The disposable food containers market is forecasted to expand from USD 135.80 billion in 2026 to USD 197.17 billion by 2035, growing at a CAGR of 4.23% from 2026 to 2035. The report analyzes quantitative trends across material segmentation (plastic leading in 2024, paper fastest-growing), capacity (medium 500 to 1000 ml dominating), lid type (vented lids leading), sustainability (recyclable leading, biodegradable fastest-growing), and applications, where food packaging held the largest revenue share in 2024.

Regionally, the study covers North America, Europe, Asia Pacific (largest market in 2024), Latin America, and the Middle East & Africa, with Europe forecast to register the fastest growth rate. It includes competitive analysis of major players such as Berry Global, International Paper, Cascades, Solo Cup Company, and Dart Container, supported by manufacturing cost (USD 1,120 to 1,270/MT), ASP (USD 1,550 to 1,740/MT), EBITDA margins (13 to 16%), trade flows, value chain mapping, installed capacity, production volumes, and global manufacturer & supplier databases.

Disposable food containers are known as single-use food containers, which are crafted for serving, storing, and transporting food. They are extensively utilized in food deliveries, catering services, takeout services, and even for household purposes. This kind of container serves an advantage, as they reduce the demand for washing or returning the containers after usage. They come in different shapes and sizes as they can be made from different materials.

Different kinds of disposable containers need different methods. Paper and plastic-based food containers often have different rules that depend on local waste management regulations. Hence, some general practices can be followed to ensure proper disposal. A simple rule to recall is that if the container carries non-greasy foods and isn’t extremely soiled, we should recycle it after giving it a wash. Rinsing out any debris before trashing makes a huge impact on the recycling procedure. It is crucial to familiarize yourself with the particular rules given by local waste management authorities or recycling facilities.

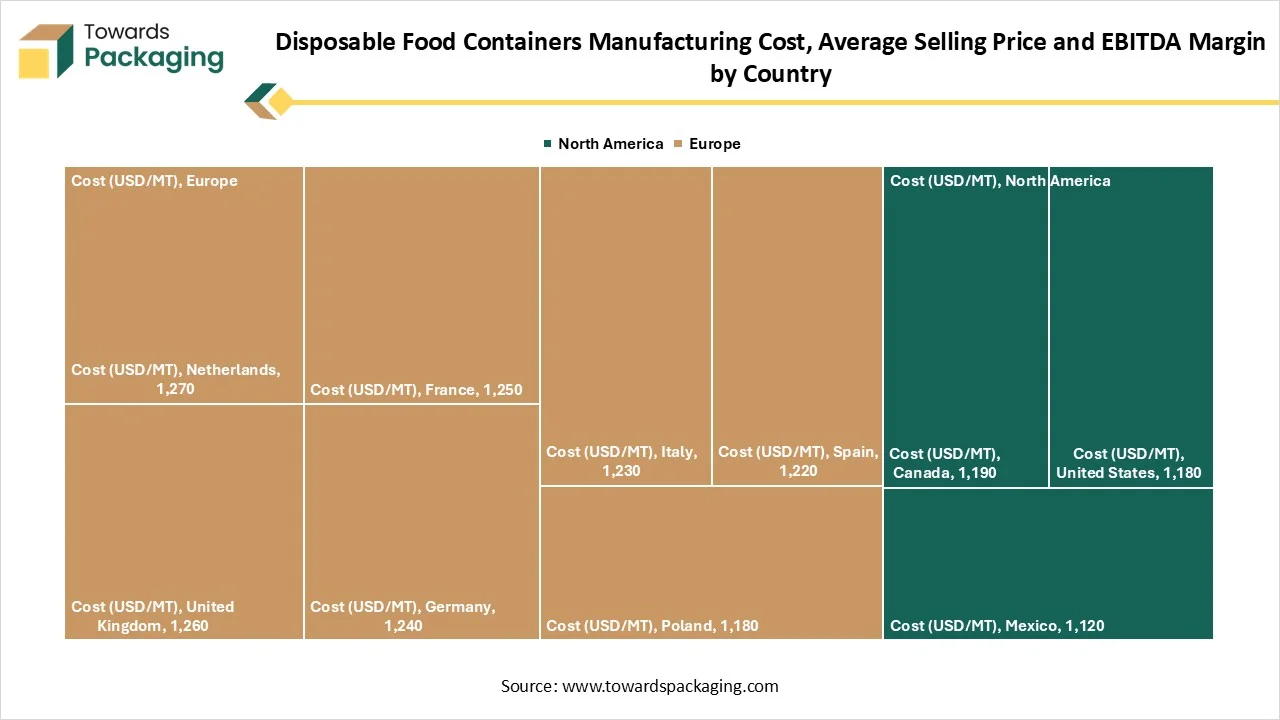

| Region | Country | Cost (USD/MT) | ASP (USD/MT) | EBITDA |

| North America | United States | 1,180 | 1,620 | 15 |

| North America | Canada | 1,190 | 1,630 | 14 |

| North America | Mexico | 1,120 | 1,550 | 16 |

| Europe | Germany | 1,240 | 1,700 | 14 |

| Europe | France | 1,250 | 1,710 | 13 |

| Europe | United Kingdom | 1,260 | 1,720 | 13 |

| Europe | Italy | 1,230 | 1,680 | 14 |

| Europe | Spain | 1,220 | 1,660 | 14 |

| Europe | Netherlands | 1,270 | 1,740 | 13 |

| Europe | Poland | 1,180 | 1,620 | 15 |

| Metric | Details |

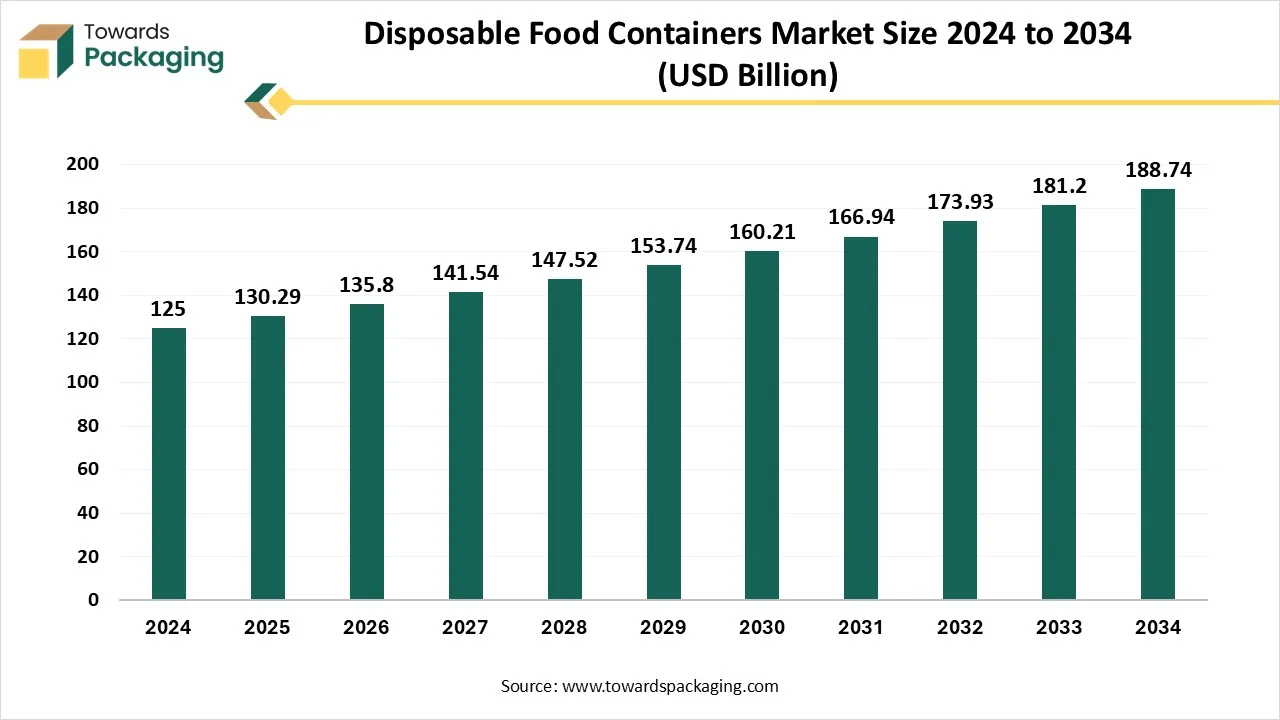

| Market Size in 2025 | USD 130.29 Billion |

| Projected Market Size in 2035 | USD 197.17 Billion |

| CAGR (2026 - 2035) | 4.23% |

| Leading Region | Asia Pacific |

| Market Segmentation | By Material, By Capacity, By Lid Type, By Sustainability, By Application and By Region |

| Top Key Players | Berry Global, International Paper, Cascades, Solo Cup Company, Clearwater Paper, Dart Container. |

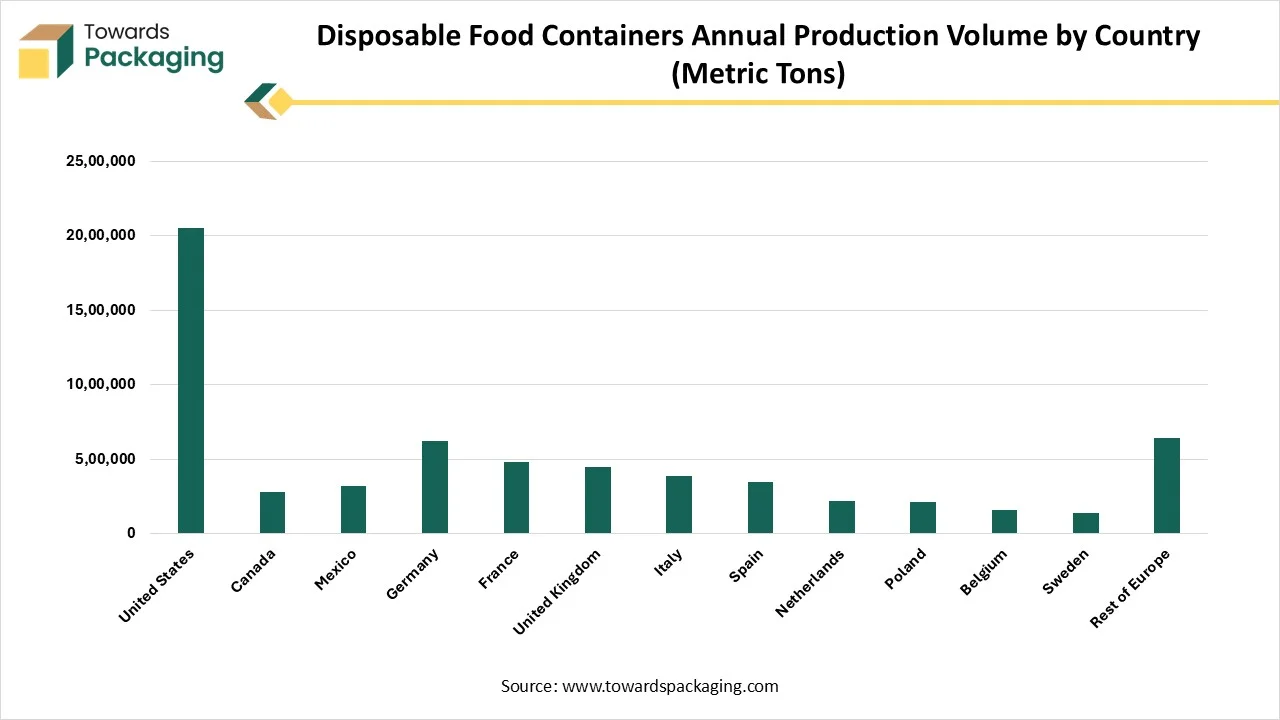

| Region | Country | Production |

| North America | United States | 2,050,000 |

| North America | Canada | 280,000 |

| North America | Mexico | 320,000 |

| Europe | Germany | 620,000 |

| Europe | France | 480,000 |

| Europe | United Kingdom | 450,000 |

| Europe | Italy | 390,000 |

| Europe | Spain | 350,000 |

| Europe | Netherlands | 220,000 |

| Europe | Poland | 210,000 |

| Europe | Belgium | 160,000 |

| Europe | Sweden | 140,000 |

| Europe | Rest of Europe | 640,000 |

Sustainability is at the frontline in terms of food packaging and is a game-changer term too. It can analyze the most eco-friendly material, calculate footsteps, and update designs to lessen waste and energy consumption. As an example, the AI algorithm can suggest packaging materials that manage recyclability, durability, and aesthetics too, in order to assist the brands in achieving sustainability aims while maintaining the honesty of their products at the current time. The usage of artificial intelligence is proving to be efficient across the entire packaging supply chain. From the guessing of demand to the tracking of inventory, as well as increasing the routes used for transportation, artificial intelligence plays an important role in making packaging operations run effectively and cost-efficiently. As an outcome, waste is minimized, times are reduced, and products are made sure to reach customers in the best possible condition.

How are Circular and Smart Packaging Strategies Shaping the Future?

A circular packaging strategy makes sure that material stays for long-term use, assisting a circular economy, reducing plastic waste, and reducing one’s carbon footprint. Several brands are shifting towards mono-material packaging, packaging made from recycled material, and refillable packaging, too. Technology-driven packaging is also improving food freshness while reducing waste. Freshness sensors, smart labels, and time-temperature indicators assist in tracking the condition of food products and warning users or retailers when food is near expiration. Less is more when it comes to sustainable packaging. With this attitude, brands are rethinking over-packaging by utilizing lightweight material, vanishing unnecessary layers, and updating designs for transportation effectiveness.

Challenges of Recycling and the Environmental Impact of Multi-material Food Containers

Inadequate disposal methods and poor waste management have resulted in significant pollution impacting both land and sea environments. Decomposing and non-decomposable waste enter the ecosystem due to illegal dumping, litter carried by the wind, and inefficient waste collection systems. Many containers are made from mixed materials, such as plastic film windows on paperboard boxes, complicating and increasing the cost of their separation and recycling. Furthermore, leftover food often contaminates these items, rendering them completely unsuitable for recycling.

Disposable Packaging Drives the Shift Toward a Zero-waste Future.

Disposable packaging plays a pivotal role in transforming toward a zero-waste future. Distinctive regular plastic, disposable materials break down naturally, leaving no harmful residues behind. By accepting these inventive solutions, businesses can specifically reduce their environmental impact while tracking the functionality and continuity of regular packaging. Disposable packaging not only assists waste reduction but also meets consumer demands for sustainable products. Businesses that grab zero-waste blueprints are driving consequential change across industries. By giving importance to disposable materials and vanishing single-use plastics, these organizations set an example for others to follow.

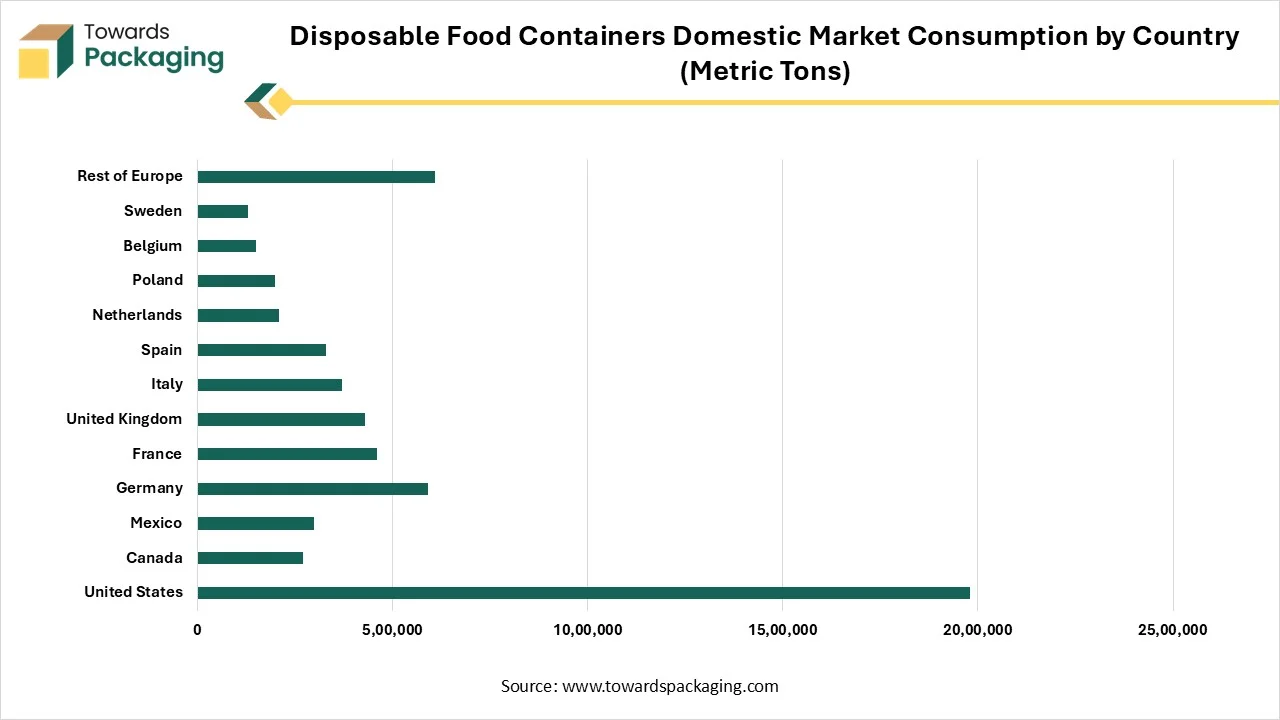

| Region | Country | Consumption |

| North America | United States | 1,980,000 |

| North America | Canada | 270,000 |

| North America | Mexico | 300,000 |

| Europe | Germany | 590,000 |

| Europe | France | 460,000 |

| Europe | United Kingdom | 430,000 |

| Europe | Italy | 370,000 |

| Europe | Spain | 330,000 |

| Europe | Netherlands | 210,000 |

| Europe | Poland | 200,000 |

| Europe | Belgium | 150,000 |

| Europe | Sweden | 130,000 |

| Europe | Rest of Europe | 610,000 |

Disposable plastics are plastic items that are specifically used once, then thrown away or recycled. It consists of plastic bags, water bottles, soda, coffee stirrers, and plastic straws in addition to many restaurant food containers and other kinds of packaging. The strength it takes to generate disposable plastics comes mostly from fossil fuels, which are the biggest source of heat abduction greenhouse gas emissions. By decreasing our dependence on disposable plastics, one can greatly lessen the effect these kinds of products have on our surroundings.

Paper packaging is created from wood fibers that are derived from trees. This material is biological, natural, and in most cases renewable. During the manufacturing procedure, the fibers are mixed with water, pressed into sheets, and then dried. Sometimes the paper is treated to make it rigid or more resistant to grease and moisture, for instance, for food packaging. Generating paper requires a relatively large amount of energy and water, though renewable energy is heavily utilized. Paper plates are famous for their versatility and flexibility. These plates are perfect for lightweight and dried fruit, such as pastries or sandwiches.

The medium-sized segment dominates the market as consumer demand for convenient, versatile, and eco-friendly packaging continues to grow. Medium containers are perfect for single-serve main courses, combo meals, meal-prep portions, and takeaway orders and are extensively used in food delivery services, restaurants, and catering businesses. With the growing popularity of food delivery platforms and cloud kitchens, medium-sized containers have become the main packaging solutions that serve the correct balance between portability and capacity.

The small-sized disposable food container is driven by the growing demand for on-the-go food packaging across urban populations. Rising trends in takeaway and food delivery services, specifically in fast food, snacks, and portion-controlled meals, have led to the acceptance of small-sized containers. These containers, typically created from materials like paperboard, plastic, aluminum, and disposable bioplastics, align with consumer demands for portion control, portability, and single-serve options. Furthermore, the growing awareness of hygiene and the demand for safe food handling, especially post-pandemic, has further boosted growth.

Vented lids dominate the disposable food container market due to their important role in protecting food quality, especially in the rising takeout and delivery sector. As consumer expectations for freshly created and visually appealing meals have grown, vented lids serve a simple yet highly effective solution to prevalent packaging limitations. Vented lids enable steam to escape, protecting condensation from building up inside the container. This assists in maintaining the texture and integrity of foods like fried items, grilled meats, and baked goods, which would otherwise become soggy in sealed surroundings.

Non-vented lids also had a crucial place in the disposable food container industry, specifically for packaged liquid-based foods and cold items in which moisture retention is needed. Unlike vented lids, which allow steam to escape, non-vented lids can make an airtight seal that assists in protecting temperature, prevents leakage, and maintains freshness, making it an attribute for sauces, soups, beverages, and chilled foods like desserts and salads.

Recyclable food packaging contributes to a solution that serves as a path to update environmental effects while aligning with rising consumer demand for sustainable products. Food packaging includes substantially to lesser waste, with millions of tons vanishing annually. Recyclable packaging can historically lessen this volume, as materials like paper, glass, and particular plastics can be reused and repurposed. Moreover, the production of regular packaging shows natural resources like oil, water, and seeds. On the opposite to that, recyclable food packaging assists in conserving these resources by reusing these materials. Recycling one ton of paper, for example, can save 17 trees and 7,000 gallons of water.

Biodegradable plastics, which come from natural sources such as sugarcane or corn starch, can degrade faster than conventional plastics, which diminishes their effect on landfills and oceans. Organizations are heavily accepting these materials for everything from bottle caps to complete containers. On top of biodegradable plastics, other companies are discovering the role of plant-based films created from cellulose or other renewable resources. These plant-based materials serve as a perfect barrier against oxygen and moisture, which makes them perfect for protecting freshness in food products.

Food packaging boxes are crafted to keep your food items free from contamination. They serve protection and prevention against external factors like heat, moisture, and dust to make sure that customers receive a product as delicious as when it leaves your kitchen. Custom food packaging boxes offer a different opportunity to display brands. One can print a tagline, logo, and even the story behind your packaging as a marketing tool. Sustainable food packaging is gaining attention as cardboard boxes, which are a prevalent food packaging material selection, are recyclable and eco-friendly. By utilizing eco-conscious packaging, we reduce our environmental footprint and appeal to eco-conscious customers.

In addition to the food industry, several beverage companies are using single-use plastic items like cutlery, straws, and stirrers, which are some of the worst culprits. The plastic straw ban has become one of the most evergreen symbols of the plastic waste issue, as billions of straws are used every year worldwide, as they contribute specifically to ocean pollution. In response, several food and beverage industries have promised to remove plastic straws from their operation. Sustainable utensils beyond straws, cafes, and restaurants are substituting single-use plastic utensils with alternatives made from bamboo, wood, or compostable materials.

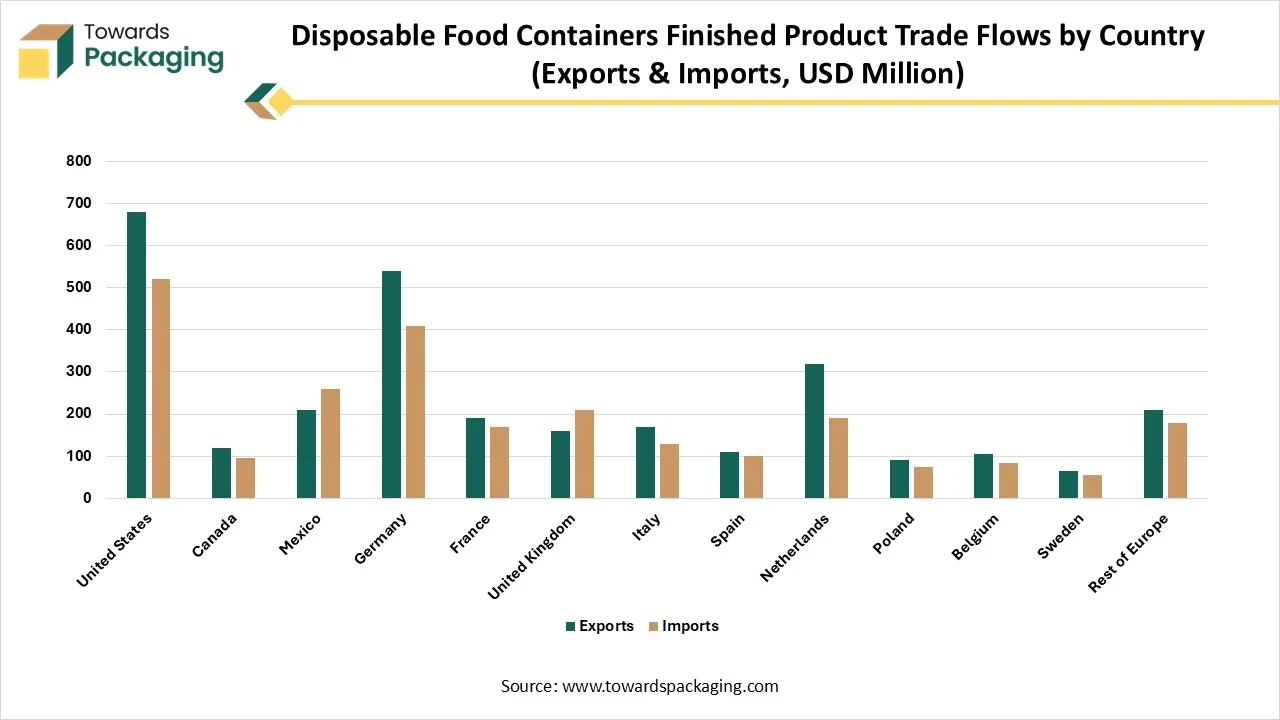

| Region | Country | Exports | Imports |

| North America | United States | 680 | 520 |

| North America | Canada | 120 | 95 |

| North America | Mexico | 210 | 260 |

| Europe | Germany | 540 | 410 |

| Europe | France | 190 | 170 |

| Europe | United Kingdom | 160 | 210 |

| Europe | Italy | 170 | 130 |

| Europe | Spain | 110 | 100 |

| Europe | Netherlands | 320 | 190 |

| Europe | Poland | 90 | 75 |

| Europe | Belgium | 105 | 85 |

| Europe | Sweden | 65 | 55 |

| Europe | Rest of Europe | 210 | 180 |

Asia Pacific’s production procedure and fast economic growth position in the region as a leader in the worldwide move toward sustainable packaging. With countries like India, China, Vietnam, and Indonesia becoming main players in the manufacturing and export of goods, there is rising pressure to transform toward low-carbon and eco-friendly packaging solutions. Users in Asia Pacific are totally aware of the environmental effects of packaging and are driving demand for sustainable alternatives.

A current survey found that 86% of the civilians in Asia Pacific consider sustainable packaging and manufacturing extremely crucial. Several large companies in the Asia Pacific are adopting sustainability aims to align with consumer expectations and regulatory requirements. Main FMCG Companies, e-commerce platforms, and food and beverage brands are substituting plastic packaging with biodegradable or recyclable options to meet global sustainability trends.

Europe’s disposable food container industry is on a rigid growth trajectory, fueled by demand from industries like beverage, food, pharmaceuticals, and automotive, too. Countries like France, Spain, and Italy are witnessing specific developments driven by both local and global pressures to accept more sustainable practices. Government incentives, laws, and growing consumer awareness are pushing the sector to innovate.

Spain’s concentration on cardboard, paper, and plastic recycling has created sustainability as a central theme in its packaging sector. At the same time, France has implemented passionate policies like the ban on single-use plastics, which reflects its promise to make a circular economy. Across Europe, companies are giving importance to eco-friendly packaging solutions to meet these regulatory and market demands.

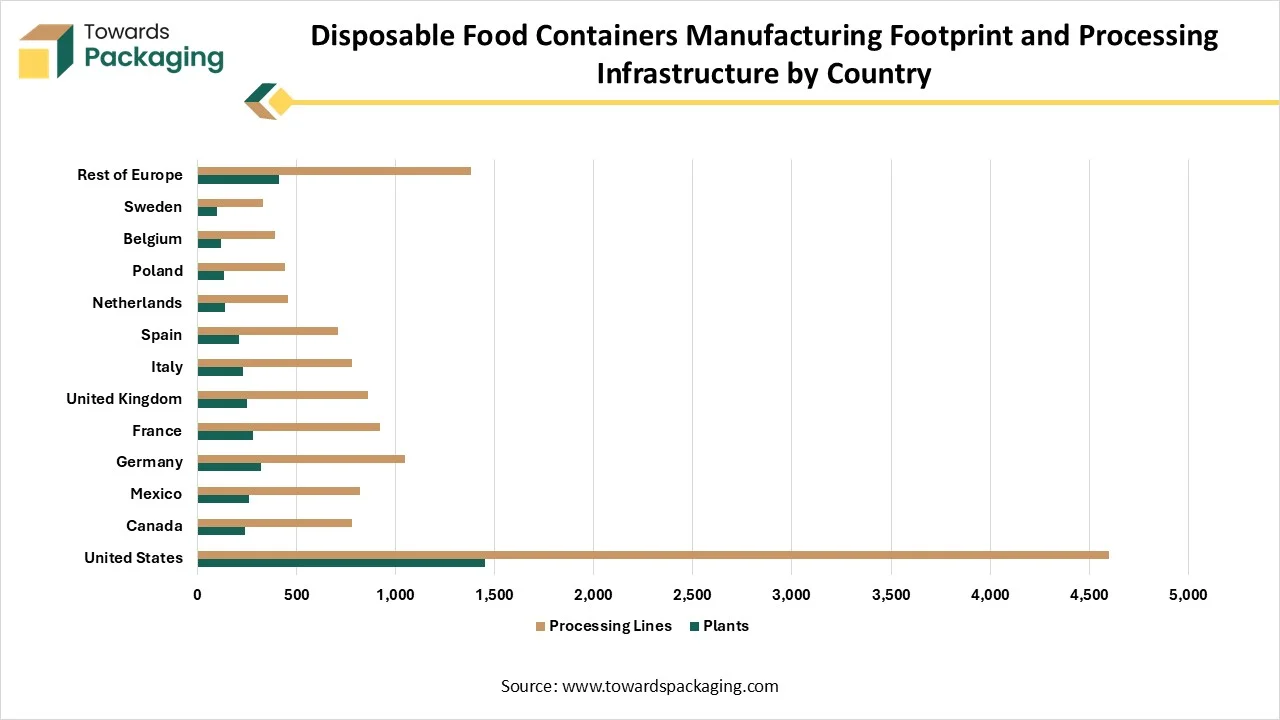

| Region | Country | Plants | Processing Lines |

| North America | United States | 1,450 | 4,600 |

| North America | Canada | 240 | 780 |

| North America | Mexico | 260 | 820 |

| Europe | Germany | 320 | 1,050 |

| Europe | France | 280 | 920 |

| Europe | United Kingdom | 250 | 860 |

| Europe | Italy | 230 | 780 |

| Europe | Spain | 210 | 710 |

| Europe | Netherlands | 140 | 460 |

| Europe | Poland | 135 | 440 |

| Europe | Belgium | 120 | 390 |

| Europe | Sweden | 100 | 330 |

| Europe | Rest of Europe | 410 | 1,380 |

By Material

By Capacity

By Lid Type

By Sustainability

By Application

By Region

February 2026

February 2026

January 2026

January 2026