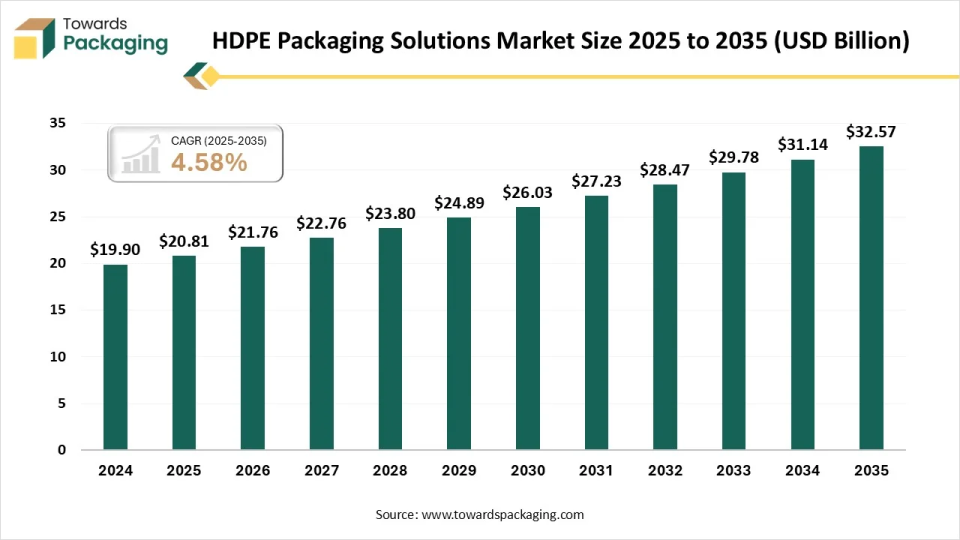

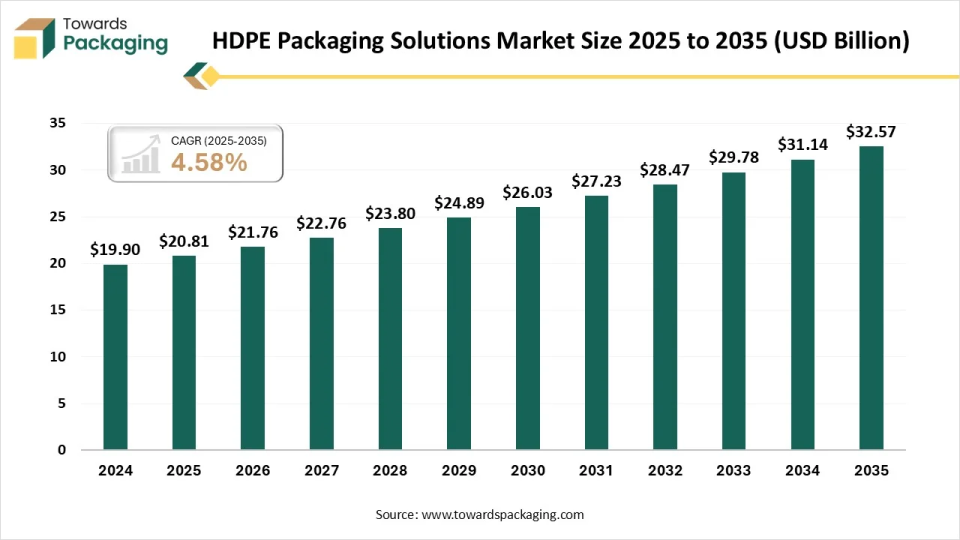

The HDPE packaging solutions market size was estimated at USD 20.81 billion in 2025 and is predicted to increase from USD 21.76 billion in 2026 to approximately USD 32.57 billion by 2035, expanding at a CAGR of 4.58% from 2026 to 2035. The increasing demand for recyclable resources, chemical-resistance, and durable packaging has influenced the growth of the market. Increasing demand for packaged products, urbanization, and changing lifestyles rising the requirement for consistent packaging.

HDPE (High-Density Polyethylene) packaging solutions refer to packaging products made from a strong, lightweight, and durable plastic known for its high strength-to-density ratio. HDPE is widely used for packaging because it is resistant to moisture, chemicals, and impact, making it ideal for containers such as bottles, jars, drums, caps, and crates used in food, beverage, pharmaceutical, agricultural, and industrial sectors. These packaging solutions are also valued for being cost-effective, reusable, and recyclable, supporting sustainability and safe storage and transportation of goods.

Technological transformation in the market plays a major role in its development by advancement of recycling technology, enhancement of material performance, digital integration and automation. Producers are integrating higher percentages of PCR content into new packaging to fulfil supervisory mandates and customer demand. Inventions in chemical recycling are allowing the adaptation of post-consumer HDPE waste generation into superior-quality virgin resin. AI and vision processes are utilized for real-time, automatic error detection and integrity assurance, fuelling efficacy and consistency.

Why Bottles Segment Dominated the HDPE Packaging Solutions Market In 2025?

The bottles segment dominated the market with highest share of 35.6% in 2025 due to versatile, recyclability, lightweight nature, and durability. Rising on-the-go feeding and e-commerce influence demand for easy-to-carry and lightweight bottles. These bottles are suitable for juices, liquids, soaps, chemicals, milk, and medicines, comprising several industries. Its lightweight nature decreases raw resources and transportation charges, profiting producers and customers. Growing pharmaceutical, food & beverage, and personal care sectors boost the requirement for reliable bottles.

The films segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to its superior protection, flexibility, and lightweight nature. These films are progressively well-suited with mono-resource recycling aim, helping circular economy exertions. They provide excellent resistance properties against light, moisture, and air, enhancing shelf life of food items, pharmaceuticals, and personal care products. The growing e-commerce industry demands cost-operative, lightweight, as well as durable packing that confirms product security during transportation which is a role effortlessly occupied by films.

Why Food & Beverage Segment Dominated the HDPE Packaging Solutions Market In 2025?

The food & beverage segment dominated the market with highest share of 38.7% in 2025 due to superior protective capacity and versatility of this packaging. Its light weight decreases carbon footprint and transportation charges, while its strong nature reduces breakage in comparison to glass. It provides a practical, superior-quality packing option at a lower charge than many substitutes. Growing urbanization and customer preference for safe, convenience, and packed food/beverages. Its capability to be moulded into rigid or flexible forms suits varied goods, from dairy and beverages to ready-to-consume meals.

The pharmaceutical segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to its chemical-resistance properties and durability. These packaging provides superior moisture and chemical resistance properties, protecting products from contamination and also prevent degradation of sensitive drugs which is an important factor for medicines integrity. HDPE packaging can be manufactured to fulfil strict guidelines for tamper-evident and child-resistant services, important for pharmaceutical goods. These are utilized for packaging of a huge range of products, from solid tablets to liquid syrups.

Why Virgin HDPE Segment Dominated the HDPE Packaging Solutions Market In 2025?

The virgin HDPE segment dominated the market with highest share of 63.4% in 2025 due to its consistent performance, superior purity, and strength. It offers superior chemical resistance, influence strength, and resistance properties against preserving product quality, moisture, and stopping spoilage. Its light weight decreases shipping charges, while its durability stops breakage. It can be easily mould into several bottle and container patterns, fulfilling varied industry requirements. Huge demand from personal care, food & beverage, and pharmaceutical sectors for reliable, safe, and aesthetically appealing packaging.

The recycled HDPE segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to favourable guidelines and performance parity. Its huge recyclability and less carbon footprint have made it a planned choice over other virgin plastics influencing the demand of this segment. Strict guidelines on one-time usage of plastics augmented the requirement for recycled resources, fuelling several industries for circular HDPE packaging option.

Why Blow Molding Segment Dominated the HDPE Packaging Solutions Market In 2025?

The blow molding segment dominated the market with highest share of 42.4% in 2025 due to increasing demand for lightweight and sustainability packaging. It is certainly durable, resistance, lightweight, and barrier to moisture, corrosion, and chemicals which is making it suitable for several containers. It provides an inexpensive, high-volume option for manufacturers, with lightweight capabilities decreasing shipping charges. The extension of e-commerce additionally fuelled the demand for cost-effective, lightweight, and protective packaging.

The injection molding segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to cost-efficiency, huge customization option, and aesthetically pleasing. The process allows rapid, huge-volume manufacturing, decreasing complete charges and meeting large orders at a faster rate. It offers enhanced strength-to-density, impact resistance, light weight, and chemical resistance which is making it suitable for sturdy packaging.

