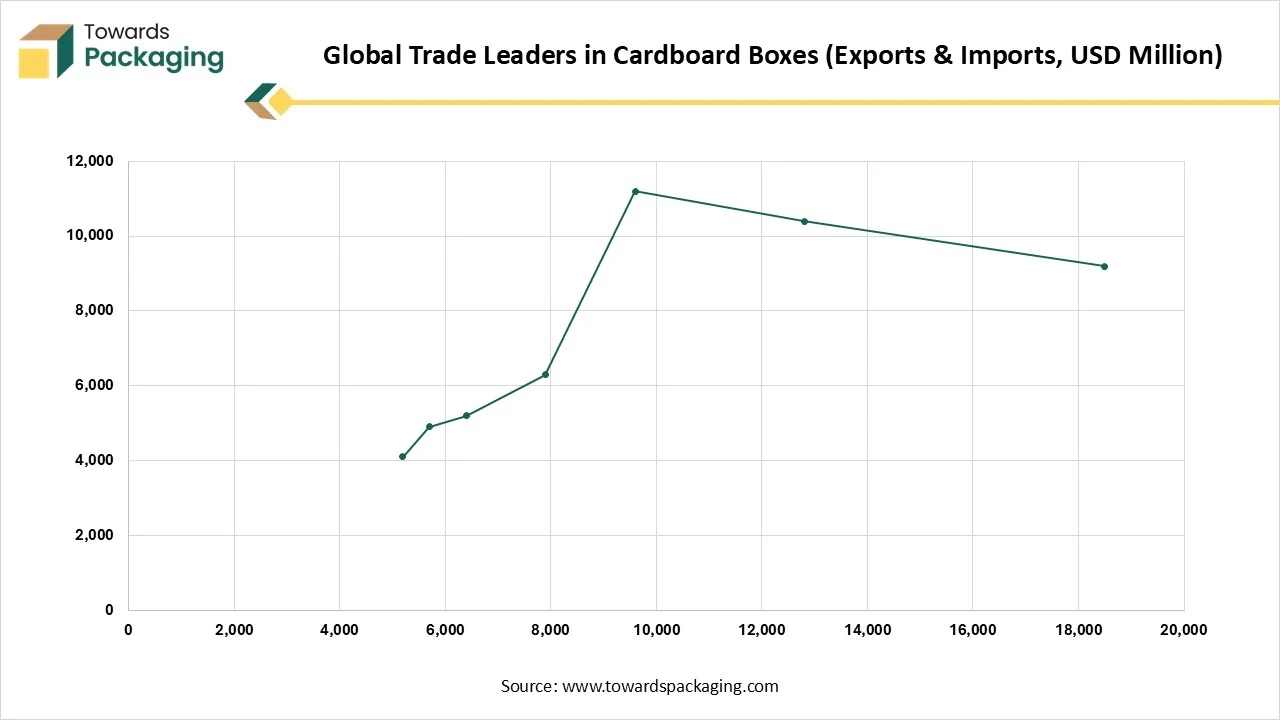

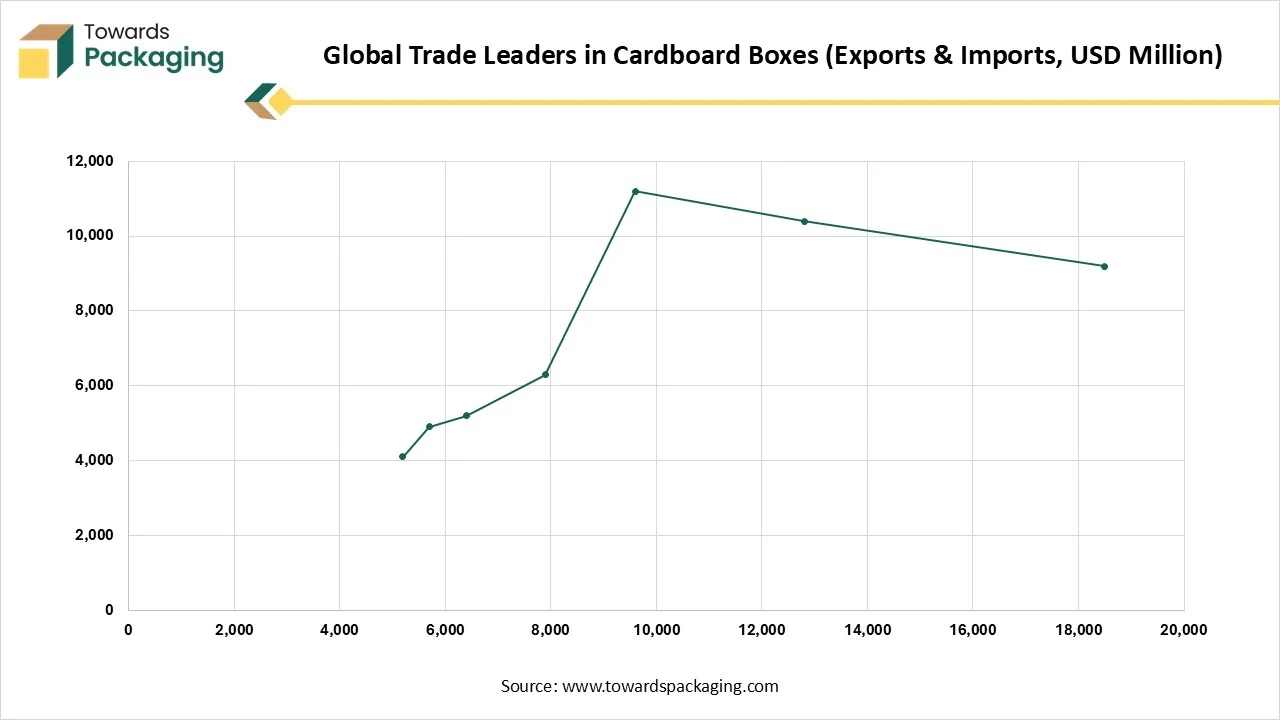

Global Trade Leaders in Cardboard Boxes (Exports & Imports, USD Million)

Cross-border trade power and supply-chain influence

| Country |

Exports |

Imports |

| China |

18,500 |

9,200 |

| Germany |

12,800 |

10,400 |

| United States |

9,600 |

11,200 |

| Netherlands |

7,900 |

6,300 |

| Italy |

6,400 |

5,200 |

| France |

5,700 |

4,900 |

| Poland |

5,200 |

4,100 |

By Region

Asia Pacific Dominates the Cardboard Boxes Market

Plant-based packaging solutions use materials that come from sustainability-grown plants, which reduces dependency on non-renewable hydrocarbon sources. For instance, mushroom packaging is created from mycelium, which is the root structure of mushrooms. It is well-known for its compostability and biodegradability, and mushroom packaging has gained fast acceptance across different industries. To fully accept sustainability, a circular approach is necessary. This includes analyzing the complete lifecycle of packaging, from the extraction of raw materials to their immediate disposal. By combining practices like down-gauging into their operations, businesses can specifically reduce their environmental footprint.

North America

