The eco-friendly flexible packaging market provides a full assessment of global revenue size, forecast growth, and evolving sustainability trends while covering every major market segment including material types, packaging formats, product functionality, end-use industries, and distribution channels. The analysis includes complete regional coverage across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, supported by 2024 baseline statistics and 2025–2034 projections. It further offers an in-depth competitive landscape of top companies such as Amcor, Mondi, Tetra Pak, Sealed Air, UFlex, and Constantia Flexibles, alongside value chain mapping, trade flow data, manufacturing footprints, supplier networks, and market share insights.

| Country | Capacity (Metric Tons / Year) |

| China | 34,20,000 |

| U.S. | 21,80,000 |

| India | 14,60,000 |

| Germany | 12,10,000 |

| Japan | 8,70,000 |

| Italy | 6,20,000 |

| Indonesia | 5,30,000 |

| Brazil | 4,80,000 |

| U.K. | 4,30,000 |

| Mexico | 4,10,000 |

The eco-friendly flexible packaging market refers to the global industry focused on the development and use of sustainable, lightweight, and environmentally friendly packaging solutions. These solutions aim to reduce plastic waste, lower carbon footprints, and meet regulatory and consumer demands for green alternatives. Packaging types include compostable films, recyclable pouches, bio-based wraps, and cellulose-based laminates, primarily serving sectors such as food & beverages, personal care, pharmaceuticals, and home care.

Eco-friendly flexible packaging continues to develop with new inventions in biodegradable and recyclable materials. By selecting flexible packaging, organizations can minimize waste, reduce costs, and invest in a healthier planet. Flexible packaging plays an important role in lowering environmental impact through lightweight design, material efficiency, expanded shelf life, and sustainability, too. With growth in multilayer flexible packaging, the sector is shifting towards a greener future. Selecting eco-friendly packaging solutions can assist businesses and consumers in contributing to a more sustainable world.

| Metric | Details |

| End-Use Industries | Food & Beverage, FMCG, Healthcare, Personal Care, E-commerce |

| Leading Region | Asia Pacific |

| Market Segmentation | By Material Type, By Packaging Type, By Product Functionality, By End-Use Industry, By Distribution Channel and By Region |

| Top Key Players | Amcor, Mondi, Tetra Pak, Sealed Air, Uflex, Constantia Flexibles |

A main benefit of Artificial Intelligence in packaging design is its potential to quickly examine a huge amount of data and draw perfect insights from it. This allows designers to create informed decisions, develop design quality, and test a large number of prototypes cost-effectively and in the shortest possible duration. AI-assisted tools access specialized databases containing information on packaging types, graphics, and materials. Utilising machine learning, they can find this data and provide design suggestions depending on the last successes and customer behaviour. This leads to quicker design cycles and greater accuracy in realization.

Additionally, AI-Powered packaging checking procedure can examine a huge range of defects, including surface defects like dents, tears, stains, creases, wrinkles, and color smudges, and any damage to logos. They can count the size of defects and choose the shade or color variations. These systems utilize high-level computer vision models to detect even subtle defects that can be skipped by human inspectors, ensuring that only high-quality packages reach the user and developing overall product integrity and customer satisfaction.

Flexible packaging owes its rising popularity to a range of advantages that make it ultimately selectable by both brands and consumers. Customers choose flexible bags and pouches over regular containers as they are convenient to open, store, and transport. Flexible packaging is selected by all for its environmental friendliness. The current flexible packaging includes a series of eco-friendly features, from the materials utilised to the intelligently designed products that expand their shelf life. It's a complete procedure that brings together sustainability and invention.

Eco-friendly flexible packaging pouches, etc., account for the use of 60% less plastic as compared to the accustomed rigid packaging. It leads to less waste reduction along with lower production costs, which means that there will be less wastage at the end of the package's shelf life, and it will assist the brand to cut some costs.

The lesser availability of sustainable and recycled materials in the industry has led to higher costs of sustainable sourcing practices. The growth of sustainable materials needs companies to invest in higher research and development, which often leads to higher costs. Recycling materials take up valuable resources to collect, clean, break down, and repurpose them. The challenge to accepting sustainable packaging is making sure that the materials serve companies as an alternative without compromising quality.

Sustainable materials must be enabled to protect the product as designed during storage, transport, and delivery to the customer. Furthermore, sustainable materials are often biodegradable. The shelf life of the product may be cut down because of the packaging material. The aim of driving towards sustainability is to reduce carbon emissions. Packaging materials are often one-time utilised and trashed after serving their purpose.

Several countries are implementing new regulations for eco-friendly flexible packaging. Green brands must adopt eco-friendly packaging to comply with these regulations. In recent years, the use of plastic packaging has been heavily criticized, and several countries have taken steps to ban or restrict its use. This growth has made it compulsory for brands to serve eco-friendly packaging solutions. In the future, eco-friendly flexible packaging is expected to become even more widespread. This trend will promote environmental consciousness and help reduce long-term costs. Green brands will both defend the environment and earn users' trust through eco-friendly packaging, staying up with developments in this space, and utilizing environmentally friendly solutions to serve as an opportunity for brands to protect a sustainable future.

Recycled plastics assist sustainability by performing more than just lowering waste. It also saves energy and reduces greenhouse gas emissions. Utilising recycled plastics rather than new materials can save a lot of energy. For instance, creating recycled PET utilises up to 66% less energy than making new PET. Utilising less energy means that we burn fewer fossil fuels and release less carbon. This is a crucial fight against climate change.

Furthermore, the recycling procedure generates fewer pollutants than the manufacturing of new plastics. Growing its environmental advantages. Recyclable packaging is a material that can be constantly collected, separated, or recovered and made for reuse or recycling as secondary raw materials. Some of these materials include cardboard, paper, glass, aluminium, and plastics, which are recyclable and are considered environmentally friendly packaging alternatives to single-use plastics.

Bioplastics refer to plastics that are made with biodegradable characteristics in hopes of helping to lower the current environmental effects of regular plastics. It is a kind of plastic made from different biological materials, such as sugarcane, corn starch, algae, or potato starch. Due to this, bioplastics were crafted as an endeavour to be more eco-friendly, with some bioplastics even being compostable and biodegradable. Bioplastics are different from regular plastics, as biodegradable or bioplastics are not, as they can take many years to fully decompose in our landfills, which contribute to huge GHG Emissions. It serves as a way for constantly utilising the flexible characteristics of plastic without further damaging the environment, as biodegradable and compostable plastics can help lower the amount of GHG emissions made by regular plastics.

Gusset bags or flat-bottom bags are designed to stand upright. They approach in rectangular shapes and have flat bottoms. The expertise of these bags is their side foldings and gussets with packed pleats. The gusset stretches as you insert products, enabling them to carry a huge quantity. These bags are usually utilised to package solutions like instant coffee, snack items, and pet food. Hence, this can be created from multilayer or plastic films. Stand-up pouches are also known as doy-pack pouches, which are more well-known and easier to use. They stand straight on shelves and can conveniently attract buyers in the industry. For better ease, these pouches come in various kinds of opening systems, such as side spout, zipper, and standard.

Wraps are a minimalist kind of flexible packaging crafted for a basic protection aim and to develop product visibility. Candies, baked goods, and fresh produce are generally covered in materials like polypropylene and cellophane. These wraps provide a simple path to protect products from pollution cases. At the same time, sachets are small flat packets that are easy for storing items like instant powders and spices. They include materials like polypropylene (PP and polyethylene (PE), which serve high barrier characteristics against oxygen and moisture, thereby confirming product freshness. Prevalent in the beverage, food, and cosmetics sector, among others, sachets are crafted for on-the-go consumption and travelling.

| Component | Weight % |

| Mono-PE / Mono-PP | 34% |

| Recycled PE/PET | 25% |

| Paper + Barrier Coatings | 17% |

| Biopolymers (PLA, PHA, PBS) | 11% |

| Water-Based Inks & Adhesives | 6% |

| Aluminum-Free Barriers | 5% |

| Others | 2% |

Recyclable packaging decreases the environmental impact of packaging waste. It assists in reducing plastic pollution and protects natural resources by keeping waste out of landfills and oceans. Utilizing recycled materials, whether plastic, glass, or paper, releases lower carbon emissions than generating single-use plastics from scratch. Imagine millions of tons of packaging waste extracted from ecosystems for clearer air, soil, and water every year. Envision the impact of the recyclable packaging lifecycle from start to processing. Due to reuse, we can recycle materials back into the packaging lifecycle to keep our planet healthy for generations to come.

Modifications in industry demand have also driven the popularity of compostable and biodegradable packaging flexible films. As users become more environmentally conscious, the urge for environmentally friendly packaging continues to grow and develop. Flexible packaging has become a new trend in the future change and updating of the packaging sector due to its environmental protection, portability, and health. Several brands have started to invest in the manufacturing of flexible packaging products to align with consumer demand for environmentally friendly packaging. With the rising ban on non-recyclable plastics, flexible packaging suppliers that offer compostable and biodegradable solutions can benefit and continue to observe the emerging laws.