Asia Pacific dominated the market with 45.5% share in 2025, due to rapid urbanization and industrial growth. A growing middle class and changing lifestyles fuel the demand for packed personal care products, foods & beverages, and e-commerce products. Its low charge, high strength, and light weight which make it an ideal resource over metal or glass for bottles, bags, containers, and films. The development of online retail necessitates durable and lightweight packaging for transportation, promoting HDPE films and containers. Guidelines enhancing domestic polymer and plastic recycling production, together with brand owner pledges to environment-friendly resources.

Why HDPE Packaging Solutions Market is Dominating in China?

Rising consumer goods demand has raised the demand for market in China. Rising cities and increasing online shopping enhance the demand for durable, safe, lightweight packaging for several products. Increasing construction, chemical, and paint sectors depends on HDPE for strong, corrosion-barrier components, containers, and pipes. Inventions in molding processes and polymer technology enhance its quality, allowing particular grades for varied usages. Its high recyclability brought into line with their efforts to accomplish plastic waste, reassuring its acceptance over less environment-friendly choices.

Excellent barrier properties, durability, and light weight nature have influenced the demand for the market. Its durability, chemical-resistant bottles confirm product security and enhanced shelf life. High-end protection for household chemicals and pharmaceuticals increases the demand for this market. Lightweight HDPE decreases transportation charges and carbon footprint which is a major advantage for this industry. Mandates inspiring decreased plastic usage and enhanced recycling further drive HDPE acceptance as an ideal material.

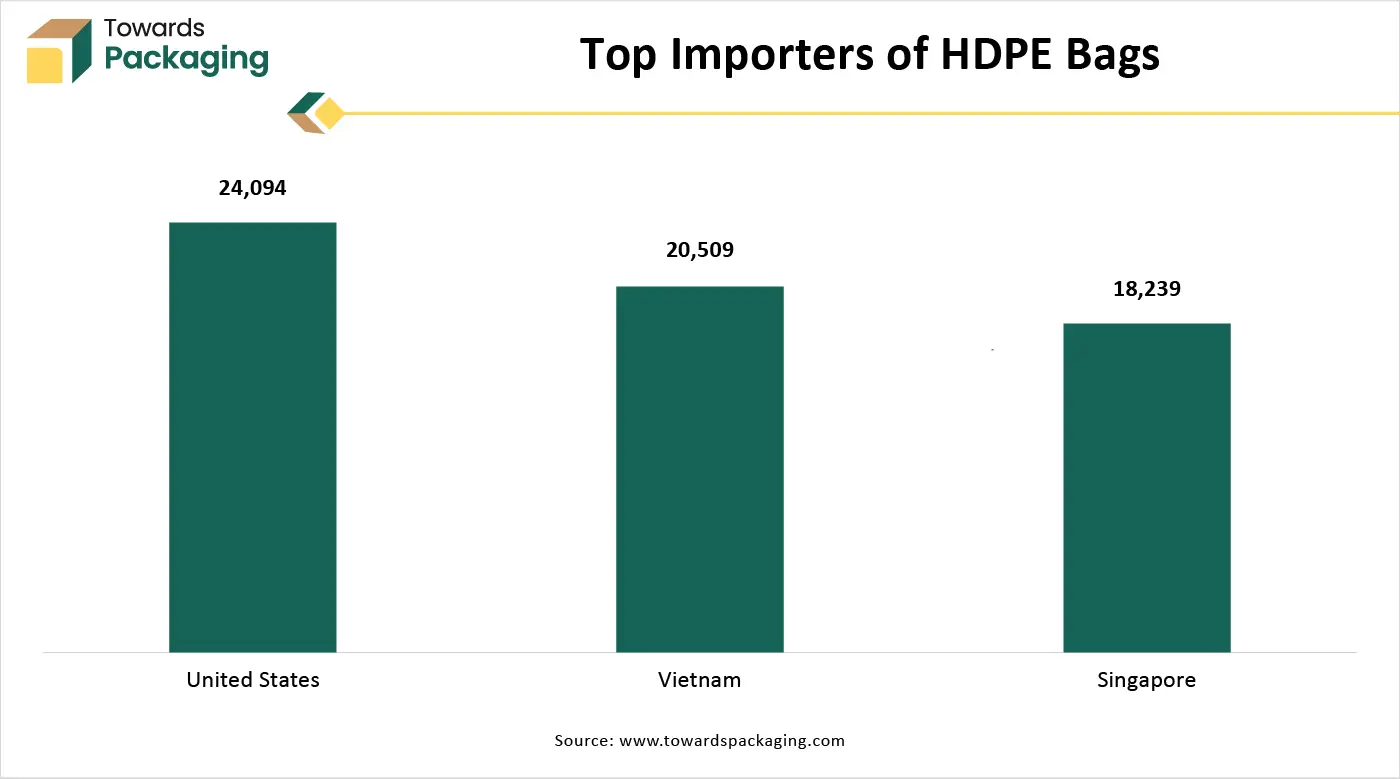

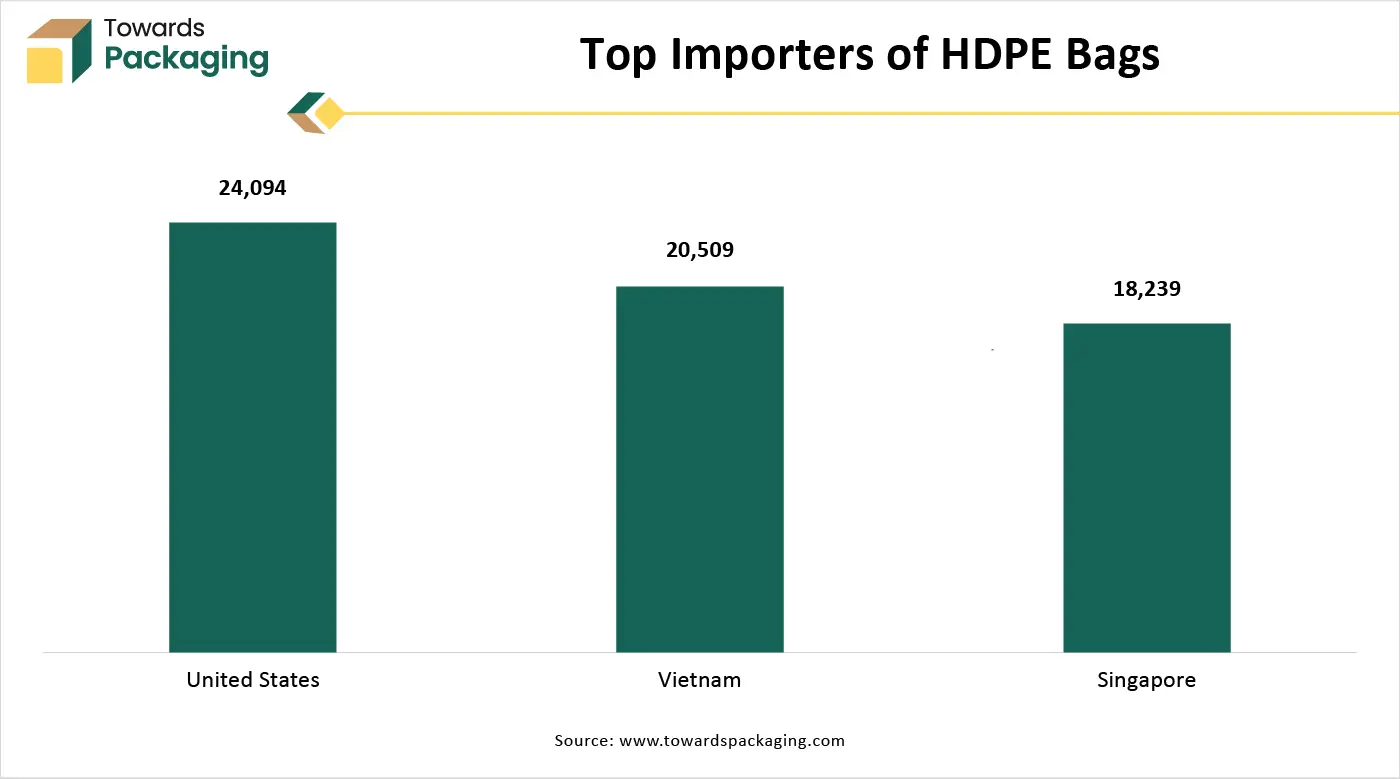

How HDPE Packaging Solutions Market is Expanding in the U.S.?

Increasing demand for lightweight and durable solutions have driven the demand of the market in the U.S. The rising demand for online shopping necessitates strong, defensive packaging, fuelling HDPE packaging utilization for transportation pouches, containers, and bags. Increasing ecological consciousness favors recyclability and the utilization of recycled content, helped by progressing recycling technology. Its lightweight nature and durability decrease resource and transportation charges which is making it economically appealing. Initiatives encouraging reduction of plastic waste and usage of environment-friendly packaging inspire invention in HDPE options, comprising bio-based choices.

The primary factors influencing the growth of market are strict ecological guidelines, circular economy, consumer preference for sustainability, and continuous technological advancement. These guidelines induce producers to accept solutions that bring into line with environment-friendly ideals. This market is influenced by both supervisory mandates and company sustainability initiates to decrease carbon footprints. Rising ecological consciousness among customers has resulted in an enhanced demand for environment-friendly and sensibly packaged goods.

Why Germany is Utilizing HDPE Packaging Solutions Market Significantly?

Rising demand for hygiene and safety concern has fuelled the development of the market. High recycling rates and increasing demand for multi-layer packaging boosting brands for the adoption of recyclable mono-resources. Its chemical inertness, water resistance, and its durability make it suitable for household products, food & beverage, and personal care containers. Growth of bio-based packaging material, PCR incorporation, and lightweight of containers are upsurging the trends.

Economic growth and rapid urbanization have enhanced the adoption of market in Middle East & Africa. The healthcare and pharmaceutical companies are also increasing, necessitating dependable and safe packaging which HDPE can offer. This type of packaging is a highly recyclable, which combined well with these developing sustainability focus and generates options for recycled content in packaging. There is an increasing emphasis on ecological concerns and management of plastic waste.

Why HDPE Packaging Solutions Market is Growing Rapidly in Saudi Arabia?

Increasing consumer demand for protective, versatile, and cost-effective packaging is the major reason behind the growth of market in Saudi Arabia. Development in healthcare and cosmetics boosts the demand for dedicated HDPE pouches and containers. These packaging are lightweight, and durable that make these suitable for transportation, decreasing carbon footprint and helping online retail to grow. Expansions of e-commerce sectors and hypermarkets influence higher demand for appealing and reliable packaging.

Enhanced disposable earning and increasing demand for convenience has influenced the growth of the market in South America. Increasing disposable earnings across this region fuel spending on packed products, helping market expansion. Excellent resistance to chemicals, moisture, and corrosion confirms product quality and security. Expansion in industries such as personal care, automotive, and chemicals, needs lightweight, robust, and cost-operative packaging boost the expansion of this market.

The HDPE packaging solutions market in Brazil is a key segment of the country’s plastic packaging industry, driven by strong demand from food & beverages, personal care, household chemicals, and industrial applications. HDPE is widely used for bottles, containers, drums, and crates due to its durability, chemical resistance, low weight, and recyclability. Market growth is supported by rising urbanization, expanding FMCG consumption, and the growth of e-commerce.

Recent Developments

In December 2025, ALPLA has announced about the development of food-safe HDPE recycled packaging material. The company has collaborated with NTCP for affordable solution of plastic food packaging. The developed recycling technology is expected to generate food-safe HDPE recycled material (rHDPE).

In November 2025, TOPPAN Group introduce hybrid production line which is capable of manufacturing both biaxially-oriented polyethylene (BOPE) and biaxially-oriented polypropylene (BOPP) film for the sustainable packaging solutions.

The major raw materials utilized in this market are virgin HDPE resin, bio-based HDPE, and recycled HDPE. It is ensuring the resource fulfils relevant values are crucial.

Key Players: Dow Chemical Company, SABIC

The component manufacturing in this market comprises manufacturing processes such as extrusion, injection molding, blow molding, and thermoforming. The precise manufacturing process relies on the end component's chosen shape and usage.

Key Players: Regent Plast, Time Technoplast

This segment comprises enhanced operational efficacy and offers protection to products. It promotes sustainability options for packaging with efficient supply chain distribution.

Key Players: Elham MultiPlast LLP, WelPack Industries Pvt. Ltd.

By Product Type

By End-Use Industry

By Material

By Technology

By Region

February 2026

February 2026

February 2026

February 2026