The demand for cardboard boxes in North America continues to grow constantly, driven by several main factors. The fast growth of e-commerce across the United States and Canada has specifically boosted the demand for lightweight, sturdy shipping boxes to protect products during delivery. Furthermore, the retail and food service industries contribute to this demand, with meal kit services and food delivery platforms heavily dependent on durable cardboard packaging. Sustainability has also grown as a main driver, as both consumers and brands find eco-friendly packaging alterations.

Pratt Industries Expands U.S. Footprint

Pratt Industries has committed to a massive expansion across multiple U.S. states. The business supports national efforts to increase domestic manufacturing and is recognized for its use of recycled paper. It is anticipated that the new facilities will highlight sustainability features and sophisticated automation. Additionally, this action shows that the U.S. is becoming more confident in its corrugated manufacturing with policy incentives and reshoring policies. (Source: NY Post)

U.S. Businesses Rethink Packaging Due to Traffic

As trade tensions rise, American businesses are getting creative with packaging to absorb cost increases from higher tariffs. To minimize shipping weight and volume, numerous brands have started switching to thinner, more compact corrugated boxes. Additionally, businesses are switching to recycled board and molded fiber in place of plastic packaging components. These changes are particularly prevalent in the consumer goods industry, where companies aim to preserve shelf appeal while maintaining profitability. (Source: AP News)

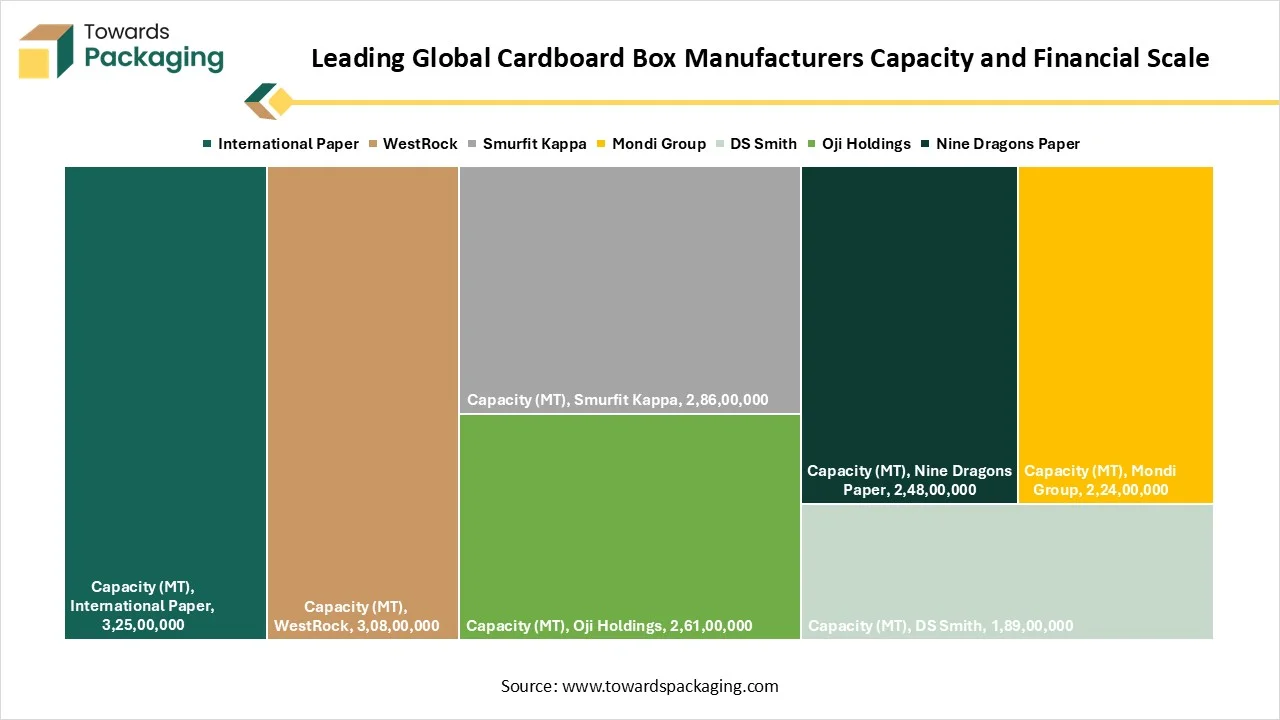

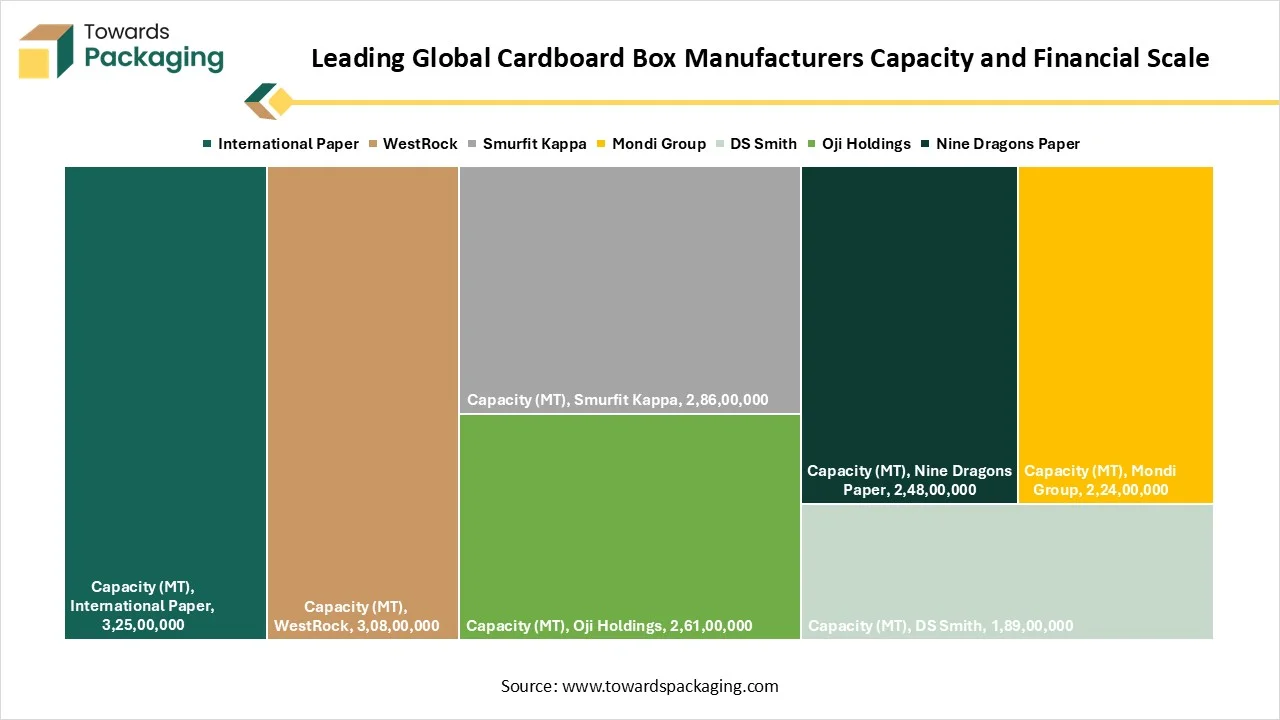

Leading Global Cardboard Box Manufacturers Capacity and Financial Scale

| Company |

Capacity (MT) |

Revenue (USD Million) |

Countries of Operation |

| International Paper |

32,500,000 |

18,900 |

24 |

| WestRock |

30,800,000 |

20,300 |

28 |

| Smurfit Kappa |

28,600,000 |

12,500 |

36 |

| Mondi Group |

22,400,000 |

9,300 |

30 |

| DS Smith |

18,900,000 |

8,700 |

34 |

| Oji Holdings |

26,100,000 |

11,600 |

20 |

| Nine Dragons Paper |

24,800,000 |

10,900 |

8 |

Cardboard Boxes Market Key Players

Recent Development

- On 7 May 2025, Amazon revealed that it would position high-level machines for making custom-fit packaging across its European network, which allows the manufacturing of custom-made cardboard boxes and paper bags for customer deliveries. (Source: ESG Today)

- On 24 January 2025, the European Commission granted conditional approval for International Paper’s acquisition of DE Smith, requiring the sale of five European corrugated box plants in France, Portugal, and Spain to address competition concerns. (Source: Packaging Dive)

- On 14 April 2025, International Paper confirmed it had entered exclusive negotiations with Germany’s PALM Group to sell five European corrugated box facilities: three in Normandy, one in Portugal, and one in Spain to comply with EU regulatory conditions. (Source: MIDLAND)

- On 3 September 2024, South Australian-based company Detpak revealed Australia’s biggest range of more than 20 commercially compostable and recyclable PBS-lined trays, cartons, and lunchboxes, meeting with legislation to cut down single-use plastics that comes into effect today. (Source: Asia Food Journal)

- On 14 June 2024, Froosh, which is a smoothie brand under Frazer, disclosed three new smoothies in particular, 750 ml cardboard packages, which is new packaging accepted by Froosh for its smoothie series that is lightweight and easy to recycle, while also specifically reducing carbon footprint. (Source: Packaging Gateway)

Cardboard Boxes Market Segments

By Type

- Corrugated Boxes

- Paperboard boxes

- Rigid Boxes

By Wall Type

- Single Wall

- Double Wall

- Triple Wall

By Box Style

- Slotted Boxes

- Telescope Boxes

- Folder Boxes

- Rigid Boxes

By Printing Technology

- Flexographic printing

- Lithographic printing

- Digital printing

- Screen Printing

By End-Use Industry

- Food and Beverages

- E-commerce and Retail

- Electronics

- Health Care

- Automotive

By Region

- Asia Pacific

- North America

- Europe

- Latin America

- Middle East and Africa