Sterile Medical Packaging Market Intelligence Report, Key Trends, Innovations & Market Dynamics

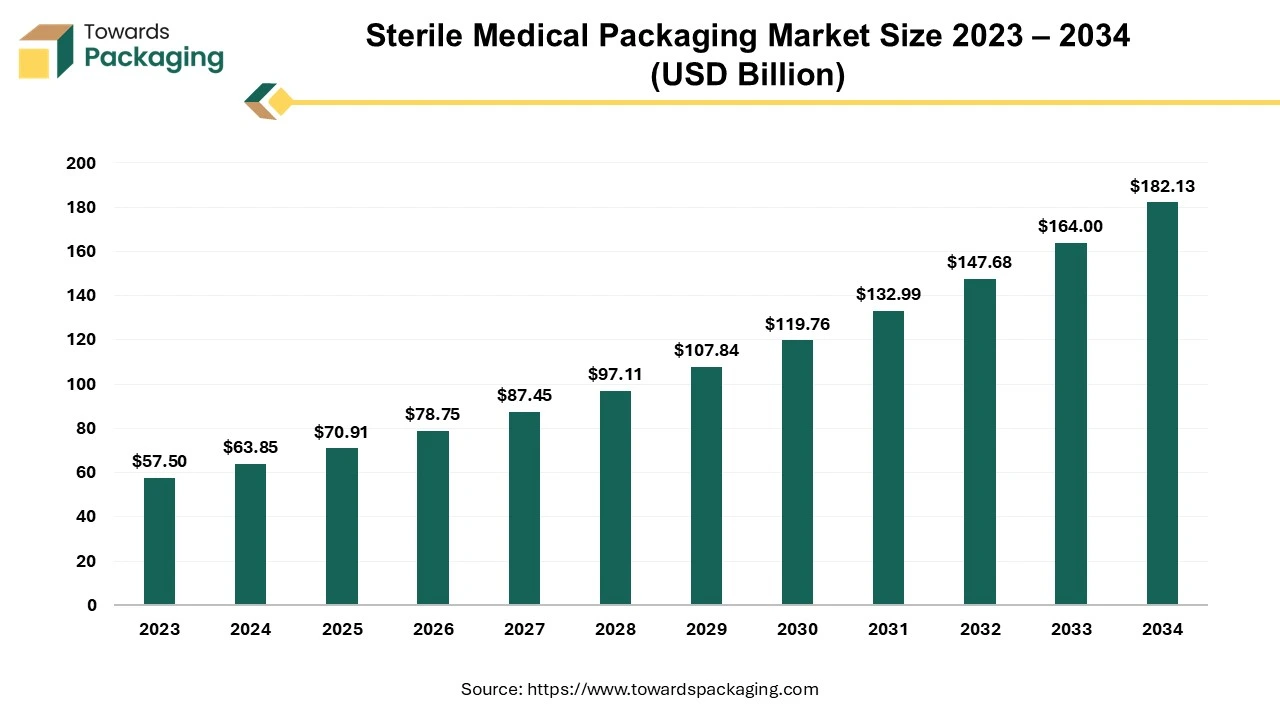

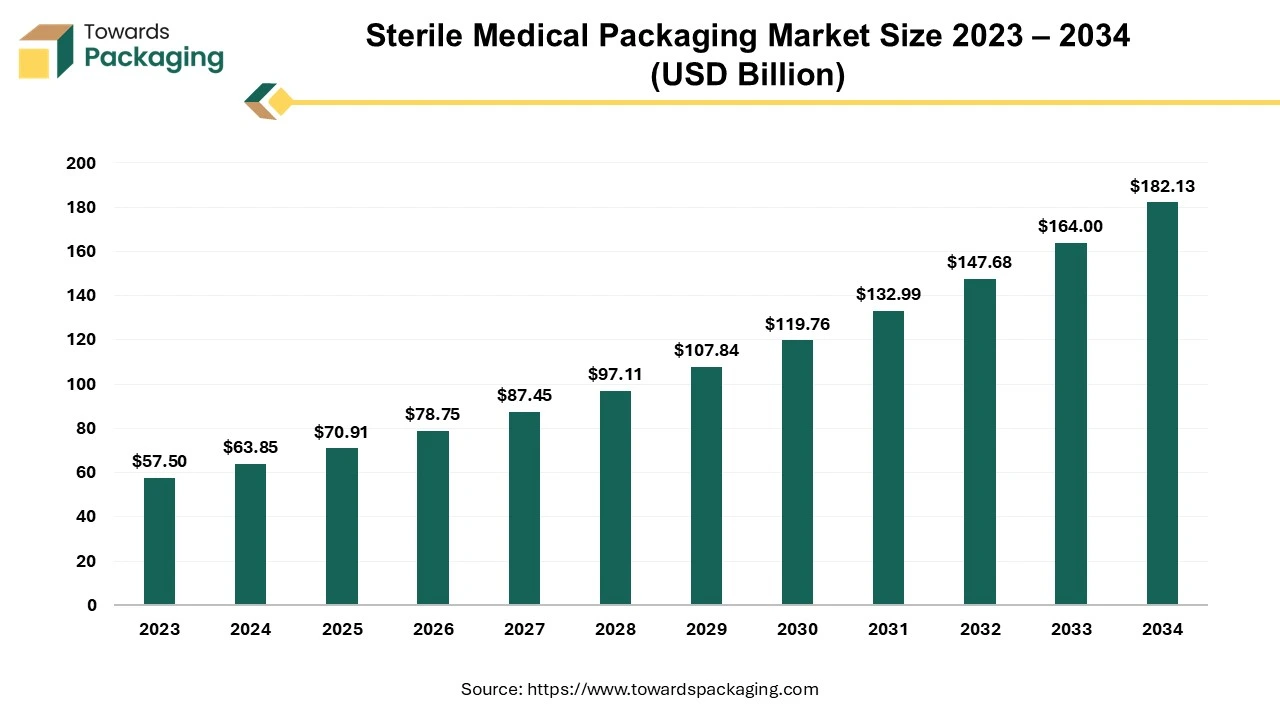

The sterile medical packaging market is forecasted to expand from USD 78.74 billion in 2026 to USD 202.24 billion by 2035, growing at a CAGR of 11.05% from 2026 to 2035.

The market is observed to grow due to the rising demand for the pharmaceutical industry. With the advancement in science and technology, the pharmaceutical industry is growing exponentially. Rapid growth in diseases of all age groups has influenced the increase in the production of medicine which has raised the sterile medical packaging market.

Market Overview

Sterilization is a significant step accomplished in the healthcare sector. Hence, the procedure of sterile medical packaging products or sterile block arrangements has achieved an important position in this market. This sterile medical packaging is a non-recyclable packaging that works as a barricade against contagious spread. The majority of such packaging, such as pouches, containers, and wraps are planned to protect medical supplies from the outside environment and unintentional spread of contamination.

Additionally, these sterile medical barrier arrangements preserve supply sterility from the fact of sterilization and packaging till the time of usage. They deliver valuable goods such as durability, tear resistance, a superior bacterial barrier, and breathability to preserve the pharmaceuticals and medical products sterile in their lifespan. These belongings would increase the request for these types of packaging in several applications extending from in-vitro diagnostic equipment to surgical & medical products.

Sterile Medical Packaging Market Trends

- Sustainability and Eco-Friendly Materials: There is growing pressure to adopt more sustainable packaging solutions. This includes the use of recyclable and biodegradable materials, thinner multi-layer films, and bio-based plastics. The challenge lies in maintaining strong barrier properties and sterility performance while reducing environmental impact.

- Smart and Intelligent Packaging: Technologies such as NFC tags, RFID, sensors, and tamper-evident indicators are increasingly integrated into sterile packaging. These features enhance traceability, ensure authenticity, and monitor breaches in sterility during transport and storage.

- Advanced Sterilization Techniques: Innovative methods like electron-beam (E-beam) sterilization, low-temperature plasma, and other non-thermal processes are gaining popularity. These allow for effective sterilization of sensitive products without material degradation, and often enable shorter cycle times compared to traditional heat or radiation methods.

- Automation, Quality Assurance, and Inspection: Automation is increasingly adopted to minimize human error, enhance consistency, and maintain sterility. Technologies such as machine vision, AI-powered inspection systems, robotics, and integrated seal integrity testing are being deployed across packaging lines.

- Cost and Material Efficiency: Manufacturers are focusing on right-sizing packaging to reduce material use and minimize waste. Single-use packaging systems and precision-engineered films are used to ensure barrier effectiveness while controlling costs.

- Regulatory Compliance and Barrier Film Innovation: Stricter global regulations are driving demand for high-performance barrier materials that protect against microbial ingress, moisture, oxygen, and light. Compliance also demands clear labeling and validated sterility assurance across packaging formats.

- Sterile packaging is experiencing huge development, especially with growing healthcare demands and the growth of biologics. A main trend is the acceptance of sustainable sterile materials, such as recyclable films and bio-based plastics, to meet environmental goals without compromising safety.

- Ready-to-sue sterile packaging is becoming more prevalent, helping pharmaceutical and medical device companies save time and ensure regulatory compliance. The sector is also seeing the integration of smart technologies, such as indicators for temperature control, sterility assurance, and tamper evidence.

- Personalised medicine and advanced therapies are driving the need for small-batch packaging solutions. Additionally, automation in sterile packaging processes is enhancing precision, reducing contamination risks, and improving efficiency.

- There is also growing emphasis on compliance with global sterilization and traceability standards, ensuring patient safety and seamless global distribution.

- Eco-design and lifecycle assessment approaches are being used more frequently to lower the environmental footprint of sterile packaging without compromising safety and performance.

- As the global healthcare industry expands, modular sterile packaging solutions that can be customized for different therapies and geographies are becoming more essential. There is a growing shift toward smarter labelling, incorporating RFID tags and QR Codes for product authentication, supply chain traceability, and patient safety, too.

- Smart Packaging: The incorporation of smart packaging has influenced the market by using advanced materials such as temperature-sensitive labels and self-sealing films.

- Thermoform Trays: Rigid materials with several compartments are used to make medical products. These are widely used for products such as testing kits, implants, sutures, and various surgical items.

- Customization Option: The customization option for medicines such as boxes, bottles, bags, and pouches has influenced the sterile medical packaging market profoundly.

- Surgical Sterilization Wrap: The demand for such wrap is majorly influenced by manufacturing respiratory masks. These are made with readily available materials.

AI Integration in the Sterile Medical Packaging Market

AI has brought significant changes in the sterile medical packaging market by adding several advantages to reshape the major factors of this important sector. AI-incorporated systems can precisely check sterile medical barrier packaging for faults and guarantee strict quality regulators. By introducing computer visualization and machine learning algorithms, producers can recognize even small inadequacies, decreasing the risk of negotiated sterility. This results in a supply of safer products and enhanced customer belief. Automation determined by AI tools can rationalize packaging processes, significant for increasing effectiveness.

Analytical maintenance set-up can predict equipment failures, reduce downtime and enhance production time. The consequences of speeding up turnaround times decreased costs and enhanced overall efficiency. AI allows modified packaging results tailored to specific needs. By identifying data on customer preferences and market demands, producers can generate packaging patterns with artificial intelligence that satisfy target patients. This level of personalization can improve brand trustworthiness and influence customer engagement and practice.

Market Dynamics

Increasing Prevalence of Diseases & Risk of Infection

The growing population combined with an upsurge in the prevalence of diseases and the incorporation of new guidelines by governments to regulate the widespread of contagious diseases are the prime aspects influencing the development of the healthcare sector. The development of the sterile medical packaging market in the healthcare sector is qualified due to its superior bacterial barricade and sturdy properties. This packaging keeps the medical and pharmaceutical devices sterile till the package is unlocked to utilise.

The growing demand for pharmaceutical injectables and the requirement for oncology and other high-strength medicines are influencing the development of the market. Moreover, using appropriate sterile medical packaging equipment is very significant as it permits the removal of packaged materials without contamination and harm. Henceforth, the growing demand for packaging resolutions in the healthcare sector will influence sterile medical packaging market development during the predicted period.

This market growth is hindered due to the high cost and environmental impact. Sterile medical packaging systems are intended to guarantee the sterility of packed products till their point of utilisation. Hereafter, strict regulatory values are made and applied to their production.

Growing Demand for Safe Packaging with Advanced Technology

The growing cases of infectious diseases such as cold, coronavirus, tuberculosis, flu, and SARS have increased demand for single-use medical products or devices. The acceptance of single-use packaging is gradually more widespread in the healthcare sector as it can decrease the risk of contamination and infection. These products include needles, syringes, face masks, bandages, applicators, gloves, suction catheters, surgical sponges, and testing kits. As these products are used only a single time, they protect from the widespread of microbes or contamination from one patient to another patients.

The packaging utilized for such products requires to be very effective in continuing their sterility. These devices are measured to be suitable packaging solutions for such products. They keep single-use medical products away from chemicals and moisture. These packaging solutions are accessible in different shapes and sizes as per the requirement of the application area. Hence, the growing demand for single-use medical devices will boost the market.

- In September 2023, Guardian Medical, announced the launch of Minimal Footprint Packaging (MFP). It is to address cost pressures while ensuring exceptional outcomes in sterile packaging.

Opportunity

Advancements in Sterilization Technology

Advancements in sterilization technologies are unlocking significant opportunities in the sterile medical packaging market by enabling safer and more efficient methods to ensure product sterility without compromising material integrity. Emerging techniques such as electron-beam (E-beam), vaporized hydrogen peroxide (VHP), and low-temperature plasma sterilization offer faster cycle times and compatibility with sensitive medical devices that traditional high-heat methods could damage. These innovations allow manufacturers to expand their packaging options, such as thinner films, complex device kits, and eco-friendly materials, while maintaining regulatory compliance and sterility assurance. As a result, packaging providers can cater to a broader range of medical products, accelerating product approvals and expanding market reach.

Segmental Insights

Lightweight and Cost-Effective: Plastic Packaging Segment Led in 2024

The plastic segment is leading in sterile medical packaging as these are lightweight, cost-effective, and easy to mould. This market is segmented into metal, plastics, paper, glass, & paperboard, and others. Plastic is a widely used and fast-increasing raw material which is utilized in the manufacture of sterile medical packaging industry. They are majorly chosen in medical packaging and comprise polypropylene (PP), polyvinyl chloride (PVC), high-impact polystyrene (HIPS), polycarbonate (PC), high-density polyethylene (HDPE), and polyethylene terephthalate (PET).

These plastic packaging are a suitable choice for sterile medical packaging products as they deliver easy moldability, protective properties, and cost-effectiveness. They shield the packed devices, medical instruments, and drugs from contamination and damage. Plastics are used in manufacturing thermoformed blister trays and packs, closures, vials, bottles, overwraps, pouches and bags.

Rigid Packaging: Thermoform Trays Packaging Segment Led in 2024

Based on product the thermoform trays are the most extensively used sterile medical packaging market. These are primarily produced utilising rigid material and have several compartments to support the medical products. These thermoform trays are widely used to pack sutures, sensitive surgical items, testing kits, and implants. The rising demand for single-use medical products and the growing importance of contamination control in healthcare are prime drivers boosting the acceptance of thermoform trays in the sterile medical packaging sector.

Most Powerful Sterilization: Chemical Sterilization Segment Led in 2024

Based on sterilization procedure, the market is categorized into chemical sterilization, high temperature/pressure sterilization, and radiation sterilization. The chemical sterilization segment is further classified into hydrogen peroxide, ethylene oxide (ETO), and others. Likewise, the radiation sterilization segment is sub-categorized into e-beam, gamma radiation and others. Moreover, the high temperature/pressure sterilization process is divided into the dry heat and steam autoclave. Chemical sterilization packaging is the fastest-growing procedure accepted in the sector, in which ethylene oxide is the most influential chemical utilized for sterilization. It has an alkyl property that disturbs the reproductive methods and cellular metabolism of microbes.

Additionally, it is suitable for many materials, comprising glass and plastics, that are reduced by heat or radiation sterilization. Chemical sterilization is an extensively used technique in the healthcare sector, and its demand is anticipated to increase because of the growing consciousness about contamination control and the rising requirement for sterile medical packaging solutions. Overall, the chemical sterilization process is anticipated to play an important role in the progress of the sterile medical packaging market, influenced by its efficiency in contradicting microbes and its extensive range of submissions in the healthcare sector.

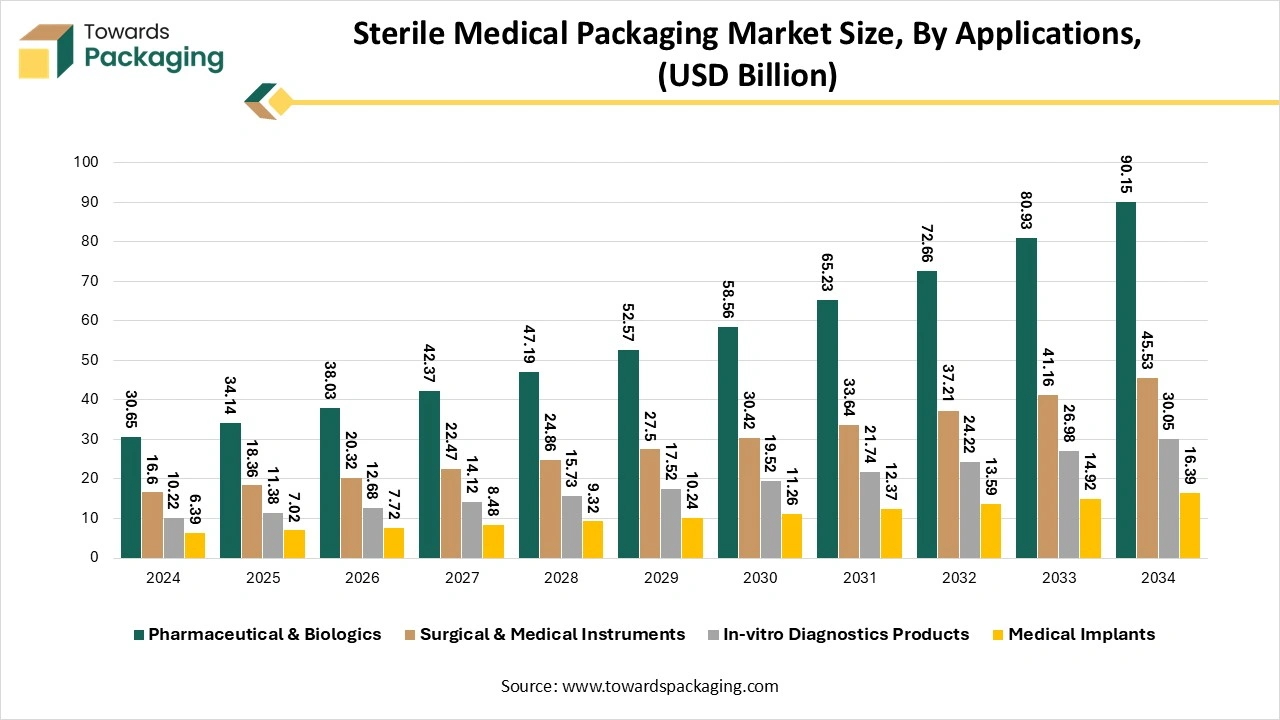

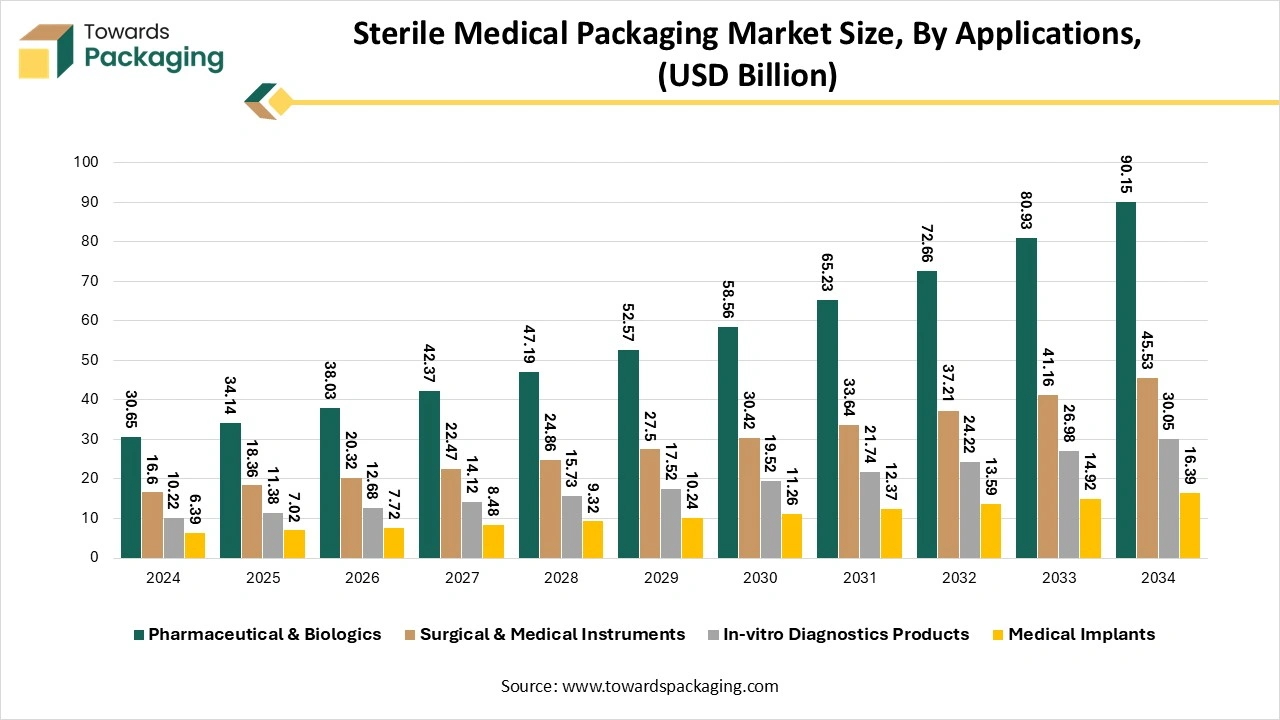

Safe and Effective Treatment: Pharmaceutical & Biologics Segment Led in 2024

The speedily growing infectious and non-infectious diseases have resulted in an upsurge in the number of patients. This has led to a growing demand for medicine and blood tests. These aspects are anticipated to raise the demand for these packaging in pharmaceutical & biological usage and thus influence the market development. The pharmaceutical & biologics segment is a noteworthy and increasing part of the sterile medical packaging market.

This sector is anticipated to lead the market because of the rising demand for safe and effective treatments. The requirement for sterile medical packaging in the In-vitro Diagnostics sector is influenced by the growing need for precise and consistent diagnostic tests, along with the rising consciousness of the importance of contamination control in healthcare sector.

Regional Insights

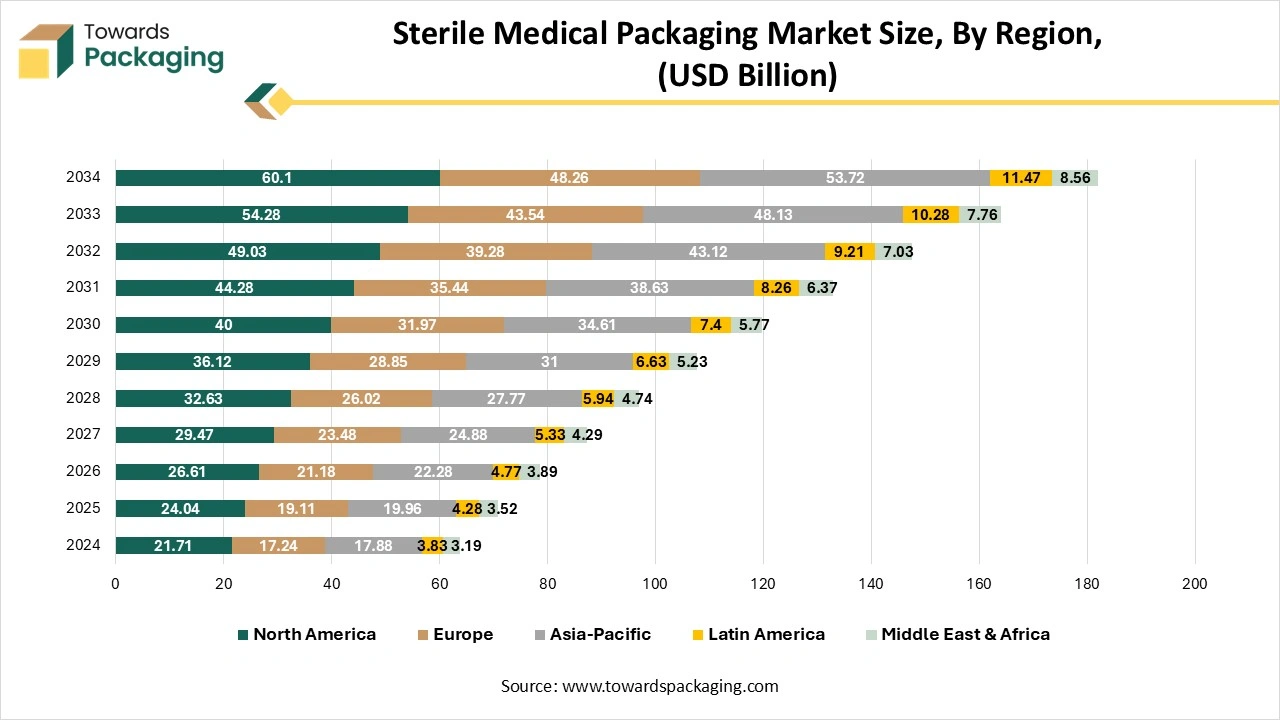

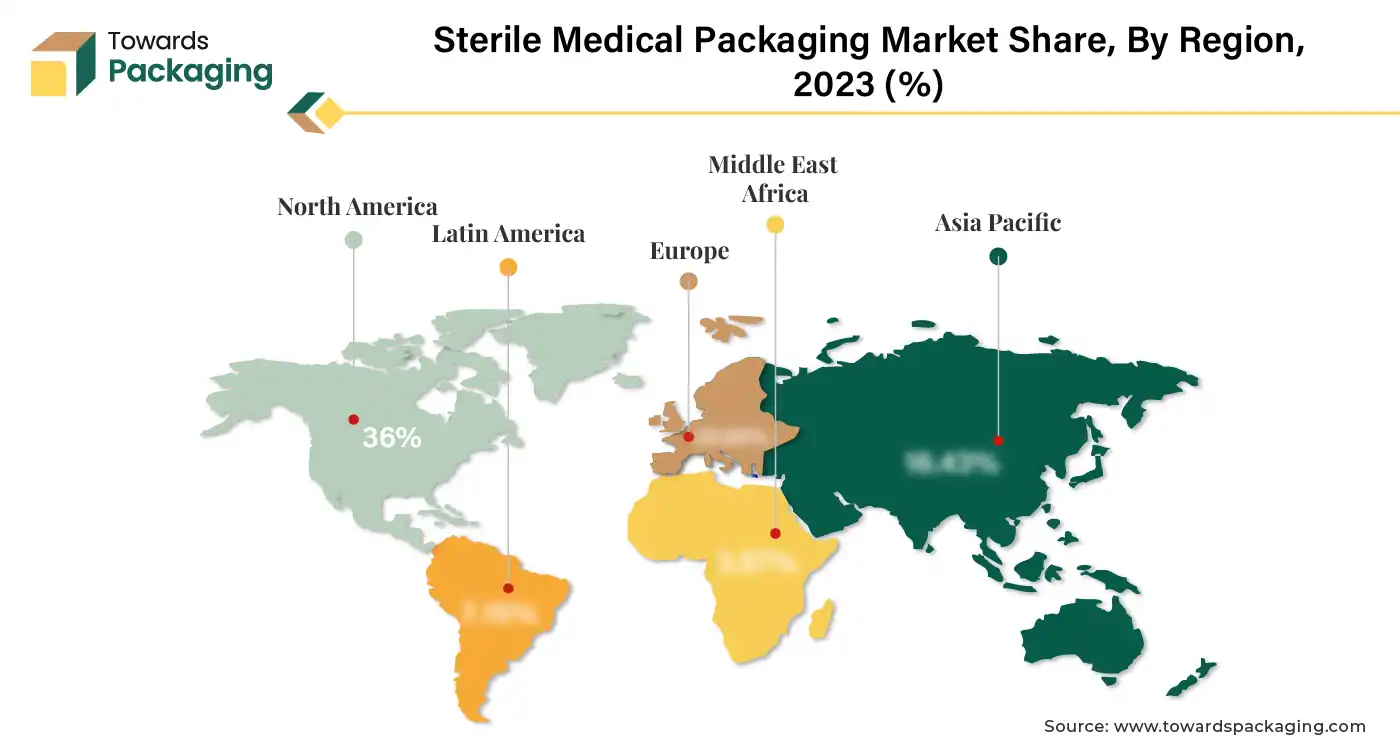

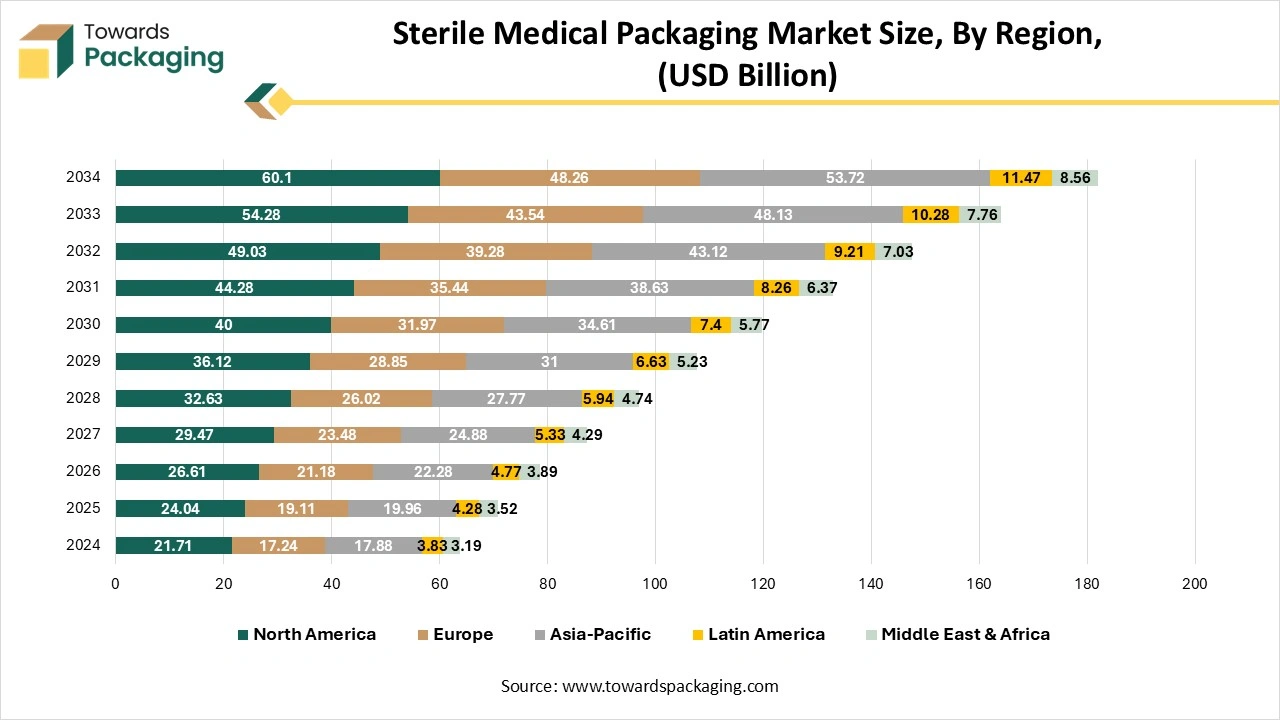

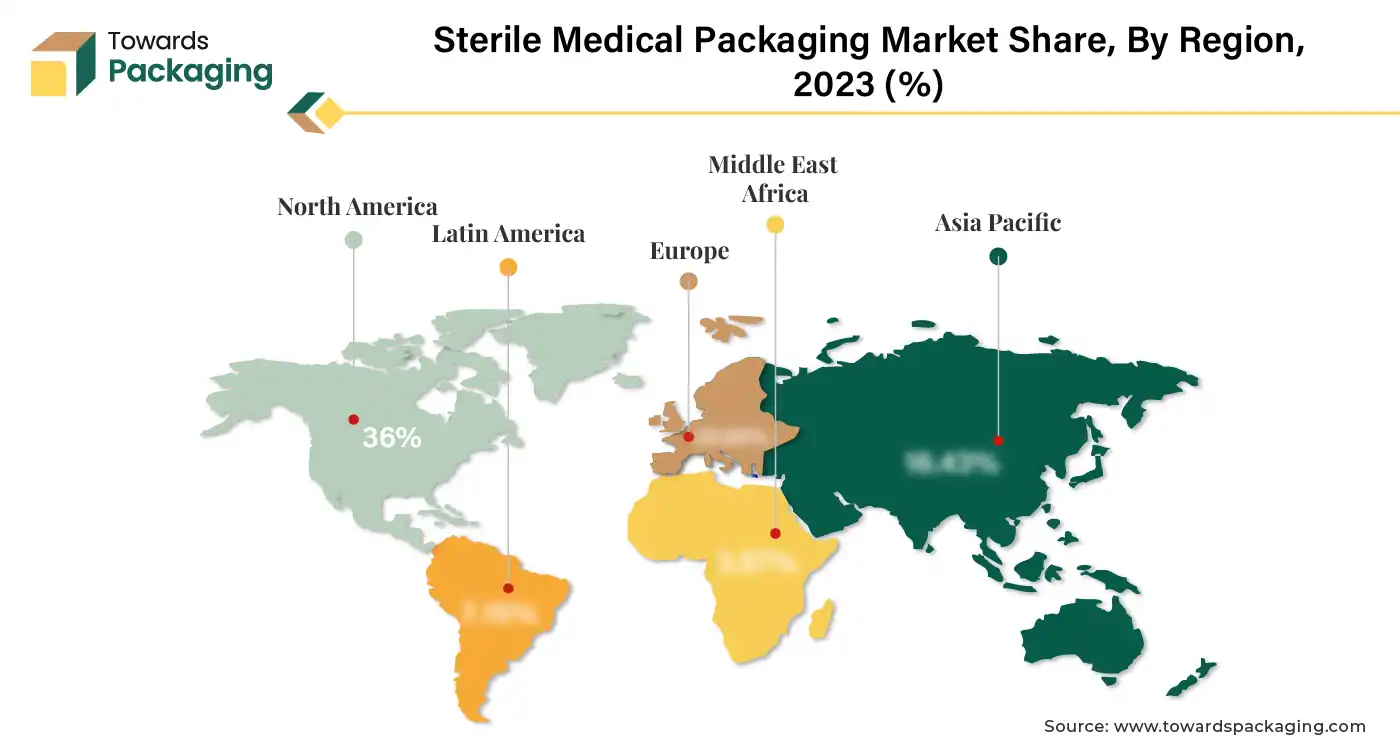

Increasing Brand Production: North America to Sustain as a Leader

North America witnessed the largest market share for the year 2024 this growth is due to the growing brand production there is a high demand for enhanced and sterilized production of excellent packaging. The government is continuously working towards the enhancement of the packaging of medical products which can be stored for a longer duration without any risk of contamination.

The growing healthcare infrastructure also contributes significantly towards the growth of the packaging industry. With the growing number of infrastructure the demand for equipment also growing which results in the rising demand for packaging production and hence enhances the growth of the market. The government plays a significant role in providing funds for research and studies which help pharmaceuticals to produce new medicines and products with growing requirements.

- In April 2023, the FDA, announced the launch of a Radiation Sterilization Master File Pilot Program for market players that sterilize single-use PMA-approved equipment using radiation, comprising gamma radiation, or ethylene oxide.

In countries such as the U.S. and Canada, there is a huge rise in the establishment of brands that manufacture sterile medical packaging using advanced technology. Major market players such as Amcor, Technipaq, SteriPack, Berry Global, Oliver, Nelipak Healthcare Packaging, Almac, West Pharmaceutical Services, and other companies play a significant role in the development of the market. As with growing brands, there is a growth in the quality of the packaging products.

- In April 2024, Almac, announced the launch of new U.S. commercial packaging operations based in Audubon, PA, by the U.S. Food and Drug Administration.

U.S. Market Trends

The U.S. sterile medical packaging market is driven by the advanced infrastructure industry and strict regulatory standards in the country. The U.S. Food and Drug Administration enforces strict regulations on medical packaging safety and integrity. Compliance with FDA standards often sets the benchmark global, making U.S.-developed packaging solutions desirable worldwide. The U.S. is home to many of the world’s largest medical device manufacturers (e.g., Johnson & Johnson, Medtronic, Boston Scientific). A high volume of medical device production creates substantial demand for sterile packaging.

Robust domestic research and development and innovation drive the development of new devices requiring specialized packaging. The U.S. has a highly developed packaging industry, especially in plastics, films, and adhesives. Access to cutting-edge technologies, including cleanroom packaging environments, helps meet strict sterilization standards. The U.S. country has a well-developed logistics infrastructure that supports the rapid distribution of sterile medical products domestically and internationally. U.S.-based companies are major exporters of sterile packaging materials and equipment, especially to Europe and Asia.

Rising Pharmaceutical Products Demand: Asia Pacific to Sustain as Fastest Growing Region

Asia Pacific is estimated to grow at the fastest rate over the forecast period. The market is growing significantly due to the rising demand for pharmaceutical products across all countries such as India, Japan, South Korea, China, and Thailand. Continuous initiatives by the government have also resulted in the growth of the production of pharmaceutical products which needed sterile packaging for safe storage and transportation of products.

Advancements in the technology of packaging to keep products safe from contamination such as moisture, air, water, light, or any external agent. In November 2023, Coveris, announced the launch of a new recyclable, flexible thermoforming film solution named Formpeel P.

Single-use packaging is highly preferred in this region to avoid any infection and advanced technology is incorporated to manufacture such products. This market is highly influenced by eco-friendly packaging due to the stringent guidelines of the packaging industry. Several market players such as SteriPack Contract Manufacturing, Nelipak Healthcare Packaging, West Pharmaceutical Services, Placon Corporation, ProAmpac, Technipaq, Inc., DuPont, and many others have continuously brought innovation to this market which resulted in the growth of the market.

China Market Trends

China's sterile medical packaging market is driven by several factors. China is the world’s largest manufacturing hub, producing vast quantities of medical devices, pharmaceuticals, and packaging materials. This scale allows high-volume, cost-efficient production of sterile medical packaging. China benefits from end-to-end supply chains from raw materials (e.g., polymers, aluminum, glass) to final packaging and labeling. This integration supports shorter lead times and lower costs, improving responsiveness to market demands. China’s lower labor costs and large domestic production of raw materials (e.g., plastics, paperboard) make it a cost leader in sterile packaging.

Chinese manufacturers are increasingly compliant with FDA, CE, and ISO standards, enabling exports to regulated markets. This boosts credibility and demand for Chinese packaging globally. Chinese companies are rapidly adopting advanced packaging technologies, such as blister packs and pre-filled syringes, barrier films, and serializable materials, and automation and robotics in packaging lines. The Chinese government supports domestic medical technology and packaging through initiatives like ‘Made in China 2025” and “Healthy China 2030”. Hence, all factors collectively make China the dominant country in the sterile medical packaging market.

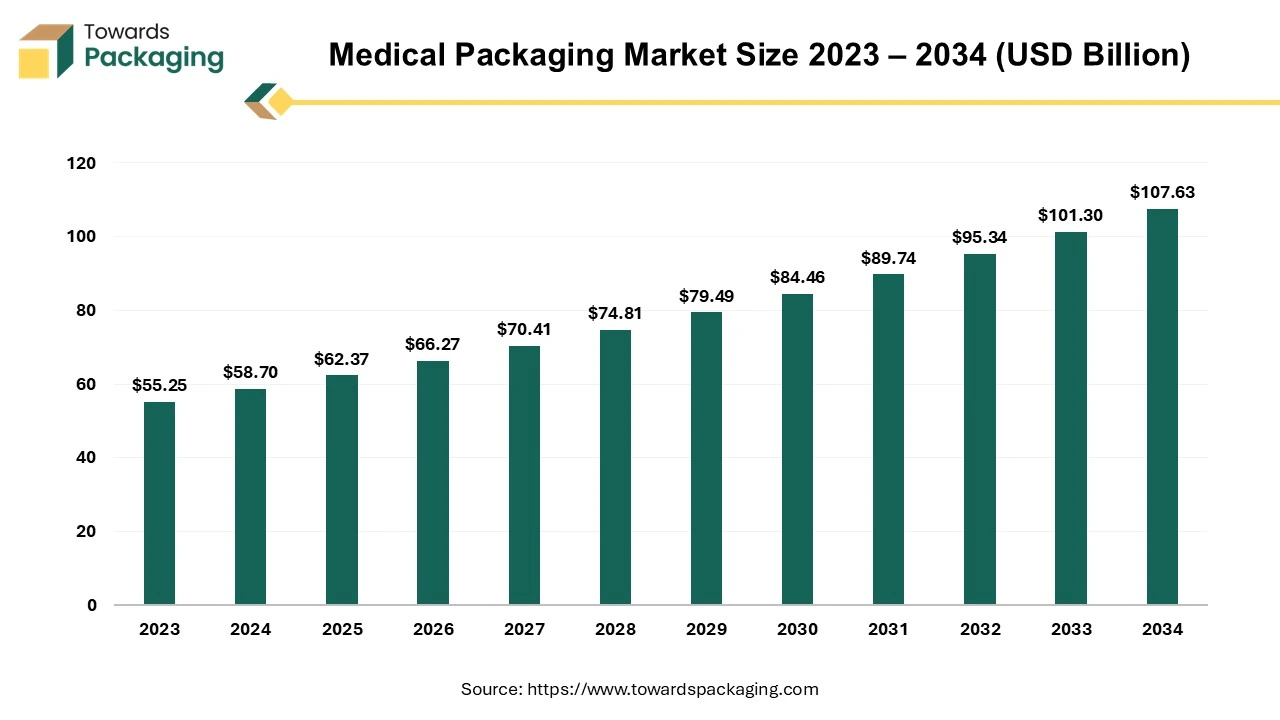

Future of Medical Packaging Market

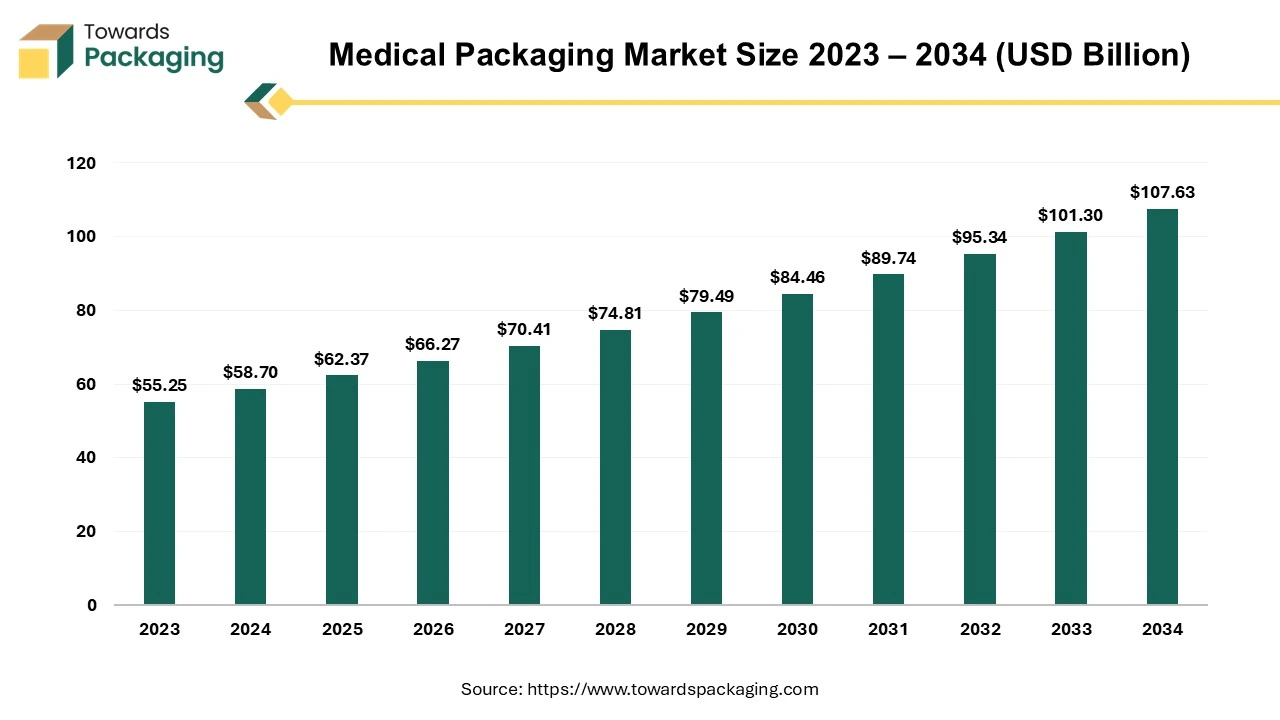

The global medical packaging market is set for robust growth, with its size projected to rise from USD 62.37 billion in 2025 to USD 107.63 billion by 2034, registering a CAGR of 6.25% from 2025 to 2034. This expansion is driven by increasing demand for sterile, sustainable, and smart packaging solutions in the healthcare sector. Innovations in biodegradable materials, tamper-evident designs, and intelligent tracking systems are shaping the industry landscape.

This market is proliferating significantly due to rising awareness towards healthcare, growing earnings among people, and increasing cases of chronic diseases such as diabetes, high blood pressure, coronary diseases, respiratory diseases, and many others. The growing concern among people about health issues and medical treatment also contributes to the growth of the medical packaging market.

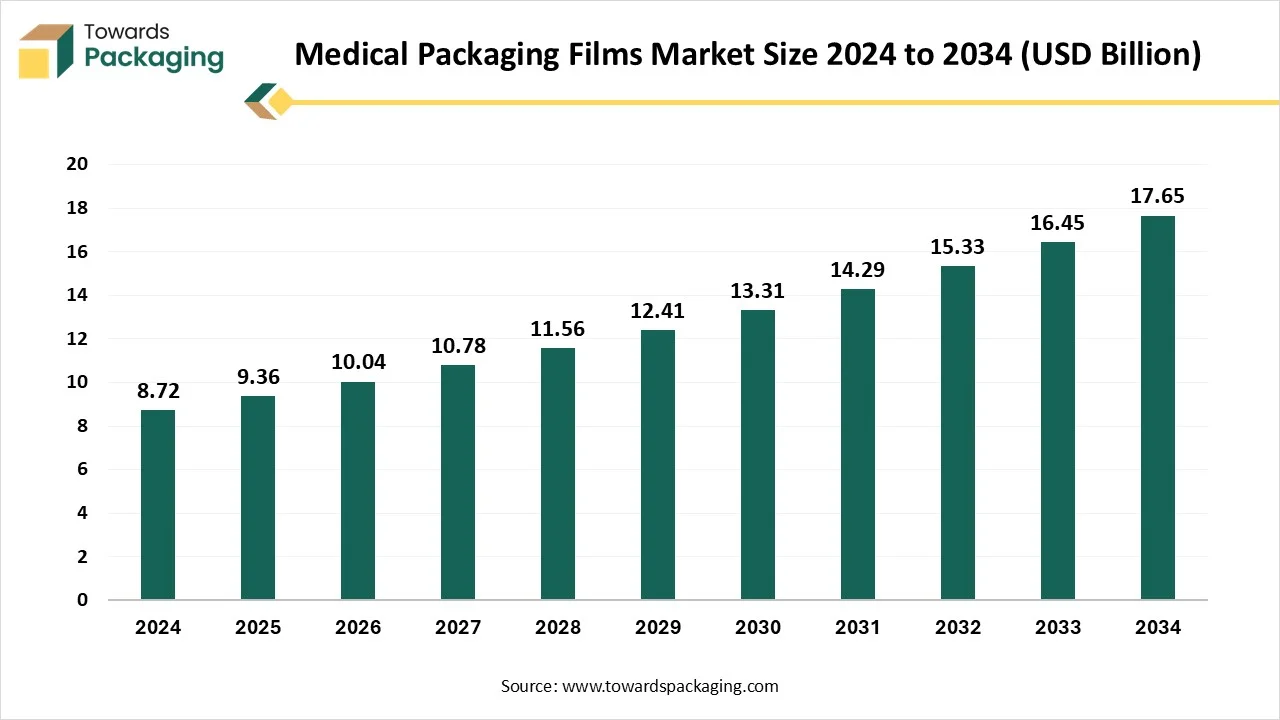

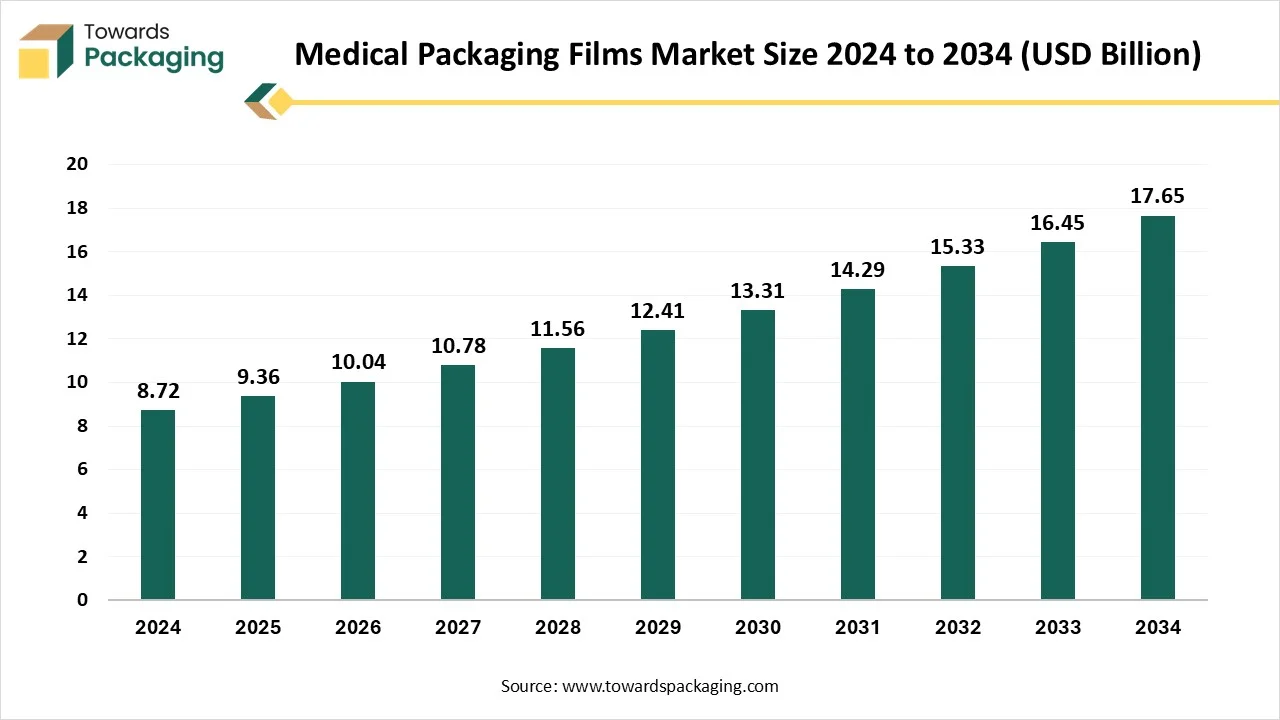

Future of Medical Packaging Films Market

The medical packaging films market is forecasted to expand from USD 9.36 billion in 2025 to USD 17.65 billion by 2034, growing at a CAGR of 7.3% from 2025 to 2034. The growing chronic diseases, rising investment on healthcare sector, and the increasing inclination towards bioplastic resources enhance the usage of medical packaging films market. The growing concern for protecting pharmaceutical products from moisture, air, dust, and pollution has evolved this market to grow rapidly.

The medical packaging films market plays a significant role in the pharmaceutical industry as it helps to protect various products from adverse climate and help to store them for a longer period. The growing use of packaging films in the pharmaceutical industry is accredited to their properties such as lightweight, non-reactive with chemicals, and transparency influence the demand for this market. The major market players such as Parekhplast India Limited, AptarGroup, Inc., Uflex Limited, Honeywell International, Inc., and many others are continuously introducing innovation in this market has boosted the development of this market.

Future of Sterile Medical Paper Packaging Market

Healthcare facilities worldwide are focusing more on infection control, leading to a surging demand for sterile medical paper packaging. As the number of surgeries, medical treatments, and new drug developments increases, hospitals and pharmaceutical companies need stronger, safer, and more protective packaging. From 2025 to 2034, this market will grow steadily, playing a crucial role in modern medical packaging solutions.

The sterile medical paper packaging market is likely to witness substantial growth during the forecast period. Sterile medical paper packaging is paper-based packaging option that is designed to maintain the sterility of medical devices, surgical instruments, pharmaceuticals and other healthcare products.

These packaging materials comprising medical-grade paper and paperboard, serve as a microbial barrier while allowing sterilization agents like steam, ethylene oxide (EtO), or gamma radiation to penetrate and effectively sterilize the contents. With features such as high breathability, tear resistance as well as reliable sealability, sterile medical paper packaging guarantees product integrity and contamination prevention and makes it essential in hospitals, laboratories and pharmaceutical industries.

Future of Sterile Medical Containers Market

The sterile medical containers market is booming, poised for a revenue surge into the hundreds of millions from 2025 to 2034, driving a revolution in sustainable transportation. The growing number of chronic diseases and rising healthcare facilities have enhanced the demand for samples with packaging that can be stored for a long period for precise diagnosis, boosting the development of the sterile medical containers market.

The sterile medical containers are special containers utilized for the collection of specimens such as urine, blood, joint fluid, stool, peritoneal exudate, sputum, and biopsy samples for diagnosis in laboratories. The sterile container is distinguished by numerous aspects. When distributed to the handler, the screw cap is inflexibly locked on the medical containers but offers a gap between the cap and container that is enough for ethylene oxide gas to spread and sterilize the inner space of the medical container. Other hand, when the cap is constricted following the specimen assemblage, it avoids any leak of the bio-risk content. The resource utilized for producing the medical container is selected for its precision to safeguard that it can be effortlessly sucked up the chute into the upstairs carousal carrier of the healthcare centres but will resist cracking when the loaded medical containers are designed to avoid side drip when a liquid sample is into a test tube or any other collector.

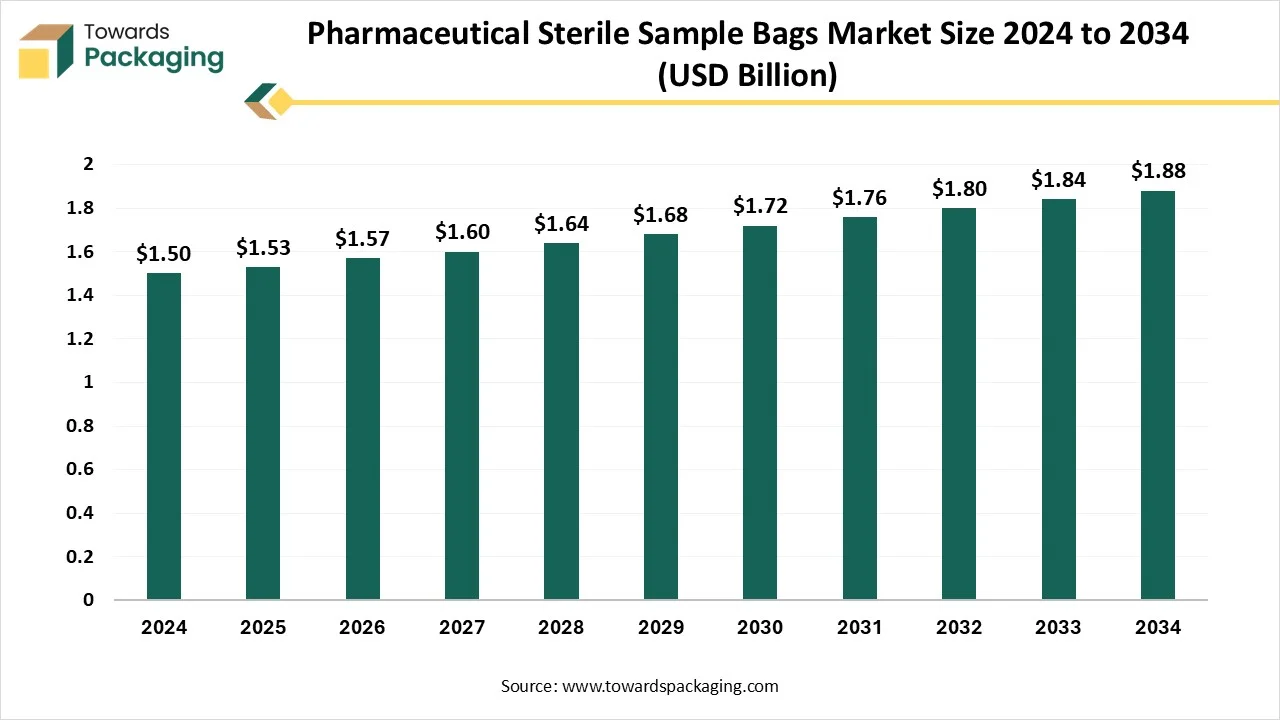

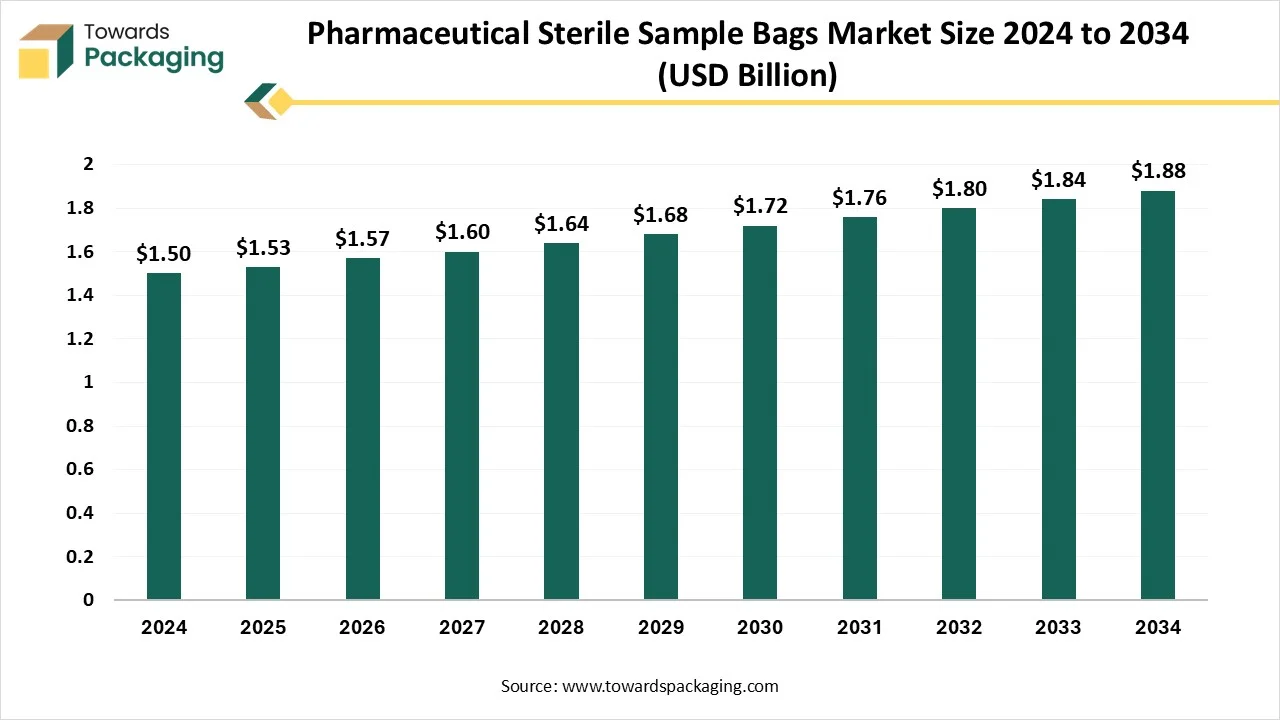

Future of Pharmaceutical Sterile Sample Bags Market

The pharmaceutical sterile sample bags market is projected to reach USD 1.88 billion by 2034, expanding from USD 1.53 billion in 2025, at an annual growth rate of 2.27% during the forecast period from 2025 to 2034. The increasing demand for sterile sample bags is gaining traction because of strong supervisory necessities for pharmaceutical packaging and the requirement for pollution-free sample management.

Major trends comprise progressions in sustainable packaging resources and the incorporation of smart technologies for improved traceability and obedience. These bags are extensively utilized in pharmaceutical production, laboratories, hospitals, and field testing to confirm sample quality and compliance with hygiene and security standards.

The pharmaceutical sterile sample bags market refers to the industry surrounding specialized, contamination-free packaging solutions used for the collection, transport, and storage of pharmaceutical and biotech samples, including powders, liquids, tissue specimens, and APIs. These bags are manufactured under strict aseptic conditions to ensure sample integrity, safety, and regulatory compliance (e.g., FDA, USP, EU GMP). Sterile sample bags are widely used in clinical trials, quality control, R&D labs, and GMP manufacturing environments. They help reduce the risk of cross-contamination and are essential for sterility assurance in pharmaceutical workflows.

Sterile Medical Packaging Market Top Companies

Latest Announcements by Market Leaders

- In September 2023, Don Kennedy, Vice President of Sales and Marketing at Guardian Medical, “Minimal Footprint Packaging redefines how decisions are made about sterile packaging. Drawing inspiration from an industry that does an exceptional job at sizing implants for patients, we took that same approach and applied it to packaging with our CapSure system.”

Recent Developments

- On 7 April 2025, Nelipak Corporation, a top global manufacturer of packaging solutions for diagnostic, medical device, and pharmaceutical drug delivery and other demanding solutions, revealed that it has announced its loyalty service to Asia Pacific on a direct basis, and through its selected partners.

- On 29 January 2025, Syensqo, a top provider of high-level performance material and chemical solutions, and MezLight LLC in medical device solutions, have partnered to serve an inventive surgical lighting system to the industry that has main components molded in Radel polyphenyl sulfone (PPSU).

- In November 2024, Billerud, announced the launch of MediKraft SealBase, a new surface-treated medical paper.

- In March 2024, STERIS, announced the launch of Verafit Sterilization Bags and Covers, which feature a new, patent-pending viewing window to visually inspect and confirm the dryness of a sterilized part.

- In February 2023, Eagle Medical Packaging Sterilization Inc., announced the launch of Novel Pre-Validated Packaging Solution.

Sterile Medical Packaging Market Segments

By Material Type

By Product Type

- Thermoform Trays

- Sterile Bottles & Containers

- Sterile Closures

- Pre-fillable Inhalers

- Pre-fillable Syringes

- Vials & Ampoules

- Blisters & Clamshells

- Bags & Pouches

- Wraps

By Sterilization Method

- Chemical Sterilization

- Radiation Sterilization

- High Temperature/Pressure Sterilization

By Application

- Pharmaceutical & Biologics

- Surgical & Medical Instruments

- In-vitro Diagnostics Products

- Medical Implants

By Region Covered

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait