Growth and Regional Insights into the Hermetic Packaging Market

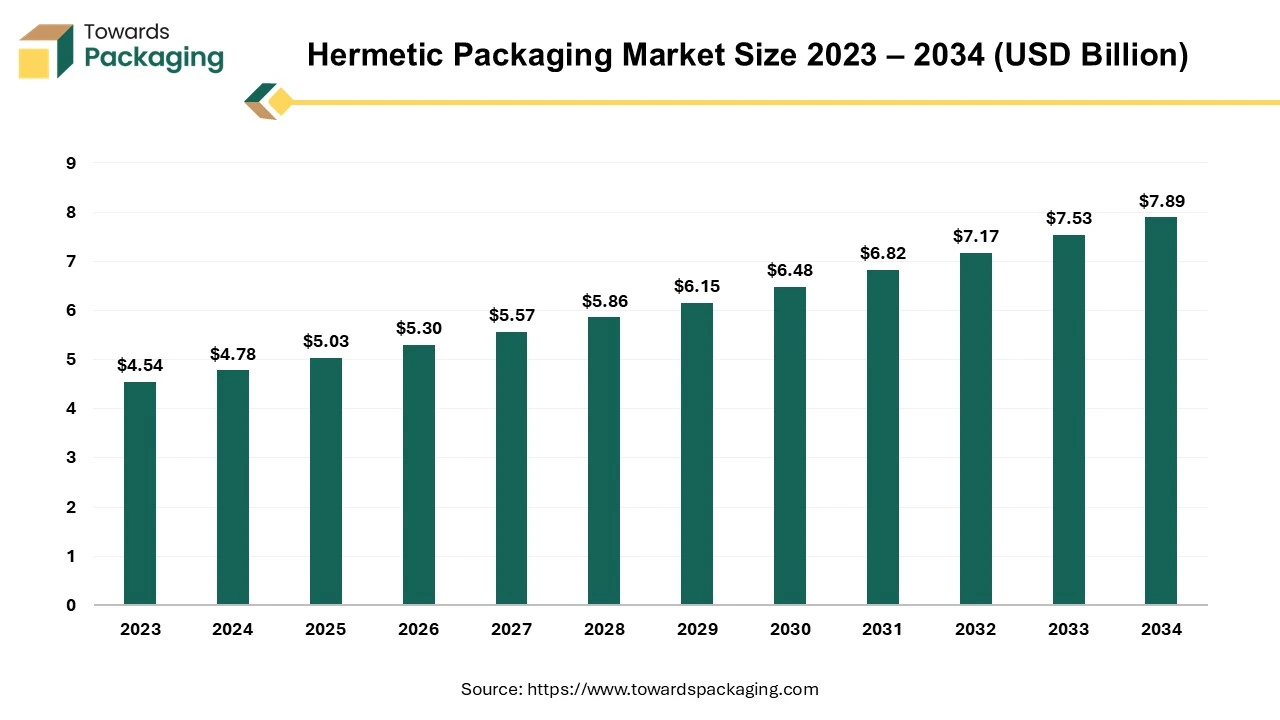

The hermetic packaging market is forecasted to expand from USD 5.30 billion in 2026 to USD 8.44 billion by 2035, growing at a CAGR of 5.3% from 2026 to 2035. This growth is supported by advancements in materials, increased miniaturization, and applications in sectors like aerospace, defense, and telecommunications.

The market is segmented by packaging configuration (multilayer ceramic, pressed ceramic, and metal can), by material type (passivation glass, transponder glass, reed glass), and by region (North America, Europe, Asia Pacific, Latin America, Middle East, and Africa). Key players such as Schott AG, AMETEK Inc., and Materion Corporation continue to drive innovation. Competitive analysis highlights strategic acquisitions and the impact of AI on production efficiency.

Important Revelations

- The global hermetic packaging market is expected to grow at a CAGR of 5.3% from 2025 to 2034.

- Advancements in materials, increasing miniaturization, emerging 5G applications, and sustainability are key trends.

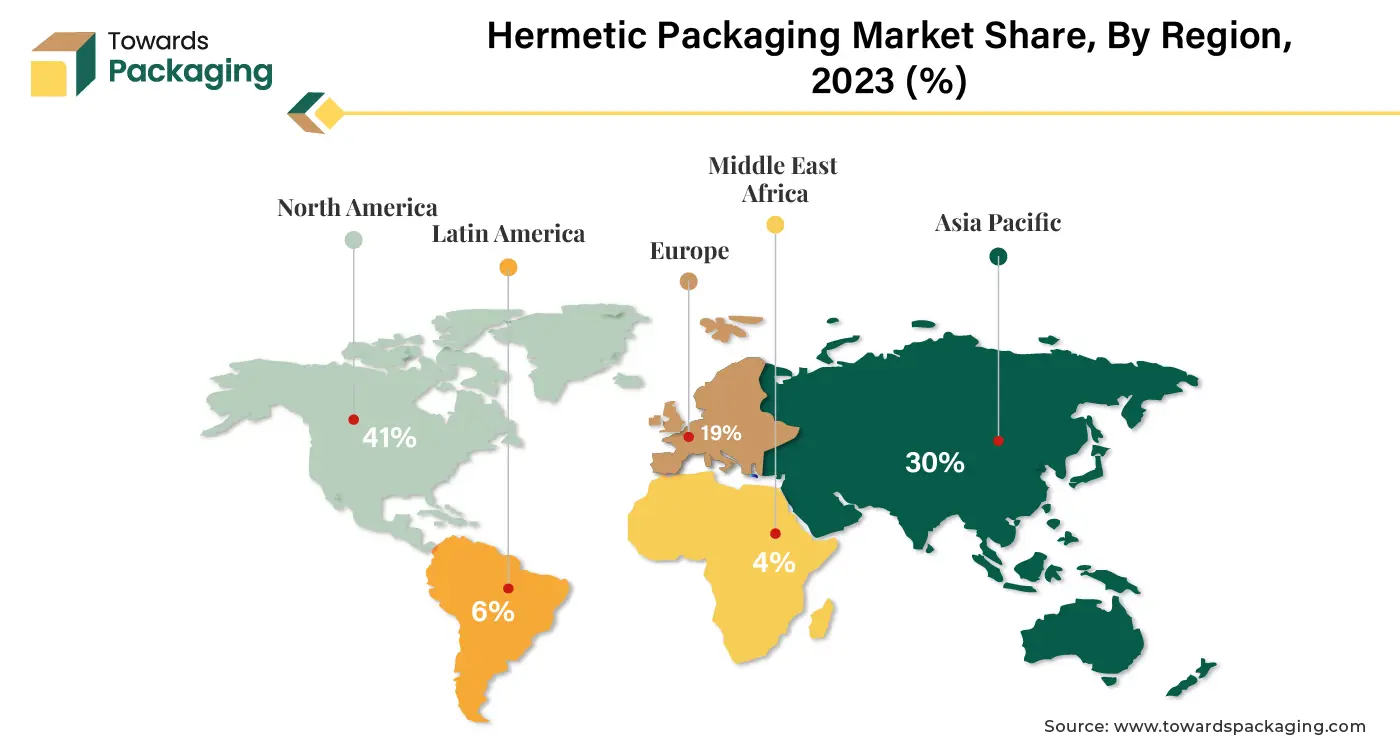

- Asia Pacific dominates the market, followed by North America.

- Major players include Schott AG., Willow Technologies, AMETEK Inc., Amkor Technology, and Materion Corporation.

- Growing demand for high-reliability electronics in industries like aerospace, defense, and telecommunications drives market growth.

- Maintaining product integrity and meeting stringent regulatory requirements pose challenges.

- AI-driven advancements, emerging 5G applications, and the increasing demand for sustainable packaging solutions offer significant growth opportunities.

Hermetic packaging refers to a method of sealing electronic or mechanical components in a way that prevents the entry of external elements such as air, moisture, or other contaminants. Hermetic sealing and packaging play a crucial role in safeguarding electronic components, preventing the infiltration of gas and moisture that could lead to premature failure of systems. The materials recognized as hermetic include glasses, metals, and ceramic packaging and seals. These inorganic materials possess enduring properties and inherently exhibit minimal penetration levels. By utilizing these materials, high-quality hermetic packages can be crafted, maintaining moisture levels inside packages well below the critical threshold of 5000 PPM (parts per million) for extended periods, ranging from years to decades based on the specific design and application.

Hermetic packages come in a diverse array of designs, tailored to meet the stringent electrical and thermal specifications required in various applications such as downhole drilling, space exploration, and medical devices. The hallmark of hermetic containers is the presence of attachment points for a metal or ceramic lid, typically in the form of a seal ring or other metallized components. This characteristic ensures the creation of a sealed environment.

Vacuum sealing and getter utilization, which may be essential for Micro-Electro-Mechanical Systems (MEMS) packages. These additional measures contribute to maintaining the desired hermetic conditions, especially in applications where stringent environmental control is imperative. The versatility of hermetic packaging makes it a vital component in preserving the integrity and functionality of electronic systems across various industries.

Key Metrics and Overview

| Metric |

Details |

| Market Size in 2024 |

USD 4.78 Billion |

| Projected Market Size in 2034 |

USD 7.89 Billion |

| CAGR (2025 - 2034) |

5.3% |

| Leading Region |

North America |

| Market Segmentation |

By Configuration, By Type and By Region |

| Top Key Players |

Schott AG, Willow Technologies, AMETEK Inc., Amkor Technology, Materion Corporation |

The Critical Role of Hermetic Packaging in Oil, Gas, and Space Exploration

The escalating demand for high-reliability electronics is evident in industries like oil and gas exploration (downhole drilling) and space exploration, where robust electronic systems are paramount. In these applications, hermetic packaging plays a pivotal role by delivering essential protection against severe environmental conditions. The hermetic sealing ensures the integrity and longevity of electronic components, meeting the stringent reliability requirements of industries operating in challenging and demanding environments. As a result, hermetic packaging serves as a crucial solution to safeguard electronic systems in high-stakes sectors where reliability is a top priority.

AI Revolutionizing the Hermetic Packaging Market with Enhanced Efficiency, Innovation, and Growth

Artificial Intelligence (AI) is revolutionizing the Hermetic Packaging Market by driving growth through enhanced efficiency and innovation. AI integration brings a range of benefits that are reshaping the industry landscape. Predictive analytics powered by AI enables manufacturers to optimize production processes, reducing downtime and improving product quality. By analyzing historical data and real-time inputs, AI systems can foresee potential issues and recommend proactive maintenance, ensuring uninterrupted operations and minimizing waste.

AI-driven automation in packaging lines accelerates production speeds and ensures precision, which is crucial for maintaining the integrity of hermetic seals. This leads to reduced costs and faster time-to-market. AI algorithms also facilitate advanced quality control through machine vision systems, identifying defects that may go unnoticed by human inspectors.

AI enhances supply chain management by predicting demand patterns and optimizing inventory levels. This not only improves efficiency but also reduces costs associated with overproduction and stockouts. As AI technologies continue to evolve, their integration into the Hermetic Packaging Market promises to drive further innovations, support sustainable practices, and create new growth opportunities for industry players.

Hermetic Packaging Market Trends

| Trends |

| Advancements in Materials and Technologies |

Ongoing developments in materials and sealing technologies contribute to more efficient and reliable hermetic packaging. Innovations in sealants, encapsulation materials, and manufacturing processes aim to enhance performance and reduce costs. |

| Increased Miniaturization |

The trend towards smaller and more compact electronic devices has driven the need for hermetic packaging solutions that can accommodate miniaturized components. This trend is particularly prominent in industries such as consumer electronics and medical devices. |

| Emerging Applications in 5G Technology |

The deployment of 5G technology involves increased use of hermetic packaging to protect sensitive electronic components in telecommunications infrastructure. The higher frequencies and greater data transfer rates in 5G networks necessitate robust hermetic sealing to maintain optimal performance. |

| Focus on Sustainability |

The industry has shown a trend toward environmentally sustainable practices. Manufacturers are exploring eco-friendly materials and production processes for hermetic packaging, aligning with broader corporate and industry-wide sustainability initiatives. |

Regional Insights

Asia Pacific Leads the Hermetic Packaging Market with Strong Growth and Market Share

Asia Pacific region has emerged as a frontrunner in the global hermetic packaging market, showcasing robust growth and a commanding market share. This leadership position can be attributed to several key factors that reflect the region's dynamism and influence in the electronics and manufacturing sectors. The Asia Pacific region is a manufacturing powerhouse, housing some of the world's largest electronics producers and suppliers. Countries like China, Japan, South Korea, and Taiwan boast advanced manufacturing capabilities and host major semiconductor and electronic component manufacturers.

The extensive production of electronic devices across various regional industries drives the demand for hermetic packaging. Leading automobile suppliers projected 15% to 20% growth as more government rules global mandated electronic stability control units and China embraced airbags on a large scale. Sensors were first used in airtight containers for airbags and antilock brake systems. These were MEMS structures in cavity packages, with pressure sensors occupying most space.

The rapid expansion of industries such as consumer electronics, telecommunications, and automotive in the Asia Pacific fuels the need for reliable hermetic packaging solutions. As these industries flourish, there is a parallel surge in demand for electronic components that require protection from environmental factors, further boosting the adoption of hermetic packaging. The region's role as a technology hub contributes to advancements in hermetic sealing technologies and materials. Research and development initiatives in countries like Japan and South Korea are pivotal in enhancing the performance and efficiency of hermetic packaging solutions and driving market innovation.

Moreover, the Asia Pacific region is witnessing substantial investments in infrastructure development, including telecommunications networks and aerospace projects. These investments increase the requirement for high-reliability hermetic packaging, particularly in applications where electronic components are exposed to challenging environmental conditions.

Asia Pacific's dominance in the hermetic packaging market can be attributed to its manufacturing prowess, expanding industries, technological advancements, and significant investments in infrastructure. As the region continues to lead in electronics production and innovation, it will likely maintain its prominent position in the global hermetic packaging landscape.

The fast growth in consumer electronics such as laptops , smartphones and wearable devices which has grown the demand of reliable semiconductor components.Hermetic packaging is important to make sure the long -term functionality in terms of these components specifically in toxic environments. Furthermore , the market is gaining attention because of growing demand of advancements in semiconductor technology, electronic devices and rigid regulatory requirement in industries such as aerospace and healthcare.

- In October 2021, the leading global manufacturer of chocolate and confectionary goods, Ferrero India Private Limited, a division of the Ferrero Group, announced the introduction of "Ferrero Rocher Moments" today. The new product is thermoresistant, and even in tropical temperatures, the rich flavour is preserved thanks to its specially created hermetic container.

North America Follows with Strong Market Presence and Technological Innovation

North America has secured a formidable position as the second-largest region, characterized by a robust market presence and influential factors driving its growth these standing results from several fundamental dynamics within the region's industrial landscape. North America boasts a thriving technology sector, particularly in the United States, with numerous companies specializing in developing and producing advanced electronic systems. The demand for hermetic packaging is propelled by the critical need to shield sophisticated electronic components from environmental factors, ensuring reliability across diverse applications.

The region's dominance in aerospace and defence industries further contributes to adopting hermetic packaging solutions. As electronic systems play a pivotal role in these sectors, the necessity for hermetic seals to withstand stringent environmental conditions elevates the market demand. Additionally, North America is home to cutting-edge research and development initiatives, fostering continuous innovation in hermetic sealing technologies. This commitment to technological advancement reinforces the region's position by providing state-of-the-art solutions that meet the evolving requirements of various industries.

Many factors, including a robust technology sector, a strong presence in aerospace and defence, and a commitment to innovation through research and development, drive North America's second-leading status in the hermetic packaging market. As electronic applications advance, North America is poised to remain a key player in shaping the global hermetic packaging landscape.

- In August 2023, North America’s EPC Space has unveiled two new rad-hard GaN transistors with ultra-low on-resistance and high current capacity for high power density applications. These gadgets come in hermetic packaging with tiny footprints.

One of the major reasons for North America’s domination in this market is the share of U.S. The aerospace and defense industry in the country has always been strong and there is a growing demand for microcontrollers as well as integrated chips utilized in these defense products. The sector of consumer electronics is seeing a massive surge in the U.S. further aiding this market’s growth in the region. The rising demand of the healthcare sector for quality and hygienic packaging in Canada will push the market ahead in this country. Such factors are significant contributors for the region of North America to be a major region for the hermetic packaging market.

- In November 2024, Micross Components, a global provider of microelectronic components and services, completed a huge investment in the modernization of its Hi-Rel Diodes foundry and manufacturing operations in Reynosa, Mexico. This state-of-the-art facility will boost the operations and the output.

Europe:

The demand for hermetic packaging in Europe is very high as this micro-controllers are very complicated in terms of spacecraft, aircraft and defense equipments.Hence , the urge for hermetic packaging is expected to grow in the upcoming years. The Canada’s hermetic packaging market is expected to rise at an fastest CAGR during the forecast period (2025-2034).

Optimizing Supply Chain Efficiency in the Hermetic Packaging Sector

In the hermetic packaging market, the supply chain operates with a focus on maintaining product integrity and extending shelf life. The process begins with raw material suppliers who provide essential components such as aluminum foils, barrier films, and sealants. These materials are then transported to manufacturers specializing in hermetic packaging solutions, where they are processed into various packaging formats like blister packs, vacuum-sealed pouches, and cans.

Manufacturers adhere to strict quality control standards to ensure that the packaging effectively protects contents from moisture, oxygen, and contaminants. Once produced, the packaging materials are distributed to end-users, including pharmaceutical companies, food and beverage producers, and electronics manufacturers. These end-users rely on hermetic packaging to safeguard their products during storage and transportation.

Logistics play a crucial role in the supply chain, involving coordinated transportation, warehousing, and inventory management to ensure timely delivery and minimize disruptions. Effective communication and collaboration among suppliers, manufacturers, and distributors are essential to address challenges and optimize the supply chain. Overall, a robust and efficient supply chain is critical to meeting the growing demand for high-quality hermetic packaging solutions.

Advancements in Multilayer Ceramic Packages for Electronic Packaging Solutions

Multilayer Ceramic Packages undergo a meticulous process involving the metallization, lamination, and firing of ceramic tape layers to create the package body. Following this, leads are brazed onto the package body. The metallized sections undergo electroplating to augment electrical performance, typically involving nickel followed by gold. Achieving an airtight seal is accomplished by soldering a metal lid onto the metallized and plated seal ring, leading to their classification as solder seal packages.

The distinctive characteristic of multilayer packages lies in their construction, providing package designers with the flexibility to integrate various electrical enhancements within the package body. This encompasses power and ground planes to minimize inductance, shield planes to reduce cross-talk, and establishing controlled characteristic impedance for signal lines. The versatility of multilayer ceramic packages positions them as sophisticated solutions in electronic packaging. Beyond ensuring hermetic sealing, these packages offer the capability for intricate electrical optimizations. This adaptability caters to diverse applications' specific and evolving requirements, making multilayer ceramic packages a preferred choice for industries demanding advanced electronic solutions with enhanced performance and reliability.

- In November 2021, LMA Packaging UK launched a new, simple-to-open flow pack package designed for the medical industry, continuing its tradition of innovative pack design.

Rising Demand for Hermetic Packaging in Defence Sector for Enhanced Security and Reliability

The imperative for collective defence is paramount. This extends to critical components such as weapons, guidance and navigation systems, countermeasures, military vehicles, and power sources.

A nation's security heavily relies on the efficiency of its military forces against external threats. Surveillance and armament must be executed precisely to ensure a robust defence system, requiring secure packaging and transportation. Hermetic packaging emerges as the optimal solution for these critical applications.

The defence industry is witnessing a notable uptick in the utilization of hermetic packaging. This trend reflects the increasing recognition of the importance of securely packaging and transporting military equipment. Consequently, companies operating in the hermetic packaging market are poised to reap continued benefits from the expanding use of hermetic packaging in the defence sector throughout the forecast period.

- In January 2023, Microchip Technology Inc. unveiled the Voltage Regulator, its first commercial-off-the-shelf rad-tolerant power device. The gadget can be obtained for prototype trial in both polyethylene and hermetic ceramic to meet the mission requirements.

Passivation Glass Leading the Way in Hermetic Packaging for Enhanced Longevity and Reliability

Passivation glass stands out as a leading type in the hermetic packaging market, playing a pivotal role in ensuring the longevity and reliability of electronic components. This type of hermetic packaging uses glass as a protective layer, creating a barrier against external elements such as moisture and gases. Passivation glass is applied to the surface of electronic devices, forming a robust shield that prevents corrosion, oxidation, and other environmental factors that could compromise the functionality of sensitive components.

One of the critical advantages of passivation glass is its effectiveness in maintaining the hermeticity of the package over an extended period. The glass layer serves as a durable and inert barrier, offering exceptional resistance to ingress harmful substances. This is particularly crucial in industries where the longevity and reliability of electronic systems are paramount, such as aerospace, defence, and medical applications.

Moreover, passivation glass is known for its compatibility with various sealing methods, contributing to its widespread adoption in the manufacturing of hermetically hematic packages. As industries continue to demand high-performance and durable electronic components, passivation glass remains a forefront choice in the hermetic packaging market, ensuring the protection and integrity of critical devices in diverse and challenging environments.

- In August 2023, SCHOTT Introduced Aerospace Lightweight Microelectronic Packages. The innovative hermetic packaging from SCHOTT weighs up to two-thirds less than traditional kovar-based microelectronic packages.

Competitive Landscape and Key Players in the Hermetic Packaging Refrigerant Market

Several key players characterize the competitive landscape of the hermetic packaging refrigerant market. Major companies in this market include Schott AG., Willow Technologies, AMETEK Inc., Amkor Technology, Materion Corporation, Sinclair Manufacturing Company, SGA Technologies, Micross Components Inc., Egide SA and Televec. These companies focus on strategies such as mergers and acquisitions, product innovations, and expanding their regional presence to gain a competitive edge. The market is also influenced by changes in regulatory requirements and consumer preferences shifts, driving the need for innovative and sustainable hermetic packaging refrigerant solutions.

Recent Developments:

- On 11 April 2025, ULMA’S packaging FM 400 has risen as an perfect solution which is an horizontal flow Pack packaging machine which is crafted to align with demand of high -speed Modified Atmosphere Packaging with fresh food applications.

- On 14 October 2024, Tronics Microsystems which is an TDK Company has upgraded its GYPRO4000 Product line which includes a tactical -grade digital MEMS Gyroscopes.

Key Players Driving Innovation in the Hermetic Packaging Refrigerant Market

Recent Strategic Acquisitions in the Hermetic Packaging Market

- In May 2023, Macross Expanded its Offering of Packaging and substrate capabilities for Multi-Chip Modules, ASICs, and PCBs with the Acquisition of Technograph Microcircuits Ltd.

- In July 2022, Electronic Products, Inc. was acquired by Douglas Electrical Component, a producer of hermetic interconnects based on epoxy.

- In November 2022, QnnectTM, an Arcline Investment Management portfolio business, acquired Hermetic Solutions Group ("HSG"). It enables Qnnect to expand its services into airtight containers and enhance its current range of speciality interconnect solutions.

- In January 2021, Cristek Interconnects, Inc., a top producer of specialist interconnect products and assemblies, was purchased by Hermetic Solutions Group ("HSG" or the "Company"), a global supplier of highly engineered performance and protection solutions for mission-critical microelectronics.

Comprehensive Segmentation and Insights into the Hermetic Packaging Market

By Configuration

- Multilayer Ceramic Packages

- Pressed Ceramic Packages

- Metal Can Packages

By Type

- Passivation Glass

- Transponder Glass

- Reed Glass

By Region

- North America

- Europe

- Asia Pacific

- LA

- MEA