Modified Atmosphere Packaging (MAP) Trays Market Analysis, Competitive Landscape, and Trade Insights

The Modified Atmosphere Packaging (MAP) Trays market is set to grow from USD 940 million in 2025 to over USD 1.53 billion by 2034, at a CAGR of 5.63%. The market expansion is fueled by rising consumer demand for sustainable food packaging that extends shelf life and maintains freshness. This report provides detailed insights into material segments including polypropylene (PP) and PETG, product types like films, liners, and trays, and end-use sectors spanning food and healthcare.

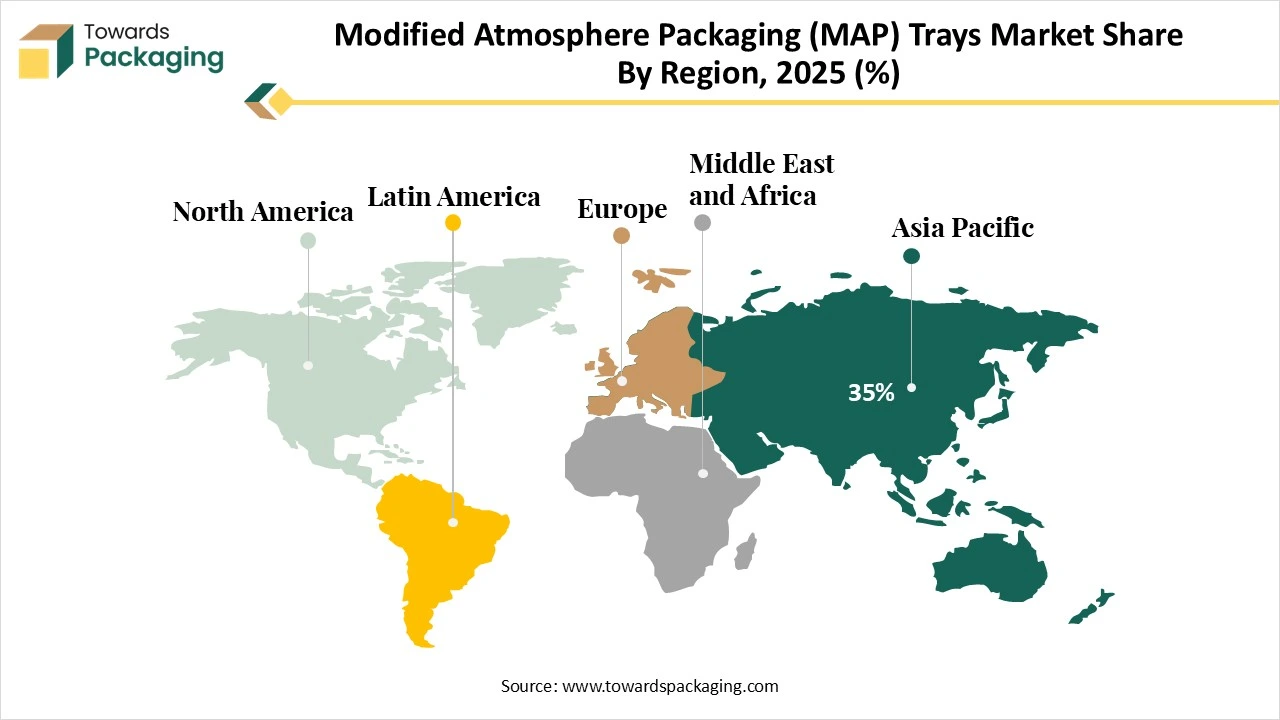

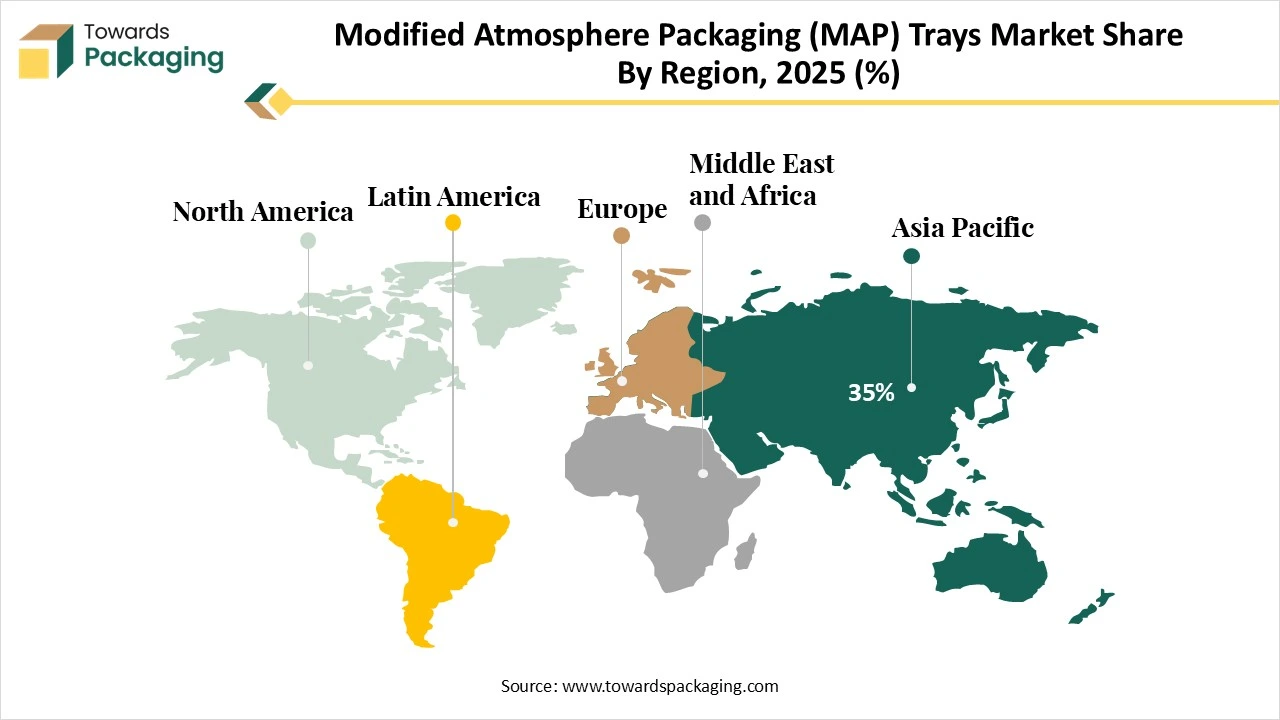

Regional analysis highlights Asia Pacific as the leading market in 2024, while North America is projected to exhibit the fastest growth due to increasing adoption of eco-friendly packaging solutions. The study also profiles key players such as Ascent Packaging Systems, REMA Engineers, Vista Techno Pack Machines, Delta Packaging Industries, and Air Products, offering competitive and value chain analyses, as well as trade and manufacturer data.

Key Takeaways

- By region, Asia Pacific region dominated the modified atmosphere packaging (MAP) trays market in 2024 due to the rising food and other industries.

- By region, North America expects the fastest growth in the market during the forecast period due to the growing demand for the sustainable packaging solutions.

- By material, polypropylene material segment dominates the market in 2024, as it is one of the absorbing elements of polypropylene in the variety of grades available for this polymer, each with its different elements and behaviors.

- By material, polyethylene terephthalate glycol (PETG) segment is the fastest-growing material in the market as it is generated through the polycondensation reaction of ethylene glycol, additional glycol modifier, and terephthalic acid.

- By product type, films and liners segment dominated the market in 2024, because of their crucial role in protecting product freshness and expanding shelf life.

- By product type, trays segment expects the fastest growth in the market during the forecast period, as they are the developed procedure to expand the shelf life for fresh food like fresh or processed meat, fruit, fish, and salads.

- By end-use/application, food packaging segment dominate the market in 2024, as these trays have gained huge popularity in the food industry because of their potential to protect food freshness, expand shelf life, and eliminate spoilage.

- By end-use/application, healthcare/pharmaceutical packaging segment is the fastest growing end-user in the market in the pharmaceutical and healthcare sector, modified atmosphere packaging plays an important role in expanding the shelf life of medicines and health supplements.

- By tray sealer type, fully automatic sealer segment dominated the market in 2024, as the TPC15 effectively packages with modified atmosphere packaging.

- By tray sealer type, semi-automatic sealer expects the fastest growth in the market as tray packaging machine is designed to expand the shelf life of perishable foods products by sealing trays in a controlled gas surrounding.

Modified Atmosphere Packaging (MAP) Trays Market Overview: Modified atmosphere packaging: Extending Freshness, Reducing Waste

Modified atmosphere packaging is a high-level packaging technology that adequately extends the shelf life of food products while maintaining their original color, shape, and flavor. It has become an important invention in terms of the packaging sector, that specifically affects the way products are protected and presented in the current market.

The aspect of modified atmosphere packaging lies in the alteration of the atmosphere inside the packaging to grow the shelf life and quality of products, specifically in the food sector. This procedure has gained huge acceptance across different industries due to its potential to strengthen freshness, reduce spoilage, and sustain the original taste and look of products over a longer time.

At its main, modified atmosphere packaging substitutes the air inside a package with a particular mixture of gases personalized to the specific demands of the product being preserved. Prevalent gases utilized in MAP include carbon dioxide, nitrogen, and oxygen, every serving a specific function to interdict microbial growth and decline the deterioration process. The technology starts by extracting the natural air from the package, which initially consists of oxygen( 21 % ), nitrogen ( 78 %), and a defined number of other gases.

Modified Atmosphere Packaging (MAP) Trays Market Trends

- Enhanced safety and hygiene: MAP encourages food safety by lowering the development of molds, bacteria, and other pathogens that contribute to food supply illness. This is specifically crucial for fresh and fragile products such as fish, meat, and dairy, where hygiene is complicated. By managing the gas composition to lesser oxygen levels, MAP can stifle the development of yeasts, aerobic bacteria, and molds which depend on oxygen to thrive.

- Sustainability and environmental benefits: Though modified atmosphere packaging is linked with plastic materials, growth in sustainable packaging solutions, that include mono-material recyclable plastic structures, have made it convincing to implement environmentally friendly options. The advantage of MAP is that it goes beyond shelf life and food safety, which can also contribute to sustainability efforts.

- Versatility in food applications: One of the most prevalent benefits of a modified atmosphere packaging tray is in poultry and meat products, in which the gas mixture manages oxygen exposure and lowers spoilage, protecting the meat's flavor, appearance, and texture.

Key Metrics and Overview

| Metric |

Details |

| Growth Driver |

Demand for sustainable packaging, food freshness, and shelf life extension |

| Leading Region |

Asia Pacific |

| Market Segmentation |

By Material, By Product Type, By End-use/Application, By Tray Sealer Type (Equipment) and By Region |

| Top Key Players |

Ascent Packaging Systems, REMA Engineers, Vista Techno Pack Machines, DELTA Packaging Industries, Air Products |

AI Integration in Modified Atmosphere Packaging (MAP) Trays Market

The modified atmosphere packaging is also being changed by smart technology. QR Codes, NFC-enabled packaging, and RFID tags were gradually utilized to provide distributors and consumers with cooking instructions, actual-time tracking, and freshness directions. Colour-changing labels that respond to temperature movement add an extra layer of safety, to make sure cold chain integrity. Augmented reality (AR) and communicative packaging (interactive packaging) further develop consumer appointments that serve a more informative and immersive shopping experience.

Artificial Intelligence (AI) is also creating incursions. Internet of Things(IoT) and artificial intelligence (AI) devices are being utilized to track humidity, temperature, and product freshness during transit and storage. At the same time, blockchain-enabled packaging ensures genuineness and traceability and assists in protecting against contamination and cheating. AI-driven automation systems simplify the packaging procedure packaging process by examining misalignment, leaks, or improper seals by using computer vision and machine learning. This system also makes sure precision in labeling, weight, and package durability, which reduces food waste and develops quality control products even reaching store shelves.

Modified Atmosphere Packaging (MAP) Trays Market Dynamics

Driver

How MAP Trays Use Gases To Keep Food Fresh and Shelf-Ready

Modified atmosphere packaging trays work by adding gas -prevalently carbon dioxide, nitrogen, and oxygen that assist the food packaging in extending the shelf life, look, and texture. The mixes of gas or simply gas utilized for specific usage are chosen based on the type of product being packaged. The gases commonly utilized for MAP each have several effects on the freshness and color of packaged food. Oxygen keeps the product looking fresh and red, while carbon dioxide minimizes bacterial growth. Product quality and shelf life are generally expanded whenever exposed to elimination and limited. For products like baked goods, chips, and nuts, freshness, instead of looks, matters more. Carbon dioxide and nitrogen work to gain this by rinsing oxygen out of the packaging to prevent oxidation, which can lead to stale lasting food.

Restraint

Key Challenges and Limitations of Modified Atmosphere Packaging Trays

One of the main disadvantages of a modified atmosphere packaging tray is the heavier cost of equipment, like the MAP tray sealer machine, and the additional equipment which counts the tailored packaging films and gases. For small-scale manufacturers, the primary investment can be specific, and this cost may be forwarded to the consumer. Modified atmosphere packaging technology needs accurate control of gas mixture, sealing conditions, and packaging procedure. For optimal outcomes, the management of MAP machines and the maintenance of constant atmospheric surroundings can be complicated, especially in high-volume manufacturing. While the choice of packaging material for MAP is rising, there are still some challenges in terms of unanimity with particular food products. Not all packaging films can resist the modified gas surrounding, and some materials may impact the appearance and taste of the product.

Opportunity

Extending Freshness With Modified Atmosphere Packaging: A Sustainable Storage Solution

With the assistance of using the correct mixture of gases, modified atmosphere packaging storage can increase the shelf life of fruits like apples and strawberries. This means they stay fresh longer, lowering waste and growing availability. Other vegetables and leafy greens maintain their crispness and color due to the accurate control of oxygen levels. This not only keeps them appearing but also protects their nutritional value. Cheese advantages from reduced oxygen exposure, that protects mold growth while enabling it to mature accurately. This banishes the demand for vacuum packaging, which can sometimes misrepresent the product's look.

By updating the atmosphere inside the packaging, modified atmosphere storage serves as a sustainable solution that advantages both consumers and producers. This technology not only improves product quality but also donates to more effective supply chains and accurately leads to lesser food waste and cost savings.

Segmental Insights

Material Insights

How did Polypropylene Material Dominate the Modified Atmosphere Packaging (MAP) Trays Market in 2024?

The polypropylene material segment dominated the market in 2024. One of the absorbing aspects of polypropylene is the variety of grades available for this polymer, each with its different elements and behaviors. While this may primarily look confusing, the advantage lies in the potential to personalize the roll stock formulation to align with the particular needs of the food packaging uses. The three key grades of polypropylene are random copolymer, homopolymer, and impact copolymer. Homopolymer PP was highlighted as the most strong grade among the three. Random copolymer PP resins include ethylene, growing impact power, and serve a soft texture as compared to homopolymers. And then finally, block copolymer PP resins include a higher ethylene pattern, outcoming in a rigid material with superior impact resistance, even in low -low-low-temperature surroundings.

Polyethylene terephthalate glycol (PETG) segment expects the fastest growth in the market during the forecast period. Polyethylene terephthalate glycol is generated through the polycondensation reaction of ethylene glycol, an additional glycol modifier, and terephthalic acid. The inclusion of glycol into the PET backbone vanishes the crystallinity of the polymer, which results in developed adaptability, chemical resistance, and impact resistance to PET. PETG displays a glass transition temperature (Tg) of around 80 -90 degrees, which is greater than that of several other thermoplastics, investing in its dimensional durability and stability. It is utilized in the production of containers, bottles, and other packaging materials in which its chemical resistance and clarity are beneficial.

Product Type Insights

How did Films and Liners Segment Dominate the Modified Atmosphere Packaging (MAP) Trays Market in 2024?

Films and liners segment dominated the market in 2024. Films and liners are the fastest growing product type in terms of modified atmosphere packaging (MAP ) tray market because of their important role in protecting product freshness and expanding shelf life. These materials act as protective barriers that regulate gas exchange, contamination, and moisture, which makes them perfect for perishable goods like seafood, meat, and fresh produce. Development in high-barrier films and resealable liners are further boosting their demand across the food industry. Their lightweight nature, adaptability, and cost-effectiveness also make them a selected choice for producers finding effective and sustainable packaging solutions.

The trays segment expects the fastest growth in the market during the forecast period. Modified atmosphere packaging trays are the developed procedure to expand the shelf life of fresh food like fresh or processed meat, fruit, fish, and salads. The technology replaces the air inside a package with a protective gas mix. The solid food tray includes a transparent barrier film to pack the tray. After taking out the product, the layers easily vanished from the solid board to enable separate recycling and disposal. The growth of this food tray solution assists sustainability loyalty to strengthen and improvise recyclable packaging solutions for our users while lowering the impact on the surroundings.

End-use/Application Insights

How did Food Packaging Segment Dominate the Modified Atmosphere Packaging (MAP) Trays Market in 2024?

The food packaging segment dominated the market in 2024. Modified atmosphere packaging trays have gained extensive popularity in the food sector because of their potential to protect food freshness, expand shelf life, and eliminate spoilage. As the urge for easiness, long-lasting, and less processed food products grows, modified atmosphere packaging technology serves as a solution that keeps food fresh without compromising its quality. Furthermore, it assists sustainability goals by lowering food waste and the demand for chemical preservatives. The potential to store sensitive products for longer duration and across huge distances has created modified atmosphere packaging, a necessary tool for retailers, food manufacturers, and consumers alike.

Its goal is to lower physiological procedures that ripen, spoil, and decay fresh produce. Fresh produce continues to breathe and happens after harvest. They utilize oxygen to break down sugars and generate carbon dioxide.

Healthcare/Pharmaceutical packaging segment expects the fastest growth in the market during the forecast period. In the pharmaceutical and healthcare industry, modified atmosphere packaging plays an important role in expanding the shelf life of medicines and health supplements. By maintaining the internal gas composition. It can prevent oxidation, moisture, and microbial contamination, which ensures the safety and efficacy of the products. The medical packaging of the healthcare sector is crafted to ensure the integrity, sterility, storage, and movement of medical products and devices. The materials utilized to produce this kind of packaging, such as paper, plastic film tissues, and nonwovens are being created to meet more urgent regulatory requirements and performance elements than other types of flexible materials and films.

Tray Sealer Type Insights

How did Fully Automatic Sealer Type Dominate the Modified Atmosphere Packaging (MAP) Trays Market in 2024?

The fully automatic sealer segment dominated the market in 2024. The fully automatic tray sealer TPC15 effectively packages with modified atmosphere packaging. Easy to use and short-step time due to tool-free change of sealing mold and mixed tray denester. The TPC15 is perfectly suited for a huge variety of packaging types and sizes and importantly increases the shelf life of food products.

Semi-automatic sealer segment expects the fastest growth in the market during the forecast period. A semi-automatic MAP ( Modified atmosphere packaging) tray packaging machine is crafted to expand the shelf life of perishable food products by sealing trays in a controlled gas surrounding. These machines need manual holding and unloading of trays but automate the sealing and gas flushing procedure. They are ideal for small to medium-scale food processing businesses because of their compact size, ease of use, and lower cost. Semi-automatic MAP tray sealers serve reliable sealing, assist and track product freshness, and reduce spoilage, which makes them an effective solution for packaging dairy, meat, and ready-to-eat meals.

Regional Insights

How Does The Asia Pacific Dominate The Modified Atmosphere Packaging (MAP) Trays Market?

Asia Pacific dominated the market in 2025. The urge for modified atmosphere packaging in Asian countries is experiencing significant growth because of growing urbanization, changing food consumption patterns, and the rising demand for convenience and packaged food. Countries like India, China, and Japan are leading this trend as consumers choose ready-to-eat-melas, fresh-cut fruits, meat, seafood, and bakery products with longer shelf life and perfect freshness. The fast expansion of organized retail, cold chain logistics, and food exports is also driving modified atmosphere packaging acceptance in the region Furthermore, increased awareness of food safety, waste reduction, and current packaging technologies is pushing food manufacturers to invest in modified atmosphere packaging solutions, that makes Asia one of the fastest-growing markets for modified atmosphere packaging. For instance to this,

- In May 2025, the 2025 edition of IFFA -the world's top international trade fair for technology in terms of meat and alternative protein sectors, ended on a high note after six dynamic days at the Messe Frankfurt exhibition center. (Source: Food Tech Biz)

North America expects the fastest-growing region in the modified atmosphere packaging (MAP) trays market during the forecast period. Fresh produce packaging experiences many demands across the supply chain. From harvesting locations to shelves, trays must balance sustainability and functionality. A well-designed tray for fruits, vegetables, and meat should align with several criteria it must adhere to food contact regulations, to make sure no chemical migration or contamination risks should be there. Most fresh produce, especially meats needs refrigeration or freezing, as the packaging must be constant in low -temperature surroundings. Accurate ventilation assists in minimizing moisture buildup, lowering the risk of mold or spillage during transportation.

For Instance,

- In January 2025, Cirkla who is a server of sustainable packaging solutions, disclosed its molded fibre-modified atmosphere packaging MAP) trays in the U.S market. The organization noted that these trays were made using its proprietary technology and are crafted to deliver as a sustainable alternative to regular plastic MAP Trays, boasting a reduction in plastic content by 85%. (Source: Packaging Gateway)

Modified Atmosphere Packaging (MAP) Trays Market Key Players

Latest Market Leader Announcements

- In May 2025, ULMA Packaging disclosed its FM 400 horizontal flow wrap packaging machine, whose goal is to align with the rising demands of high-speed Modified Atmosphere packaging uses in the fresh food industry and crafted with hygiene, durability, and efficiency in mind. (Source: Packaging Europe)

Recent Developments

- In January 2025, thermoformed molded pulp packaging specialist Rottneros Packaging AB will reveal its NATURE series at Packaging Innovations and Empack 2025. These trays are designed using FSC-certified raw materials and produced with 100% renewable energy. (Source: Packaging Scotland)

- In June 2025, Air Products, which is a worldwide gas company opened the center for food freezing, processing, and storage technologies in Tashkent. It is situated at the Agricultural University, as the center goal is to assist the growth of advanced food preservation methods in Uzbekistan. (Source: HortiDaily)

- In April 2025, DS Smith and Primeale ( part of the agricultural and food processing group) partnered to create a plastic-free and fiber-based punnet for the Primeale vegetable kit range, crafted to prevent fresh produce during transportation and on the supermarket shelf. (Source: Packaging Europe)

- In May 2025, Colorcon, a top company in film coating systems that has specialty excipients, controlled atmosphere packaging, and controlled release formulations, for the healthcare industry, collaborated with ASHA Cellulose, a top provider of organo-soluble Ethyle cellulose polymers that are exclusively used in the dietary and pharmaceutical supplement industries. (Source: PR Newswire)

Modified Atmosphere Packaging (MAP) Trays Market Segments

By Material

- Polypropylene (PP)

- Polyethylene Terephthalate (PET)

- PETG

- Other plastics

By Product Type

- Films & Liners

- Trays

- Bags & Pouches

- Boxes & Containers

- Others

By End-use/Application

- Food (meat, seafood, ready-to-eat)

- Healthcare/Pharmaceuticals

- Electronics

- Others

By Tray Sealer Type (Equipment)

- Fully Automatic

- Semi-Automatic

- Manual

By Region

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait