Base Paper for Heat Sealable Packaging Market Size, Trends, Share and Innovations

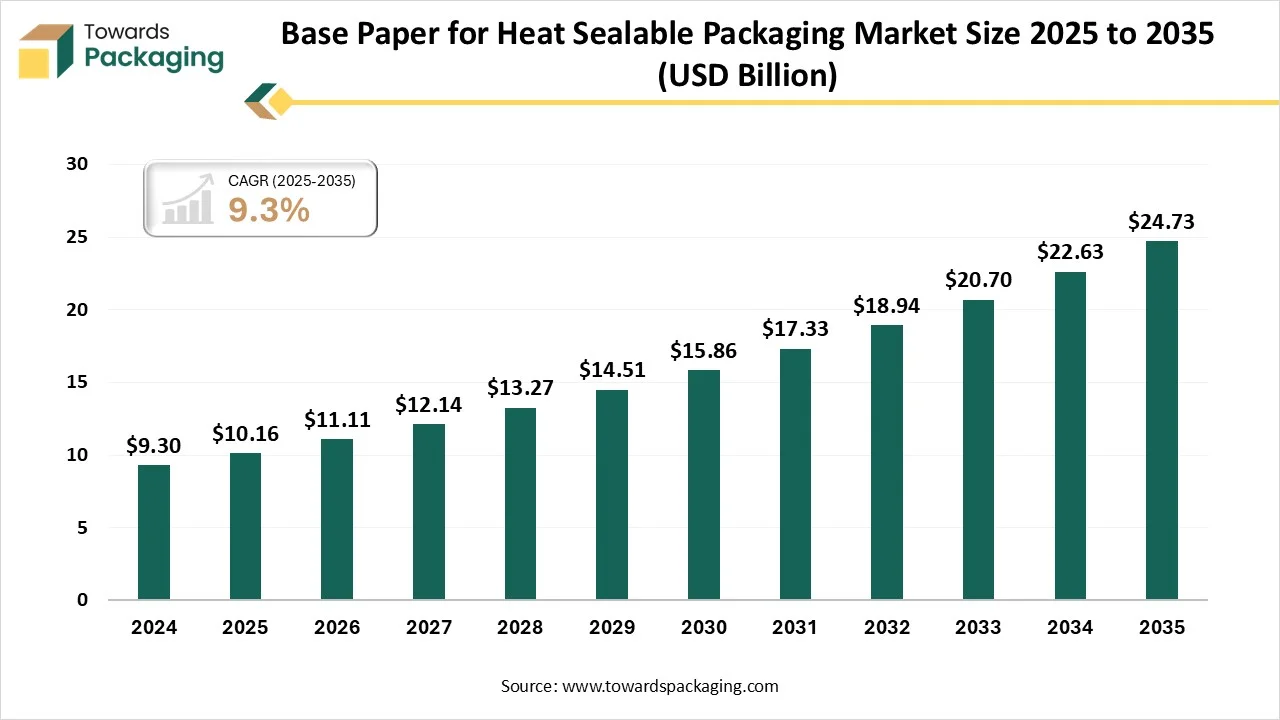

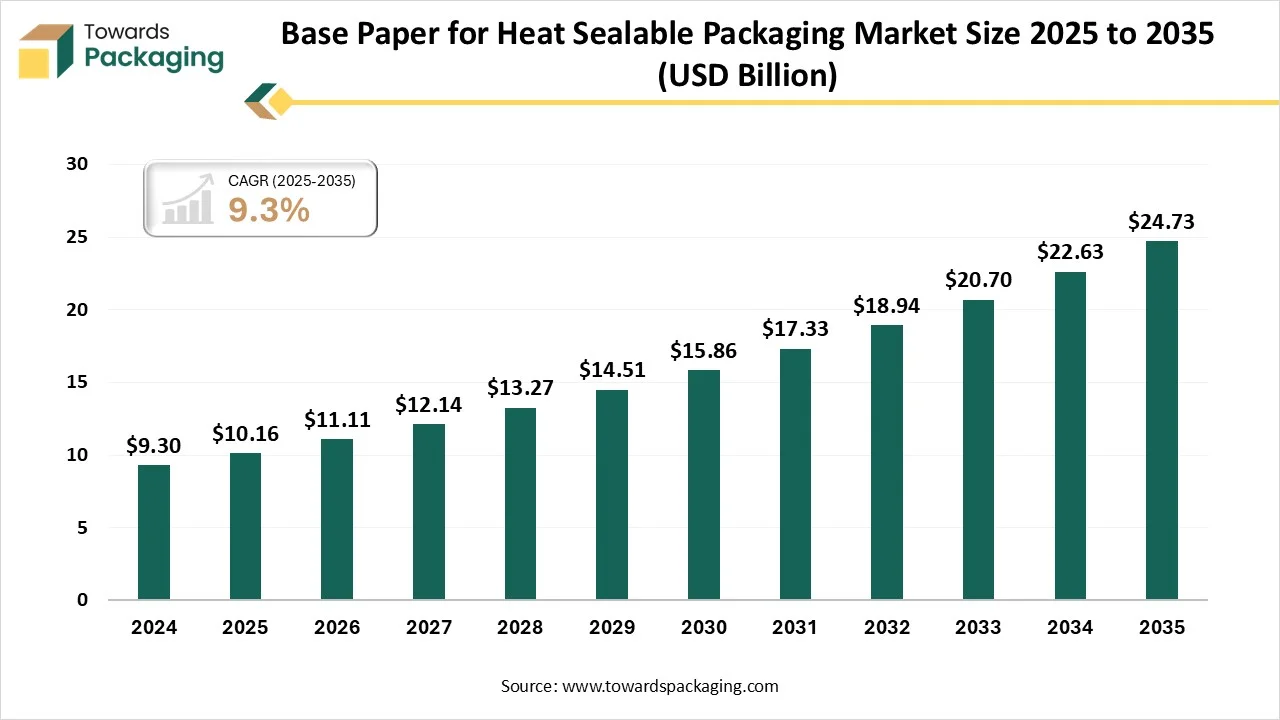

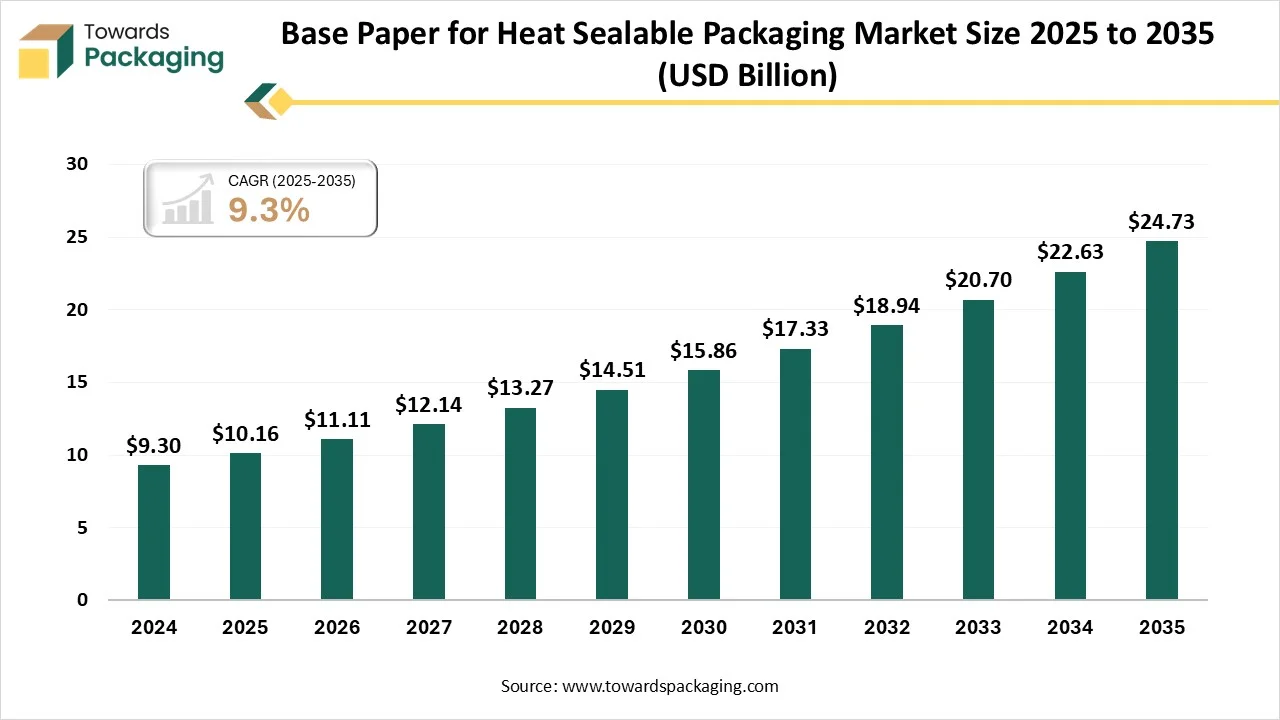

The base paper for heat sealable packaging market is forecasted to expand from USD 11.11 billion in 2026 to USD 24.73 billion by 2035, growing at a CAGR of 9.3% from 2026 to 2035. The urge for the base paper in heat-sealable packaging is initially being driven by the rigid encouragement for environmental sustainability, integrated with the regular advantages that paper serves as a base material.

Major Key Insights of the Base Paper for Heat Sealable Packaging Market

- In terms of revenue, the market is valued at USD 11.11 billion in 2026.

- The market is projected to reach USD 24.73 billion by 2035.

- Rapid growth at a CAGR of 9.3% will be observed in the period between 2026 and 2035.

- By region, Asia Pacific has dominated the global market by holding the highest share in 2025.

- By region, North America is expected to grow at the fastest CAGR from 2026 to 2035.

- By sealing technology, the hot bar sealing segment is expected to hold the largest market share in 2025.

- By sealing technology, the clamshell sealing segment will be developing at a fastest CAGR between 2026 and 2035.

- By material type, the plastics segment is predicted to carry the largest market share in 2025.

- By material type, the multi-layer / composite materials segment will be growing at a fastest CAGR between 2026 and 2035.

