PET VCI Shrink Film Market Intelligence Report, Key Trends, Innovations & Market Dynamics

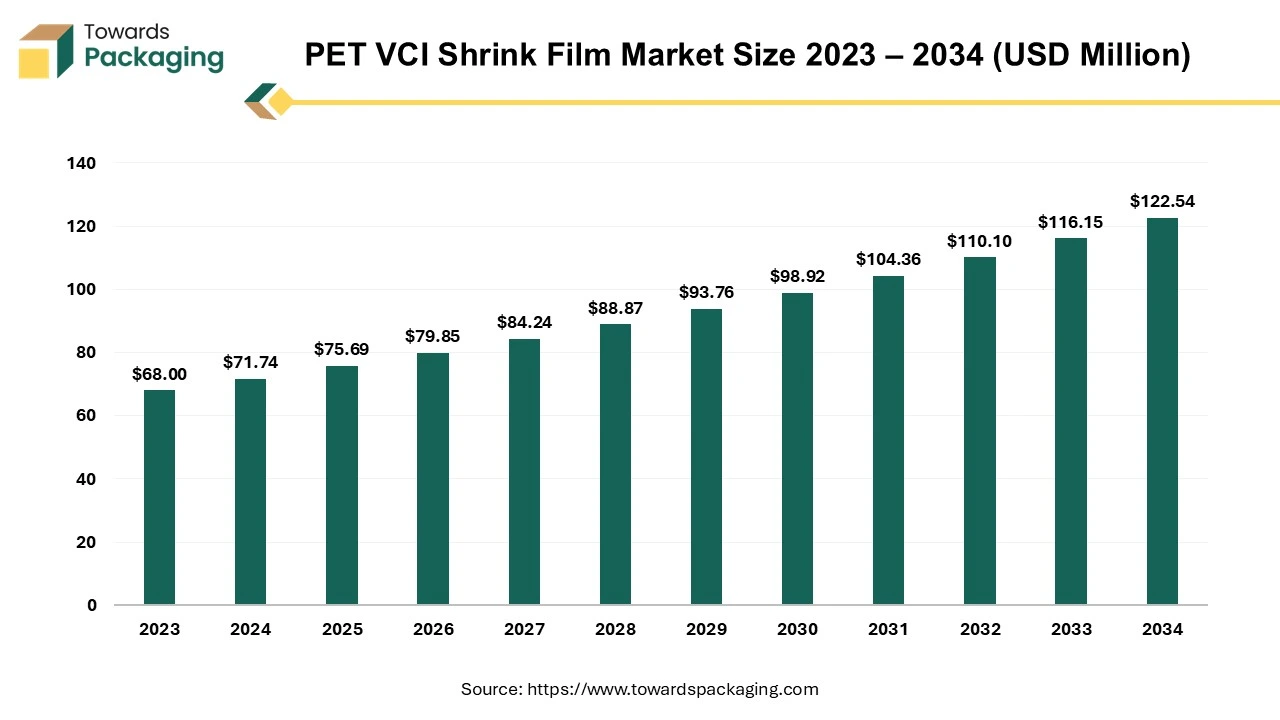

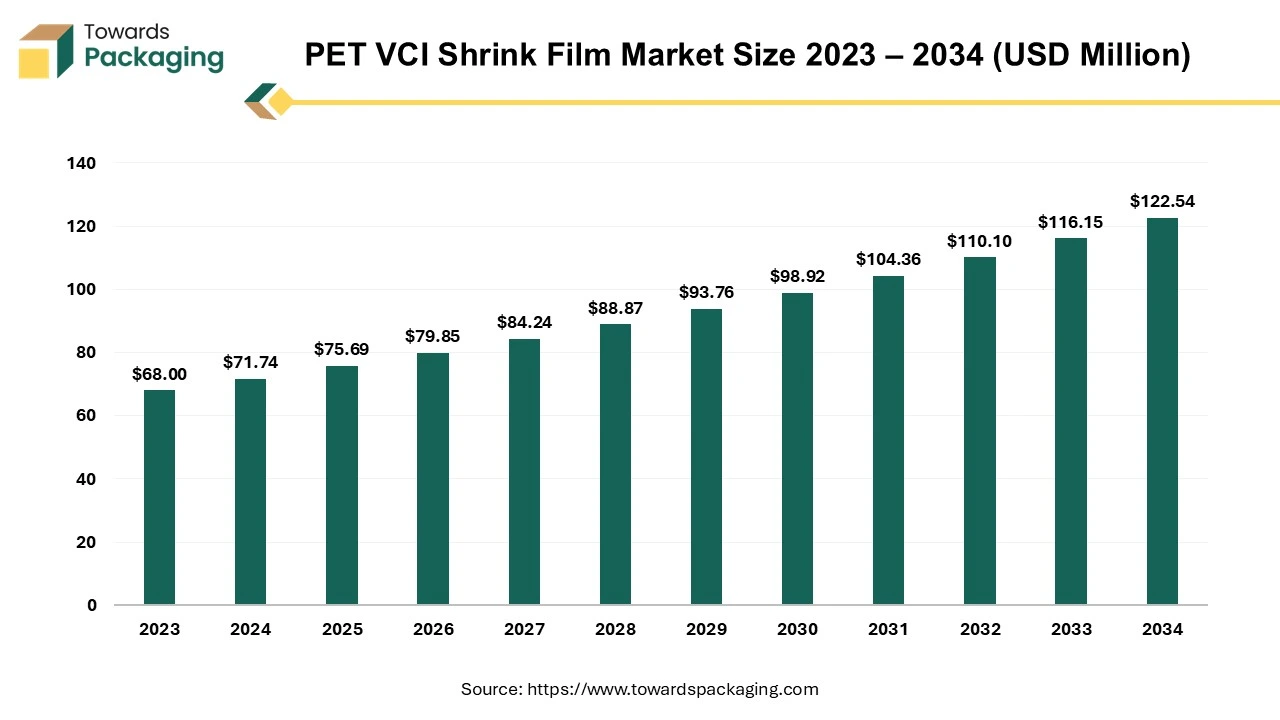

The PET VCI shrink film market is forecasted to expand from USD 79.85 billion in 2026 to USD 129.28 billion by 2035, growing at a CAGR of 5.5% from 2026 to 2035. This market is driven by the increasing need for rust and corrosion protection in industries like automotive, aerospace, and electronics. Key segments include material types such as PE, PET, and PP, with aerospace and defense leading the demand.

