Industrial Packaging Market Data-Rich Analysis on Size, Segmentation, Regional Dynamics, Company Strategies, Porter’s/PESTLE, Value Chain Economics, Trade Metrics, and Vendor Mapping

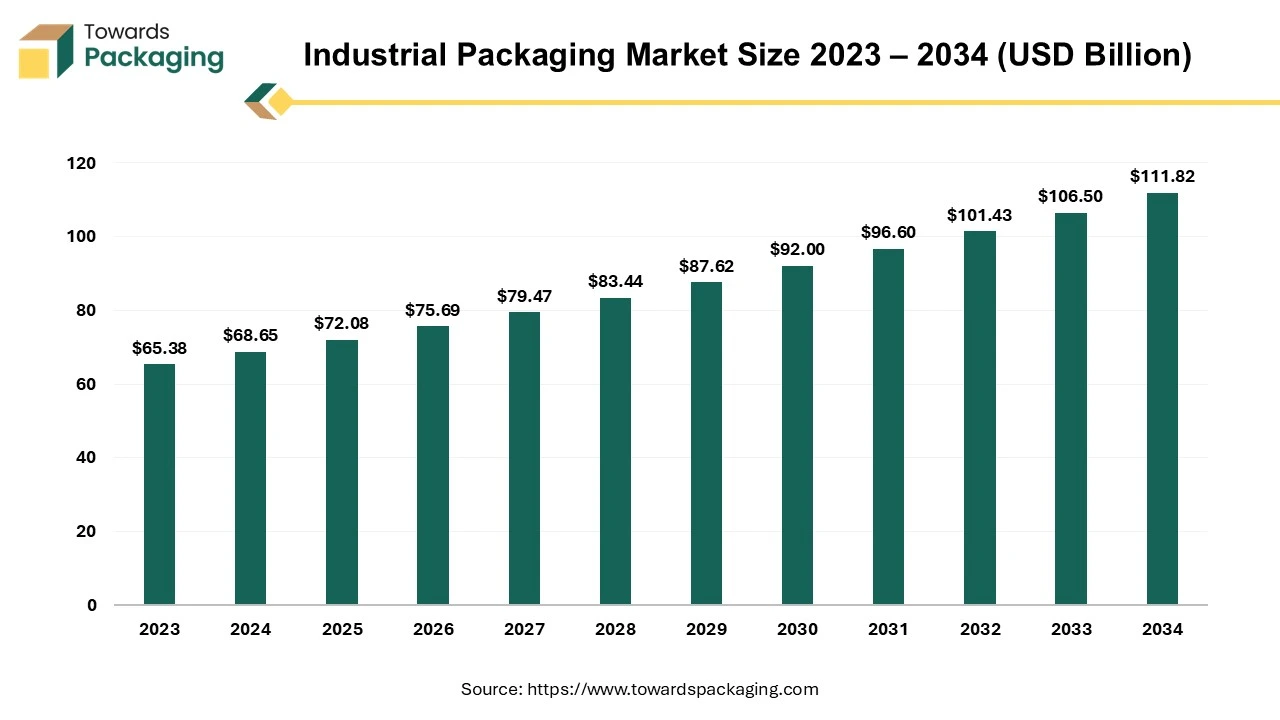

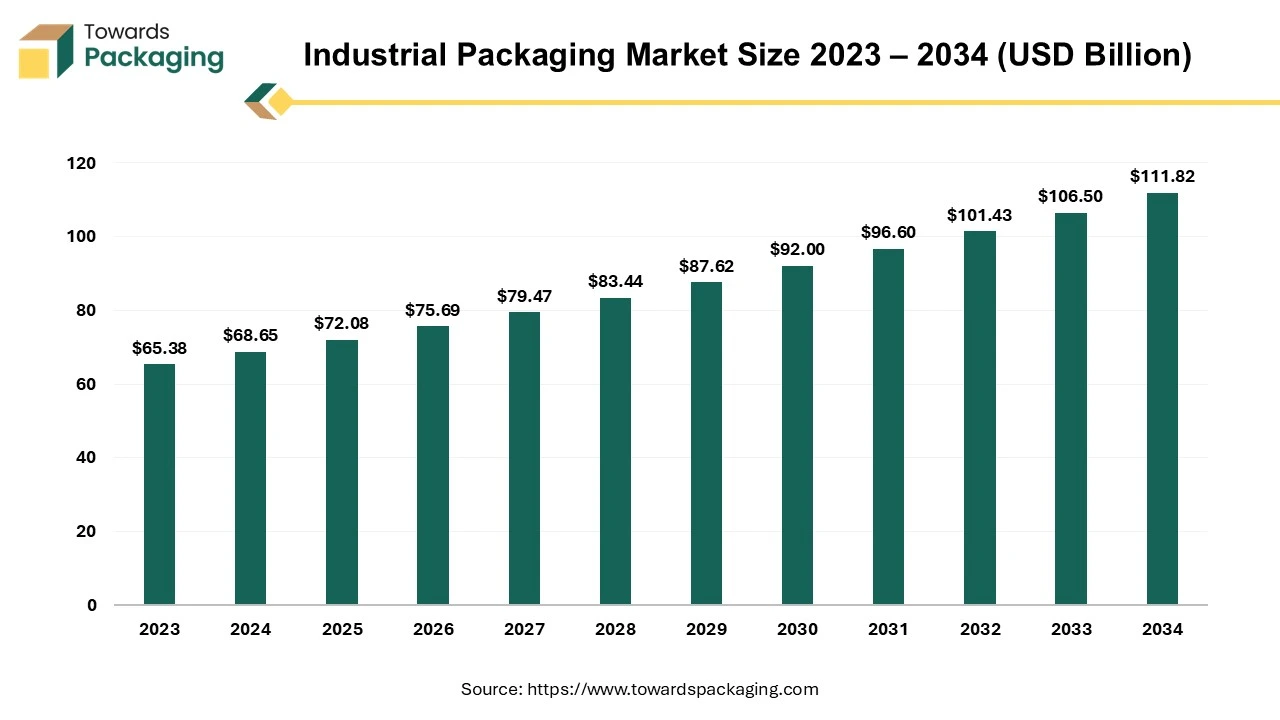

The industrial packaging market is forecasted to expand from USD 75.69 billion in 2026 to USD 117.41 billion by 2035, growing at a CAGR of 5% from 2026 to 2035. This report quantifies the market by material (plastic, metal, wood, paper/cardboard, steel, others), product (IBCs, drums, corrugated boxes, sacks, crates, pails, wrappers, others), and end use (chemicals, food & beverage, pharmaceuticals, automotive, building & construction, personal care/cosmetics, electronics, textile). It provides regional datasets for North America, Europe, Asia Pacific, Latin America, and Middle East & Africa, with country-level splits, growth rates, and share evolution.

Report Highlights: Important Revelations

- Advancements influencing industrial packaging in the Asia-Pacific region.

- Exploring the vital role of industrial packaging in North American sectors.

- Dominance of industrial packaging in today's era unveiled by plastic innovations.

- Progress of industrial storage through intermediate bulk containers.

- Ensuring chemical safety during transit and storage with industrial packaging.

Industrial packaging is essential to companies that ship or deliver items to clients. Whether it's a retail shop, product manufacturer, distributor, wholesaler, or an e-commerce portal selling products around the globe, relying on industrial packaging solutions is essential for ensuring the protection and security of goods while in transit. Over the last few decades, the use of industrial packaging for direct delivery to customers' doorsteps has steadily grown. Distribution systems that involved multiple interactions and storage periods presented difficulties, significantly reducing a product's shelf life. The use of industrial packing has enabled for faster and less destructive transit, consequently abolishing these time restrictions. This benefit has reduced manufacturing cycles and improved possible amounts for companies.

Industrial packaging has enabled manufacturers and merchants save costs on inventories. Significantly the potential to transfer products more quickly and with less damage, firms are increasingly choosing for purchasing on a daily basis opposed to periodic or weekly purchases, significantly eliminating inventory holding expenses. An important part of industrial package design is ensuring that items be transported safely and with little damage from point A to point B. Palletization stacking patterns and pallet material choices are among the design factors. The global market for industrial packaging market is expanding rapidly due to the extensive usage of packaging to protect goods or materials during transit. This development indicates the vital role that industrial packaging plays in modern supply chains, allowing items to travel efficiently and securely across sectors.

- In February 2024, Antalis, a paper and industrial packaging firm, has entered into a formal agreement to buy Pakella, another packaging company.

Industrial Packaging Market Trends

- Embracing sustainable packaging: Brands should balance durability, weight, logistics, and efficiency, while also solving the rising demand for recyclable, sustainable, and lightweight solutions. As e-commerce continues to expand, the complexity of packaging increases, needing a design that can withstand shipping pressures, lower environmental effects, and track product integrity.

- Digitally connected packaging: The advantages of smart packaging are several, such as extending shelf life, improving product safety, and developing consumer safety and engagement. Technology not only develops the consumer experience but also provides valuable data to organizations for product development and marketing.

- Personalized and aesthetic packaging: Aesthetic considerations play a major role in the manufacturing process of packaging. Brands are discovering design features such as material choice, texture, and innovative closures to develop the tactile and visual look of the products. The attentive integration of additional design elements like interactive features, sustainable-oriented colours and images, and luxury finishes can mainly elevate the user experience.

- The rising technological advancements such as automation, sustainable material, and smart packaging are expected to enhance the market growth.

- The creation of safety and tracking technologies is enhancing the efficiency and functioning of industrial packaging and further contributing to propel market growth.

- The increase in demand for industrial packaging in various sectors such as construction, agriculture, pharmaceuticals, food and beverage, and chemicals is expected to increase the demand for the industrial packaging market.

- The increasing preference for environment-friendly packaging solutions and sustainability is offering a favorable market outlook. Furthermore, the rising demand for intelligent packaging technologies to improve safety and tracking is supporting the market expansion.

AI Integration Driving Innovation in the Industrial Packaging Market

The integration of Artificial Intelligence (AI) is transforming the Industrial Packaging Market by enhancing operational efficiency, product innovation, and supply chain management. AI technologies, such as machine learning and computer vision, are revolutionizing industrial packaging processes through advanced automation and data analytics.

AI-driven automation improves production efficiency by optimizing packaging lines and minimizing human error. Intelligent systems can adjust packaging parameters in real-time, ensuring consistent quality and reducing waste. Predictive maintenance powered by AI anticipates equipment failures, thereby reducing downtime and lowering maintenance costs. AI also plays a crucial role in supply chain optimization. Through data analysis and predictive analytics, AI systems forecast demand, manage inventory more effectively, and streamline logistics. This leads to reduced lead times, lower costs, and improved customer satisfaction.

Market Dynamics

Driver

- Increasing demand for product protection of Industrial products and supplies are frequently heavy, bulky, and susceptible to environmental conditions such as moisture, stress, vibration, and corrosion.

- For instance, in March 2024, 3M launched the world's first innovation, the first known padded, paper-based curbside recyclable mailer material that businesses can also use to automate their packaging process to help redefine how the world packs, ships, and sells goods across all industries. This new material is called 3M Padded Automatable Curbside Recyclable Mailer Material.

Opportunity

- Embracing digital technology like the Internet of Things (IoT), sensors, and RFID allows for smart features in industrial packaging.

- In February 2024, the launch of a flexible packaging manufacturer producing custom solutions was announced by NBi FlexPack. To allow for quick turnaround times for shipping in the U.S., its products are made in the U.S.

Restraint

- Industrial packaging must adhere to several rules and standards controlling packaging materials, labelling, transportation, and hazardous material management.

Innovations Shaping Industrial Packaging in Asia-Pacific

Asia Pacific is expected to grow fastest during the forecast period. The market growth in the region is driven by the increasing demand for food and pharmaceutical products. China, India, Japan and South Korea are the fastest growing countries propelling market growth. China’s industrial packaging is dynamic and vast and offer a wide range of higher quality solutions.

- In December 2024, the value added of industrial enterprises above the designated size increased by 5.8 percent over the previous year, the total value added of industrial enterprises above the designated size increased by 0.64 percent over the previous month and the total value added of industrial enterprises above the designated size increased by 6.2 percent year on year.

Industrial packaging offers an essential part in supply chain management in the Asia-Pacific region, ensuring the secure and effective movement of goods across a range of sectors. The need for effective and dependable packaging solutions has increased dramatically due to the region's quick industrialization, increasing urbanisation, and growing trade networks.

The Asia-Pacific region's industrial packaging incorporates an extensive variety of materials and technologies that are customised to satisfy the unique requirements of different industries, such as manufacturing, electronics, automotive, food and beverage, pharmaceuticals, and retail. Packaging is essential to these sectors as it helps to protect goods during transportation, reduce damage, and meet legal requirements.

