The Leak-Proof Flexible Packaging Market covers complete insights on market size, segment-wise performance, and regional growth across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. This report includes statistical data such as the 2024 market shares Asia Pacific leading the industry, stand-up pouches holding 36% share, plastic films contributing 52.4% revenue, heat sealing accounting for 60% and forecasts strong CAGRs across emerging segments like spouted pouches, bioplastics, and ultrasonic sealing through 2034.

It also covers trade flows, import–export volumes, competitive analysis of companies like Amcor, Mondi, Sealed Air, Berry Global, Huhtamaki, and Uflex, along with value chain mapping, manufacturer–supplier data, and technological trends such as MAP systems, high-barrier films, and AI-enabled quality control.

| Metric | Details |

| Innovation Drivers | - AI-powered quality control & design - Smart packaging (QR codes, freshness sensors) - Eco-friendly adhesives and monomaterials |

| Leading Region | Asia Pacific |

| Market Segmentation | By Packaging Type, By Material Type, By Technology, By Application, By End-User Industry and By Region |

| Top Key Players | Amcor plc, Mondi Group, Sealed Air Corporation, Constantia Flexibles, Berry Global Inc., Huhtamaki Oyj, Coveris Holdings |

The leak-proof flexible packaging market refers to the global industry focused on producing flexible packaging solutions that ensure product containment without leakage. These include pouches, sachets, wraps, and bags made from high-barrier materials and designed to hold liquids, semi-solids, and perishable items. Leak-proof packaging is critical in sectors such as food & beverages, pharmaceuticals, household chemicals, and personal care, where product integrity, hygiene, shelf-life, and transportation safety are paramount.

Flexible packaging is a kind of packaging that can be easily bent or folded without breaking. It can have a shape of its own, or it can accommodate the shape of the product's interior. Prevalent materials include foil, plastic films, and paper, too. Flexible packaging is exceptional because it is affordable, lightweight, and space-effective. Soft packaging needs fewer materials, takes up less storage, and is easy to transport. It's also the most efficient option among all types. This kind of packaging also allows space for reasonable zippers, spouts, custom shapes, and more. It is widely used for frozen foods, snacks, personal care products, and condiments. Patterns like sachets, pouches, warps, mailers, and vacuum-sealed bags are widely seen in retail.

Artificial intelligence (AI) is greatly changing the flexible packaging sector, affecting every stage from material development and manufacturing to consumer experience and sustainability. AI algorithms examine material performance data and simulate many combinations to achieve lighter, stronger, and more sustainable packaging. Machine learning models can foretell how a material will behave under certain conditions, like humidity, temperature, and handling. That reduces the urge for physical testing. AI-powered platforms assist engineers in crafting packaging that lowers waste and improves recyclability or reuse.

AI-driven vision systems detect scars and automatically adjust production elements that reduce wastage. AI-tracked tools and intelligent production lines develop accuracy, speed, and resource effectiveness. AI algorithms update ink distribution and substrate usage, which develops graphic quality and reduces printing costs. Tools like DALL-E or MidJourney, accepted for packaging, allow for the instant creation of inventive concepts. Integrating AI and blockchain will allow real-time traceability of packaging materials, checking recycled or biodegradable origins.

Why does Proof Flexible Packaging Win On Efficiency and Freshness?

Leak-proof flexible packaging is also lightweight, which means lower transportation costs. During transportation, fuel usage will be relatively lower if our product has flexible packaging as compared to strong packaging. As compared to rigid packaging, the barrier characteristics of flexible packaging are exceptionally great. The packaging keeps out oxygen and moisture, which keeps the food product fresh for a longer time. Since there are no joints or seams, it's challenging for any external elements to break down. In terms of waste management, flexible packaging is more positive than rigid packaging. It takes up less space in landfills because of its lightweight and compact nature. As for supermarkets and grocery stores, flexible packaging serves to make more effective use of shelf space.

Challenges of Sustainability and Cost in Flexible Packaging

Flexible packaging companies must continuously invent to align with consumer demands, which requires constant technology upgrades and significant capital investments. These companies face scrutiny due to waste and the non-recyclable nature of most materials. They must solve the environmental issues, reducing greenhouse gas, end-of-life disposal, and water footprints, which can be costly. Achieving circularity remains one of the sector's biggest challenges. It must safeguard the packaged content from external surroundings like UV rays, sunlight, and temperature variations.

Flexible Packaging: Less waste, More Value

Flexible packaging is more lightweight and cost-effective. The barriers and films that generate the pliable materials need fewer resources and energy to produce while serving a more effective strategy for shipping, logistics, and warehousing. Businesses can save across the complete supply chain while tracking good quality standards, but the advantages don't end here. These kinds of packaging solutions, even after expanded shelf life, provide protection against contaminants. This packaging makes a barrier against oxygen, moisture, micro-organisms, and light, which can cause spoilage, oxidation, contamination, and discoloration too. This developed protection advantage the product's shelf life and lowers the risk of product wastage due to spoilage.

A stand-up pouch is an adaptable, flexible packaging solution crafted with a bottom gusset that allows it to stand upright on the shelves. This structural benefit makes it a selected choice for premium products, as it grows visibility, branding, and convenience. Whether it's pet products, food, or personal care items, stand-up pouches serve as a modern and sleek packaging alternative that integrates aesthetics and functionality, too. Stand-up pouches are the go-to choice for brands seeking to develop visual appeal, enhance user experience, and ensure product protection. Hence, for budget-conscious brands or single-use products, stand-up pouches may be a more practical solution. The selection ultimately depends on storage requirements, product type, and brand positioning.

Spouted pouches are pouches that have an easy spout, often with a resealable cap, which makes them perfect for liquid pouches and semi-pouches. This feature allocates the liquid in a measured way and without disclosing or wasting the liquid. It also has a resealable characteristic that allows the product to be closed after use to prevent leakage of air. This kind of packaging is especially utilised for liquid packaging like sauces and juices, detergents and liquid soaps, and some food products like purees or yogurt, too. Because of flexible pouches, they have been hugely utilised by both consumers and producers in their quest for suitable packaging material

The acceptable nature of PE (Polyethylene) and PET (Polyethylene terephthalate) plastic films packaging materials means that it complies with a series of performance requirements needed for packaging uses across the end-use market industry. For instance, the usage of PE is prevalent in the food packaging sector to safeguard products ranging from fresh vegetables and fruits to frozen items and liquids, due to its moisture resistance and ability to protect freshness. The healthcare industry totally depends on the protective nature and hygienic nature of PE, and its opposition to contamination, while among the consumer goods, this material serves as a sturdy, lightweight, and economical procedure to protect products, and provide chemical resistance to packaging products like laundry detergents. At the same time, the molecular structure of PET plastic is heavily symmetrical and has a certain degree of crystallinity, which gives excellent film forming and moulding characteistics. It even has good optical performance and weather resistance, and huge PET plastic has perfect optical transparency.

The bioplastics are derived from plant starch, sugarcane, corn, or other sources. In some cases, microorganisms like yeast or bacteria are used to ferment sugars from plant sources into lactic acid or other biobased monomers, and these biobased monomers can be derived directly from plants. Further, it experiences the polymerisation, finishing, and cooling process. Multilayer barrier film packaging materials and structures are the main parameters to define packaging in the current world, which serve sophisticated product packaging solutions to solve distinct needs of preservation, protection, and ease of various products or goods.

Heat sealing (or heat welding) is a procedure of fusing two plastic materials together using heat. This procedure is used to make airtight seals on food packaging to ensure optimum protection of products against moisture, air, and other contaminants. Heat sealing is specifically famous for custom flexible packaging because it serves as a seal and a high-quality aesthetic outcome. The procedure includes applying heat to the surfaces of the plastic films to be packed. When these surfaces melt, they integrate together, making a constant bond which solidifies after cooling. This welding is necessary to guarantee the preservation and safety of packaged goods, specifically in the food industry, where hygiene and freshness are important.

Flexible food packaging, with ultrasonic sealing, is a high-level technique created using high-frequency sound waves conformally concentrating on an accurate point, which applies frictional heat that leads to melting of the material, making a secure and clean seal. This is a perfect method for packaging lightweight products, such as dry foods and snacks, which need accuracy and leakproof sealing. Because of its capacity to create tight, constant seals without the need for high temperature, ultrasonic sealing is a highly beneficial alternative to regular heat sealing for heat-sensitive packaging material. Ultrasonic and zipper-based sealing is one of the most energy-efficient sealing processes, as it needs less energy than heat sealing, which makes it perfect for organizations seeking to run their operation more cost-efficiently and also sustainably. Also, moisture and air are tightly packed out by applying the accurate amount of heat, which allows the packaged food to keep fresh and stay on the shelf for a longer time.

Flexible packaging procedures have changed the retail food business. Like regular rigid packaging, flexible packaging is customizable, evergreen, and cost-effective. It adds materials like bags, pouches, wraps, and films, which can be easily molded to fit various product sizes and shapes. This acceptability makes packaging materials suitable for a huge range of food items that include snacks, frozen food, beverages, and dry goods. One of the main reasons food retailers choose flexible packaging technologies is their potential to provide excellent protection while utilising fewer materials. This not only lowers production costs but also lowers environmental effects, which meets with growing customer demand for sustainability.

In the healthcare and pharmaceutical industry, tracking product sterility and ensuring easy handling are important. Flexible packaging serves secure containment for medicines, personal care products, and medical devices. Sachets, blister packs, and sterile pouches are prevalently used for different healthcare products. These solutions protect medicines from light, moisture, and contamination to ensure product safety throughout their shelf life. Flexible packaging also serves tamper-evident characteristics and child-resistant features, which are important for safeguarding products in this sensitive sector.

Flexible packaging can serve as a superior barrier protection against light, moisture, and oxygen, and expand the shelf life of pet food products. This means less food waste, which is the main concern for both consumers and manufacturers. By keeping food fresher for longer, flexible packaging not only stores quality but also reduces the frequency of buying, further lowering the environmental impact linked with production and distribution.

Flexible packaging is widely utilised in the fast-moving consumer goods (FMCG) industry because of its high resource efficiency, reliability, and capability to serve functionality while lowering raw material use. It is broadly used by both small regional brands and large national and multinational brands. Given its huge spread of usage and relatively low manufacturing costs, flexible packaging is produced by several large and small operators, which leads to a variety of packaging compositions being placed in the sector. Hence, in spite of the fact that flexible packaging meets the demand of the FMCG accurately, its post-consumer management showcases main limitations on the ground.

Because of their unique qualities, polymer films are most frequently used in flexible medical packaging. For example, polyethylene materials (PE films and laminates) are widely used to create hygienic films such as medical laminates, breathable films, cast breathable film, embossed film, etc., due to their softness, flexibility, and resistance to moisture. High-density polyethylene (HDPE) is utilised for applications that need more power, whereas low-density polyethylene (LDPE) is perfectly suited for heat sealing packaging. Another main material is polypropylene, which is well-known for its perfect chemical resistance and accuracy for sterile packaging, which is used for sterilizable packaging.

The flexible packaging industry in Asia Pacific is classified by demand across a huge spectrum of products, ranging from cost-effective sachets to high-end luxury packaging. The industry is expected to witness robust development, specifically in the pharmaceutical, food, and industrial packaging segments, driven by growing consumer demand for easier and protective packaging.

As one of the biggest producing hubs in the world, China is expected to import a significant amount of flexible packaging in the year 2025. The country's growing e-commerce sector and growing consumer spending contribute to the growing demand for flexible packaging.

Japan is a momentous importer of flexible packaging because of its high level of technology and inventions in the packaging sector. In the current year, the country is expected to import a heavy volume of flexible packaging to meet its various consumer base. India's quickly growing population.

Latin America's flexible packaging sector is as diverse as its geography, with countries like Mexico, Brazil, and Colombia leading the charge. The region's rising middle class and growing focus on exports are the main growth drivers. The growth of modern retail formats and e-commerce is driving demand for standard packaging. E-commerce in Latin America is a worldwide agricultural powerhouse that necessitates high-level packaging solutions to ensure product integrity. Consumers are urging packaging that shows transparency and sustainability, specifically in the food and beverage industry. Clean-label and tamper-evident packaging are gaining attention in the region.

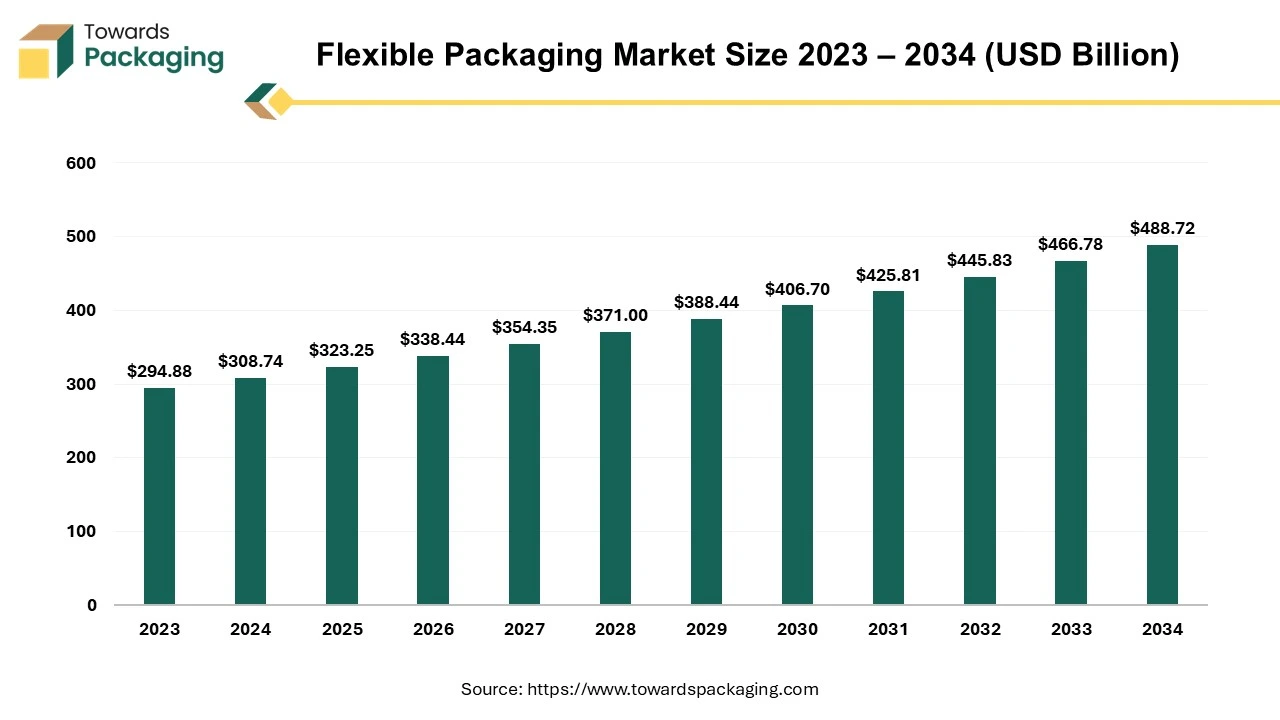

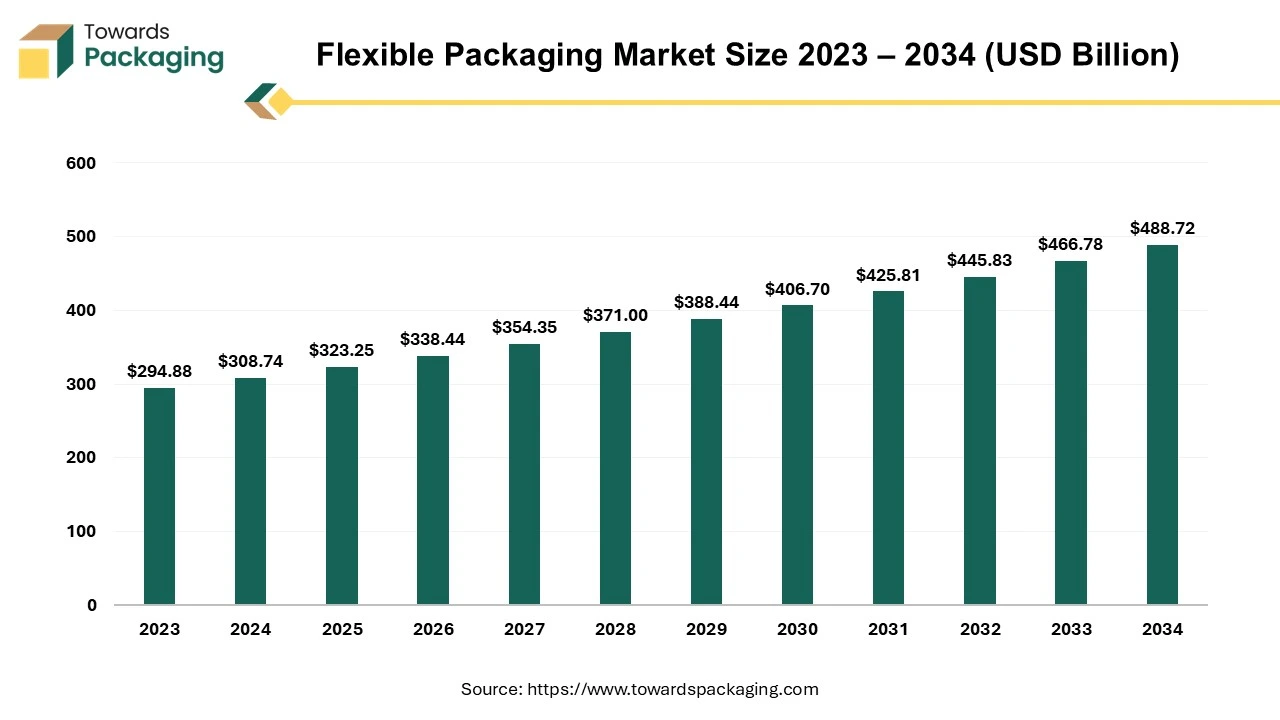

The flexible packaging market is expected to increase from USD 323.25 billion in 2025 to USD 488.72 billion by 2034, growing at a CAGR of 4.7% throughout the forecast period from 2025 to 2034. The shift in consumer behavior toward convenience, coupled with regulatory pressure for eco-friendly solutions, has accelerated market adoption across industries.

The packaging type in which packaging materials is used which can easily change shape, typically manufactured from paper, plastic, foil, or a combination of these. Unlike rigid packaging such metal cans or glass jars, bottles, flexible packaging is lightweight, durable adaptable to various product types. The common types of flexible packaging are bags, pouches, sachets, and wraps & films. The flexible packaging is lightweight, cost effective, has extended shelf-life, sustainable option and convenience features. The flexible packaging is extensively utilized for personal care, pharmaceuticals, industrial applications and food & beverages.

By Packaging Type

By Material Type

By Technology

By Application

By End-User Industry

By Region

February 2026

February 2026

February 2026

February 2026