Regional data shows Asia Pacific dominating in 2024 due to the high demand for packaging solutions in manufacturing. The market features major players like Pep-Cee Pack Industries, Anu Industries, and Euro Tapes Private Limited Technologies, focusing on sustainable and advanced PET VCI shrink films.

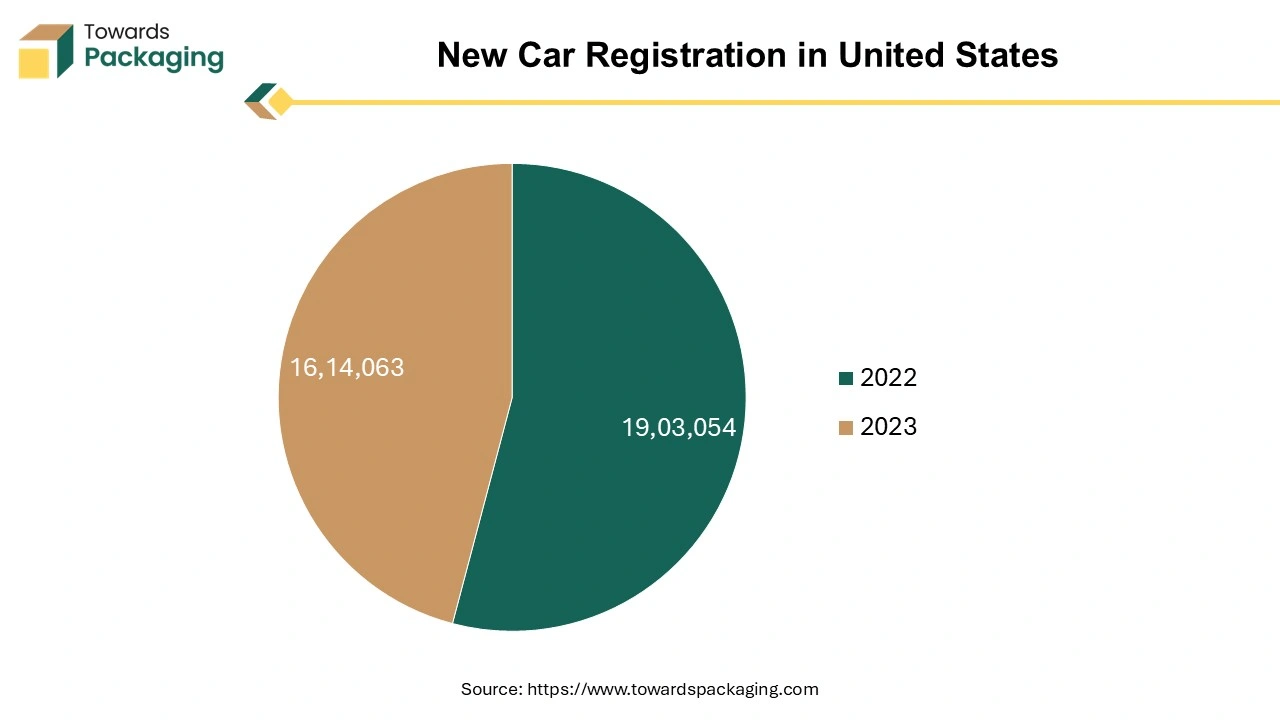

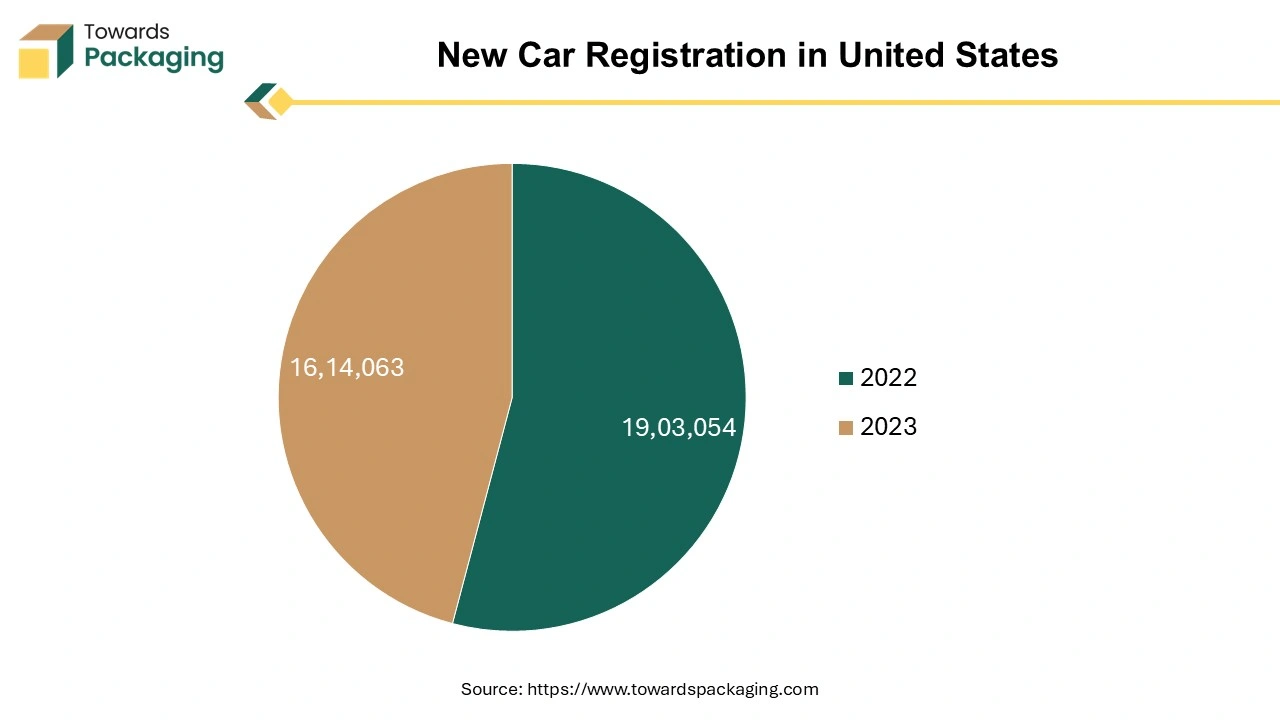

The market is increasing due to the growing automotive, machinery, and electronics packaging that needs to protect from rusting. The rising automotive market is boosting the PET VCI shrink film market.

PET VCI shrink film packing is heat-sealable and shrinkable packaging film that is used to wrap metals or any machinery items to protect them from rust during storage or transportation. It is an alternative to expensive multi-layer packaging film to reduce the requirement of dehumidification and vacuum paging.

These shrink films wrap tightly around the object which avoids contact with the metal body and moisture and protects it from any kind of damage. These films are made up of polyethylene terephthalate (PET) that includes volatile corrosion inhibitors (VCI). These films when heated wrap tightly as the PET film shrinks and creates a vacuum around the metal body. This technology is mainly valued in markets where metal parts are vulnerable to corrosion and rust, such as aerospace, automotive, and manufacturing.

Driver

Increasing Globalization and Industrialization of Trade Drive the PET VCI Shrink Film Market

The PET VCI shrink film market is facing noteworthy development influenced by the growing industrial sector and globalization in trade. As worldwide supply chains enlarge, the requirement for actual packaging solutions to protect products during transit has become crucial. These films are mainly valued for their ability to protect metal products from rusting and make them crucial for sectors such as aerospace, automotive, and electronics.

PET, has received importance as a wrapping material because of its incomparable strength, versatility, and clarity. PET VCI shrink film, a focused arrangement of PET, is extensively manufactured for packaging due to its exclusive shrink nature. Traditional shrink substances such as POF (Polyolefin) and PVC are good for metals but the PET shrink film delivers higher precision and lustre which makes it a perfect option for goods where visual demand is decisive.

- In February 2024, Innovia Films which is a part of CCL Industries, announced the launch of floatable polyolefin shrink film. It is designed for light-sensitive products and it will be known in the market by the name of RayoFloat white APO (WAPO).

PET VCI Shrink Film Market Trends

- Sustainability Inventiveness: The rising demand for eco-friendly packaging material for automotive parts boosts the market of PET VCI shrink film. The biodegradable options of machine and electronics packaging are drawing the attention of the customers.

- Technological Innovation: These PET VCI shrink films are manufactured in such a process to enhance the barrier quality and durability of the film. With the advancement in technology, the field of the use of shrink film is expanding.

- Versatility and Customization: There is an option for customization of such shrink film which has enhanced the scope of packaging machines. With this tailored facility, its utility in the packaging sector is enhanced.

- Rising Concern for Corrosion Issues: The growing concern for issues such as rusting and corrosion of automotive parts. The financial impact of rust on numerous industries is driving the request for real corrosion shield solutions.

Market Opportunity

Adoption of Environment-Friendly Option Expanding the PET VCI Shrink Film Market

With the evolving automotive industry increasing a huge demand for technological advancement. As the global automotive market is growing the demand for such films also increasing along with environmental concerns. A significant driving factor of PET VCI shrink films are commonly transparent. These films permit high prominence, allowing customers to see the packed product. This feature is mainly beneficial for trade wrapping, where the visual performance of the machines plays a vivacious role in appealing to customers. Moreover, PET VCI shrink film claims excellent stretchable strength and slit resistance, safeguarding that goods remain strongly packaged during transport and management. Its sturdiness makes it appropriate for an extensive variety of applications such as food & beverage packing to different consumer products.

- In November 2023, two companies Duo and Plastix collaborated and announced the launch of shrink film which are made from waste fishing gear. These films are made up of 98% maritime waste like fishing ropes and nets.

While PET VCI shrink film has multiple profits, it is important to accept the challenges linked with its use. A major concern is its low resistance towards heat during storage this property can result in premature contraction. Market Players often face such issues through advanced technologies and formulations, improving the firmness and performance of PET VCI shrink films.

Regional Insights

Growing Manufacturing Needs: Asia Pacific’s Lead in the Industry

Asia Pacific witness the highest revenue share for the year 2024. The PET VCI shrink film market is speedily growing, influenced by the rising demand for manufacturing industries influence the growth of demand for good-quality films. All the developing countries such as China, India, Japan, South Korea, and Thailand have influenced the packaging market to expand. The eco-friendly, durable, and cost-effective nature of the shrink films increases their demand in the packaging market.

- In December 2023, Gunze Limited, announced the launch of GEOPLAS™ HCX1 that is an eco-friendly film. It is a lightweight shrink film which is used for an automatic sleeve applicator.

Well-known players are introduced by expanding their quality packaging by enhancing customer expectations. This region has a high demand for durable packaging that is driving this shrink film market by producing biodegradable and recyclable films. All the major market players are constantly working to provide eco-friendly PET VCI shrink film to the manufacturing industry. The rising demand for new model vehicles has also influenced this market as it enhances the scope of films that are crucial for protecting metal parts in the market.

- In June 2024, Dow collaborated with RKW and announced the launch of REVOLOOPTM which is a recycled plastic resin. It is developed to transform waste materials.

North America is estimated to grow at the fastest rate over the forecast period. The rising concern for innovative packaging solutions is due to the rising demand for innovation in the automotive sector. The existence of well-known market players with innovative industrial abilities and strong supply networks further reinforces North America's situation as a leading market for PET VCI shrink films.

Furthermore, strict monitoring standards and superiority needs in North America influence the acceptance of high-performance rust protection formulations such as PET VCI shrink films. Manufacturers in the region focused on film quality and durability, demanding the usage of cutting-edge packaging films to protect metal components from rust during storage and transportation of the products.

There is a huge demand for shrink film in the food and beverages industry to keep food fresh and contamination-free by creating a strong barrier between food and bacteria. In April 2024, Kuhne Anlagenbau announced the launch of Triple Bubble lines. It is the thinnest and most recyclable shrink film developed at NPE 2024.

Segmental Insights

By material type, the PE shrink film segment led the PET VCI shrink film market in 2024. PE-based VCI shrink films have strong rust shields and also provide superior machine-driven capacity and sturdiness, making them appropriate for an extensive variety of applications in the market. Industries like electronics, automotive, and aerospace depend on PE VCI shrink films to protect their metal apparatuses during the process of transportation, storage, and export.

By end user, the aerospace & defence segment led the PET VCI shrink film market in 2024. This development is due to its vital role in shielding raw resources and semi-finished and also finished metal goods from rust. Markets are intricate in the manufacture and handing out of key metals like aluminum, steel, and copper depending on VCI shrink films to confirm the integrity and excellence of their metal resources during shipping, storage, and handling.

