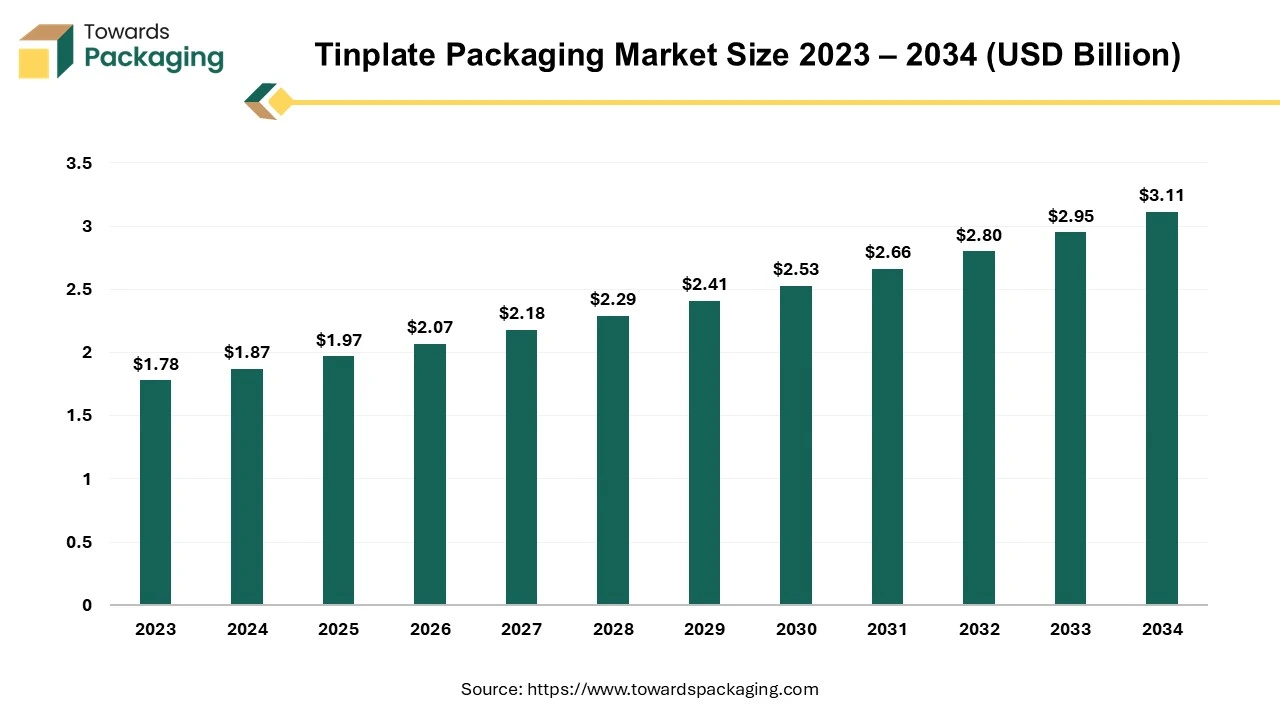

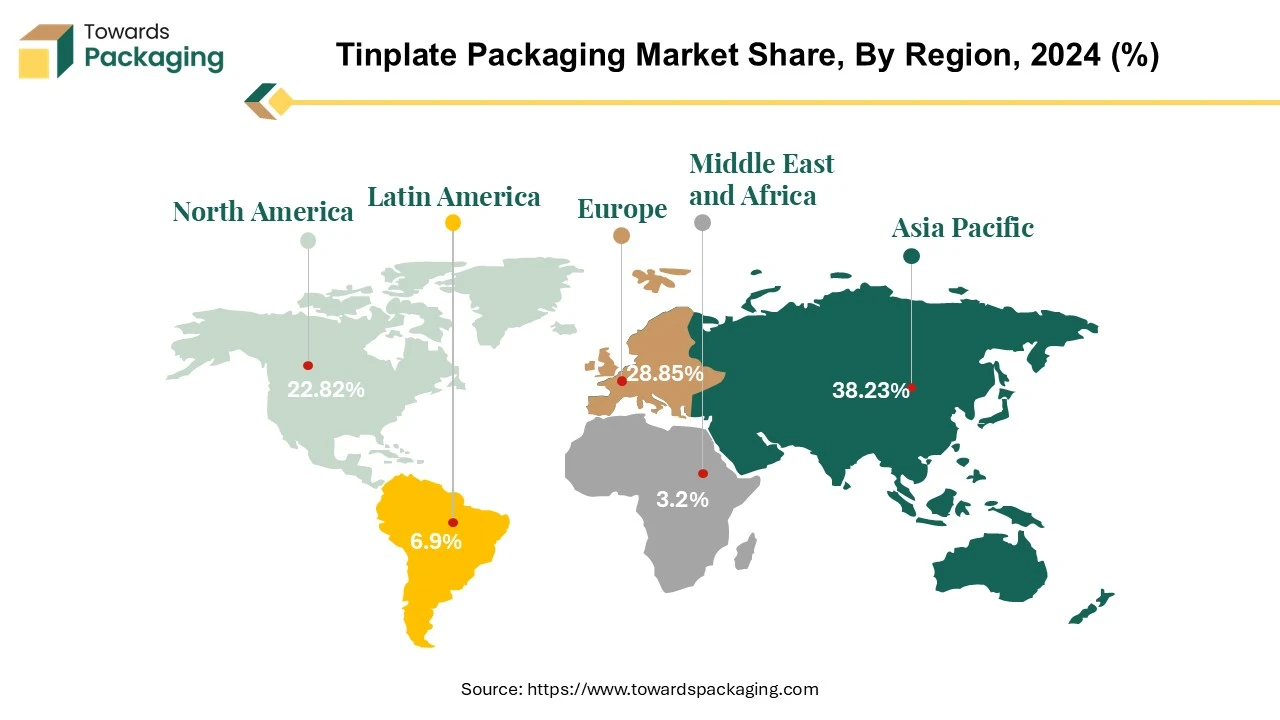

The tinplate packaging market is forecasted to expand from USD 2.07 billion in 2026 to USD 3.26 billion by 2035, growing at a CAGR of 5.17% from 2026 to 2035. The report comprehensively covers market segmentation by product type, thickness, and end-use industries, offering detailed insights into key regions North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. North America accounted for 22.82% of the market share in 2024, while Asia Pacific is set to expand at a 7.01% CAGR.

The study further presents an in-depth competitive benchmarking of top manufacturers such as Tata Steel, ArcelorMittal, CPMC Holdings, and Crown Holdings, along with trade statistics, supply chain mapping, and import-export data analysis.

The tinplate packaging market is set to grow prominently during the forecast period. Tinplate is a thin sheet of steel or iron metal with a tin coating deposited by electroplating or dipping. Tinplate is a highly effective packaging material due to its efficient recycling systems and excellent recycling qualities. As packaging steel is so prevalent in daily life—for instance, as jar and bottle tops, aerosol spray cans, food and drink cans and packaging for chemical and technical products, thus individuals can have a significant impact on the circular economy. Additionally, by selecting tinplate packaging, companies may easily promote multiple recycling and a complete material cycle by simply placing the used tinplate packing into the recycling bin.

The increasing focus on the sustainability and the rising demand for the premium and aesthetically appealing packaging in the luxury goods sector are expected to augment the growth of the tinplate packaging market during the forecast period. Furthermore, the growth in the ready-to-eat and processed food segments coupled with the surge in the e-commerce segment is also likely to support the growth of the market. Additionally, the growing consumer preference for long-lasting and protective packaging as well as the stringent regulations regarding food safety and packaging materials is also projected to contribute to the growth of the market in the years to come. The packaging market size is growing at a 3.16% CAGR.

The increasing demand from end-use industries such as food and beverages, chemicals and cosmetics, among others is projected to support the growth of the tinplate packaging market during the forecast period. In the food, beverage and other industries, tin containers are a common choice of packaging. Tinplate packaging has a longer shelf life, which is one of the main benefits when it comes to storing the food.

Tin packaging greatly slows down the process of the food deterioration, thus guaranteeing that the food stays fresh for extended period of time. It is also airtight as well as resistant to the external elements such as the light and the humidity. The capacity of the tin packing to preserve the food's nutritional value is an additional advantage. Food that is kept in the tin packaging retains its nutritional value since the vital nutrients are sealed inside. Tin containers are also utilized for transporting items across large distances. Food cans are utilized to store food such as the ready meals, pet food, fruit, veggies, soup, meat, fish and olive oils, among others.

Furthermore, as far as the production complies with regulatory regulations, it is also feasible to package medications in tinplate. Additionally, due to their easy operation and straightforward use, aerosol or spray cans have been widely used in both daily life and industrial production. Some examples of such products include pesticides, paint aerosols, deodorants, cosmetics and hair care products, shaving foams, rust removers, car care items, antifreeze, air fresheners and more. These tin aerosols can be formed into a variety of shapes that complement the identity of the brand.

Additionally, tinplate is used not just to make can ends but also to make bottle closures, such as crown corks with their distinctive corrugated rims and cork or plastic pad sealant that creates a tight, hermetic seal once applied to a bottle. Tinplate pressed from sheet is also used to make twist-off closures. As these industries continue to grow owing to the urbanization, rising disposable incomes as well as changing consumer lifestyles, demand for the tinplate packaging is also likely to surge, establishing its position as an essential component in the global packaging ecosystem.

The availability of different alternative packaging materials and options is anticipated to hamper the growth of the tinplate packaging market within the estimated timeframe. For example, plastics are a feasible substitute to tinplate owing to its cost-effectiveness, lightweight design and adaptability. Even though glass packaging is more delicate and heavier, it is regarded as high-end and is frequently utilized for products where luxury and visual appeal are important, like in the alcohol and cosmetics sectors.

Nothing in contact with glass will be impacted or changed since it is a non-reactive material. This characteristic is particularly vital for the protection of the contents of the container. A sealed glass jar with the right closure prevents air from entering or leaving, keeping contents dry, safe and fresh. Glass packaging is currently accepted by the consumers as one of the recyclable and sustainable options available.

Furthermore, flexible packaging has also gained popularity. This kind of packaging is used to make storage bags, pouches and other products across industries like the food and beverage, pharmaceutical, and cosmetics, among others. Numerous products are distributed, marketed, and secured using flexible packaging. The affordability of flexible packaging is among its one of the primary benefits. Brands don't have to go over budget to pack their products in an elegant and useful way.

Furthermore, flexible packaging saves producers cost on shipping since it is lightweight. Other factors also contribute to the growing popularity of flexible packaging. Due in large part to their lower production and shipping costs as well as their capacity to meet the growing demand for convenience, these alternatives is popular with both manufacturers and the customers. The increasing inclination towards substitute materials has the potential to decrease the market share of tinplate packaging, especially in markets with limited budgets where material efficiency and cost are important factors.

The shift towards sustainability and capability of recycling is expected to create opportunities for the growth of the tinplate packaging market in the near future. Tinplate has an excellent environmental balance when it comes to the packaging materials. It is nearly 100% recyclable, infinitely reusable and doesn't even lose quality when recycled. Tinplate is a recycling pioneer and a promoter of the circular economy; in 2020, the rate of recycling for the tinplate from residential buildings in Germany was 91.4%. Since tin is fully recyclable, meaning it can be processed as well as put back into the production cycle without losing its quality, it is regarded as a sustainable packaging substrate.

Tin recycling rates have reached over 90% in several countries globally, which is evidence of the metal's recyclability. At the end of the recycling process, tin remains capable of being melted down and repeatedly reformed when utilized as a coating over other metals. It is a magnetic metal as well. Tin cans therefore are readily and swiftly removed from the streams of waste. Tin is a great option for the high-end and luxury firms who want to increase their sustainability standards without sacrificing the premium feel and appearance of their packaging.

Additionally, if today's consumers properly segregate their garbage and recycle their cans, these cans may one day be used as parts of a bike and another day as parts of a car. By assuring that packaging metal is recycled for both the industrial sectors as well as the private sector; companies are contributing to the successful closure of the material cycle.

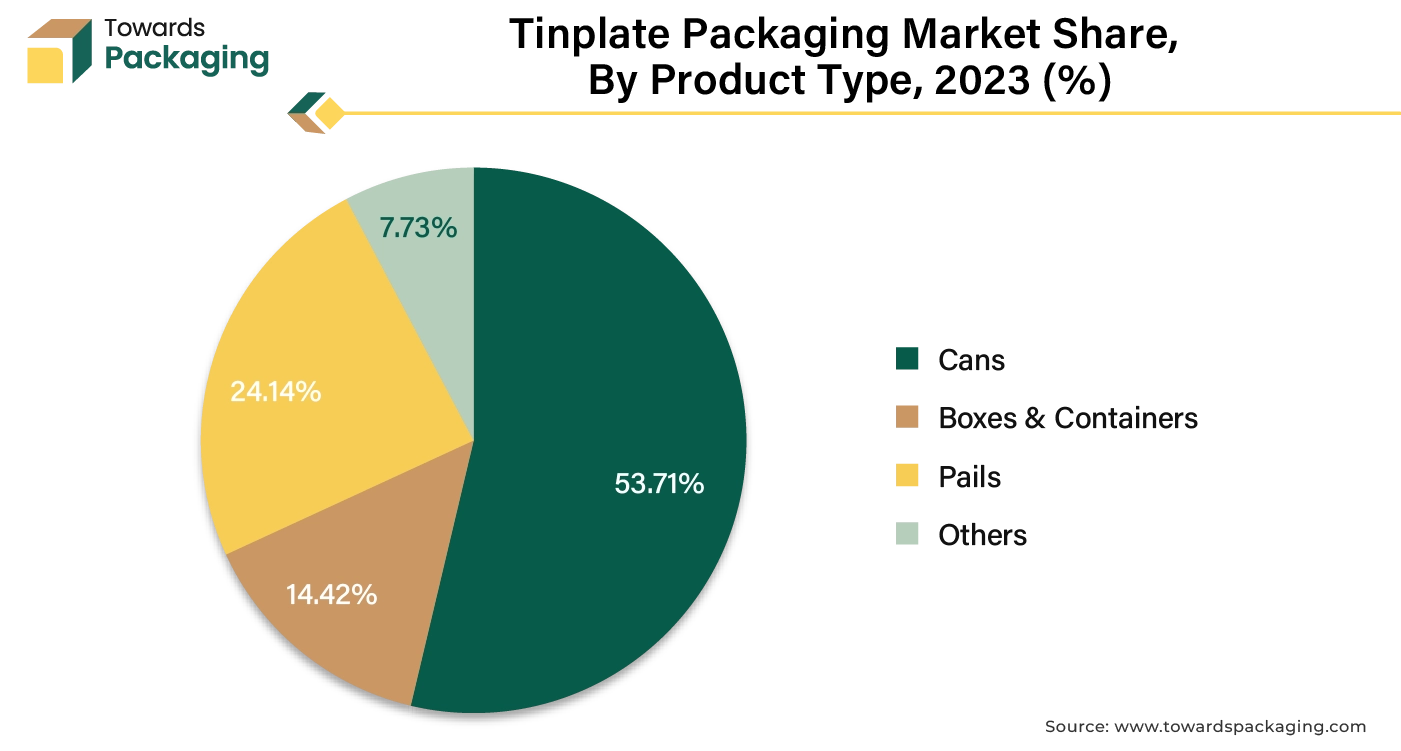

The cans segment captured largest market share of 53.71% in 2024. This is owing to the widespread use of tinplate cans in the food and beverage industry, particularly for the canned foods, soft drinks and the alcoholic beverages. Thick cans are used to preserve things like beef, tuna and sardines, whereas the thinner cans are utilized to store beverages. Typically used for tuna, sardine, and ready-meal cans, single-drawn cans are produced in a single drawing procedure.

Large, tall cans known as "drawn and redrawn" are typically used to store bulk foods like salmon and canned fruit. Cans marked Drawn and Wall-Ironed, or DWI, are frequently utilized for beer and other beverages. Furthermore, tin cans are also widely used for aerosol packaging, which includes products like deodorants, air fresheners, spray paints, insecticides and hair sprays. It is frequently used as a sustainable substitute for the conventional plastic products.

The beverage segment held largest market share in 2024. This is owing to the increasing consumption of both alcoholic as well as non-alcoholic beverages across the globe. Cans are becoming more and more common in drink packaging since they can be recycled, utilized for products other than carbonated beverages and they can also be manufactured at a low cost. Drink packaging serves as a link between a product and its consumers, acting as a mediator beyond its external appearance. It is essential to stand out from the competition on the shelves and in online stores in order to generate interest, engagement and sales from the customers as well as establish brand awareness. In the end, the goal is to prevent customers from passing by or scrolling by. Packaging is altering in response to the changing consumer demands as a way to remain competitive in the drink categories. Traditionally associated with sodas, the simple can is now being utilized for beer and functional beverages, among other types of drinks.

Asia Pacific held is likely to grow at fastest CAGR of 7.01% during the forecast period. This is owing to the rising disposable income that is leading to increased demand for packaged food, beverages, and consumer goods across the region. Additionally, the growing food and beverage sector in countries like China, India and Japan along with the rapid expansion of e-commerce industry are also anticipated to promote the growth of the market in the region in the years to come. China's leading beverage manufacturers saw double-digit output increases in 2021. Major beverage makers saw a 12 percent year-over-year increase in output in 2021, reaching over 183 million tons, as reported by the Ministry of Industry and Information Technology. The beverage output reached 13.59 million tons in December 2021 alone, an increase of 8.3 percent from the previous year.

China Market Trends

China tinplate packaging market is driven owing to advancements in manufacturing technologies in the country. China's commitment to reducing plastic waste has led to policies that favor recyclable materials like tinplate. The government's emphasis on sustainable packaging solutions is encouraging industries to adopt tinplate, which is 100% recyclable and aligns with environmental goals. The increasing urban population and changing lifestyles have boosted the demand for packaged and ready-to-eat foods.

Tinplate's durability and ability to preserve food quality make it a preferred choice for packaging in the food and beverage industry. Chinese manufacturers are investing in automation and intelligent manufacturing technologies to enhance production efficiency and product quality. The integration of AI and IoT in production processes is optimizing operations and meeting the growing market demand. There is a growing trend towards personalized and aesthetically appealing packaging.

Advancements in printing technologies allow for intricate designs on tinplate surfaces, catering to consumer preferences for unique and attractive packaging. Major players in the Chinese market are engaging in mergers and acquisitions to strengthen their positions. For instance, China Baowu Steel Group's acquisition of CPMC Holdings aims to expand its customer base and enhance its capabilities in the metal packaging sector. China's advanced recycling and waste management systems support the use of tinplate by ensuring efficient collection and processing. This infrastructure not only aligns with environmental objectives but also appeals to eco-conscious consumers.

North America held considerable market share of 22.82% in 2024. This is due to the well-established recycling infrastructure along with the strong consumer and regulatory focus on sustainability and reducing environmental impact across the region. Also, the mature food and beverage industry is further expected to support regional growth of the market in the years to come. Furthermore, the growing consumer demand for convenient, long-lasting products, such as canned goods and beverages as well as the changing lifestyle is also expected to support the regional growth of the market in the near future.

U.S. Market Trends

U.S. tinplate packaging market is driven owing to strong demand from food & beverage sector in the country. U.S. consumers and manufacturers are increasingly prioritizing eco-friendly packaging solutions. Tinplate, being 100% recyclable, aligns well with these sustainability goals. Its recyclability reduces environmental impact and supports circular economy initiatives, making it a preferred choice over less sustainable alternatives. The food and beverage industry in the U.S. significantly drives the tinplate packaging market. Tinplate's excellent barrier properties protect contents from contamination and extend shelf life, making it ideal for canned foods and beverages.

The convenience and durability of tinplate packaging meet the needs of both manufacturers and consumers in this sector. U.S. companies are at the forefront of adopting advanced manufacturing technologies, including automation and intelligent systems, to enhance production efficiency and product quality in tinplate packaging. These innovations enable scalable production and customization, catering to diverse industry requirements. The United States benefits from a well-established manufacturing infrastructure, providing a reliable supply chain for tinplate packaging. This infrastructure supports consistent production and distribution, ensuring timely delivery to various industries and reinforcing the country's market dominance.

Europe’s Growing Sustainability Initiatives to Support Steady Growth

Europe region is seen to grow at a notable rate in the foreseeable future. The European Union's stringent environmental regulations have significantly influenced the packaging industry. Policies promoting recyclability and the reduction of plastic waste have encouraged the adoption of tinplate, a material known for its 100% recyclability and alignment with circular economy principles.

Countries like Germany, the United Kingdom, and France have well-established food and beverage industries that drive the demand for tinplate packaging. Tinplate's excellent barrier properties make it ideal for preserving the quality and extending the shelf life of canned foods and beverages. The increasing consumer preference for convenient and ready-to-eat products further fuels this demand. European manufacturers are investing in technological advancements to improve tinplate packaging production.

By Product Type

By Thickness

By End Use

By Region

February 2026

February 2026

February 2026

February 2026