The Asia-Pacific region is the centre for packaging design and material innovation due to its extensive geographic scope and varied market dynamics. Manufacturers in Southeast Asian, Chinese, Japanese, Indian, South Korean, and other countries constantly invest in R&D to improve packaging's cost-effectiveness, sustainability, and efficiency. The expansion of online shopping and e-commerce has increased demand for package delivery-optimized packaging solutions, which contributed to the development of durable yet lightweight packaging materials and designs.

Asia Pacific region have largest share plastic applications in industrial packaging of various sectors such as automotive, electrical, building and constructions and others. In the Asia-Pacific region, industrial packaging has become more sustainable due to legislative restrictions and increasing environmental awareness. To mitigate the environmental impact of packaging processes, businesses are investigating circular economy concepts, introducing recycling programmes, and utilising eco-friendly materials. The Asia-Pacific region's industrial packaging is defined by its ingenuity flexibility, and commitment to resolving environmental issues while satisfying the changing demands of a changing market environment.

Perstorp declared its acquisition by PETRONAS Chemicals Group Berhad (PCG), a division of PETRONAS Group and the top integrated chemicals supplier in Malaysia.

Backbone of North American Industries Exploring the Power of Industrial Packaging

North America dominated the industrial packaging market in 2024. The market growth in the region is attributed to the increasing need for distribution and logistics, rising improvements in supply chain, rising sustainability trends and growing e-commerce industry. The U.S. and Canada are dominated the market share in 2024. The U.S. is the major leading contributor in this market. International Paper, West Rock, Ball Corporation, Berry Global, Crown Holdings, Graphic Packaging and others are top leading companies in the U.S. These are the most sustainable packaging and largest companies in the U.S. To ensure the safe storage and transport of merchandise, these companies include electronics, automotive, chemicals and manufacturing rely upon specialized packaging solutions.

- For instance, in July 2024, AkzoNobel launched Securshield 500 series of easy open end coatings. The aim behind this launch was to help manufacturers and their consumers meet future and current regulatory requirements, which improved performance.

- In July 2024, a leading fiber-based packaging manufacturer, DS Smith launched a hybrid collaboration experience, PackRight 2.0. The aim behind this launch was to help businesses in e-commerce, fast moving consumer goods (FMCG) and other industries enhance and innovate sustainability.

North America's strong manufacturing and distribution industries are built on the backs of industrial packaging. It includes a wide range of materials and solutions that meet the demanding needs of many industries, such as consumer goods, automotive, aerospace, medicines, and food & beverage. In North America, industrial packaging is essential to the safe and effective movement of commodities across long distances. Smart packaging techniques are used by businesses to reduce waste, safeguard goods from harm during transportation, and enhance handling and storage procedures. Packaging technologies are consistently advanced in the region due to the significant emphasis on quality control, regulatory compliance, and customer satisfaction.

Manufacturers and suppliers in the US, Canada, and Mexico conduct research and development investments to improve the strength, sustainability, and affordability of packaging materials. One of the world's top manufacturers of chemical goods is the United States. The Department of Transportation, the International Air Transport Association, and the Environmental Protection Agency monitor chemical exports within the United States. Chemicals are transported by any means of transportation under the control of the Pipeline and Hazardous Materials Safety Administration and the U.S. Department of Transportation. the products' transit while protected in premium packaging.

The growing e-commerce industry in North America has increased demand for specialised packaging solutions made for online retail fulfilment. Industrial packaging in the area is constantly developing to match the changing demands of contemporary supply chains and transportation networks, from corrugated boxes to protective cushioning materials. North American industrial packaging supports the secure transit of goods throughout the continent's vast production and distribution networks by demonstrating a dedication to innovation, efficiency, and sustainability.

- In November 2023, Complete Packaging, a portfolio firm of the Spell Family Office and located in Monroe, Michigan, has been acquired by Specialised Packaging Group (SPG), a prominent vertically integrated manufacturer of protective packaging goods. automotive, aerospace, energy, industrial truck, defence, heavy equipment, and general industrial are just a few of the end areas for which Complete offers custom-designed packaging solutions.

- In September 2024, RENW launched a fully integrated, industrial hemp-based solution for brands seeking to reduce the use of fossil fuels and reduce deforestation with regenerative materials without compromising performance or cost. Packaging accounts for nearly 40% of global plastic production and makes it a prime target for environmentally conscious regulators, companies and consumers focused on reducing pollution.

- In April 2024, with 30% post-consumer recycled content produced from FDA-compliant resins, ForeFront Supply Chain Solutions is proud to supply the first polyethylene bag in the United States. This is the highest level of PCR available in flexible food packaging, which exceeds multiple new retailer requirements and extended producer responsibility.

Plastic Power Unveiling the Dominance of Industrial Packaging in the Modern Era

Plastic's cost-effectiveness, durability, and adaptability contribute to it being a major player in the industrial packaging companies. For the transportation and protection of goods, industrial packaging composed of plastic materials including polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and polystyrene (PS) offers a number of advantages. Packaging made of plastic is essential to the safe and secure transportation of hazardous products. Plastics are an essential raw material used to make the packaging that is utilised to ship dangerous goods across international borders. Drums, jerricans, composite intermediate bulk containers (IBCs), non-bulk composite packaging, and some inner packaging’s used in combination packaging’s are all composed of plastic.

The Central Pollution Control Board estimates that India produces over 25,940 tonnes of plastic garbage every day, despite the fact that plastic is a common material in most Indian homes. Every year, over 9.46 million tonnes of plastic garbage are produced. Plastic packaging is extremely adaptable when it involves automated packaging procedures, which increases production and efficiency in manufacturing and distribution facilities. Plastic packaging can be recycled, and developments in recycling technology keep raising the sustainability level of plastic packaging solutions.

- In January 2024, Apex Plastics, a US-based producer, has been bought by plastic blow moulder Container Services Inc (CSI). Apex specialises in extruded high-density polyethylene and unique single-stage packaging solutions for polyethylene terephthalate.

IBCs, or intermediate-capacity bulk containers, are industrial containers used for bulk and liquid product storage and transportation. Three frequently utilised forms of IBC are used today: flexible, foldable, and stiff. 600 litres and 1000 litres are the capacities of the two most popular rigid IBC tanks. Bulk items can be stored in medium-capacity containers for several uses. Containers can be reused after being cleaned and dried. This is dependent on multiple factors, such as whether the IBC will be recycled, if it has to be durable, and if there are any regulatory restrictions. Rigid containers in the shape of cubes are frequently composed of plastic, namely polyethylene or high-density polyethylene (HDPE). A strong external container, often in the form of a cage, constructed mostly of iron or galvanised tubular steel.

The foldable IBC is composed of extremely robust polyethylene that is empty inside and does not form a stiff outside cage. Various heavy materials, such as woven polypropylene or polyethylene, are used to make flexible IBC or wholesale bags.

IBCs are made to be portable and easy to handle. Their uniform measurements enable a smooth connection with current forklift and pallet systems. Pallet tanks, also called pallecons, allow IBCs to be safely and stacked during transit, reducing the possibility of damage. This effectiveness lowers expenses related to human handling and optimises logistics.

The Intermediate Bulk Container (IBC) industry leads the way in technical developments as the need for effective packaging and transportation solutions keeps rising. To improve IBC technology and make it even more efficient and flexible to the changing demands of global enterprises and industries, manufacturers are constantly investing in R&D.

- In October 2023, A new production line for Form-Fit intermediate bulk container (IBC) liners has been launched by DF Corporation.

Industrial Packaging Safeguards Chemicals in Transit and Storage

The chemical industry is the most significant consumers of industrial packaging due to the extensive variety of chemicals it makes and distributes, many of which require specialised packaging solutions for safe handling, transportation, and storage. Chemical compounds differ widely in their qualities, ranging from caustic acids to delicate powders, necessitating packaging that can efficiently contain, preserve, and identify them.

Global chemical companies are upgrading the industrial packaging for better environmental aspects and consumer preferences. Chemical industries rely on industrial packaging to maintain compliance with stringent safety rules and to reduce the dangers connected with dangerous products. Drums, intermediate bulk containers (IBCs), totes, and specialised containers are popular packaging materials for transporting chemicals in bulk. These containers are frequently made of strong materials like as high-density polyethylene (HDPE) or steel, which are designed to withstand the corrosive nature of many chemicals while also providing containment in the event of a spill or leakage.

For Instance,

- In November 2023, Amcor, a leader in the development and production of environmentally friendly packaging solutions worldwide, and NOVA Chemicals Corporation (NOVA Chemicals), a top manufacturer of sustainable polyethylene, have signed an MOU for the purchase of mechanically recycled polyethylene resin (rPE), which will be used in flexible packaging films. Amcor is committed to supporting packaging circularity, and one key component of that commitment is the increased usage of rPE in flexible packaging applications.

Streamlining the Supply Chain in the Industrial Packaging Market

The supply chain in the industrial packaging market involves a multifaceted network designed to efficiently manage the flow of packaging solutions across various industries. The process begins with raw material suppliers who provide essential inputs like plastics, metals, and paper products. These materials are transported to packaging manufacturers where they are converted into various packaging forms such as pallets, drums, containers, and stretch films.

Once produced, the packaging materials enter the distribution phase. Here, logistics companies play a crucial role in managing inventory, warehousing, and transportation. This stage ensures that packaging solutions are delivered promptly to end-users in sectors such as chemicals, pharmaceuticals, food and beverages, and industrial goods.

Quality control is integral throughout the supply chain, with rigorous testing to meet industry standards and regulations. Packaging must withstand the rigors of transportation and storage while protecting the contents.

Industrial Packaging Market: Core Elements and Major Industry Contributions

The Industrial Packaging Market is essential for safeguarding a wide array of products across various sectors. Key components include primary packaging, which directly contains the product (e.g., cans, bottles, and drums), secondary packaging, which groups primary packages for handling (e.g., boxes and shrink wraps), and tertiary packaging, which aids in bulk handling and logistics (e.g., pallets and stretch film).

Major players contribute significantly to this market's ecosystem. Companies like Amcor and Mondi are renowned for their advanced flexible packaging solutions, offering durability and customization for diverse industrial needs. Sealed Air and Smurfit Kappa excel in providing innovative protective and sustainable packaging options that enhance product safety during transit and storage. WestRock and International Paper specialize in robust paper-based packaging solutions, catering to bulk handling and logistics efficiency.

Companies like Berry Global and Sonoco Products focus on delivering high-quality plastic and composite packaging, addressing specific requirements of industries such as chemicals, food and beverages, and pharmaceuticals. Collectively, these companies ensure that industrial products are well-protected, efficiently handled, and meet regulatory standards, highlighting the complexity and critical nature of the industrial packaging market.

Exploring the Key Competencies of Industrial Packaging Leaders

The competitive landscape of the industrial packaging market is dominated by established industry giants such as DS Smith (U.K.), Mondi (U.K.), Sonoco Products Company (U.S.), Sealed Air (U.S.), Huhtamäki Oyj (Finland), Smurfit Kappa (Ireland), WestRock Company (U.S.), UFP Technologies, Inc. (U.S.), Stora Enso (Finland), Pregis LLC (U.S.), Shenzhen Hoichow Packing Manufacturing Ltd. (China), International Paper (U.S.), Dordan Manufacturing Company (U.S.), Hangzhou Xunda Packaging Co. (China), Mosburger GmbH (Austria), Universal Protective Packaging Inc. (U.S.), Parksons Packaging Ltd. (India), Neenah Paper and Packaging (U.S.), Plastic Ingenuity (U.S.), and JJX-Packaging (U.S.). These giants compete with upstart direct-to-consumer firms that use digital platforms to gain market share. Key competitive characteristics include product innovation, sustainable practices, and the ability to respond to changing consumer tastes.

Mondi produces lightweight, recyclable packaging that is simple to use and has several advantages over conventional non-paper-based packaging methods. Examine the advantages of our industrial solutions to get a new perspective on heavy-duty packaging like cartons and boxes.

For Instance,

- In February 2024, The Hinton Pulp mill in Alberta, Canada, was acquired by Mondi plc (Mondi), a leading worldwide producer of sustainable packaging and paper, from West Fraser Timber Co. Ltd (West Fraser) for a sum of USD 5 million.

The industrial markets have high standards. Durability, accuracy, adaptability, and ingenuity are all qualities that industrial goods must possess. Since Sonoco was founded to cater to the industrial sectors, we have a solid understanding of the challenges that our clients face and the resources they require to succeed. Using that information, a variety of solutions were created to assist them in achieving their objectives.

For Instance,

- In September 2022, Leading global packaging company Sonoco announced that it has finalised an acquisition deal to buy S.P. Holding, Skjern A/S (Skjern), a privately held paper mill with headquarters in Skjern, Denmark.

Sustainable packaging options from Smurfit Kappa are made to showcase and safeguard your goods, no matter how big or little. All of our packaging is made to guarantee that items reach their destination in the best possible shape because supply chains can be difficult.

For Instance,

- In September 2023, Smurfit Kappa (SKG. I) of Ireland has opened a new tab for the agreed-upon $11 billion purchase of WestRock (WRK. N), a rival in the United States, to become the largest paper and packaging firm globally and attempt to better navigate the sluggish economy on both sides of the Atlantic.

UFP Packaging offers OEM components and packaging solutions to small and big organisations in a variety of sectors as a full-service supplier. From wood pallets and boxes to highly customised packing solutions with integrated tracking systems, we develop and produce the widest range of custom packaging solutions on the market.

For Instance,

- In November 2021, for about $13.5 million, UFP Global Holdings, a subsidiary of US-based UFP Industries (UFPI), acquired a 70% share in Ficus Pax, a manufacturer of industrial packaging. With this transaction, UFP is entering the Indian industrial packaging market for the first time.

Industrial Packaging Market Player

Industrial packaging leading market players are DS Smith (U.K.), Mondi (U.K.), Sonoco Products Company (U.S.), Sealed Air (U.S.), Huhtamäki Oyj (Finland), Smurfit Kappa (Ireland), WestRock Company (U.S.), UFP Technologies, Inc. (U.S.), Stora Enso (Finland), Pregis LLC (U.S.), Shenzhen Hoichow Packing Manufacturing Ltd. (China), International Paper (U.S.), Dordan Manufacturing Company (U.S.), Hangzhou Xunda Packaging Co. (China), Mosburger GmbH (Austria), Universal Protective Packaging Inc. (U.S.), Parksons Packaging Ltd. (India), Neenah Paper and Packaging (U.S.), Plastic Ingenuity (U.S.), and JJX-Packaging (U.S.)

Industrial Packaging Market Recent Developments

- On 16 July 2025, UFP Packaging revealed the U-Loc 200, the latest cart with the first tool-free disassembly and assembly. This patient-pending quicker vanishes the demand for staple guns and nails, a tool that includes a calculated 37,000 emergency room visits annually.

- On 2 July 2025, Dow revealed the main development in sustainable packaging with the launch of its INNATE TF 220 Precision Packaging resin, which assists the growth of high-performance biaxially oriented polyethylene (BOPE) films personalized for recyclability.

- On 2 June 2025, Industrial Physics, a top leader in measurement and test solutions, revealed its state-of-the-art automated gauges aimed at encouraging accuracy and productivity in metal packaging: the Torus Z606 Automatic Score Inspection Gauge and the Torus Z345 Automatic Color Inspection Gauge.

- In April 2025, the K J Somaiya Private IPMMI and ITI launched certificate course in the maintenance and operation of packaging machinery.

- In November 2024, the largest privately owned industrial packaging company in North America, Atlantic Packaging announced its newly designed CanopyTM Wrap system.

- In September 2024, a manufacturer of compostable packaging solutions, Pakka launched a new range of flexible compostable packaging solutions. The innovative product line has been established with the vision to serve the rising demand for flexible packaging in the food and beverages industry with compostable solutions and contribute towards a cleaner planet.

- In July 2024, 2M Group launched a Sustainable Packaging Technologies focused on packaging. The aim behind this launch was to address the growing consumer demand for bio-based packaging.

- In August 2022, the leading coatings manufacturers, BASF and Nippon Paint China launched eco-friendly industrial packaging. The new packaging material is commercialized for the construction of dry mortar products of Nippon Paint, with BASF's water-based acrylic dispersion Joncryl® High-Performance Barrier (HPB) as the barrier material.

Industrial Packaging Market Segments

By Material

- Plastic

- Wood

- Metal

- Steel

- Cardboard

- Others

By Product Type

- Intermediate Bulk Containers

- Drums

- Corrugated boxes

- Sacks

- Crates

- Pails

- Wrappers

- Others

By End User

- Chemical

- Automotive

- Building & Construction

- Pharmaceutical

- Food & Beverage

- Personal Care

- Cosmetics

- Electronics

- Textile

By Region

- Asia Pacific

- North America

- Europe

- LA

- MEA