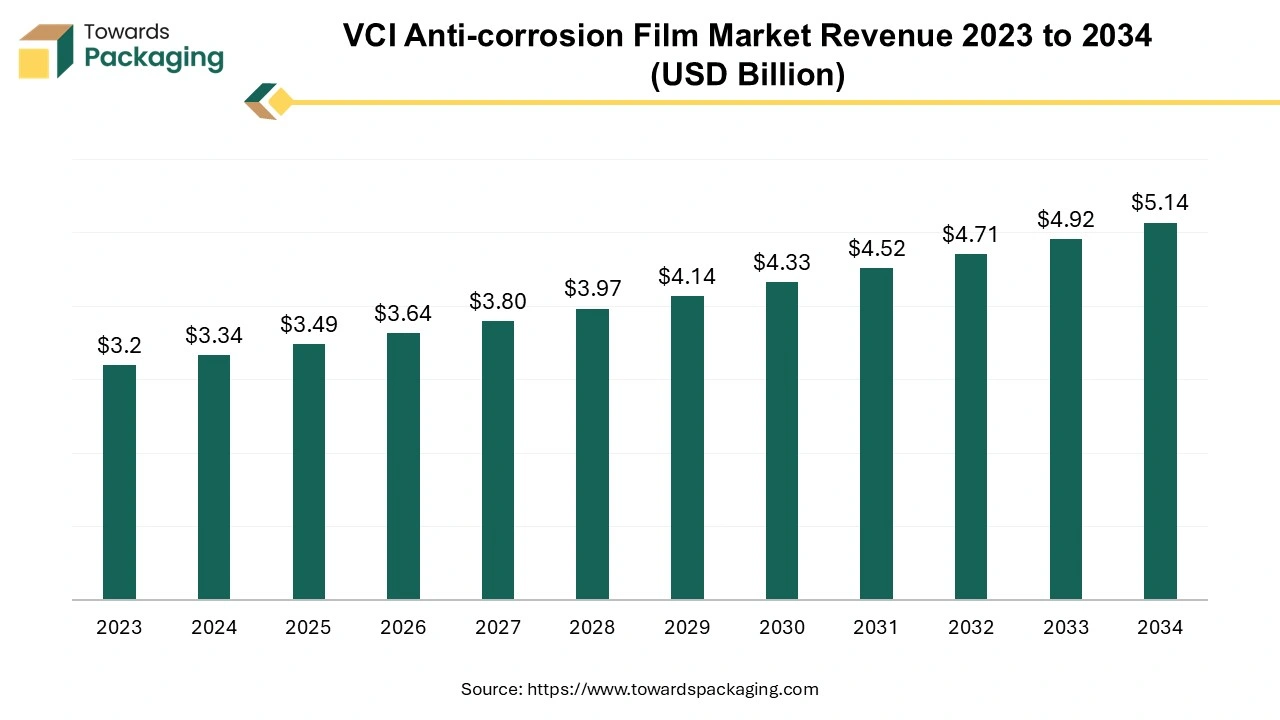

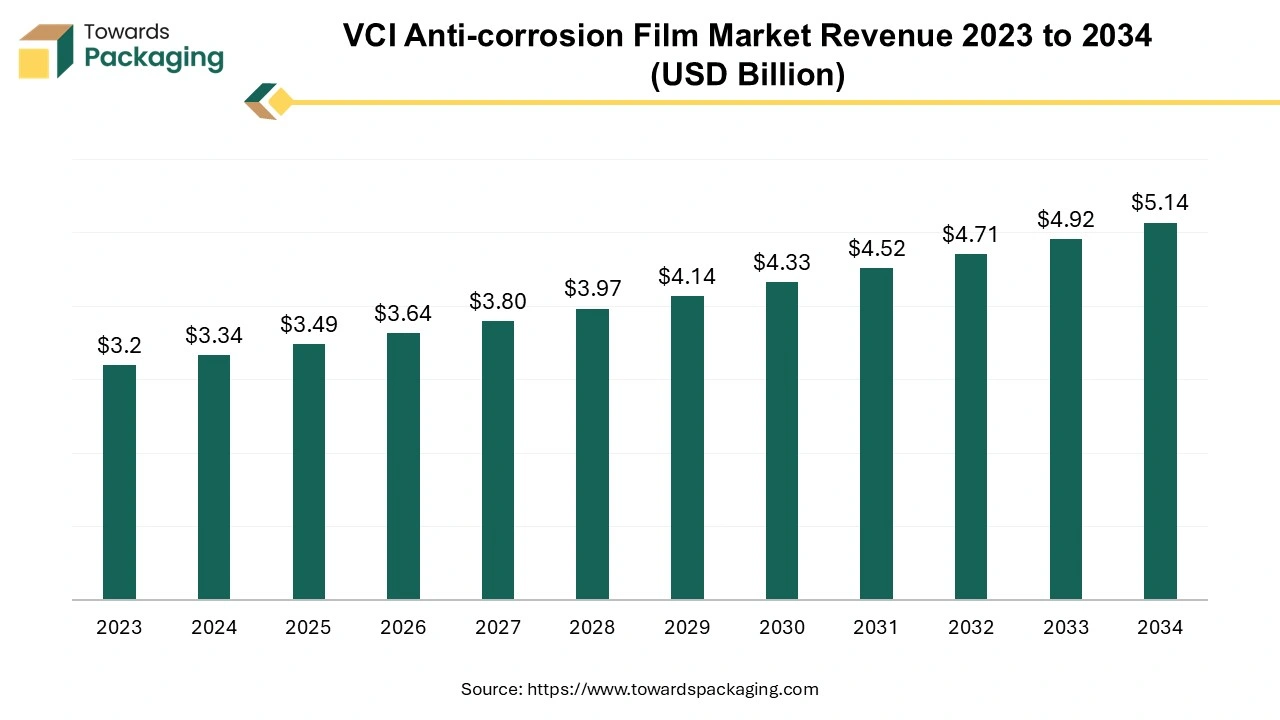

VCI Anti-corrosion Film Market

The VCI anti-corrosion film market is set to grow from USD 3.49 billion in 2025 to USD 5.14 billion by 2034, with an expected CAGR of 4.4% over the forecast period from 2025 to 2034.

The market is expanding due to the expansion of food business worldwide. With the increasing demand for food, there is a high demand for storing hot or cold foods, such as desserts, salads, and sandwiches. However, storing food in containers with VCI anti-corrosion film prevents contamination of these food items.

