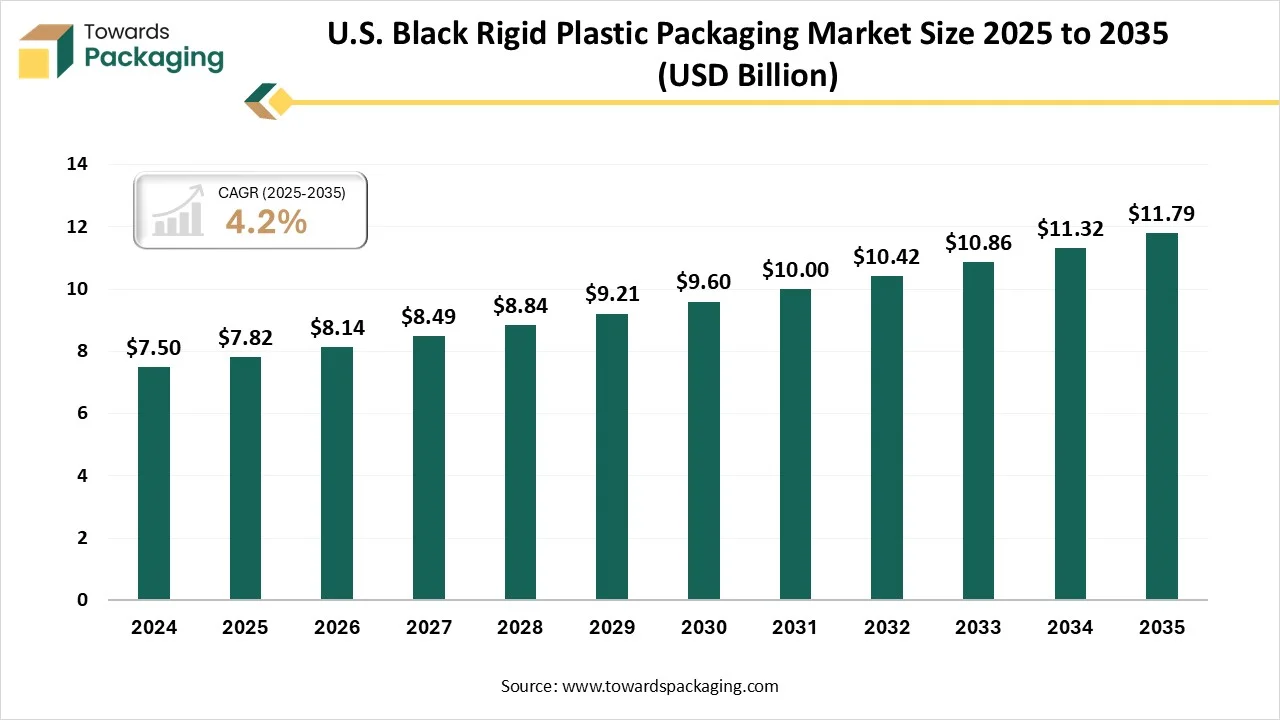

The U.S. black rigid plastic packaging market is forecasted to expand from USD 8.14 billion in 2026 to USD 11.79 billion by 2035, growing at a CAGR of 4.2% from 2026 to 2035. Increasing demand for cost-efficient and durable packaging has influenced the demand for market. Continuous innovation in this sector to meet the rising demand of the consumers has evolved the manufacturing process of this packaging.

The black rigid plastic packaging is focusing on rigid plastic containers, bottles, trays, and other solid packaging formats manufactured in black or dark hues for enhanced UV protection, branding, and recycling sorting efficiency. These products serve food & beverage, pharmaceuticals, consumer goods, and industrial sectors where durability, barrier properties, and visual differentiation matter. Adoption is driven by strong domestic demand, e-commerce growth, sustainability initiatives, and regulatory support for recyclable and high-performance rigid plastics.

Technological transformation in the U.S. black rigid plastic packaging market plays a major role in its extension. Advancement in the manufacturing process of these packaging to ensure the production of high-quality packaging. The major advancement in the production of carbon-free and special grade black pigments. There is a robust shift toward utilizing inherently recyclable resources in lighter colours. Rising demand for recyclable packages in several sector has influenced the technological transformation in this market.

The major raw materials utilized in this market are polypropylene (PP), polyethylene (PE), polyethylene terephthalate (PET), and polystyrene (PS). It is extensively utilized due to its opacity and UV ray protection.

The component manufacturing in this market comprises carbon black masterbatch for aesthetics and UV protection. It also includes extrusion and injection molding where plastics are melted and moulded.

This segment comprises manufacturing and primary distribution with supply chain efficiency. It utilizes effective packaging options to transport with low charges.

| Segment | Market Share (%) |

| High-Density Polyethylene (HDPE) | 45.5% |

| Polyethylene Terephthalate (PET) | 25% |

| Polypropylene (PP) | 15% |

| Others (PVC, PS, Bioplastics) | 14.5% |

The high-density polyethylene (HDPE) segment dominated the market with 45.5% share in 2025 due to its chemical resistance potential. Rising demand for recyclable and lightweight packaging has influenced the production process of this segment. This type of packaging is widely accepted by industries such as pharma, personal care, and food & beverages. Its exceptional material quality offers impact-resistance and raise the adoption of this material.

The polypropylene (PP) segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to its cost-effectiveness and compatibility. Its versatility, designing and processing flexibility, moisture barrier capacity has enhanced the demand for this segment. It can be swiftly molded into intricate, inflexible shapes utilizing common process such as injection thermoforming and molding, that is extremely effectual for massive production.

The bottles & jars segment dominated the market with 43.6% share in 2025 due to their luxury look and UV protection. Presence of black pigments block products from UV light exposure which plays a significant role for products that are light sensitive. It looks appealing in high-end brands as well as in mass-market. These are considered as strong packaging for shipping fragile products and provide complete protection from moisture, air, and light.

The trays & containers segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to sustainability, ready-to-eat food demand, and online groceries has influenced the growth of this segment. It is widely utilized as it fulfils ecological needs and convenience in consumption. This is highly used in personal care, electronica, and food sector because of its cost-effectiveness and protective nature. Its capacity to maintain the quality of the packaged products and enhance shelf life has enhanced its utility.

The food & beverages segment dominated the market with 40.8% share in 2025 due to increasing focus towards sustainability and innovations. Strong, transportation-friendly black rigid packaging is important for online food selling, confirming products reach intact, enhancing this segment. Its black color offers UV rays safety, vital for light-sensitive food products, while options such as resealable ends, microwave-safe patterns, and tamper-resistance seals fuel customers satisfaction and product safety. Enhanced usage of bio-polymers and recycled content (rPET), fulfilling supervisory demands and environment-conscious customer preferences.

The pharmaceuticals & healthcare segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to product integrity and safety. It provides superior safety against physical injury, light, contamination, and moisture, which is important for maintaining the efficiency and security of sensitive pharmacy goods and sterile medical equipment. These are ideal to meet precise need of the consumers in comparison to other resources. Its formats enable the incorporation of these services, improving patient devotion and supply chain efficacy.

West Coast held the largest share in the market share in 2025, due to rising disposable earning. There is a huge requirement for protective and durable packaging which has boost the demand of the market. These materials such as HDPE and PP are widely utilized due to its high recyclability properties. It has high capacity to protect products from UV light which enhance the storage period. Advancement in e-commerce and healthcare sector has raised the usage of this packaging rapidly.

Why U.S. Black Rigid Plastic Packaging Market is Growing Rapidly in South & Southeast?

Rapid expansion of food and beverages sector has driven the demand for the market. These are cost-effective, lightweight, and durable packaging which has made it ideal for various sectors. The upsurge of online shopping needs packaging which can resists the severities of transport and handling. These packaging are extensively utilized for medical devices, vials, and medicine bottles because of their shielding qualities.

How U.S. Black Rigid Plastic Packaging Market is Expanding in the Midwest?

Rising focus towards recycled mandates has driven the development of the market in the Midwest. Presence of strong industrial infrastructures with durability, UV resistance, and thermal stability of the packaging has boost the advancement of this market. The upsurge of e-commerce sector has enhanced the requirement for packaging that can resist the severities of shipping. Increasing demand for high-quality as well as sustainable packaging has raised the demand for this packaging.

Which Factor is Responsible for Notable Growth of U.S. Black Rigid Plastic Packaging Market in Northeast?

The primary factors influencing the growth of market are increasing focus towards recyclability and sustainability of packages and technological advancement. Major companies are investing significantly in post-consumer recycled (PCR) content which boost the adoption of this market. These advancements enhance product safety and operational efficiency, further stimulating market expansion. Black rigid plastic containers, jars, and bottles provide superior barrier potential, enlarged shelf life, and suitability, which attract to customers in this region. The requirement for sterile, strong, and tamper-resistance packaging for medical equipment, medicines, and special drugs initiatives demand among consumers.

By Material Type

By Product Type

By End-Use Industry

February 2026

February 2026

February 2026

January 2026