Flexible packaging is changing the food and beverage sector by serving cost-effective, sustainable, and consumer-friendly solutions. With constant growth and development in technology and materials, flexible packaging is ready to play an important role in the future of packaging, which not only aligns with consumer demand but also contributes to a more sustainable and effective supply chain. Flexible packaging materials frequently have good barrier properties, which protect contents from light, moisture, and oxygen, hence expanding the shelf life of food and beverage products. This is specifically advantageous for sensitive goods, helping to reduce food waste.

Flexible packaging has come up with a breakthrough in the personal care and pharmaceutical sector. Like regular rigid packaging, flexible packaging is lightweight, versatile, and often needs fewer resources to generate. This not only lowers the overall environmental effect but also results in cost savings for pharmaceutical organizations. The flexibility of these materials enables inventive and space-effective designs, updating storage and transportation. Moreover, the lower weight of flexible packaging translates to lower transportation costs and decreased carbon emissions linked with the logistics of pharmaceutical products.

For B2B companies, the supply chain is generally constructed around long-term stability and scale, too. Think of producers sending huge shipments to distributors, with rigid delivery schedules and managed agreements. These supply chains flourish on predictability and deeper supplier relationships. B2B and industrial supply have completely dominated the eco-friendly flexible packaging industry due to large producers and distributors heavily giving importance to sustainability commitments and regulatory compliance. Bulk shipments, protective packaging for sensitive parts, and branded industrial sacks are now widely used with recycled or bio-based materials. This range of industrial demands has driven quicker invention and economies of scale, creating eco-friendly, flexible packaging that is viable and cost-effective across the huge industry.

The acceptance of flexible packaging is driven by its outstanding capability to lower material usage, carbon footprint, and energy consumption. Retailers are heavily conscious about their environmental effect, motivated by regulatory pressures and consumer demand for greener products. Main supermarkets and brands across the UK are now initiating the use of completely recyclable flexible packaging solutions. These efforts not only align with regulatory needs but also reverberate with strong sustainability credentials. Furthermore, the adaptability of flexible packaging enables inventive designs and developed product protection.

The growing demand for flexible packaging in Europe can be connected to different factors, including the highlighted consumer choice for portable, convenient, and eco-friendly solutions. Flexible packaging serves a different blend of benefits, such as product protection, expanded shelf life, and ease of transport, which have made it a favored choice for both producers and consumers. Furthermore, the shift toward sustainability in Europe has prompted the sector to focus on developing biodegradable and recyclable packaging options, driving innovation in the sector. The demand for sustainable solutions is especially revealed in the food and beverage sector, in which flexible packaging is utilised to track product quality and freshness while lowering environmental impact.

Due to rising urbanization, growing awareness, and flexible packaging options, the Asia Pacific region is at the forefront of the worldwide acceptance of sustainable packaging. Nations like India, China, and Indonesia have gained attention. Because of the heavy space for the growth in urbanization and e-commerce, India is selected as the Nation with the fastest-growing packaging industry. Although this expansion has problems. Growing environmental leakage from packaging waste is the outcome of infrastructure that has not kept up with the surge. Nevertheless, the sector is being ambitious with government programs and inventions.

Asia Pacific has managed the overall sustainable packaging growth, despite limitations such as limited recycling infrastructure. Rise in e-commerce, especially in growing economies, has mainly led to the growing need for flexible packaging to ensure durability and product safety. The choice for bio-based and recyclable materials is also developing the acceptance of flexible packaging across the region. Countries like India and China are the main contributors, with a rigid demand for packaged consumer goods driving this growth.

North America is experiencing strong growth in the eco-friendly flexible packaging market as consumer demand for sustainable, low-waste products intensifies. Major brands in food, beverage, and personal care sectors are adopting recyclable, compostable, and bio-based packaging to meet corporate sustainability goals and comply with evolving environmental regulations. The region’s advanced recycling infrastructure, investment in circular-economy technologies, and rising preference for lightweight packaging solutions are accelerating the shift. With innovation hubs and strong R&D capabilities, North America is positioning itself as a leader in next-generation sustainable flexible packaging.

Latin America is emerging as one of the fastest-growing regions for eco-friendly flexible packaging, driven by expanding consumer awareness, government initiatives aimed at reducing plastic waste, and a growing middle class demanding greener products. Countries across the region are adopting regulations that encourage biodegradable and recyclable materials, prompting manufacturers to shift toward sustainable alternatives. The rapid growth of the food, agriculture, and personal care industries is further fueling demand for cost-effective, lightweight, and environmentally responsible packaging. As investment in local production capabilities increases, Latin America is becoming a dynamic and influential market for sustainable flexible packaging solutions.

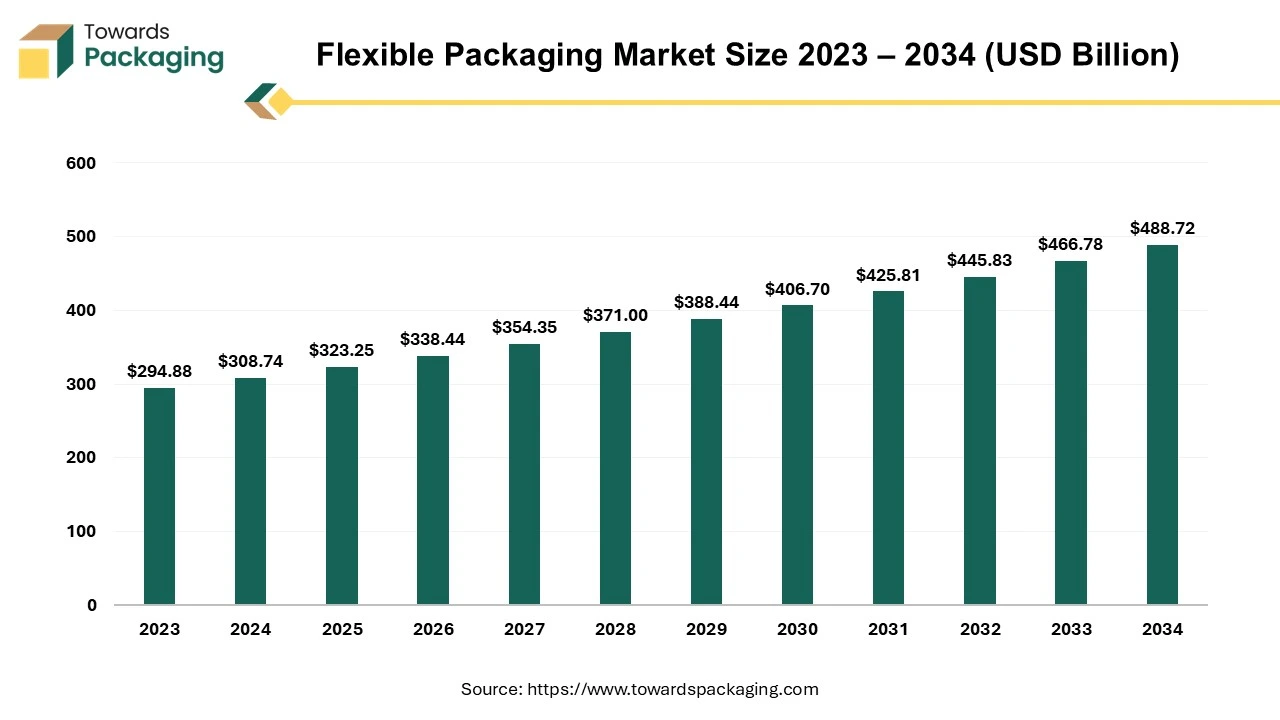

The flexible packaging market is expected to increase from USD 323.25 billion in 2025 to USD 488.72 billion by 2034, growing at a CAGR of 4.7% throughout the forecast period from 2025 to 2034. The shift in consumer behavior toward convenience, coupled with regulatory pressure for eco-friendly solutions, has accelerated market adoption across industries.

The packaging type in which packaging materials is used which can easily change shape, typically manufactured from paper, plastic, foil, or a combination of these. Unlike rigid packaging such metal cans or glass jars, bottles, flexible packaging is lightweight, durable adaptable to various product types. The common types of flexible packaging are bags, pouches, sachets, and wraps & films. The flexible packaging is lightweight, cost effective, has extended shelf-life, sustainable option and convenience features. The flexible packaging is extensively utilized for personal care, pharmaceuticals, industrial applications and food & beverages.

By Material Type

By Packaging Type

By Product Functionality

By End-Use Industry

By Distribution Channel

By Region

January 2026

January 2026

January 2026

January 2026