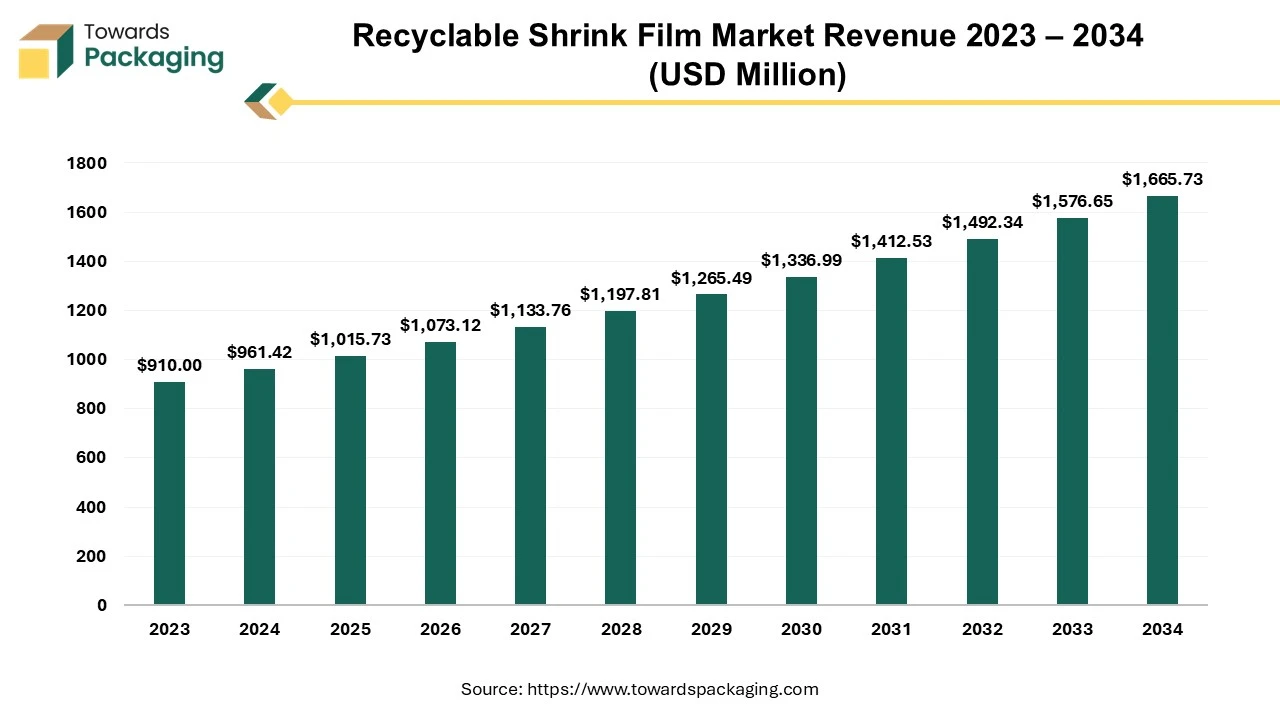

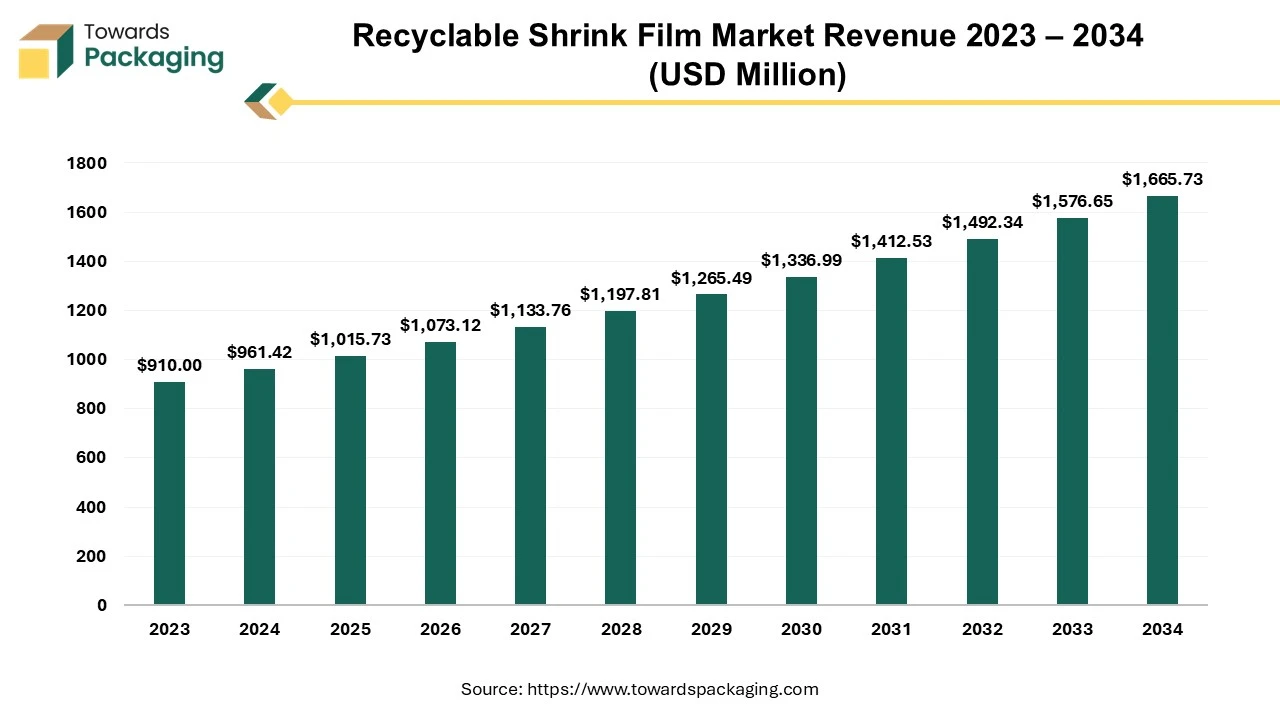

Recyclable Shrink Film Market

The recyclable shrink film market is projected to reach USD 1,665.73 million by 2034, expanding from USD 1015.73 million in 2025, at an annual growth rate of 5.65% during the forecast period from 2025 to 2034.

The demand for sustainable packaging solutions is driving the expansion of global recyclable shrink film market. increasing awareness of environmental responsibilities are encouraging circular economy. Advancement in shrink film technology is expecting to fuel market.

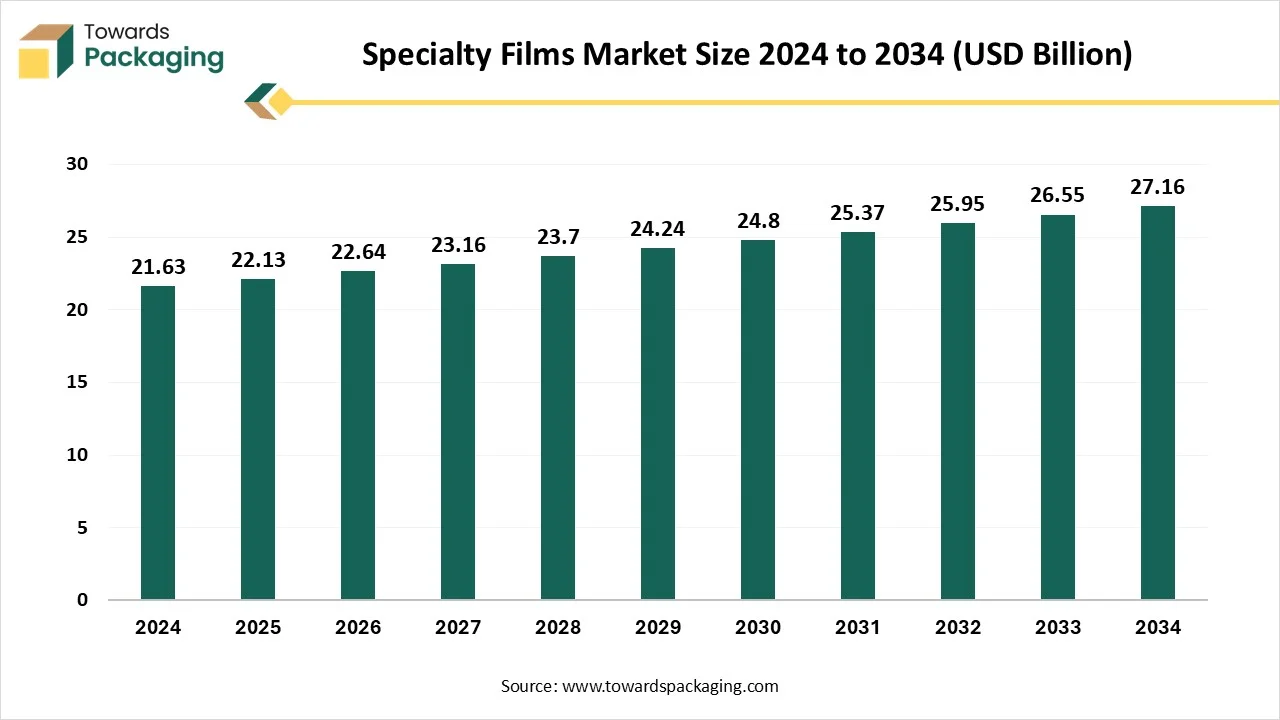

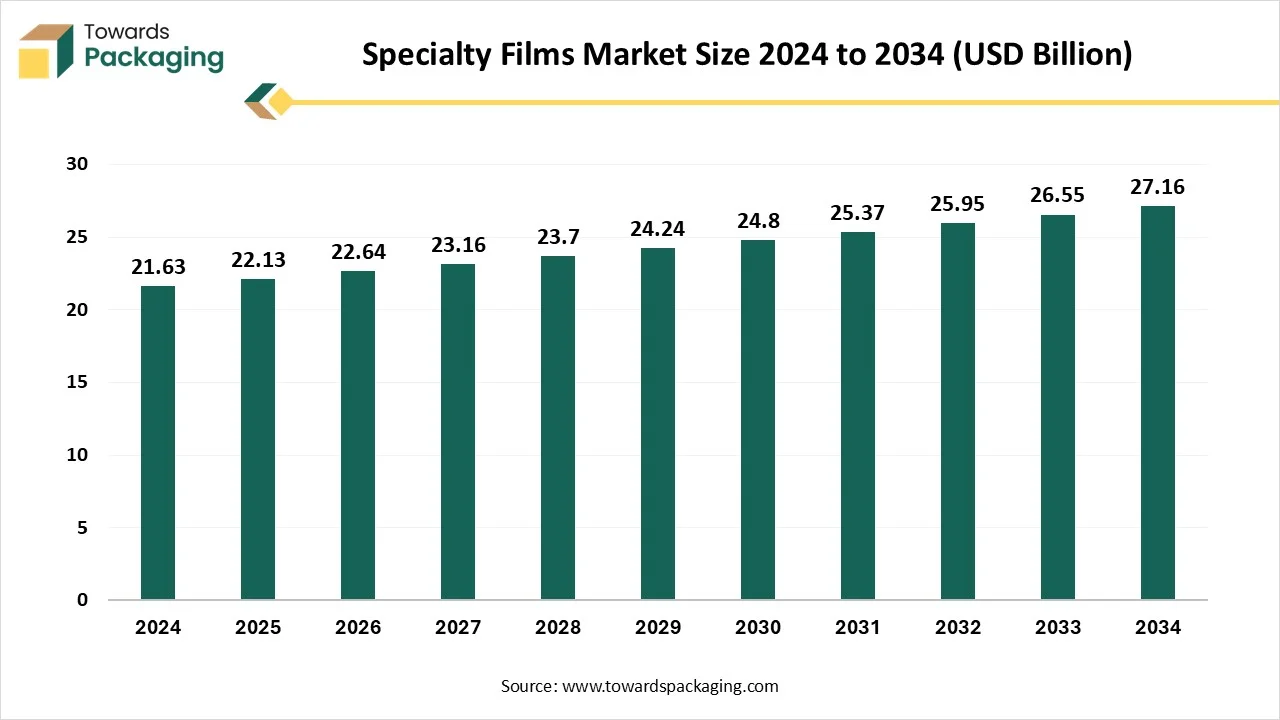

Specialty Films Market

The global specialty films market is expected to increase from USD 22.13 billion in 2025 to USD 27.16 billion by 2034, growing at a CAGR of 2.33% throughout the forecast period from 2025 to 2034. The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing specialty packaging filmswhich is estimated to drive the global market over the forecast period.

Speciality packaging films refer to high-performance, engineered plastic films that are specifically designed to meet unique packaging requirements. These films offer special functional properties that go beyond conventional packaging, such as barrier protection, mechanical strength, thermal properties, optical properties, and chemical resistance.

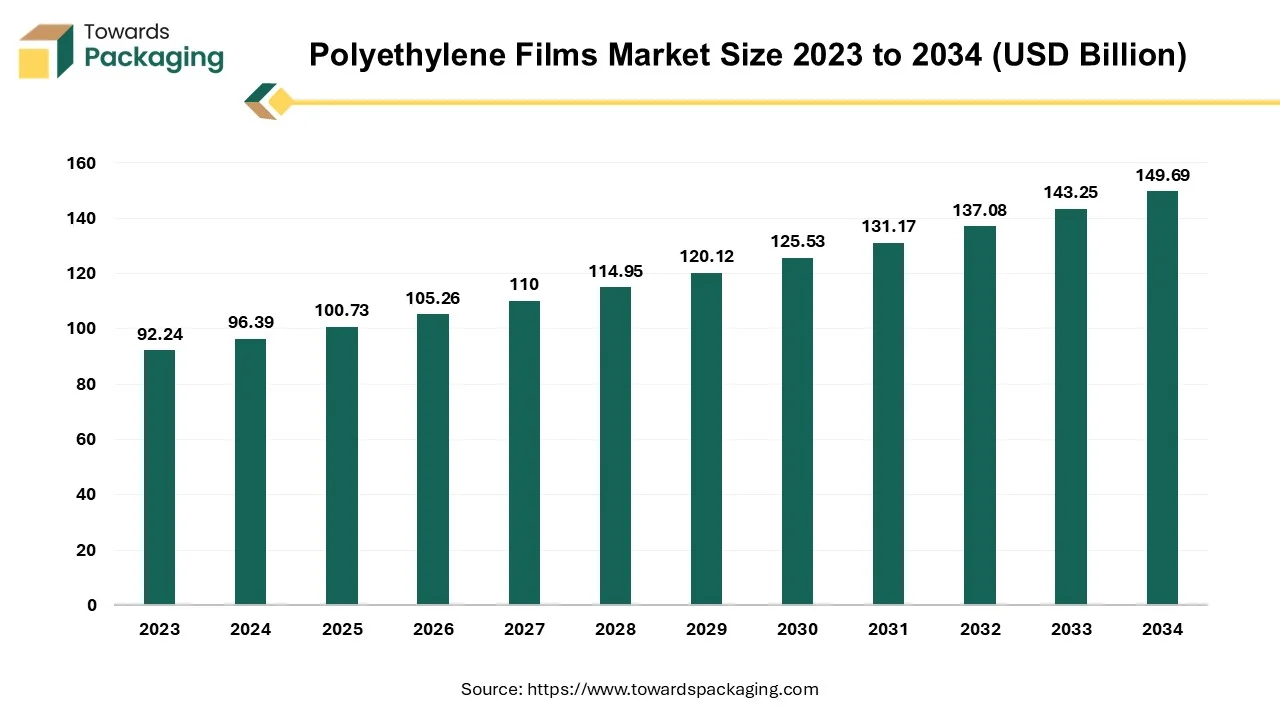

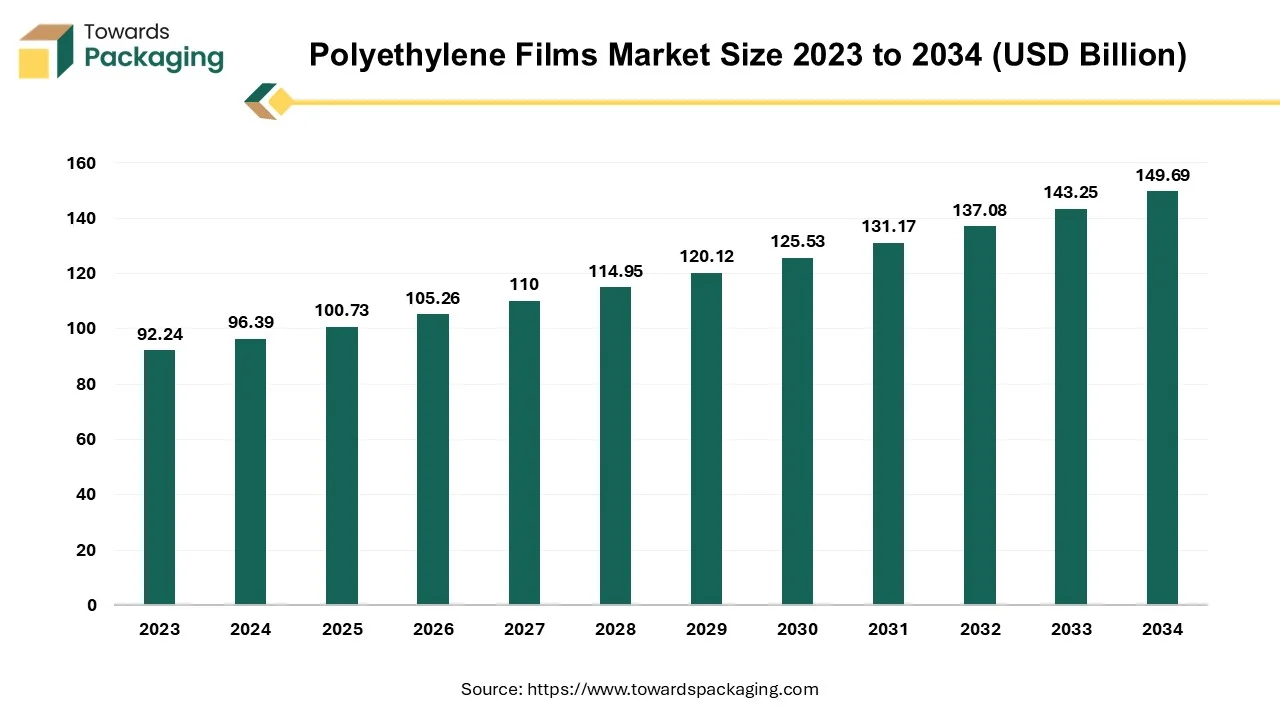

Polyethylene Films Market

The polyethylene films market is expected to grow from USD 100.73 billion in 2025 to USD 149.69 billion by 2034, with a CAGR of 4.5% throughout the forecast period from 2025 to 2034.

The chemical ethylene, which is present in natural gas and petroleum, is the source of the polymer film that is called polyethylene (PE). considering its many uses, PE film is referred to by many different kinds of names, including plastic sheeting, polyethylene sheet, poly sheeting, and poly film. Despite over 100 million metric tonnes of PE resin generated annually, polyethylene has become the plastic material that is used the most globally. PE makes up nearly 34% of all polymer produced globally. The production of polyethylene is expected to be 22.67 million metric tonnes. An extensive selection of packaging materials, such as bags, wraps, pouches, and sacks, are able to be manufactured by moulding polyethylene films.

Recent Developments

- In February 2024, CCL Label announced the launch of EcoFloat WHITE. It is developed to recycle transparent PET bottles.

- In May 2023, Innovia announced the launch of APO45. It is a sustainable and floatable shrink-sleeve material which is developed to enhance PET recycling rates and support a circular economy for packaging.

PET VCI Shrink Film Market Top Companies

PET VCI Shrink Film Market Segments

By Material Type

By End-Use

- Aerospace & Defence

- Primary Metal

- Electricals & Electronics

- Automotive

By Region

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait