The metalized biaxially oriented polypropylene films market is forecasted to expand from USD 8.21 billion in 2026 to USD 13.93 billion by 2035, growing at a CAGR of 6.05% from 2026 to 2035. This report provides an in-depth analysis of market trends, regional performance across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, as well as insights into leading applications such as packaging, electronics, and insulation. The study also covers key manufacturers like Cosmo Films Ltd, Taghleef Industries Group, and Jindal Poly Films Limited, along with trade data, competitive analysis, and value chain insights.

BOPP is called the " packaging queen" in terms of the packaging film industry. It plays an important role in the flexible packaging industry. This kind of material is perfectly notable for transparency, exceptional power, and adaptability which makes it a perfect choice for improving product presentation and protection.

Polypropylene films that are expanded in cross directions and machine are termed Biaxially oriented polypropylene films. It has received huge appreciation as a heavy-growth film as it is a perfect barrier for water vapor, acts as a barricade to oil and greases, can be recycled, and is not affected by surrounding changes. The biodegradability and non-toxic characteristics of BOPP films make it one of the most eco-friendly films on the market. With the rising awareness about environmental and pollution problems, it is more crucial than ever to include such issues. They are available in various types such as:

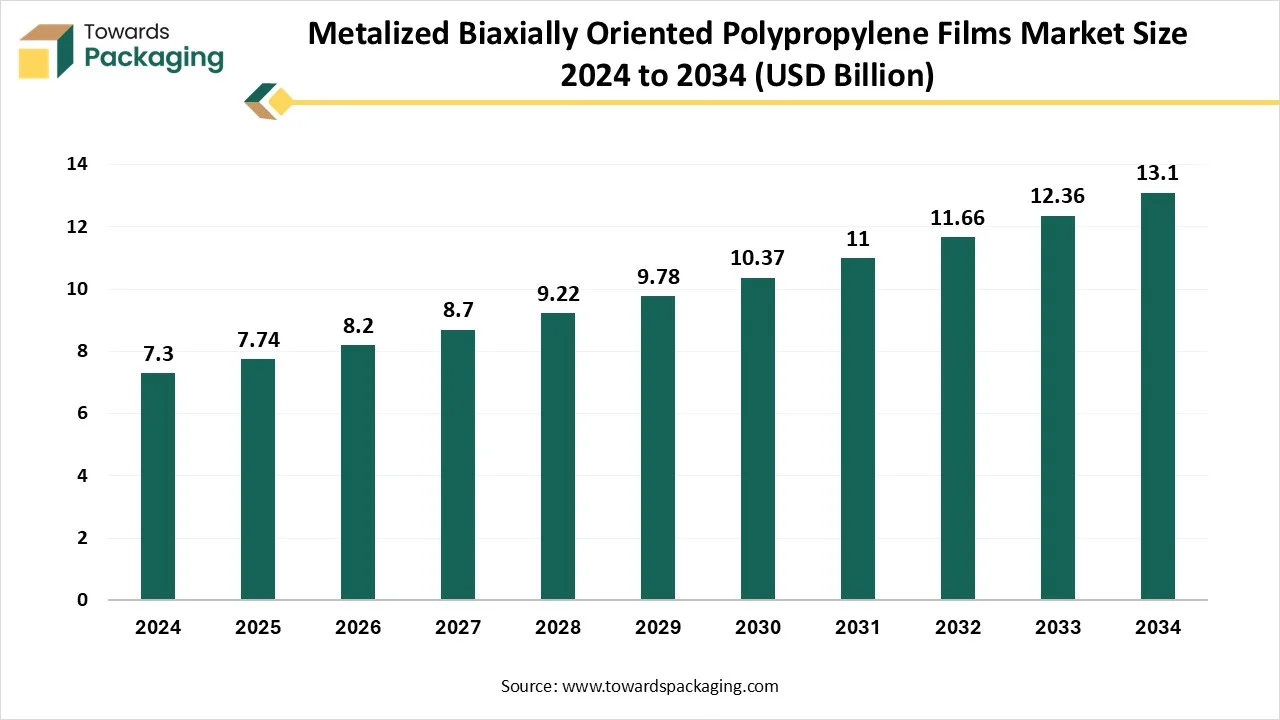

| Metric | Details |

| Market Size in 2025 | USD 7.74 Billion |

| Projected Market Size in 2035 | USD 13.93 Billion |

| CAGR (2025 - 2035) | 6.05% |

| Leading Region | Asia Pacific |

| Market Segmentation | By Application and By Region |

| Top Key Players | Cosmo Films Ltd, Taghleef Industries Group, Jindal Poly Films Limited, POLIBAK PLASTIC, Political SA |

Artificial Intelligence is heavily utilized in the manufacturing and quality control of metalized biaxially oriented polypropylene (BOPP) films. AI-powered systems assist in monitoring and updating film thickness, metal coating uniformity, and surface quality in actual time during manufacture. Machine learning algorithms examine huge data from sensors to detect defects like wrinkles, pinholes, or uneven coatings, which enables faster adjustments and reduces waste. AI also assists predictive maintenance of machinery, lowering downtime and developing efficiency. Overall, AI enhances product consistency, reduces material costs, and ensures higher performance in metalized BOPP film applications.

BOPP Films Lead the Low-carbon Shift

The most significant benefit of BOPP films is thinning. Because of their high mechanical power, BOPE Films can receive equal or better performance at half the thickness of regular PE Films. Customer trials confirm that "thinned" BOPP Films display higher mechanical strength than standard PE Films. Beyond substituting conventional PE Films, BOPP's different properties, such as superior low-temperature performance -allow entry into the main market where regular PE Films fall short. Instances include frozen seafood packaging and fast frozen food packaging. Customer feedback suggests that BOPP films vanish the "bag breakage bag" in terms of frozen packaging from 7-8% to nearly 0%. Furthermore, in the area of low-carbon economies, BOPP films meet sustainability aims. By splitting PE Consumption, BOPP Films not only solves the urgent demands of climate negotiations but also contributes specifically to the shift towards a low-carbon economy.

Limitations and Competitive Dynamics of Metalized BOPP Films

Large-scale production and international logistics demand specific investment that can put pressure on exporters that work on capital, specifically with large orders. The BOPP sector is extremely competitive with producers in China and other regions serving similar products. To stay competitive, Indian exporters must balance cost-effectiveness with good-quality production. Exporters contacting international buyers may experience delayed payments or non-payment, which affects cash flow and operational stability One of the key disadvantages of metalized biaxially oriented polypropylene film is poor heat sealability, so it is usually utilized as the outer film of composite films. For instance, after compounding with polyethylene films, its transparency, power, moisture resistance, printability, and stiffness are all perfect and it is suitable for dry food.

Innovations Driving Sustainable BOPP Films

Inventions in metalized biaxially oriented polypropylene film include metallization, in which thin aluminum layers grow barrier performance for oxygen and light-sensitive products. High-level coatings improve adhesion for laminating, printing, and functional surfaces. To align with sustainability goals, manufacturers are now creating bio-based polypropylene and chemically recycled resins, that contribute to circular economy initiatives and vanishing environmental footstep. Sustainability continues to drive metalized biaxially oriented polypropylene film production. Technologies such as lightweight and high-level recycling methods like pyrolysis and materials like bio-based resins are allowing more eco-friendly solutions. These developments support closed-loop systems to lower carbon emissions, reduce waste, and grow recyclability that make sure metalized biaxially oriented polypropylene film remains the main part of the circular economy.

How Will Packaging Applications Dominate the Metalized Biaxially Oriented Polypropylene Films Market in 2024?

The packaging segment dominated the market in 2024. Metalized BOPP films are greatly used in the food and beverage industry. Their perfect barrier properties make them an ideal choice for flexible food packaging. , keeping ingredients safe from environmental factors and contaminants. Brands in the beverage sector favor these films for their potential to maintain product freshness while also serving high-quality printing surfaces for bright designs and labels. In the pharmaceutical industry, the safety and cleanliness of packaging are important. Metalized BOPP films are utilized as raw material for medical packaging due to their non-harmful and food-grade qualities. The characteristics of BOPP, which include stiffness and clarity, make it perfect for strip packaging and adhesive tapes to ensure the secure transport and storage of medical products. Thermal lamination films created from BOPP serve additional protection, while non-heat sealable options enable easy access to medications. For cosmetics products, packaging must be attention-grabbing. Metalized BOPP films serve a high -end look while protecting items from moisture and other damaging elements. Their perfect barrier properties and superior printability enable cosmetic brands to make stunning and durable packages that stand out on the shelves.

For instance this,

Electronics and insulation expects the fastest growth in the metalized biaxially oriented polypropylene films market during the forecast period. They are widely utilized in electronics and insulation due to their perfect electrical and thermal properties. In electronics, they serve as dielectric layers in capacitors that offer high voltage resistance and low power loss. Their metalized coating provides effective electromagnetic interference(EMI) shielding in circuit boards and electronic components. For insulation, BOPP Films are used in cables and flexible insulation layers, thanks to their durability, thermal stability, and moisture resistance. Their lightweight and flexible nature makes them ideal for compact electronic devices and efficient thermal insulation systems.

Asia Pacific dominated the market in 2024. The Asia-Pacific region, including China and India, will witness huge growth. With rising manufacturing platforms and increasing demand for packaged food, this region will maintain its top position in the metalized biaxially oriented polypropylene films market. This is fueled by both growing domestic demand and export opportunities.

India is all ready to become the most crucial market for BOPP films. Hence, top companies in the packaging industry, such as Uflex and Cosmo Films, are growing their production capacities. These organizations are investing in the latest metalized biaxially oriented polypropylene film production lines in response to growing demand from sectors like consumer goods, food packaging, and pharmaceuticals.

China remains a main producer and user of metalized biaxially oriented polypropylene films, and many manufacturers are growing their potential to align with growing domestic and international urges. Furthermore, there is a focus on growing manufacturing techniques, specifically for high-performance films, to meet the rising demand for specialized packaging solutions in the medical, food, and consumer goods sectors.

For instance to this,

Europe expects the fastest growth in the market during the forecast period. In European countries, the urge and manufacturing of metalized biaxially oriented polypropylene film are steadily growing, driven by the region's growing focus on sustainable and lightweight packaging solutions. Main industries like pharmaceuticals, food, and personal care contribute to high consumption due to BOPP's moisture resistance, printability, and clarity. European manufacturers are investing in high-level production technologies to align with strict EU regulations and consumer demand for recyclable and eco-friendly materials. Countries like Germany. Italy and France are the main producers, with a rigid export market across Europe and beyond, that assists both regional supply and international trade.

For instance to this,

The North American BOPP industry is classified as a mature packaging sector with a heavy demand for sustainable and high-performance films. The region is experiencing a development of recyclable packaging solutions and the acceptance of advanced barrier films for food safety and shelf-life extension. Invention in specialized BOPP film for industrial and non-packaging uses is also a main trend, driven by technological advancements and strategic investments in Research and Development.

The Middle East and Africa region is a promising industry for BOPP, initially driven by industrialization, rising demand for packaged food and consumer products, and population growth. Investments in manufacturing capabilities and infrastructure are also contributing to market growth. The demand for films that can withstand toxic environmental conditions, such as humidity and high temperature, also displays particular opportunities for advanced BOPP solutions in the region.

The Latin American BOPP industry is undergoing constant development, driven by growing economic conditions, stretching retail infrastructure, and growing consumption of packaged goods. The regions display opportunities for both established and latest players, as industries find cost-effective and effective packaging solutions. The acceptance of modern packaging procedures and growing awareness of product safety are driving the demand for BOPP Films.

By Application

By Region

January 2026

January 2026

December 2025

December 2025