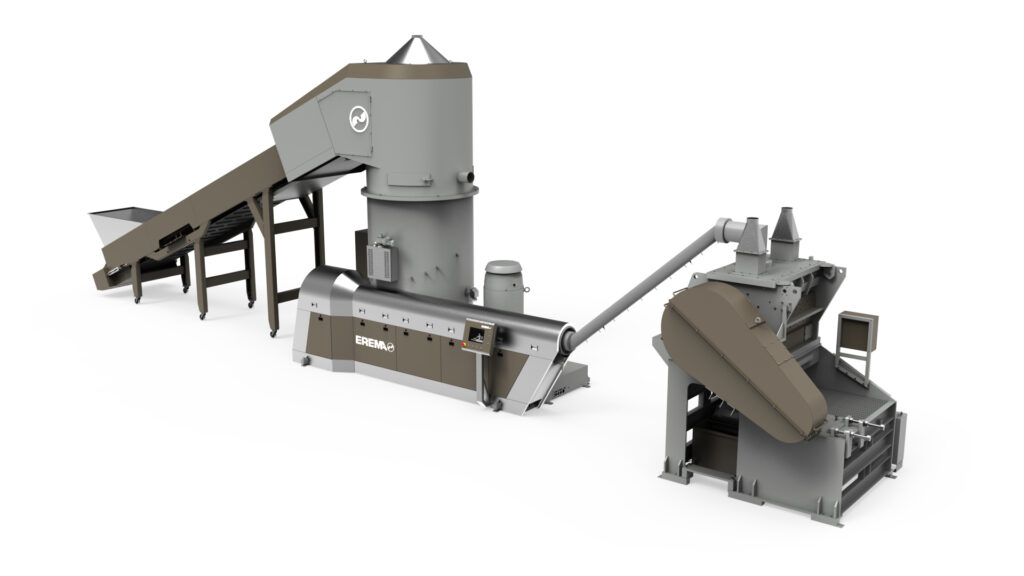

AGGLOREMA Works on Chemical Recycling

Image Credits: EREMA

AGGLOREMA procedures heavily polluted waste streams with a short density and moisture fillings of up to 12%. This is conceivable by compounding the EREMA Preconditioning Unit (PCU) with untested Counter Current® technology and a specially designed extruder secure. Even when the arrangement of the fodder resource differs significantly, for example, in relations of moisture, polymer, and geometry, this amalgamation confirms constant procedure control. The resource is preheated, homogenised, degassed, and incessantly nourished into a short extruder without upstream aeration. It grips up to 2.3 tonnes each hour, with sufficient headroom to upsurge quantity. From the extruder, the moderately melted resource strand is nourished straight through a soften pipe into the water-cooled melt mincer. Here, it is shaped into agglomerates with high densities of 280 to 380 kg/m³ and a distinct particle extent. Reliant on the shape, downstream drying can decrease the remaining dampness up to less than 1%. The procedure layout is intentionally reserved, candid, and robust. The arrangement capitalises on the rewards of extrusion, but significantly decreases procedure temperature and energy consumption.

The AGGLOREMA can be utilized to formulate feedstock resources for mechanical recycling as well as for chemical recycling. In addition to the new AGGLOREMA system, EREMA also provides the CHEMAREMA® series, a resolution for chemical recycling in which soften is fed straight into the vessel. In recent months, the corporation has been operating numerous CHEMAREMA® machines with amounts of between 2 and 3.5 tonnes per hour. EREMA provides these systems with an amount of up to 4.5 tonnes per hour.

- In order to survive the harshness of the polluted input resource over the long term, CHEMAREMA® arrangements feature a plan that is significantly strong.

Business Development Manager Chemical Recycling at EREMA, Klaus Lederer, expressed, "It is our job to build machines that support chemical recyclers in the recovery of low-grade waste fractions. AGGLOREMA closes the gap between highly contaminated, heterogeneous, and often thin-film waste streams and reliable feedstock for the reactor. This is a particularly robust and energy-efficient system."

Top Stories

- A Simple Guide to Understanding Benefits of Rigid Boxes

- A Packaging Guide for Artisanal and Handmade Product Brand

- UFLEX Expands PET Recyclable Woven Polypropylene Food Packaging to Mexico

- Tetra Pak Launches India’s First Carton Packaging with Certified Recycled Polymers

- PepsiCo Reinforces pep+ Strategy with Sustainable Packaging Goals