- By packaging format, the pouches segment is predicted to carry the biggest market share in 2025.

- By packaging format, the flexible films segment will be developing at a fastest CAGR between 2026 and 2035.

- By end-use industry, the food and beverage segment is expected to hold the largest market share in 2025.

- By end-use industry, the pharmaceutical and healthcare segment will be developing at a fastest CAGR between 2026 and 2035.

What is Base Paper for Heat Sealable Packaging?

Heat-seal coatings are the thin layers of adhesive material that are used for paper layers, which activate when exposed to pressure and heat. These coatings are crafted to create a link between two materials, generally paper-to-paper or paper-to-other substrates, like metal or plastic. This procedure is complicated in terms of packaging, in which the reliability of the seal ensures product freshness, protects against pollutants, and delivers tamper-evident security.

It operates by softening and becoming inappropriate when it gets exposed to heat. Once the heat is used, the coating bonds to another layer, and as it cools down, it gets updated, which creates a tight and durable seal. The bond is made rigid enough to firmly stand with different eco-friendly conditions, which include changes in moisture, temperature, and mechanical stress.

Trends in Base Paper for Heat Sealable Packaging Market

- E-commerce-centric packaging: Users currently choose the convenience of ordering the product with fewer clicks and delivering it directly to their doorstep. The prediction is that the items must be served in a maximum state. E-commerce organizations are discovering options of box designs and water-resistant packaging that are convenient to assemble, smooth, and safe for logistics, too.

- Anti-Counterfeiting measures: As worldwide markets continue to stretch, the risk of counterfeit products increases. 2025 will serve more services like tamper-evident seals, holographic labels, and product serialization, too. Brands experience issues with fake products that threaten their reputation, which gives them reason to breathe a sigh of relief.

- Smart Interactive Packaging: Organizations are getting insightful with what they can operate with, like smart technology, such as NFC tags, QR codes, and Augmented reality experiences. Many studies disclose that users are willing to pay extra for the user experience rather than the real cost of the product.

- Paperization Trends: The concentration is on moving to fibre-based alternatives that align with sustainability goals and the regulatory needs. Kraft and corrugated paper packaging not only aligns with fewer design choices of consumers but also creates packaging that is more attention-grabbing.

- Market Growth Overview: The base paper for the heat -sealable packaging is stretching because of powerful drivers like user demand for ease and fresh food, rigid environmental regulations that encourage avoidance of plastics, main developments in paper technology, and perfect strength, which is driving markets like Asia.

- Global Expansion: The worldwide expansion of the base paper for heat -sealable packaging is developing in 2025, which is initially being driven by the plastic-free, recyclable alternatives in the pharmaceutical, food and beverage, and e-commerce sectors.

- Major Market Players: The main market players in the base paper for the heat-saleable packaging are Mondi Group, Stora Enso, Sappi, Walki, Billerud, International Paper Company, and WestRock Company, too.

- Startup Ecosystem: As eco-friendly issues drive organizations towards more sustainable packaging solutions, heat-sealable paper has come up as a game-changing alteration to regular plastic packaging. This invention material integrates the natural requests and sustainability of appearance with the actual sealing potential that is regularly linked with the plastic films.

Technological Developments in the Base Paper for Heat Sealable Packaging Market

The inventions in heat sealing technology serve a bunch of advantages which are insightful to the packaging professionals, as the developments in heat sealing machines point out that they can run at greater speeds while tracking the accurate control over the sealing procedure. This results in lesser energy usage, less waste, and a more effective complete manufacturing line. With the assistance of temperature controls and automated sealing processes, the productivity of the seals is more constant. This is complicated for the items that need airtight packaging to ensure freshness or security, such as medical and food supplies, which are delivered.

Trade Analysis of Base Paper for Heat Sealable Packaging Market: Import & Export Statistics

- As per the global data, the globe has officially imported 959 shipments of base paper and HSN Code 4804 during the period May 2024 to April 2025. Such imports were supplied by the 89 exporters to 82 global buyers, which has marked a development rate of 68% as compared to the previous twelve months.

- During this period, in April 2025, the World imported 56 base papers and HSN Code 4804 shipments.

- The world imports majority of its base papers and HSN Code 4804 from China, Chile, and Japan.

- Worldwide, the leading three importers of base paper and HSN Code 4804 are Vietnam, Mexico, and Malaysia. Mexico has topped the globe in terms of Base Paper and HSN Code 4804 imports with 696 shipments, which is being followed by Vietnam with 650 shipments, and Malaysia, which takes the third position with 275 shipments.

Base Paper for Heat Sealable Packaging Market - Value Chain Analysis

Package Design and Prototyping: Base paper packaging design involves choosing the accurate paper material and structural form so as to protect the product, develop branding, and ensure sustainability, too. Main design considerations count barrier properties, material strength, functionality, and the printing potential too.

- Key Players: WestRock Company, Huhtamaki Oyj, and Amcor plc.

Recycling and Waste Management: Recycling starts with the collection and separation of the paper waste. It is crucial to collect paper separately from other kinds of waste in order to prevent pollution. Paper waste can be classified depending on its type and quality, as this affects the complete recycling procedure. Once they are collected, the paper is sorted into.

- Key Players: DuPont Teijin Films, Winpak Ltd, and Glenroy, Inc.

Logistics and Distribution: The logistics and the distribution of the base paper count on a highly tailored supply chain that concentrates on high-volume transport and moisture -sensitive carrying too. A specialized machine shifts these rolls as it needs forklifts filled with “roll clamps” in order to protect the sensitive outer layers from tearing or crushing.

- Key Players: HEAT SEAL, LLC, Glenroy, Inc., and Winpak Ltd.

Segmental Insights

Sealing Technology / Type Insights

Why Has The Hot Bar Sealing Segment Dominated The Base Paper For Heat Sealable Packaging Market In 2025?

The hot bar sealing segment has dominated the market in 2025, as these sealers utilise heated bars in order to make a seal by melting the packaging material and linking it collectively. Such machines are typically used for sealing pouches, bags, and tubes made of thermoplastic materials like polypropylene, polyethylene, and laminated films, too. Hot bar sealers are smooth and generate robust seals that are reluctant to leak or tamper with both.

The clamshell sealing segment is predicted to witness the fastest CAGR during the forecast period. It is a procedure of protecting the two halves of a hinged plastic container's ingredients from pollutants, tampering, or theft. A portable clamshell sealer is beneficial for small manufacturing operations. The sealer is being delivered to its running operator and temperature locations that match the flanges of the clamshell in between the jaws of the sealer. Also, the jaws are being clamped together and placed for the period as proposed by the producer.

