Retort Packaging Market Size and Important Insights

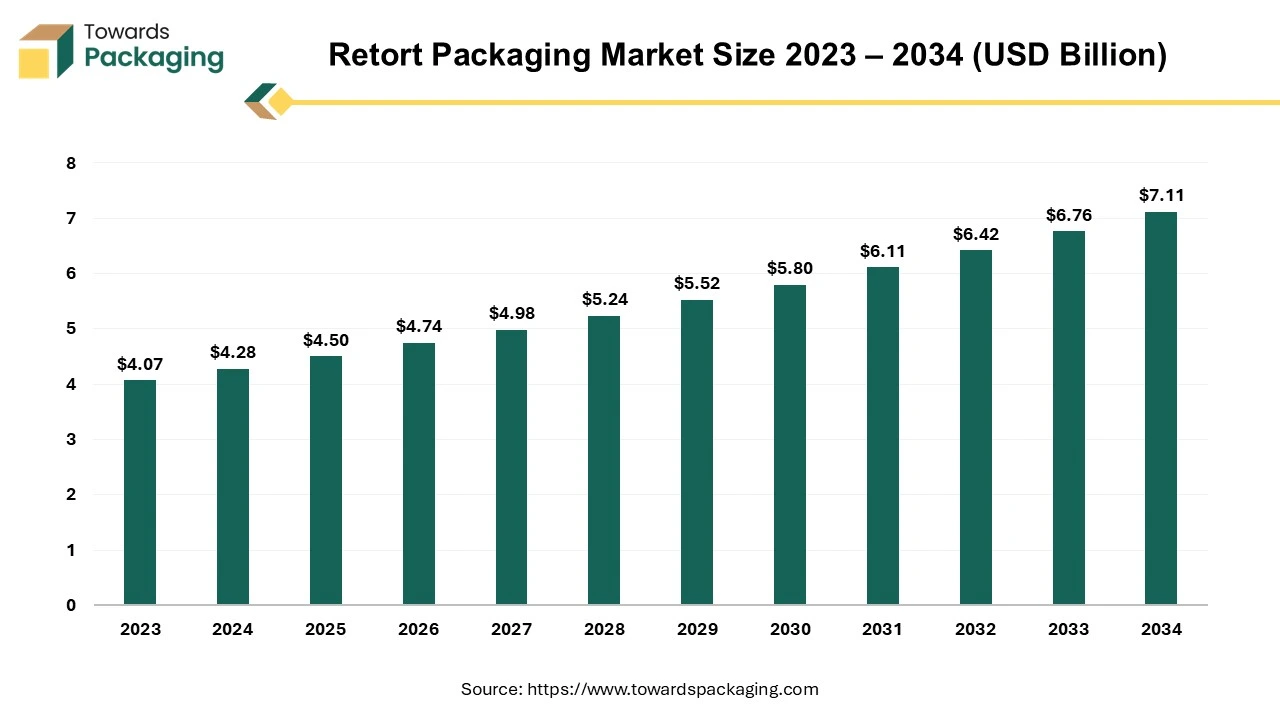

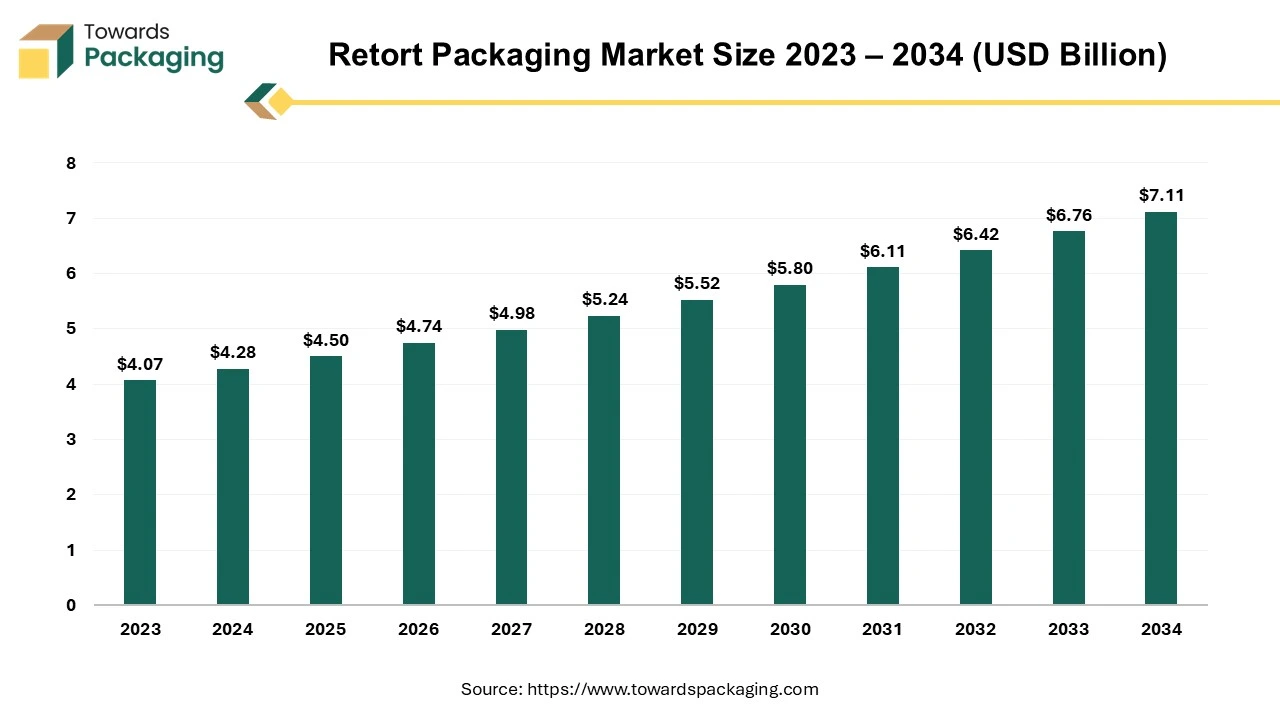

The retort packaging market is forecasted to expand from USD 4.74 billion in 2026 to USD 7.48 billion by 2035, growing at a CAGR of 5.2% from 2026 to 2035. The market is driven by increased demand for convenient, portable food solutions and innovations in sustainable packaging materials. This report covers detailed market segmentation by material (polypropylene, polyamide, aluminum foil, PET, paperboard), end-use (food, beverages, pet food, pharmaceuticals), and region (Asia Pacific, North America, Europe, LATAM, and MEA). Key players include Amcor plc, ProAmpac, Mondi, and others.

Report Highlights: Important Revelations

- Japan's progress in curry retort food packaging production volume of retort pouch food reaches 138.48 thousand tons in 2022.

- The transformative period in retort pouch development.

- Global growth in retort packaging fueled by technological innovations.

Retort packaging material is a sterilizable packaging material, constructed with thin and bonded layers that can withstand processing a product inside at 120°C. Retort pouches are a relatively new variety of food packing container that weighs less than glass jars or metal cans. Before serving, the contents can be rapidly reheated in about three minutes by heating the entire bag in a microwave or by immersing it in boiling water. As a novel method and material for food preservation, the pouch has been gaining traction alongside glass jars, metal cans, and other plastic materials.

That a product in a retort pouch is cooked inside the sealed bag may surprise a lot of customers. Retorting, which is the same as autoclaving, is a novel method of packaging that involves heating and sterilising the container and its contents. In the food and non-food manufacturing sectors, the process of heat-treating items in their packaging is used to either commercially sterilise equipment, packaging, and parts, or to complete cooking the product for an extended shelf life. The product to be heated is placed within the retort pouch, which is then hermetically sealed, such as airtight and heated following industry standards for both duration and temperature.

Retort pouches and bags make up 60% of all food packaging globally. The invention of heat-resistant plastic film and non-toxic adhesive substances hastened the retort pouch movement. Recognising the enormous potential of using plastic bags to package food for battle rations, the US Army, through its Natic Development Centre, initiated a programme to make use of this novel approach. The Centre accomplished a lot of noteworthy things. The Centre tested the retort pouch's seal integrity, sterilisation properties, and percentage of defects in the container food production. The results showed that the retort pouch was just as reliable as metal cans in demonstrating its suitability as a safe food preservation tool. The global market is expected to reach at 4.50 U$D Billion by 2025.

Retort pouch foodstuff is now made in numerous more nations in addition to these. Retort foods are packaged in trays and cups instead of pouches in the US and Europe. Food in retort pouches is becoming more and more popular in Asian markets, including Korea and Taiwan.

Key Metrics and Overview

| Metric |

Details |

| Market Size in 2025 |

USD 4.50 Billion |

| Projected Market Size in 2035 |

USD 7.48 Billion |

| CAGR (2026 - 2035) |

5.2% |

| Leading Region |

Asia Pacific |

| Market Segmentation |

By Material, By End Use and By Region |

| Top Key Players |

Amcor plc, ProAmpac, Sonoco Products Company, Mondi, Coveris, CLONDALKIN GROUP |

Key Factors Influencing the Market Trends

- Sustainable Materials: One of the main trends in retort packaging is the move towards sustainability. As environmental issues develop, manufacturers are heavily discovering eco-friendly materials. Regular retort packaging often depends on multilayer films created from various plastics that can be challenging to recycle.

- Smart Packaging: The growth of smart packaging is another growing development in the retort packaging sector. Smart packaging includes the mixing of sensors and indicators that serve real-time information about the surroundings of packaged food. For instance, time-temperature indicators can display whether the product has been exposed to temperatures within the safe range during storage or temperature.

- Improved barrier properties: Tracking the safety and freshness of food products is important in retort packaging. Inventions in barrier technology have led to the growth of films with developed moisture barriers and oxygen too. These developments assist in stretching the shelf life of products without adjusting the products.

- Lightweight and flexible design: Users can select portable and lightweight packaging, which is easy to store and carry. Inventions in retort packaging have led to the growth of thinner and more flexible designs without compromising durability. Such lightweight pouches are easy for users and lower shipping costs for producers due to their lighter weight.

- Enhanced labelling and printing: With growth in printing technology, retort packaging can now display in good-quality graphics and detailed information, which makes products more attention-grabbing. Digital printing enables greater customization, which allows brands to make limited-edition packaging or provide feedback quickly to market updates.

- One of the most momentous trends in retort packaging is transformation towards sustainability. As environmental problems rise, manufacturers are rising and exploring eco-friendly materials. Regular retort packaging often depends on multilayer films made of different plastics, which can be challenging to recycle.

- Maintaining the freshness and safety of foods is extremely important in retort packaging. Inventions in barrier technology have led to the growth of films with enhanced oxygen and moisture barriers. These advancements help expand the shelf life of products without compromising on quality. Nanotechnology is playing a crucial role in this sector. By including nanoparticles into packaging films, manufacturers can create ultra-thin layers that serve superior protection against oxygen and moisture which makes sure that food inside remains fresh for a longer time.

- The growth of smart technology is another exciting development in terms of retort packaging. Smart packaging includes the mixing of sensors and indicators that serve actual time information about the condition of packaged food. For instance, time-temperature indicators display whether the product has been exposed to temperature outside the safe duration during transportation or storage.

- Inventions in retort packaging have led to the growth of thinner, more flexible designs without compromising on quality. These lightweight pouches are easy for consumers and reduce shipping costs for producers due to their lower weight.

Market Outlook

- Industry Growth Overview: The retort packaging market is growing because of the rising demand for convenience shelf-stable and ready-to-eat food items. Retort pouches are perfect for meals, soups, sauces, and baby food because they provide a longer shelf life without refrigeration. Compared to metal cans, their lightweight design lowers transportation expenses. Market adoption is further accelerated by the growing trend of busy lifestyles and on-the-go eating.

- Sustainability Trends: Traditional multi-layer laminates are being replaced by recyclable and mono-material retort pouches. Compared to rigid canning retort packaging uses less energy and plastic, which helps reduce carbon emissions. To satisfy sustainability requirements, eco-friendly inks and high-barrier recyclable films are becoming available. Compostable and bio-based retort materials are being investigated by businesses for potential future uses.

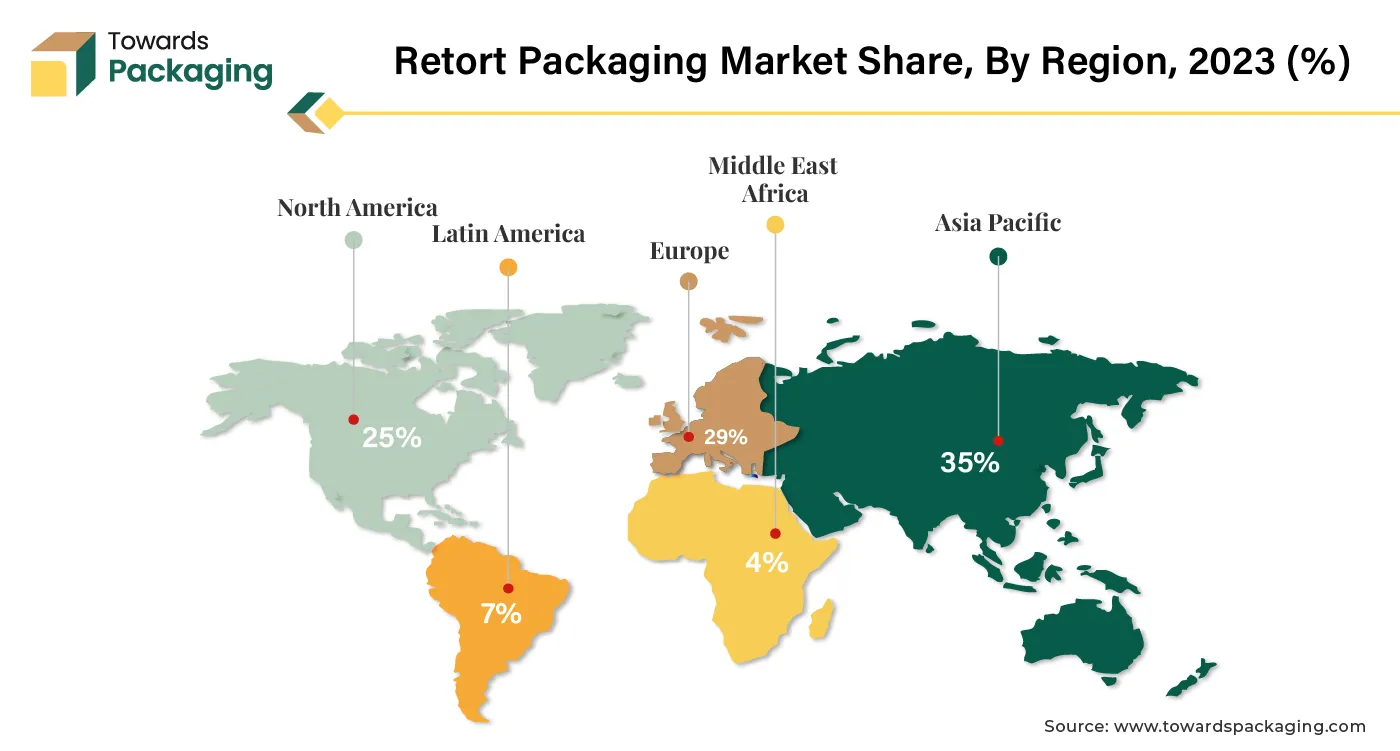

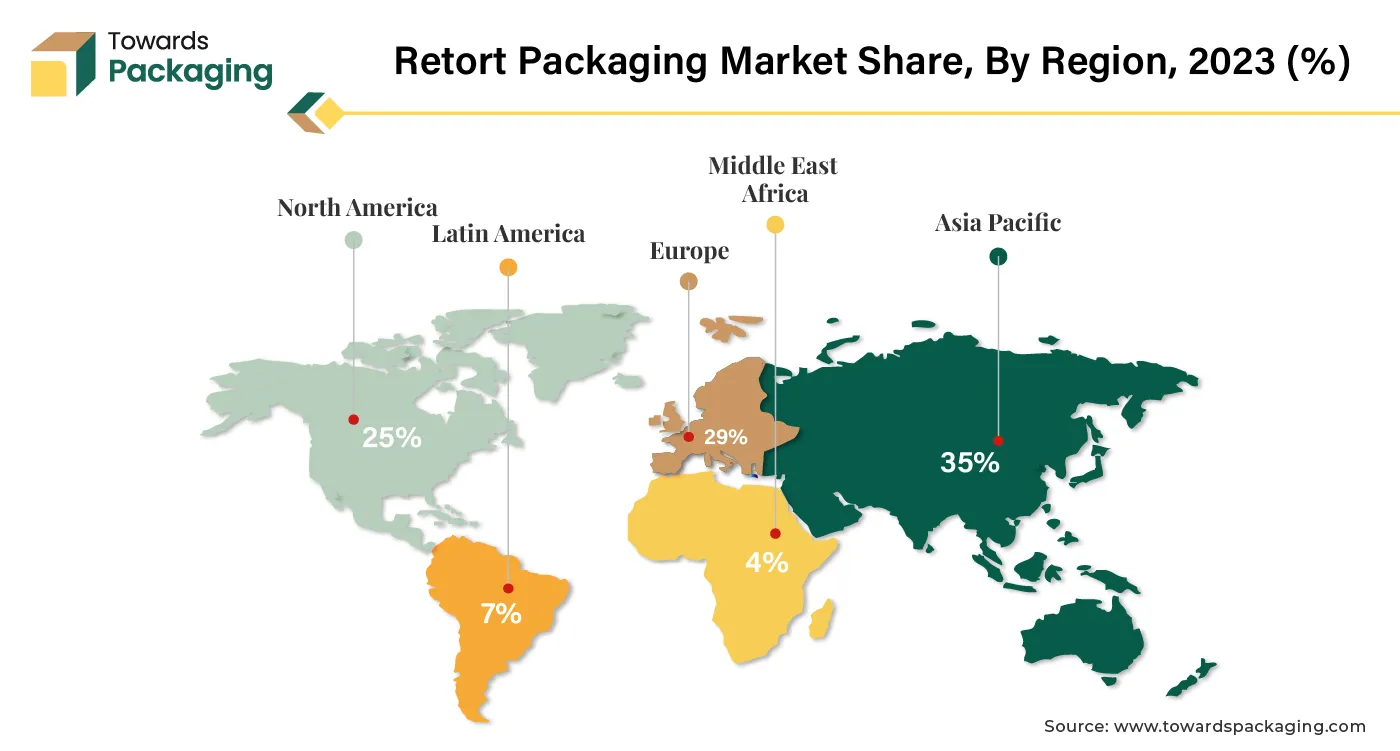

- Global Expansion: Asia-Pacific dominates due to high demand for packaged food, expanding retail, and rising urbanization. North America and Europe are adopting premium and microwaveable retort formats for ready meals and pet food. Emerging markets in LATAM, Africa, and the Middle East are growing fast with increased acceptance of packaged convenience foods. Global exports of ready meals and seafood further strengthen retort packaging growth.

Future Demands

- Rising demand for long-shelf-life, ready-to-eat meals as consumers seek convenient and time-saving food options. Retort pouches offer safe, hygienic, and preservative-free packaging.

- Increased adoption of microwaveable and ovenable retort pouches offering greater convenience and premium meal experiences.

- Surge in pet food, baby food, and functional food products requiring sterile and high-barrier retort formats.

- Higher usage of recyclable mono-material retort pouches as sustainability regulations tighten globally.

- Growing preference for lightweight and travel-friendly packaging for camping, defense, outdoor food kits, and emergency rations.

Retort Packaging Market Leading Manufacturers by Market Share (2024)

| Rank |

Manufacturer |

Market Share (%) |

| 1 |

DNP America (Dai Nippon Printing) |

18% |

| 2 |

Amcor plc |

10% |

| 3 |

Mondi Group |

9% |

| 4 |

Sonoco Products Company |

7% |

| 5 |

Berry Global |

5% |

| 6 |

Sealed Air Corporation |

6% |

| 7 |

ProAmpac |

11% |

| 8 |

Coveris |

8% |

| 9 |

Huhtamaki |

4% |

| 10 |

Clondalkin Group |

13% |

Manufacturer Explanations

- DNP America (Dai Nippon Printing): Holding the largest market share at 18%, DNP America is a global leader in retort pouch technology. Their medium-temperature retort pouches are renowned for superior barrier properties and extended shelf life.

- Amcor plc: With a 10% market share, Amcor is a significant player in the retort packaging sector, offering high-barrier flexible formats to multinational corporations.

- Mondi Group: Mondi holds a 9% market share, focusing on stand-up pouches and acquiring assets like the Hinton mill to enhance its capabilities.

- Sonoco Products Company: At 7%, Sonoco is known for its rigid trays and has expanded its production capacity with new facilities, such as the Wisconsin plant.

- Berry Global: With a 5% share, Berry Global specializes in barrier films and has partnered with companies like Mars to enhance its product offerings.

- Sealed Air Corporation: Holding a 6% market share, Sealed Air is recognized for its Cryovac bags and has launched initiatives like a digital print line to innovate in packaging solutions.

- ProAmpac: At 11%, ProAmpac is a significant player, known for its retort rollstock and recent acquisitions, such as the purchase of Gelpac assets, to expand its product portfolio.

- Coveris: With an 8% share, Coveris focuses on food pouches and has invested in extrusion technology to improve its manufacturing processes.

- Huhtamaki: Holding a 4% market share, Huhtamaki specializes in rigid-flex combinations and has secured deals with major clients like PepsiCo to supply packaging solutions.

- Clondalkin Group: At 13%, Clondalkin is recognized for its foil lids and is actively involved in research and development to innovate in mono-PP packaging solutions.

Opportunity

Rising Demand for Organic Products

For brands that are loyal to natural ingredients, retort pouches frequently serve a clean and chemical-free protection procedure. Since no synthetic additives are needed, it matches the organic food industry’s values. One of the main advantages of retort packaging is its long shelf life, which frequently has 12-24 months without refrigeration. This makes it convenient to store and serve organic food products while lowering food waste.

As more users experience organic lifestyles, retort packaging in the organic food sector protects taste, texture, and nutrients. It also protects the food from light, moisture, and air, which ensures better quality over time.

The rapid rise of online food ordering has a notable impact on the food and beverage industry. This rise has helped the growth of retort packaging market too. The number of consumers opting for online delivery leads to growing demand for packaging that is easy to handle and convenient for customers as well as delivery persons. With retort packaging, the shelf life of the food products is extended which is key factor for online delivery.

The products with this packaging are able to be stored for a longer duration without the need for refrigeration. This helps maintain the quality of the food products and reduce chances of food wastage. The retort packaging makes it easier for the food products to be transported, cooked, and reheated. This makes them a popular choice for the for packaging of meals or snacks that are quick and easy-to-eat. These factors provide ample opportunity for the retort packaging to grow along with rising demand for online food delivery services.

- In May 2024, Prepack, Sun Chemical and Comexi collaborated which led to an important breakthrough in the retort pouch technology. They were able to successfully incorporate high-quality offset printing technology into retort packaging.

- In February 2024, a leading supplier of packaging and processing solutions, ProAmpac, announced their acquisition of Zacmi (Zanichelli Meccanica SpA), an Italian producer of seaming filling and pasteurization systems.

Retort Packaging Market Key Trends

|

Shift in consumer preferences:

- More people are consuming goods like Food, Beverages, and Pharmaceuticals while they are on the go.

- Convenient and portable packaging solutions are becoming more and more in demand, and the retort packaging industry stands to gain immense.

- More customers, particularly those in younger age groups, are likely to shop for groceries more frequently and in smaller quantities because of the shift to single-person households.

- This has increased demand for more convenient, smaller-size forms and spurred expansion in the convenience store retailing industry.

Recycle ready retort packaging:

- Standard retort pouches used to be multilayer packaging with heat stability for sterilization, but they were not recyclable.

- In recent years many brands come up with innovative recyclable retort pouches that have high heat stability and more environment-friendly.

|

Brand recognition through packaging:

- As businesses search for new, high-growth markets and industries, the number of fast-moving consumer goods brands that have gone global is increasing.

- Consumers are attracted to the packaging of the brands which helps them to choose their brand product without any difficulties.

- In major developing economies, greater exposure to Westernised lifestyles will hasten this process until the coming years.

- Brand owners are becoming more and more in need of components like RFID labels and smart tags to guard against counterfeit goods and for improved distribution tracking, thanks to e-commerce and the globalisation of international trade.

Economic and demographic growth:

- Over the next decade, it is anticipated that the global economy will continue to expand generally, helped by the rise of emerging consumer markets.

- There is a chance that the effects of Brexit may cause short-term disruptions and that the US-China trade fights could intensify. However, income growth is anticipated, boosting consumer spending on retort packaged products.

|

Revolutionizing Retort Packaging: How AI is Accelerating Market Growth

Artificial Intelligence (AI) is poised to transform the retort packaging market by enhancing efficiency, quality, and innovation. With AI-driven analytics and machine learning, manufacturers can optimize the design and production processes of retort packaging, leading to improved product safety and extended shelf life. AI algorithms analyze vast amounts of data to predict and prevent potential defects, ensuring higher-quality packaging that meets rigorous standards.

AI also enables real-time monitoring and quality control, allowing for immediate adjustments during production. This reduces waste and minimizes the risk of costly recalls. Predictive maintenance powered by AI helps in identifying equipment issues before they lead to failures, thus improving operational efficiency and reducing downtime.

Moreover, AI facilitates the development of innovative packaging solutions by analyzing consumer trends and preferences. This insight enables companies to design packaging that caters to evolving market demands and enhances user experience. Overall, AI integration in the retort packaging market not only streamlines operations but also drives innovation, positioning companies for sustainable growth in a competitive landscape.

Key Technological Shifts

- High-barrier recyclable materials (PP-based or PE-based structures) are replacing aluminum laminates for improved sustainability. These maintain performance while meeting recycling standards.

- Advanced sterilization and retort processing technologies that reduce energy use and preserve food quality more effectively.

- Mono-material retort solutions improve end-of-life recyclability without compromising thermal resistance.

- Enhanced sealing and burst-resistance technologies ensure product safety during high-temperature sterilization.

- Smart packaging integrations like QR/traceability codes enable transparency, batch verification, and supply-chain visibility.

Asia-Pacific's Dominance in Retort Pouch Demand and its Impact on Regional Packaging Dynamics

One of the markets' fastest-growing regions is Asia Pacific. Retort pouch demand is predicted to be particularly high in the Asia-Pacific region due to the growing need for more convenient food and beverage packaging options. Furthermore, a sizable demand for retort pouch packaging has been generated by China's quick economic growth and rising standard of living.

The transformative forces driving the adoption of retort pouches in the Asia-Pacific region are multifaceted. Urbanization, notable lifestyle shifts, and a concurrent rise in annual disposable income collectively propel the demand for processed foods. This, in turn, catalyses the increased utilization of retort pouch packaging. The rise of convenient, ready-to-eat meals aligns with the fast-paced lifestyles prevalent in urban centres, further amplifying the demand for these versatile packaging solutions.

India, another economic powerhouse in the region, has witnessed a surge in sustainable packaging practices. The uptick in the consumption of packaged foods, coupled with heightened consumer awareness regarding environmental impact, has fuelled the demand for eco-friendly packaging solutions, including retort pouches. The Packaging Industry Association of India (PIAI) reports an annual growth rate of 22 to 25 per cent, emphasizing the significant strides made by the packaging sector. Notably, the food processing industry, a major player in India's economic landscape, accounted for 32 per cent of the nation's total food market, ranking fifth in terms of production, consumption, exports, and anticipated growth.

Retort pouches and other flexible packaging solutions are expected to be in high demand in South Korea, particularly from the FMCG (fast-moving consumer goods) industry. Retort pouches combine the benefits of lightweight, convenient packaging with the changing preferences of consumers. These pouches are positioned for quick acceptance because of their adaptability in meeting the changing needs of the food and beverage industry. As a result, the packaging business in South Korea stands to benefit from the growing demand for retort pouches, which will encourage innovation and expansion.

The demand for retort pouches is astoundingly rising throughout the Asia-Pacific region, led by economic giants like China and India. The food and beverage industry's adoption of retort pouches is transforming the packaging environment due to factors like urbanisation, changing lifestyles, and a growing middle class with more discretionary income. Retort pouches' adaptability and sustainability allow them to remain a key component of the competitive and dynamic packaging market in the Asia-Pacific region, even as the sector continues to evolve.

- In April 2023, Global food packaging expert Huhtamäki Oyj created ground-breaking mono-material technology by applying its scientific knowledge. It is cutting-edge and Eco- friendly flexible packaging in PP, Paper, PE Retort, and is innovative and satisfies the needs of its customers as well.

Evolutionary Era of Retort Pouches

Retort Pouch Food was still used for domestic purposes, despite an increasing trend towards commercial use for use in commerce. Pouch for Retort Food keeps gaining traction with Asia-pacific customers because of the abundance of goods, ease of use, and decreased quantity of extended shelf life and kitchen waste. Japan evolved and developed retort food packaging.

One of Japan's earliest commercially released products was a retort curry. At the period, Japan's fast economic expansion was changing people's everyday lives and increasing demand for quick and simple meals. The single-serving curry, in response, just required reheating the pouch in hot water. Dipping sauces, Seasoning sauces, Pasta sauces and soups were among the many other cuisines that gained popularity because of this curry. Additionally, Japanese tofu, meat fisheries and other agricultural products caught a quite attraction in Japan for retort pouches food products.

- In January 2023, a food firm located in Osaka declared that their Bon Curry brand has been officially recognised by Guinness World Records as the globe’s longest-selling retort pouch curry brand.

Revolutionizing Retort Packaging in the Global Food Industry

In the ever-evolving landscape of the food industry, one innovation stands out as a game-changer: retort packaging. This cutting-edge packaging solution has become a cornerstone in the sector, catering to a spectrum of products ranging from ready-to-eat meals and meats to sauces, baby food, and frozen delicacies. Its impact on the market is nothing short of transformative, combining enhanced flexibility and robust protection against pathogens, thereby propelling its widespread adoption.

The United States Department of Agriculture (USDA) recommends retort packing, which is a popular option because of its adaptability and usefulness. Because of its streamlined shape, the flat, space-saving pouch not only makes storing in pockets or bags easier but also provides processing with operational benefits.

Retort packaging is used for many different types of food products. When it comes to preserving the freshness of seafood like prawns, tuna, salmon, and mackerel as well as meats like beef, chicken and pig, retort pouches are the go-to option. Furthermore, the packaging expands its reach to encompass a variety of food products such as sauces, grains, pasta meals, organic products, fruits, vegetables, and baby food variations. This thorough examination establishes retort packing as a cornerstone of modern food preservation.

Two factors are driving the food industry's adoption of retort packaging: protection and flexibility. The adaptability of the packaging satisfies the changing needs of contemporary consumer lifestyles, where convenience is of the utmost importance. It also guarantees the safety and durability of the packaged goods due to its strong defence against infections. This mutually beneficial link between protection and flexibility drives the market for retort packaging's constant growth. Retort packaging is a shining example of advancement in the ever-evolving global food sector. Food preservation is anticipated to change in the future due to innovations in this field that are motivated by a dedication to sustainability and environmental friendliness. Retort packaging is evolving on a trajectory of constant improvement, from the use of biodegradable materials to the integration of smart packaging technologies, suggesting a future where the freshness of culinary creations is balanced with an environmental conscience.

- In April 2022, ProAMpac announced the launch of a unique PROACTIV PCR Retort Pack due to increased market demand for Post-consumer Recycled PCP packaging solutions. The ProActive PCR Retort pouches have been specially formulated for the packaging of animal and edible products.

- In September 2020, Amcor, a leading packaging company in the world, and Nestlé introduced the first-ever recyclable flexible retort pouch. October 2020 will mark the debut of the new high barrier pouch in Dutch retail locations, which is made with Amcor's AmLite HeatFlex Recyclable solution.

Technological Innovations Driving Global Growth in Retort Packaging

In the ever-evolving landscape of the global packaging industry, technological advancements play a pivotal role in shaping the trajectory of growth, with retort packaging emerging as a prime beneficiary of innovative solutions. These technological applications not only enhance the efficiency and functionality of retort packaging but also contribute significantly to its widespread adoption, fostering a conducive environment for market expansion.

One of the noteworthy technological applications in retort packaging is the integration of modified atmosphere packaging (MAP) technology. MAP involves altering the gaseous composition within the packaging to extend the shelf life of the contents. This technology mitigates oxidation, moisture, and microbial activity, preserving the freshness and quality of the packaged food. The controlled atmosphere created by MAP technology enhances the overall safety and longevity of the products, aligning perfectly with consumer expectations for convenient and long-lasting ready-to-eat meals.

Additionally, advancements in barrier materials have proven instrumental in enhancing the protective properties of retort packaging. The utilization of high-performance films and laminates acts as a barrier against external elements such as light, oxygen, and moisture. This not only safeguards the integrity of the packaged products but also ensures that they remain visually appealing and palatable to consumers. Government agencies, such as the European Food Safety Authority (EFSA), and U.S. Food and Drug Administration (FDA) play a critical role in regulating and approving the use of these innovative materials, ensuring that they meet stringent safety standards.

Smart packaging technologies have also found their way into the realm of retort packaging, contributing to its market growth. Incorporating features like smart packaging QR codes, RFID (Radio-Frequency Identification) tags, and sensors provides real-time information about the product's condition and history. This not only enhances traceability and quality control but also addresses consumer concerns regarding transparency and authenticity. Government initiatives focusing on food safety and traceability further underscore the importance of these technologies in the retort packaging sector.

Moreover, the advent of nanotechnology has opened new frontiers in the development of advanced packaging solutions. Nanocomposites, with their enhanced mechanical, barrier, and antimicrobial properties, have been integrated into retort packaging materials. These nanomaterials contribute to improved durability and protection, further extending the shelf life of packaged products. Regulatory bodies such as the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA) closely monitor the safety and environmental impact of nanomaterials, ensuring responsible innovation in the packaging industry.

The global push toward sustainability has spurred the development of eco-friendly materials in retort packaging. Biodegradable and compostable packaging materials are gaining prominence, aligning with the environmental goals set by various governments. Regulatory frameworks, such as the European Union's Circular Economy Action Plan, encourage the adoption of sustainable packaging practices, driving the market toward greener alternatives.

The technological applications in retort packaging are instrumental in propelling its global growth. From modified atmosphere packaging to smart packaging technologies and nanocomposites, these innovations address key challenges in the industry while aligning with regulatory standards set by government authorities. As the market continues to evolve, the synergy between technological advancements and regulatory frameworks will remain crucial, shaping the future of retort packaging as a cornerstone in the global food packaging industry.

Navigating the Supply Chain in the Retort Packaging Market

The supply chain in the retort packaging market involves a complex network of processes designed to ensure efficient production and delivery of packaging solutions. It begins with raw material procurement, where suppliers provide essential materials such as aluminum, plastic, and laminated films. These materials are then transported to manufacturing facilities, where they are processed into retort pouches or cans.

At the manufacturing stage, advanced technologies are employed to create high-quality, durable packaging that can withstand high temperatures and pressures during sterilization. Once produced, the packaging materials are shipped to food and beverage companies, pharmaceutical manufacturers, and other end-users. These clients utilize the retort packaging for preserving and extending the shelf life of their products.

Logistics play a crucial role in this supply chain, ensuring timely delivery of packaging materials and finished products. Distribution networks are optimized to reduce lead times and minimize costs. Additionally, effective inventory management and coordination between suppliers, manufacturers, and end-users are vital to prevent disruptions and maintain a steady flow of goods.

Overall, the retort packaging supply chain is a dynamic system requiring precise coordination and efficient logistics to meet market demands and ensure product quality.

- In October 2021, Retort Pouch Recyclable is a new addition to Mondi's line of sustainable premium food and pet food packaging. Mondi is a leading global leader in packaging and paper which replaced the multilayer unrecyclable pouch with high-barrier packaging material.

Future of Recycle Ready Retort Pouches Market

The recycle ready retort pouches market is accelerating, with forecasts predicting hundreds of millions in revenue growth between 2025 and 2034, powering sustainable infrastructure globally.

The recycle ready retort pouches market is expected to grow at a substantial CAGR during the forecast period. Recyclable retort pouches are intended to be recovered and repurposed after they are utilized in order to prevent waste from reaching the landfills. For better sorting and recyclability, they generally utilize mono-material architecture with a single polymer type in all layers.

Prominent mono-polymer configurations consist of retort pouches made entirely of polyethylene or polypropylene and does not have composite layers like nylon or aluminum foil as they are difficult to recycle. Solvent-free adhesives enable appropriate separation and to avoid heavy metals, water-based inks are used. Mono-material retort pouches are capable of being recycled through processing those using methods such as density separation, flotation, infrared sorting as well as manual separation. This will yield a homogenous stream of polymers that can be remanufactured. By doing this, precious resources are kept out of landfills and in use.

The rising environmental concerns and the stringent government regulations on plastic waste is expected to augment the growth of the recycle ready retort pouches market during the forecast period. Furthermore, the increasing consumer demand for eco-friendly and recyclable packaging along with the investments in the circular economy initiatives and corporate sustainability goals are also anticipated to augment the growth of the market. Additionally, the growing processed and ready-to-eat foods industry as well as the expansion of the pet food and pharmaceutical packaging sectors coupled with the improvements in the manufacturing efficiency and cost-effective production methods is also projected to contribute to the growth of the market in the near future.

Competitive Perspectives in the Retort Packaging Market

The market for retort pouch packaging is characterised by intense competition because there are several key players such as Amcor plc, ProAmpac, Sonoco Products Company, Mondi, Coveris, CLONDALKIN GROUP, Sealed Air, and others. This market has a medium level of market concentration, and several major players are present, using tactics such as product innovation, acquisitions, mergers and to obtain a competitive edge.

Bimbosan and flexible packaging manufacturer ProAmpac collaborated to create the ProActive renewable pouch for the infant food industry in August 2020. The sealing layer of this new pouch contains 65% bio-based glue, which can lessen its carbon footprint on the environment. Coveris Holdings inaugurated its new Pack Innovation Centre in Halle, Germany, in July 2020. Positioned as a European hub for technical product development, sustainable innovation, and education, the centre helps clients innovate, educate and validate the flexible packaging of the future.

Value Chain Analysis

1. Raw Materials & Film Production

Retort packaging uses multi-layer structures of PET, PP, nylon, aluminum foil, and high-barrier coatings. Material suppliers design films that withstand high temperatures and pressure during sterilization. The shift toward recyclable mono-material films is transforming sourcing strategies. Raw material quality determines pouch strength, seal integrity, and shelf-life performance.

2. Lamination, Printing & Retort Pouch Manufacturing

Films undergo lamination, slitting, and high-definition printing to create pouches with strong seals and durability. Manufacturers use advanced forming and sealing equipment that maintains performance under retort processing. Automation and robotics enhance precision and production speed. Lightweighting and recyclable designs are driving investments in new machinery and materials.

3. Filling, Distribution & End-of-Life

Filled pouches go through heat sterilization (retorting) to ensure food safety and long shelf life. Products are distributed to retail, foodservice, and export markets due to their transport efficiency. End-of-life includes mechanical recycling for mono-material pouches and material recovery initiatives for multilayer structures. Brand–recycler partnerships are accelerating circularity improvements.

Retort Packaging Market Companies

- Amcor plc

- ProAmpac

- Sonoco Products Company

- Mondi

- Coveris

- CLONDALKIN GROUP

- Sealed Air

- Huhtamaki

- FLAIR Flexible Packaging Corporation

- WINPAK LTD.

- Floeter India Retort Pouches (P) Ltd

- Proampac LLC

Recent Developments

- On 5 March 2025, Amcor officially launched an inventive 2oz retort bottle which includes proprietary StromPannel Technology. This growth comes in collaboration within Symmetry which solves the rising demand for shelf-stable packaging and durable low-acid beverages such as coffee and dairy products.

- On 7 June 2024, For a move towards sustainable packaging solutions, Ball Corporation which is a top company in sustainable packaging disclosed its collaboration with Cavinkare, a leader in the dairy industry.

- On 20 November 2023, ProAmpac which is a top leader in terms of flexible packaging and material science revealed that its proActive PCR Retort pouches include post-consumer recycled material and its sustainability.

- In December 2022, Ferlo, a pasteurising tunnel supplier, was acquired by ProMach. ProMach intends to strengthen its position in the retort and processing equipment markets with this acquisition.

- In January 2021, Amcor innovated the first recyclable retort packaging which is used in baby foods, pre-cooked rice, soups, and others. They have pledged to make their packaging material recyclable and reusable by 2025

Segments Covered in the Report

By Material

- Polypropylene

- Polyamide

- Aluminium foil

- Polyethylene Terephthalate (PET)

- Paperboard

By End Use

- Food

- Beverage

- Pet food

- Pharmaceuticals

- Others

By Region

- Asia Pacific

- Europe

- North America

- LA

- MEA