Material Type Insights

Why Has The Plastic Segment Dominated The Base Paper For Heat Sealable Packaging Market In 2025?

The plastic segment dominated the market in 2025, as different types of packaging materials that can be used with heat sealing equipment, such as polyethylene (PE), polypropylene (PP), polystyrene (PS), and polyvinyl chloride (PVC). Such packaging materials are utilized in bags and pouches and are conveniently packed with a heat sealing machine to seal the ends or the plastic bag collectively. Two of the most prevalent types of polybag materials are manufactured from polyethylene and polyethylene terephthalate (PET). They are a lightweight material that can be heated up, fused together, and will cool down soon after avoiding the heating element. So, low-density polyethylene (LDPE) is specifically a perfect choice for the polybag material in order to be heat-sealed.

The multi-layer / composite materials segment is expected to experience the fastest CAGR during the forecast period. Multilayer film packaging is at the frontline of current packaging inventions, which gets updated on how products are protected, preserved, and displayed across sectors. As users' demands for the huge shelf life, sustainable solutions, and rigid product protection continue to develop, multilayer film packaging has emerged as a complicated technology that solves these demands.

Why The Pouches Segment Dominated The Base Paper For Heat Sealable Packaging Market In 2025?

The pouches segment has dominated the base paper for heat sealable packaging market in 2025, as flexible packaging, such as stand-up pouches, flat pouches, or flat bottom pouches, serves many advantages. They are particularly space-saving, attention-grabbing, and sustainable on the retail shelves. Additionally, they are exceptionally practical for filling -whether in person or with a machine. On the other hand, stand-up pouches (which are also known as Doypacks) that have a standard press-seal zipper, for very flat bottom pouches, are also capable of adding a so-called Pocket Zipper, which enables a big opening.

The flexible films segment is predicted to witness the fastest CAGR during the forecast period. Heat-resistant films are tailored in multi-layered polyolefin films created to withstand higher levels of heat. They are utilised over more regular shrink films in order to make a seal with extra power and tear resistance. The higher sealing temperature, along with the several layers of plastic, generally makes a sturdy closure that operates well in many packaging applications, such as pharmaceutical and food packaging, that need a higher level of security.

End-User Insights

How the Food and Beverages Segment Dominated the Base Paper for Heat Sealable Packaging Market in 2025?

The food and beverages segment has dominated the base paper for heat sealable packaging market in 2025, as heat sealing is one of the most prevalent and reliable sealing procedures, particularly for the smooth, flexible packaging made of plastic foils or films. It operates by using heat and pressure on the packaging material, which causes the surfaces to fuse and melt together to make an airtight seal. This procedure is widely used for ready meals, snacks, and frozen foods as it smoothly protects moisture and air entry, thus protecting the freshness and extending the shelf life.

The pharmaceuticals & healthcare segment is predicted to witness the fastest CAGR during the forecast period. Heat seal machines make airtight and strong seals, which ensure product integrity, lower the risk of pollution, and prevent leaks or tampering, all of which are important for the particular pharmaceutical sector. Additionally, it avoids the demand for additional materials like staples or tapes, adhesives, and reduces the material costs. Pharmaceutical and healthcare packaging gets advantages from heat-sealable films, which are used to package capsules, pills, and other medicinal items.

Regional Insights

How Asia Pacific Dominated the Base Paper for Heat Sealable Packaging Market?

Asia Pacific dominated the market in 2025, as the region is witnessing major development, which is driven by the growth of e-commerce, a move towards sustainable packaging, and growing demand in the food and healthcare sectors. There are strict eco-friendly regulations, and the Extended Producer Responsibility (EPR) laws in countries such as Australia, Japan, Thailand, and Vietnam are forcing an official move towards plastic-to-recyclable paper-based sealing materials.

Why is India using the Base Paper for Heat Sealable Packaging Market? Importantly?

The Indian base paper is initially being driven by the growing urge from the printing, packaging, and tissue paper sectors. Fast urbanization and economic development in developing economies are driving the usage of packaged goods, hence filling the demand for sustainable packaging solutions, such as base paper. There is technological growth in the paper manufacturing industry that develops cost-efficiency and products that attract more producers.

Why is the Base Paper for Heat Sealable Packaging Market Growing Rapidly in the North America?

North America expects the fastest growth in the market during the forecast period as technological invention is an important element that encourages the updation of the North America-based paper, which affects everything from manufacturing smoothness to product quality. Developments in industry inventions count the growth of eco-friendly pulping procedures, such as waterless manufacturing techniques and chemical -free bleaching, which have mainly lowered the eco-friendly footprint. Further, digitalization and automation in production plants develop operational efficiency, improve product consistency, and reduce waste too.

How is the Base Paper for Heat Sealable Packaging Market Growing in Canada?

The stretched demand for food and beverage, logistics, and retail industry includes mainly market development that needs protective and cost-effective packaging selections. The technological growth in paper band manufacturing has enhanced durability and strength, and also developed acceptance. The regulatory pressure that supports recyclable and biodegradable packaging materials has further encouraged market development. Furthermore, the growing e-commerce sector in Canada makes it compulsory to have smooth packaging solutions that are easy to use and lightweight too.

The Base Paper for Heat Sealable Packaging Market in the European region is growing as RHOBARR barrier technology can be used by a large number of paper coating machines, which makes it attention-grabbing to converters, mills, and brand owners who seek to update to more sustainable packaging. This barrier technology serves solutions to a variety of demands, whether we are finding developed recyclability for the fibre -based on the shelf packaging and ultra-thin coatings for fast -delivered food uses, or convenient-to-recycle options for non-food user goods.

Germany Base Paper For Heat Sealable Packaging Market Trend

The implementation of nanotechnology and bio-based paper serves as a main possibility, leading to developed performance with a smaller environmental footprint. Also, the digital printing compatibility and the smart coating technologies are meant to update the market, which serves tailored and communicative packaging solutions. The market also has a competitive surrounding with main players that focus on strategic partnerships, sustainability initiatives, and technological growth to develop their market share.

The Base Paper for Heat Sealable Packaging Market in the Middle East &Africa (MEA) region is growing quickly, as the urge for this paper is initially being filled by a region-wide move from plastic to sustainable and paper-based flexible packaging. There are sustainability regulations that have strong bans on single-use plastics in Saudi Arabia, the UAE, and South Africa, and the UAE is forcing a transformation to paper-based alternatives for pouches and bags.

UAE Base Paper For Heat Sealable Packaging Market Trend

The UAE market is driven by sustained funding in the healthcare sector, developing regulatory emphasis, and technological developments in sustainability and safety, too. The acceptance of smart packaging solutions that include antimicrobial coatings and IoT-enabled tracking will further develop product classification and market entry, too. Industry players are predicted to concentrate on developing biodegradable and eco-friendly materials to match global environmental standards, which creates new opportunities for invention and luxury product services.

In South America, the base paper for heat sealable packaging market is growing steadily as it has rigid agricultural and export-linked food industries in dairy, meat, and produce, which are the main drivers, as it urges the high-barrier films and updated atmosphere pouches, which increase the shelf life. There is a growing urban demographic and on-the-go usage, which are moving towards tamper-evident and lightweight flexible designs, such as stand-up pouches, that are the fastest-developing product in this region.

Brazil Base Paper for Heat Sealable Packaging Market Trend

The Brazilian base paper for heat-sealable packaging has advantages from strict food safety regulations imposed by national bodies, which pushes the acceptance of relevant sealing technologies that expand the shelf life and lower the contamination risks. Furthermore, government incentives whose goal is to market sustainable packaging have developed R&D investments in environmentally friendly heat-sealable films, which match the growing choice for recyclable and biodegradable solutions.

Recent Developments

- In September 2025, SeamanPaper is a top company in terms of sustainable paper-based packaging, which recently revealed the launch of its latest line of heat-sealable and curbside paper.

- In August 2025, Mondi revealed Ad/Vantage Smooth Brown Semi Extensible, a latest kraft paper that is made to mix extensibility, strength, printability, and puncture resistance. The substitute can be used to form, fill, and pack the packaging for sharp-edged or heavy products, such as toys, dry food, construction materials, and spare parts, too.

- In April 2024, Parkside disclosed Recoflex, which is a series of recyclable paper-based flexible packaging materials in order to deliver barrier results, resilience, and heat sealability.

- In July 2025, UFlex is an Indian flexible packaging and solutions company, which has officially granted an Indian patent for the aim of the current invention in the field of “Waterborne Heat Seal Coating Composition and a Procedure for its Preparation” as this coating has been made as a sustainable substitute to regular fossil-based plastic coatings.

Top Companies in the Base Paper for Heat Sealable Packaging Market

- Amcor Limited: Amcor plc is a top packaging giant that produces and develops flexible packaging, specialty cartons, rigid containers, and closures for healthcare, beverages, food, and personal care, too, and concentrates on sustainability and invention.

- Constantia Flexibles: Constantia Flexibles is an Australian producer of flexible packaging, which is headquartered in Vienna. It has employed around 8,650 people at 37 manufacturing sites in 18 countries, such as Africa, North America, and Asia.

- Berry Global Inc: Berry Global Inc is a main producer of plastic packaging, which is well known for making solutions in personal care, healthcare, and food and beverages, as it has partnered with a Swiss packaging organization that has become a bigger part of the complete Amcor team.

- Sappi Limited: Sappi Limited is a worldwide company that makes a more circular economy with manufacturing facilities in North America, Europe, and South Africa that concentrate on sustainable procedures and products.

- Huhtamaki Oyj: Its packaging plays a main role in ensuring safety and hygiene, and in assisting to protect food waste too. They are loyal to creating packaging that is more circular, and we have sustainability in everything we do.

- Mondi Group: Mondi Group is a top company in paper and packaging, that invests in the perfect globe by making inventive packaging and the paper solutions which are sustainable by creativity.

- Sealed Air Corporation: Sealed Air is in business to solve complicated packaging issues and to create the perfect product that anyone searches for. Our automated packaging solutions serve a safer, more resilient, and less wasteful worldwide food, liquids, and fluids supply chain, which allows e-commerce and goods to move without damage.

- Sonoco Products Company: It is a top producer of industrial, user, healthcare, and secure packaging that has more than 19,000 employees operating in more than 34 countries, as Sonoco delivers many of the globe’s best-known brands.

- Coveris Holdings S.A.: At Coveris, they make and produce sustainable, high-performance plastic and paper packaging solutions that align with the biggest urges of our users and consumers, such as serving safety, product security, preservation, ease, promotional impact, and sustainability.

- Uflex Ltd: UFlex is India's biggest multinational flexible packaging and solutions company. It has developed from power to power and has built a rigid presence across every sector of the packaging value chain, such as chemicals, packaging films, flexible packaging, aseptic packaging, engineering, printing cylinders, and holography too.

Base Paper for Heat Sealable Packaging Market Segments Covered

By Sealing Technology / Type

- Hot Bar Sealing

- Continuous hot bar sealing

- Intermittent hot bar sealing

- Flat hot bar sealing systems

- Impulse Sealing

- Single-impulse sealing

- Double-impulse sealing

- Low-temperature impulse sealing

- Clamshell Sealing

- Hinged clamshell heat sealing

- Pressure-assisted clamshell sealing

- Retail-ready clamshell sealing

- Blister Packaging

- Paper–plastic blister sealing

- Fully paper-based blister packs

- Thermoformed blister sealing

- Skin Packaging

- Vacuum skin packaging (VSP)

- Heat skin packaging on paperboard

- Food-grade skin packaging

- Other Heat-Sealing Methods

- Ultrasonic-assisted heat sealing

- Dielectric heat sealing

- Hybrid heat-sealing technologies

By Material Type

- Plastics

- Polyethylene (PE)

- Polypropylene (PP)

- Polyester (PET)

- Polyvinyl Chloride (PVC)

- Paper & Paperboard

- Aluminum

- Multi-layer / Composite materials

- Specialty and bio-based materials

By Packaging Format / Application

- Pouches

- Flexible films

- Trays

- Bags

- Lids

- Sachets

- Blister packs

- Other custom formats

By End-Use Industry

- Food & Beverages

- Pharmaceuticals & Healthcare

- Personal Care & Cosmetics

- Consumer Goods

- Industrial & Chemicals

- Agriculture

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Rest of North America

- South America

- Brazil

- Argentina

- Rest of South America

- Europe

- Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

- Eastern Europe

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

- Asia Pacific

- China

- Taiwan

- India

- Japan

- Australia and New Zealand

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

- MEA

- GCC Countries

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

- Rest of MEA