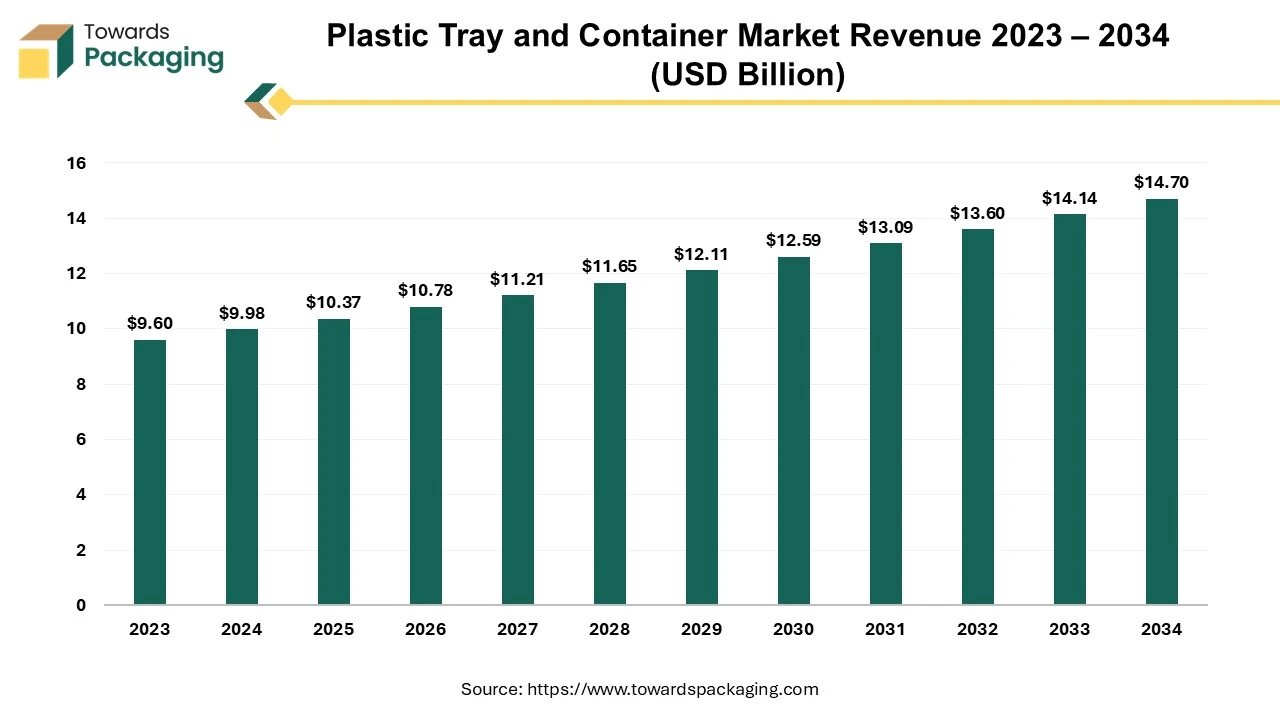

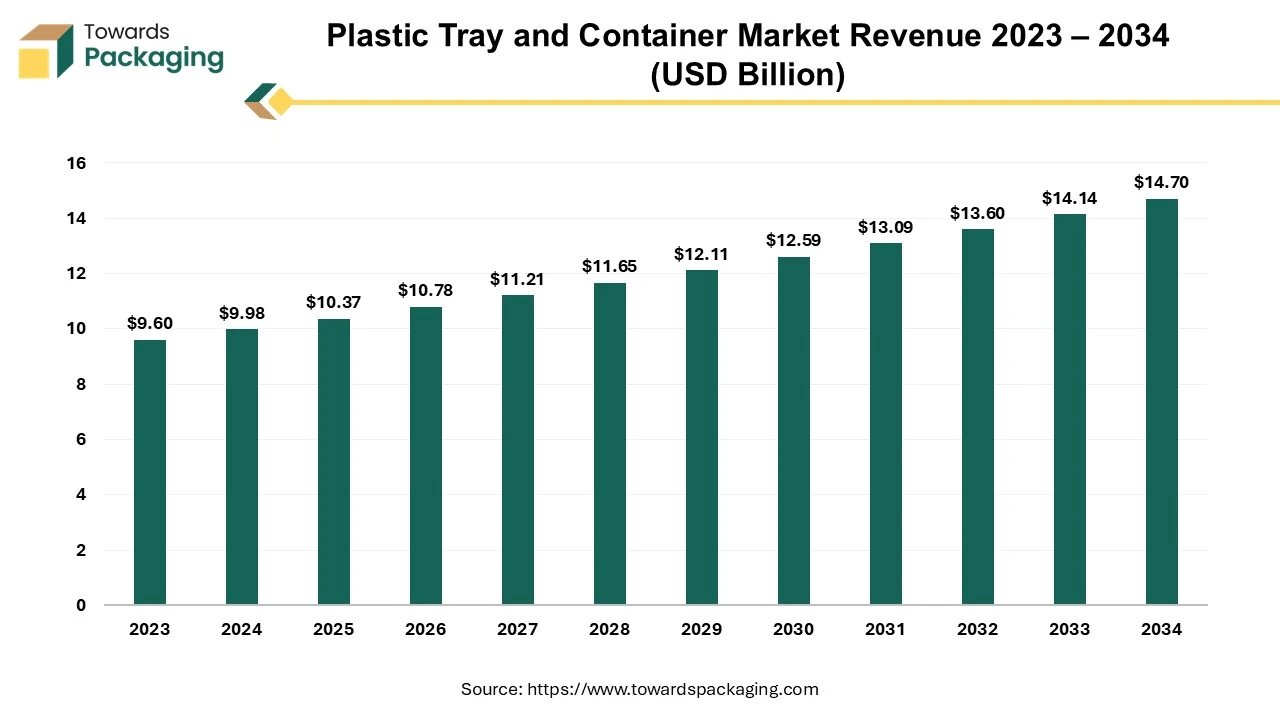

The plastic tray and container market is forecasted to expand from USD 10.78 billion in 2026 to USD 15.28 billion by 2035, growing at a CAGR of 3.95% from 2026 to 2035. This report provides an extensive analysis of market trends, including sustainability innovations, recyclable packaging, and the rise of smart and biodegradable plastics. It covers detailed segmental insights by type (PP, PE, PVC) and application (agriculture, food & beverage, pharmaceuticals, industrial). The study evaluates regional dynamics across North America, Europe, Asia Pacific, Latin America, and MEA, supported by company profiles, value chain mapping, and global trade statistics.

The market is proliferating due to the increasing business retail market of food& beverage, healthcare services, horticulture, e-commerce, personal care & cosmetics, hotels & cafes, catering, offices, bakeries, and many others which require plastic trays and containers for storage, packaging and delivery purposes. The growing trend of online ordering facilities is boosting the plastic tray and container market.

The plastic tray and container market is in high demand as numerous market players prefer this due to its affordability. These trays and containers are useful in several ways as they are sturdy, moisture-resistant, and lightweight, making them perfect for storing and transporting various products. The need for plastic packing is rising due to its accessibility, artistic visuals, and advanced environment-friendly choices. The plastic tray and container market is observing noteworthy development, determined by the accessibility of advanced, inexpensive, and sustainable packaging results.

These can be modified easily according to the purpose of different industries and also to encourage brands. Plastic trays and containers provide excellent quality protection against oxygen and water vapour to the food items and beverages packed. As businesses are continuously prioritizing sustainable and recyclable products this plastic tray and container market is anticipated to grow in upcoming times with an effort on recycling materials and ecological packaging solutions. The global packaging industry size is growing at a 3.16% CAGR.

Recyclable plastic trays and containers are in high demand in the market as these are useful for numerous purposes. With the rapid growth of the consumer goods, food & beverage industry, cosmetic industry, and many others have started shifting toward better packaging possibilities that are recyclable, lightweight, safe and sustainable for transporting purposes. Plastic tray and container packaging is well-known for its sturdiness and, confirms that foods are tightly packed and endangered.

Whether it is about the hustle while transporting goods or the push while shopping with carts, plastic containers are suitable in all cases. Furthermore, it is lightweight which makes it preferable for several uses. Apart from food & beverages, in the personal care and cosmetics industry, polypropylene is extensively used for manufacturing jars and bottles for packaging powders, creams, and various other cosmetic products. The durability and compact size of such containers protect products from light, dust, air, moisture, and dirt, confirming the integrity of the packaging.

The rise of the circular economy is one of the most significant trends shaping the plastic industry. When organizations adopt a circular economy strategy, they invest in reducing the environmental impact of plastics and shift towards a more resource-efficient, sustainable model. Central to this is the focus on reducing waste while promoting the reuse and recycling of plastics. Companies are designing products with recycling in mind, using materials that can be easily processed by biodegrading and recycling systems.

Masterbatch manufacturers are now producing a range of smart plastics, offering enhanced features such as protection against rodents, insects, and fire, as well as food preservation. These innovations include insect-repellent plastics for water irrigation systems and rodent-deterring materials, showcasing the advanced capabilities of modern plastics as "supermaterials."

Biodegradable plastics are becoming a key part of efforts to reduce the environmental impact of traditional plastic. Materials like polyethylene and polypropylene can be designed to biodegrade faster if released into the environment, leaving no microplastics behind. This can be achieved through the use of d2w masterbatch, which enables biodegradability at little or no additional cost.

The development of anti-microbial plastics, which can kill bacteria and viruses, has accelerated since COVID-19, driven by heightened concerns over hygiene, especially in healthcare settings. This innovation integrates anti-microbial or anti-viral substances directly into the plastic manufacturing process to enhance product safety and cleanliness.

Plastic products remain highly useful due to their versatility and favorable Life Cycle Assessment (LCA). Plastics are primarily made from by-products of oil refining, and as long as oil is needed for fuels, using these by-products makes sense. However, as regulations evolve, there is increasing pressure to minimize plastic waste and improve sustainability practices across the industry.

A major factor restraining the growth of the plastic tray and container market is environmental concerns and increasing regulatory pressure related to plastic waste. With growing awareness about the harmful environmental impact of single-use plastics, many countries and regions have introduced stricter regulations, such as plastic bans, extended producer responsibility (EPR) policies, and initiatives aimed at reducing plastic waste. These regulations push companies to look for sustainable alternatives, such as biodegradable or recyclable packaging, which may not yet offer the same cost-effectiveness or performance as plastic trays and containers.

Additionally, the increasing focus on circular economy models and the demand for recyclable or reusable materials further reduces the demand for traditional plastic packaging. This shift toward more eco-friendly solutions limits the growth potential of the market.

In the pharmaceutical sector, earlier glass containers were widely used for packaging purposes of medicines, drugs and vaccines. But now it has shifted towards plastic trays and containers as they are considered easier to use, lightweight, resistant to leakage, and cost-effective in comparison to glass packaging. The major chosen materials in the healthcare sector for trays and containers are polypropylene, polystyrene, polyethene, and polyvinyl chloride. Plastic-based trays and containers are chemically inactive and unaffected by corrosion this quality protects the medicines and drugs and increases their shelf-life.

Hence, the speedily rising pharmaceutical sector will boost the demand in the predicted period. The air management system is of supreme position in these situations, continuing the essential antiseptic and sterile situations as well as superior quality access and covering measures. Enhanced-quality plastic trays and containers are widely used by the pharmaceutical sector for drug and vaccine packaging. Polyethylene works as a good barrier against several germs that keep products contamination-free.

The decay of plastic material is slower in comparison to the quantity it is produced every year. The recycling procedure of plastic trays and containers is an extensive procedure that comprises melting, selling, resolving, and shipping. Moreover, chemicals used in making plastic are dangerous and can generate toxic waste.

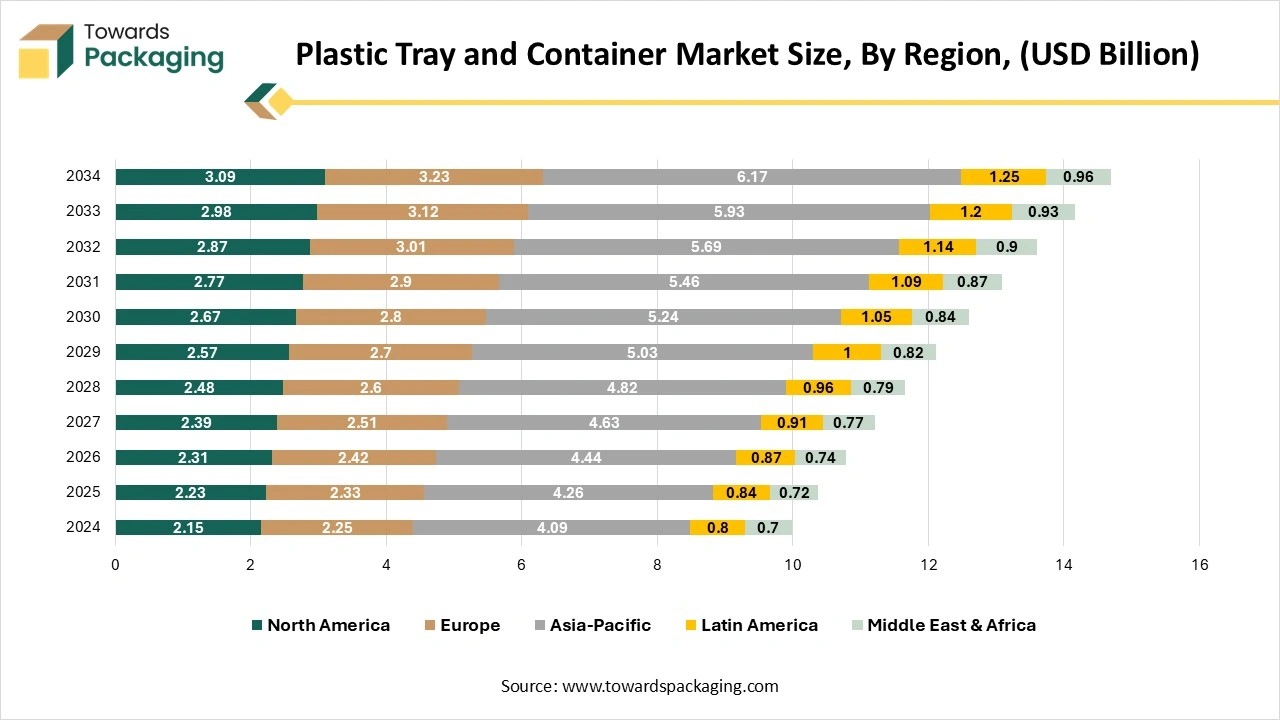

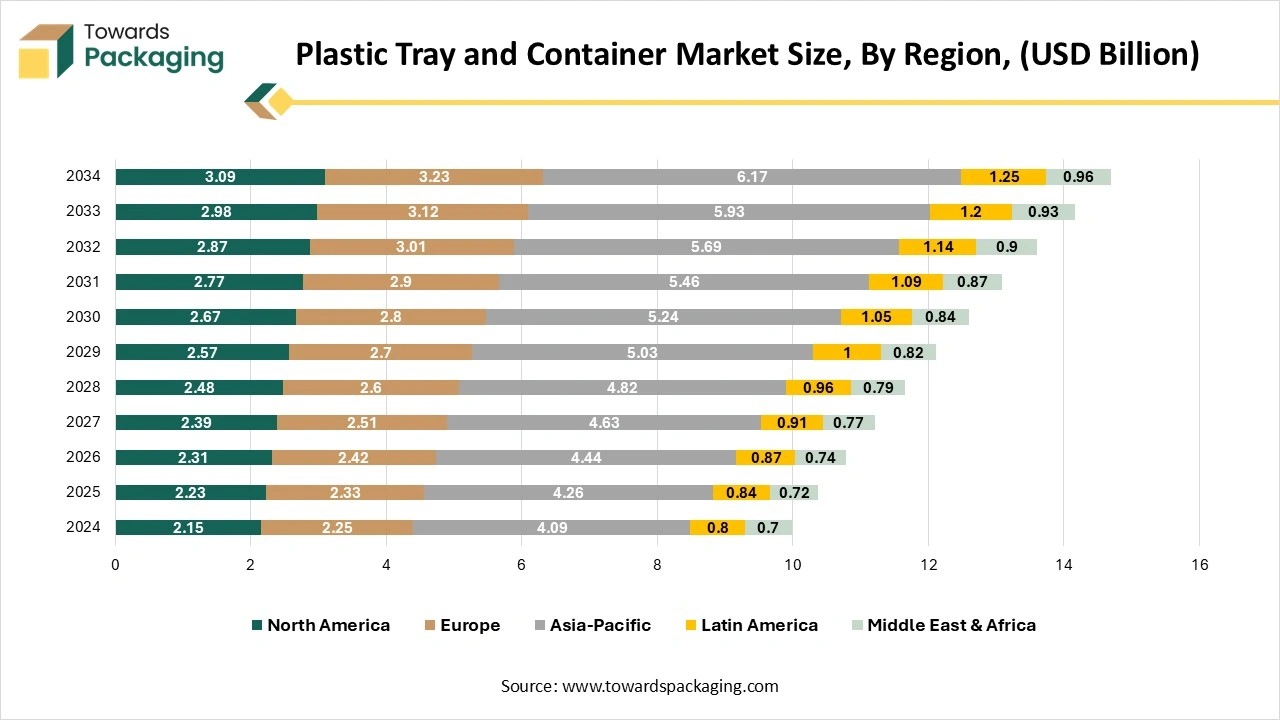

Asia Pacific witnessed the highest revenue share for the year 2024. This packaging material is in high demand in food & beverage packaging as it is non-toxic and keeps food safe while transporting. Its property of resistance to moisture, dust, dirt, and any external factors makes it the most preferable packaging solution for the food industry. Rising food & beverage firms have a direct influence on the plastic tray and container market.

The wide expansion of e-commerce mobile applications has provided ease to consumers for ordering online food products which enhances this market. Developing countries such as India, China, Japan, South Korea, and Thailand are progressively working toward innovative facilities for online orders of food and also sustainable measures for plastic products.

North America is estimated to grow at the fastest rate over the forecast period. The growing demand for online order systems in the e-commerce business comprises several factors such as rising inhabitants, economic situations, start-up culture, expansion, and many others. The demand for such plastic trays and containers for packaging purposes is growing in this region as these are cost-effective choices as well as provide progressive security to any type of delicate substances which makes them perfect for shipping.

With the progress of the e-commerce sector, there has been a massive upsurge in the capacity of products that are essential to be delivered, which has resulted in a continuous expansion in the demand for the packaging of materials. This has formed various new openings for the plastic tray and container market, with several market players emerging with new packaging initiatives that are only designed for e-commerce product shipment.

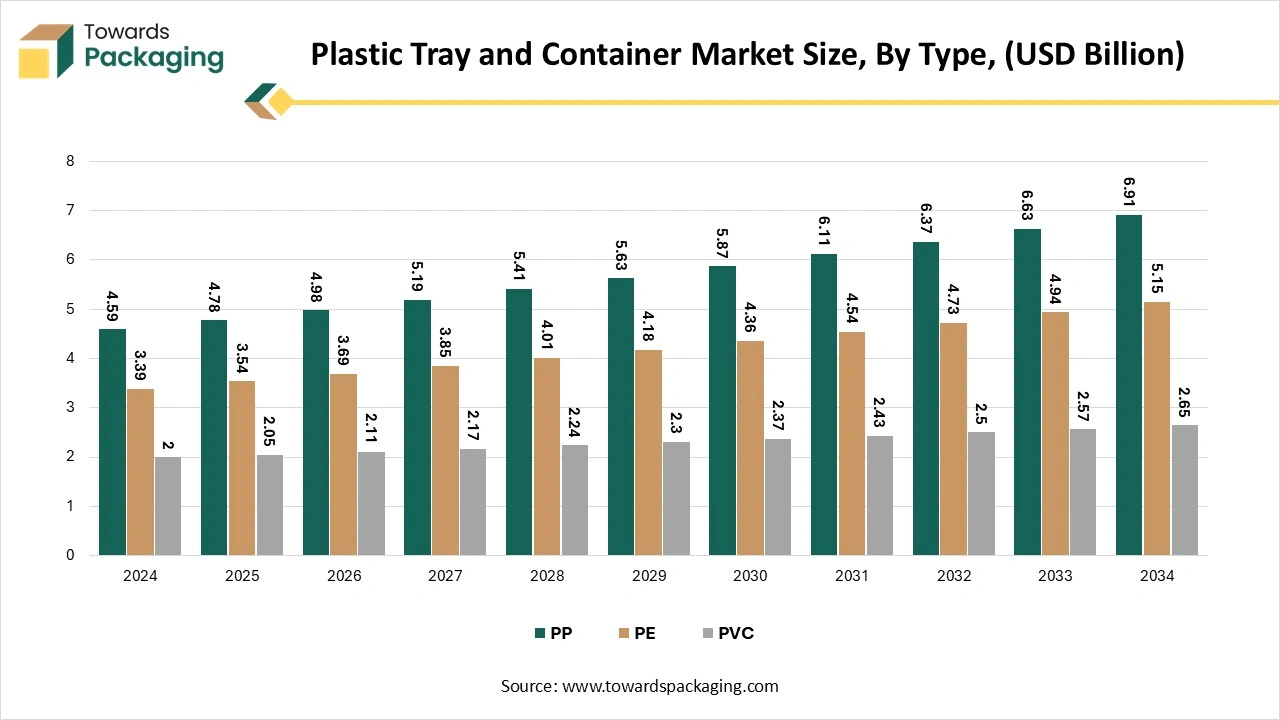

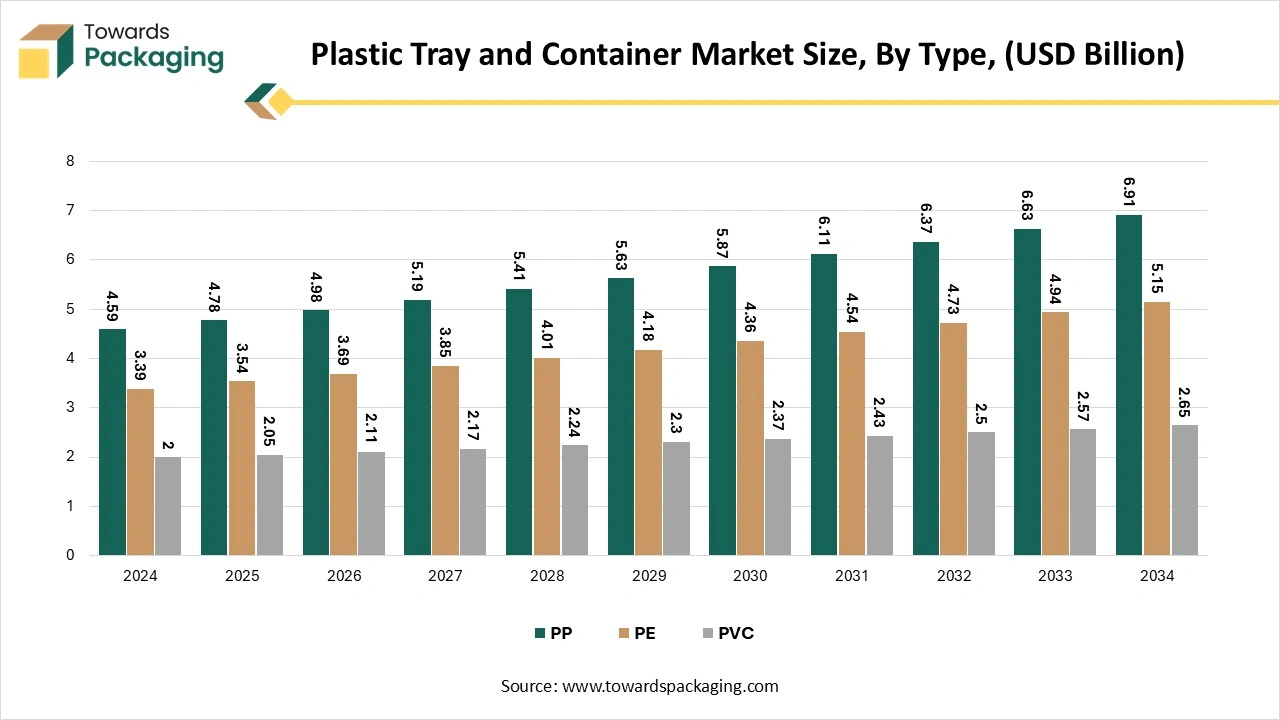

By type, the PP segment led the plastic tray and container market in 2024. These polypropylene trays and containers are in demand widely due to their versatile, durable and lightweight nature. These are widely used in all sectors such as pharmaceuticals, consumer goods and food & beverages as these are suitable for maintaining both high and low temperatures. Innovation in packaging techniques has improved the performance of PP products. The growing trend of ready-to-eat food has also driven this market as it requires air-tight packaging solutions.

By application, the agriculture packaging trays and containers segment led the plastic tray and container market in 2024. These products are majorly used in seedling propagation, plant delivery, and packaging agriculture products. Biodegradable plastic trays and containers are highly preferred in this sector due to sustainable practices in the agriculture field. The growing influence of greenhouse farming and vertical agriculture enhances the demand for special trays and container patterns which are precisely manufactured for crops.

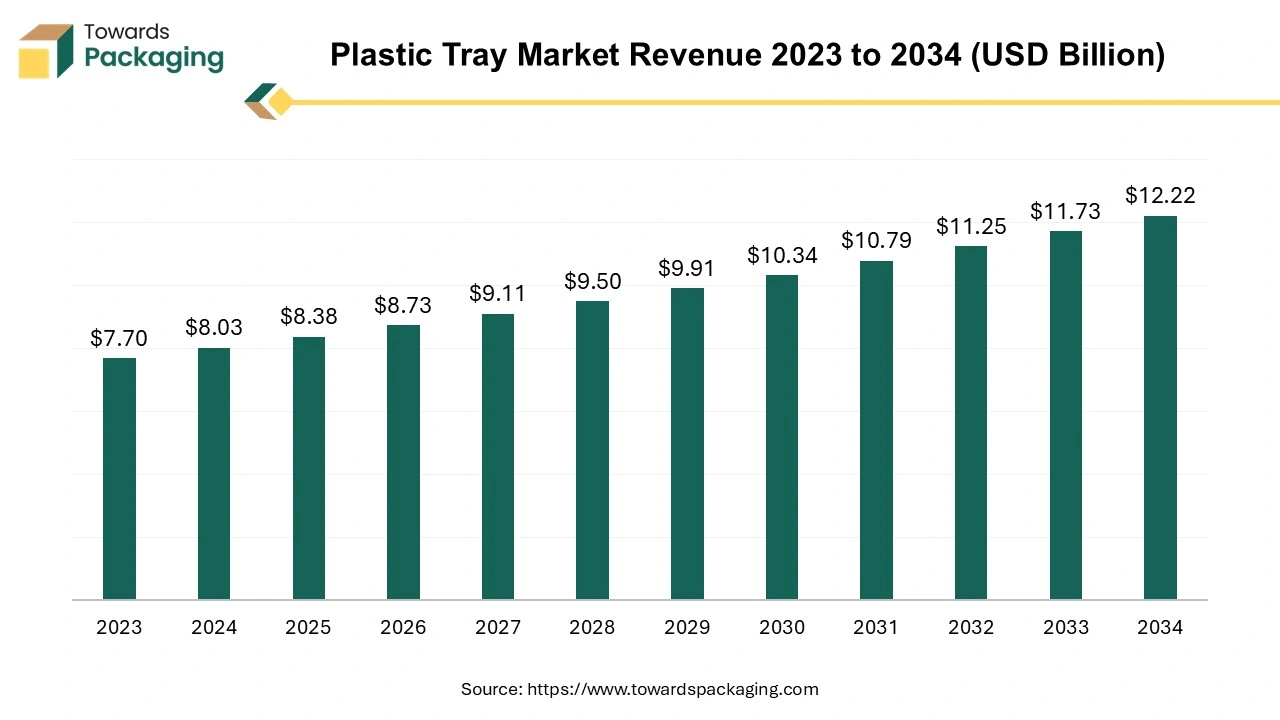

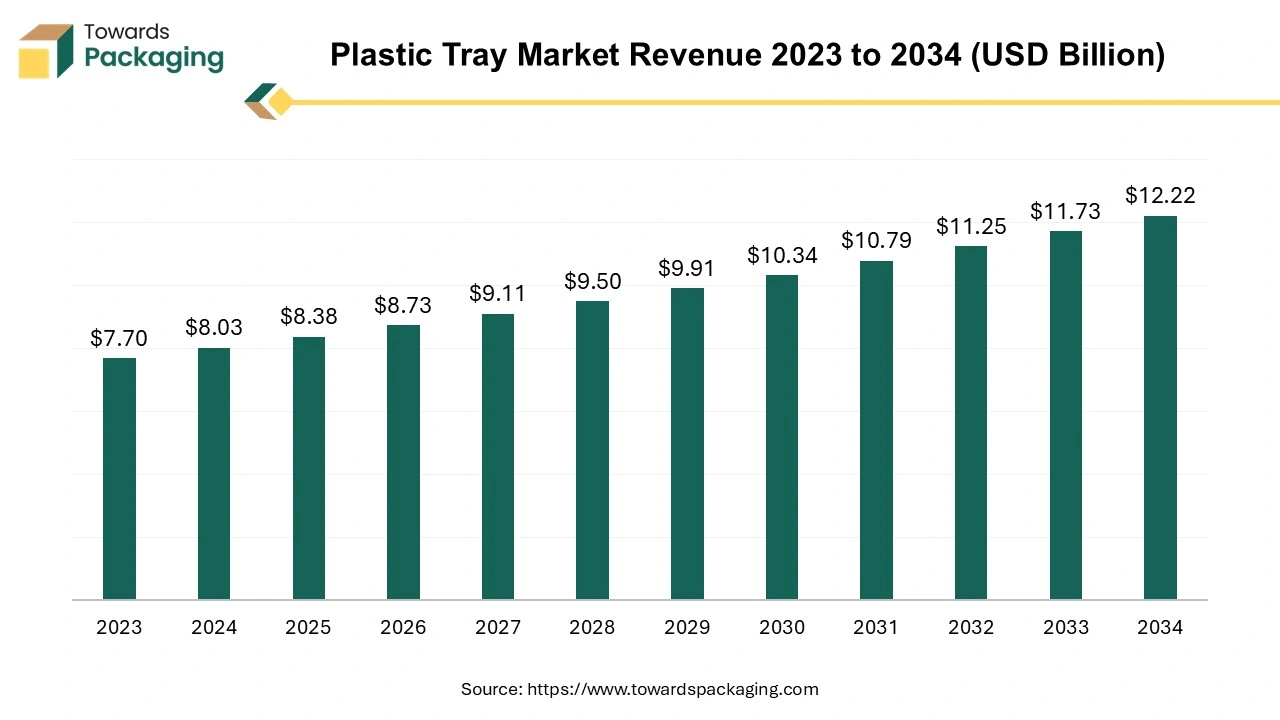

The plastic tray market is forecast to grow from USD 8.38 billion in 2025 to USD 12.22 billion by 2034, driven by a CAGR of 4.4% from 2025 to 2034.

The market is proliferating due to the increasing business retail market of personal care & cosmetics, horticulture, e-commerce, hotels & cafes, catering, bakeries, offices, healthcare services, and many others which require plastic bags for packaging for shipping and delivery purposes. The growing trend of online ordering facilities is boosting the plastic tray market.

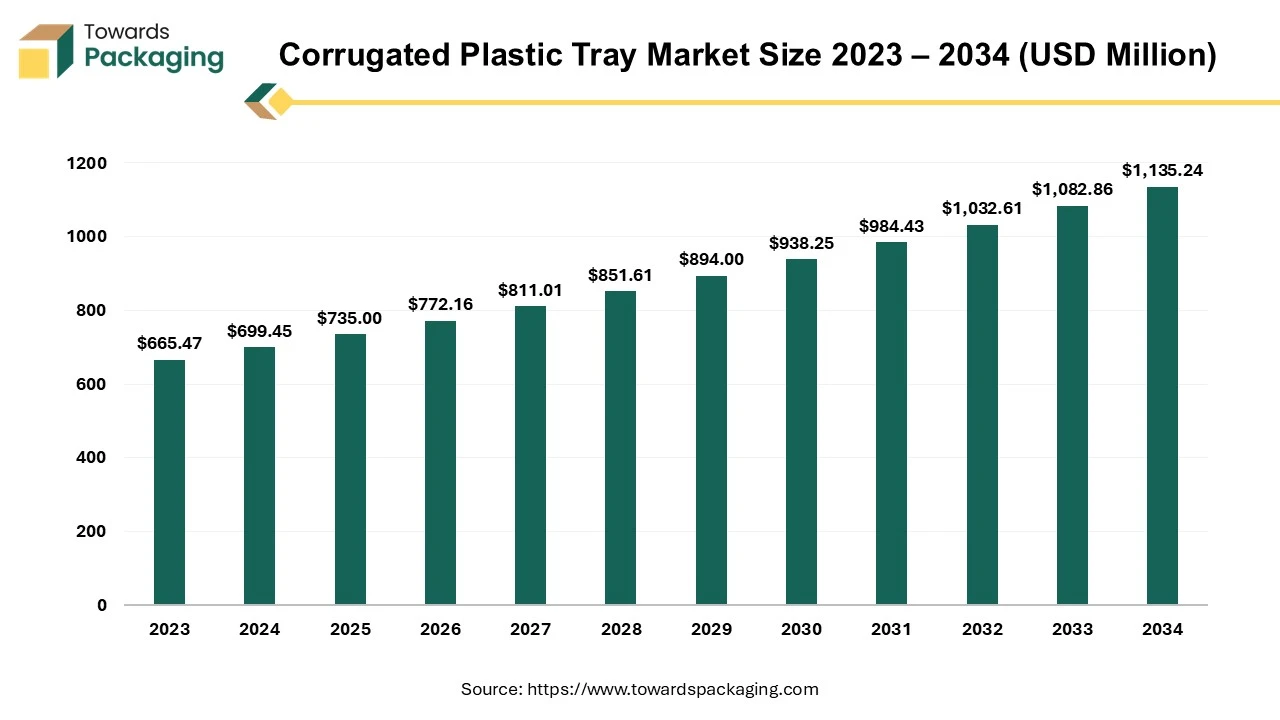

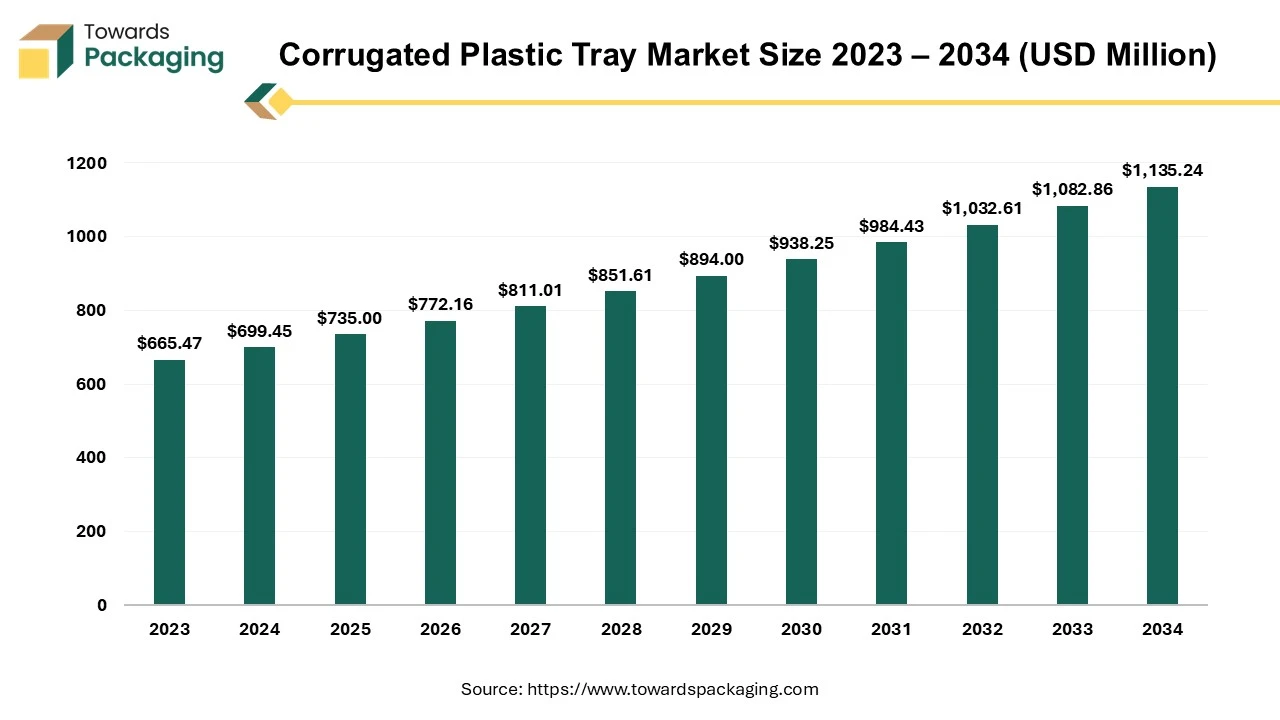

The corrugated plastic tray market is forecast to grow from USD 735.00 million in 2025 to USD 1135.24 million by 2034, driven by a CAGR of 5.14% from 2025 to 2034.

The corrugated plastic trays are manufactured out of light-weight tough material. Corrugated plastic trays are chemically inert and resistant to impacts and water. It is 100% recyclable and reusable. The corrugated plastic tray has ability to withstand cold environments and humidity. The use of corrugated plastic tray is easier to handle and offers low costs as transportation fair as it is light in weight. A corrugated plastic tray is a type of packaging product made from corrugated plastic material, typically polypropylene or polyethylene. It features a structure similar to cardboard but is made from plastic, which provides added durability, moisture resistance, and strength.

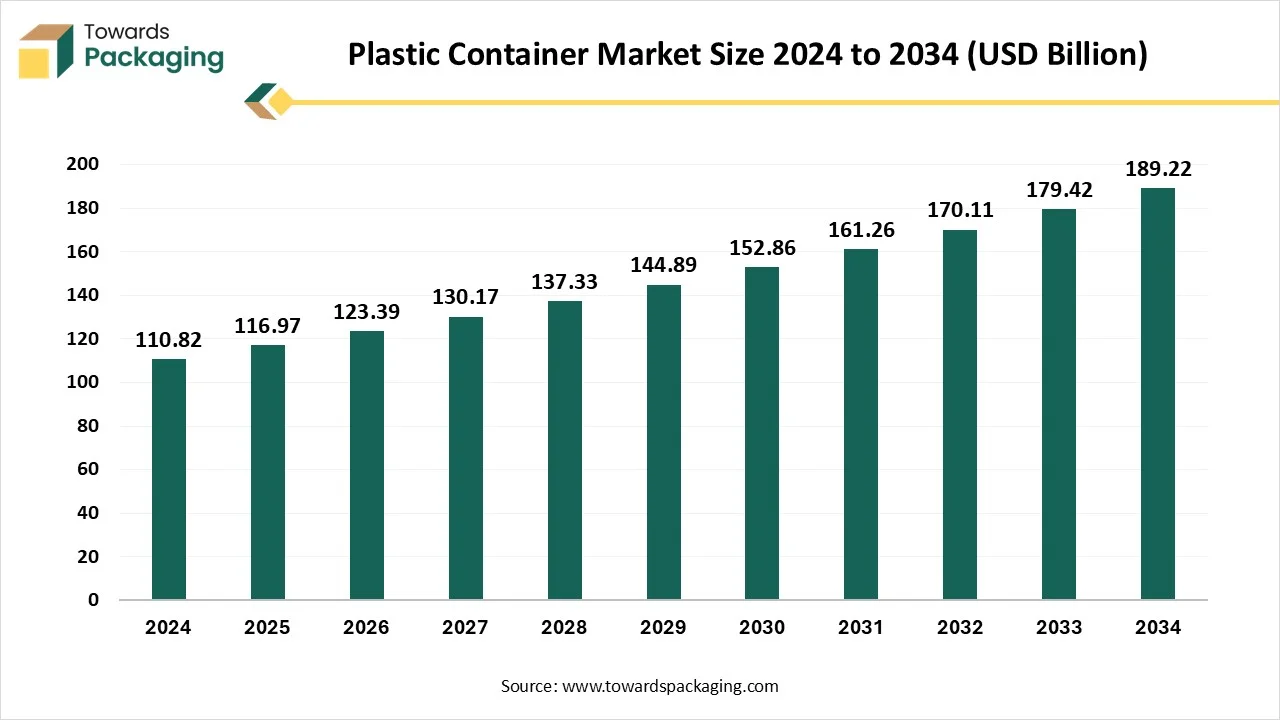

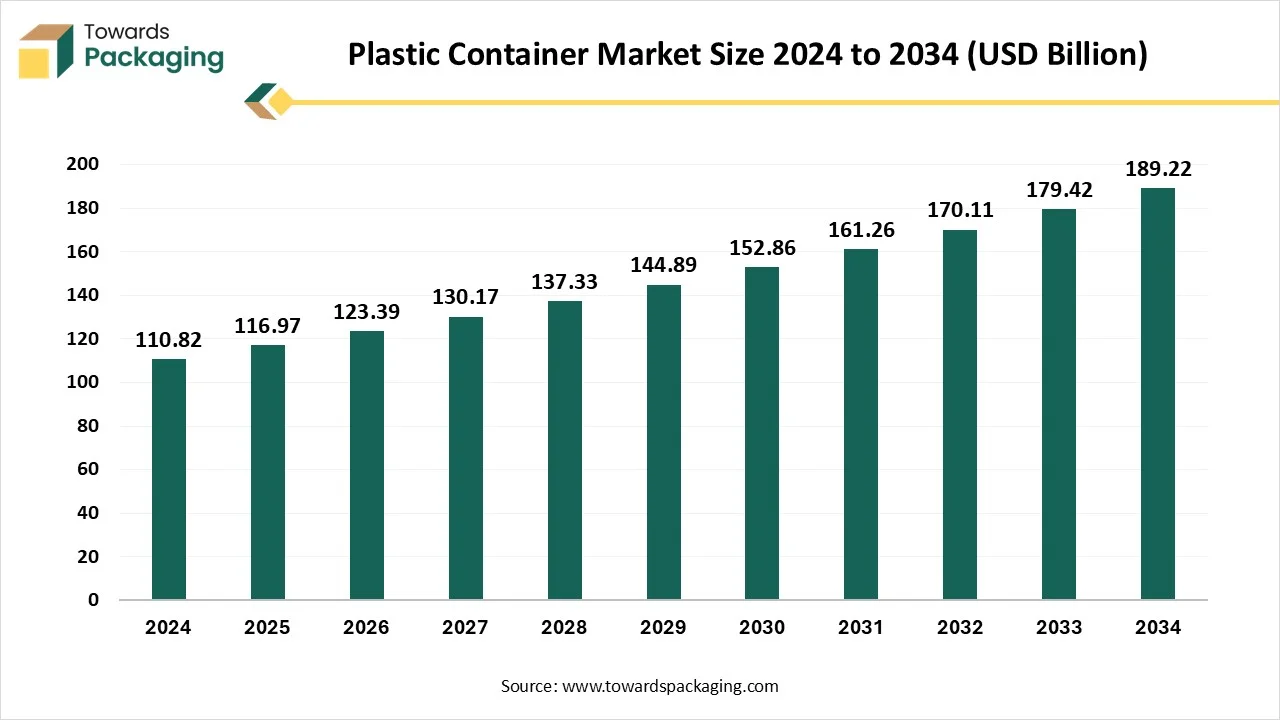

The plastic container market is expected to increase from USD 116.97 billion in 2025 to USD 189.22 billion by 2034, growing at a CAGR of 5.54% throughout the forecast period from 2025 to 2034. Due to their power and reliability, plastic containers can be utilized to transport different types of food products, cargo to chemical reagents, and industrial parts too.

Plastic containers are storage units that are created by using different types of polymers that come from crude oil or natural gas. These kinds of polymers are made from a range of complicated chemical procedures that transform raw petroleum into thermoplastics. Such materials are particularly engineered to be shaped, molded, and created into rigid, long-lasting transport, greatly durable, and storage boxes. Due to their growth during the Industrial Revolution, plastic containers have become essential components for industrial uses and logistics operations.

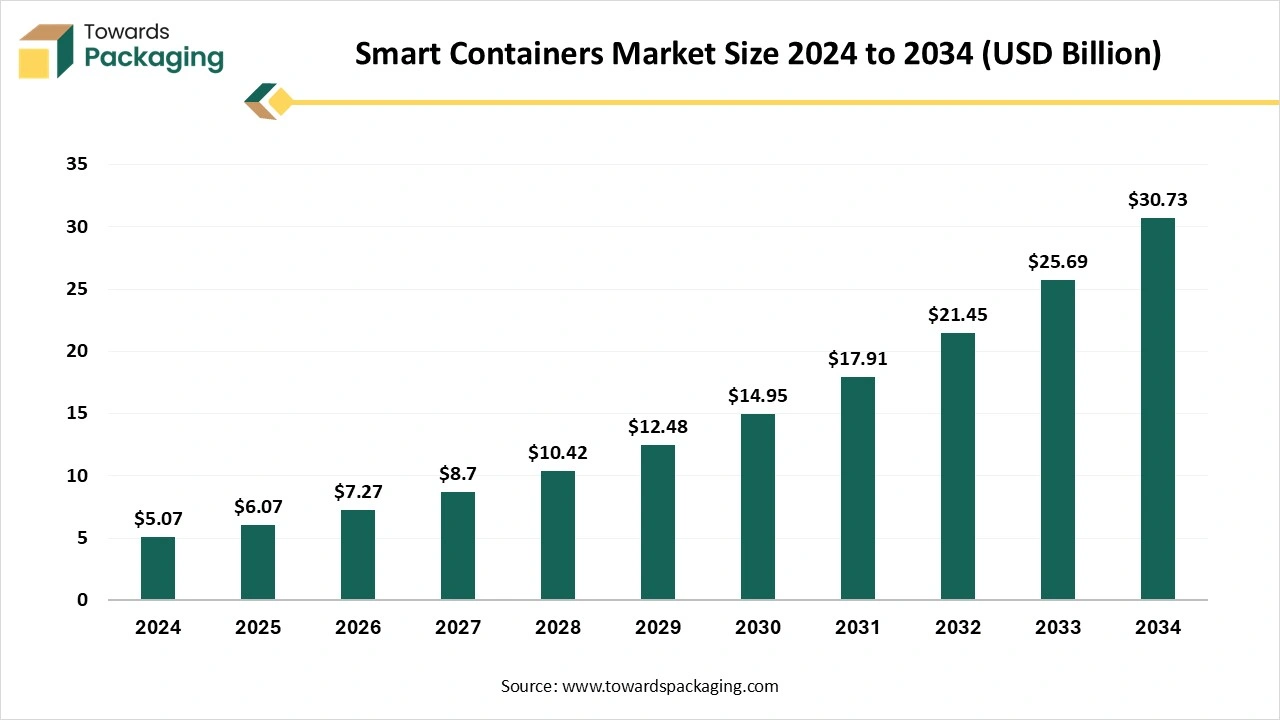

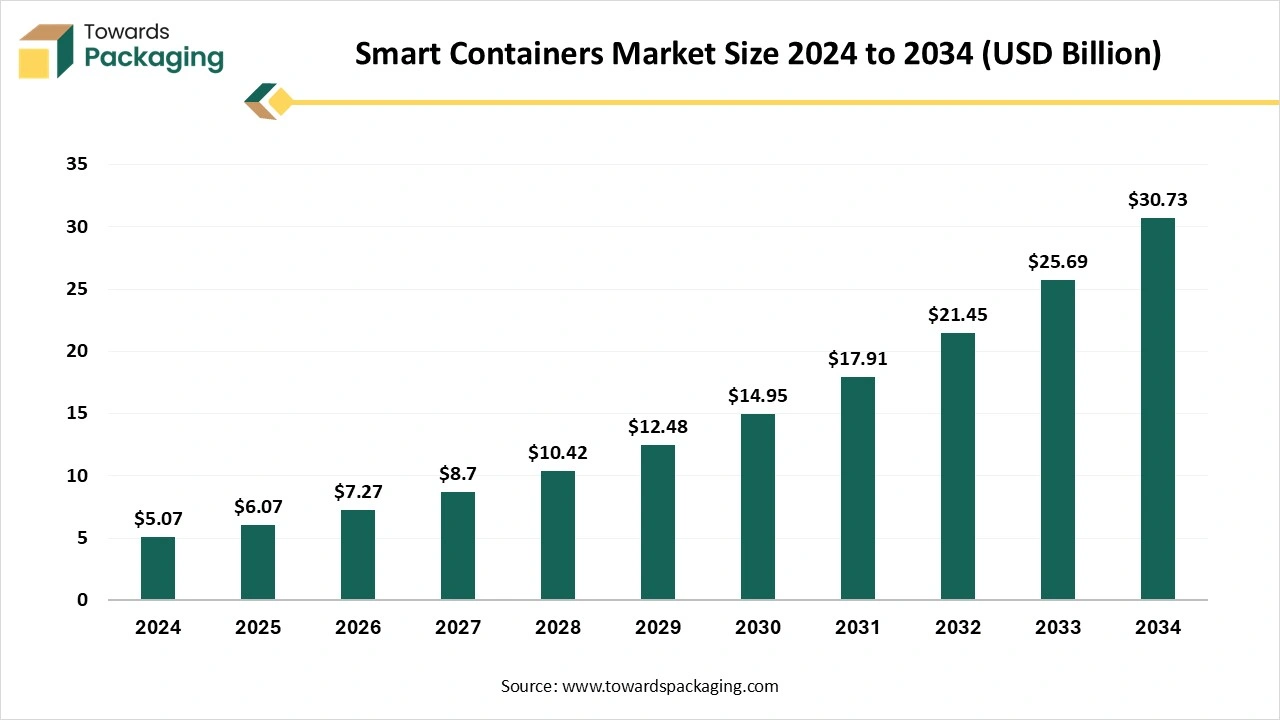

The smart containers market is projected to reach USD 30.73 billion by 2034, expanding from USD 6.07 billion in 2025, at an annual growth rate of 19.63% during the forecast period from 2025 to 2034. The growing e-commerce industry has raised the demand for safe transportation of products with advanced technology, such as tracking systems, product quality updates, and various other facilities enhanced the demand for the market.

Smart containers are shipping containers with advanced technologies such as communication devices, sensors, and various other facilities. These are useful in providing real-time information such as temperature, location, humidity, condition of the cargos, and various other aspects. These containers data bring security and efficiency to intermodal transportation. These are of three types: dry storage containers, open side containers, and half-height containers. Growing awareness about cargo security and the necessity to comply with worldwide certification values are influencing the acceptance of progressive container technologies. Businesses are capitalizing on smart resolutions to safeguard their shipments and meet strict security guidelines and quality standards. The importance of supervisory obedience and improved safety events is enhancing the demand for cultured tracking and monitoring systems.

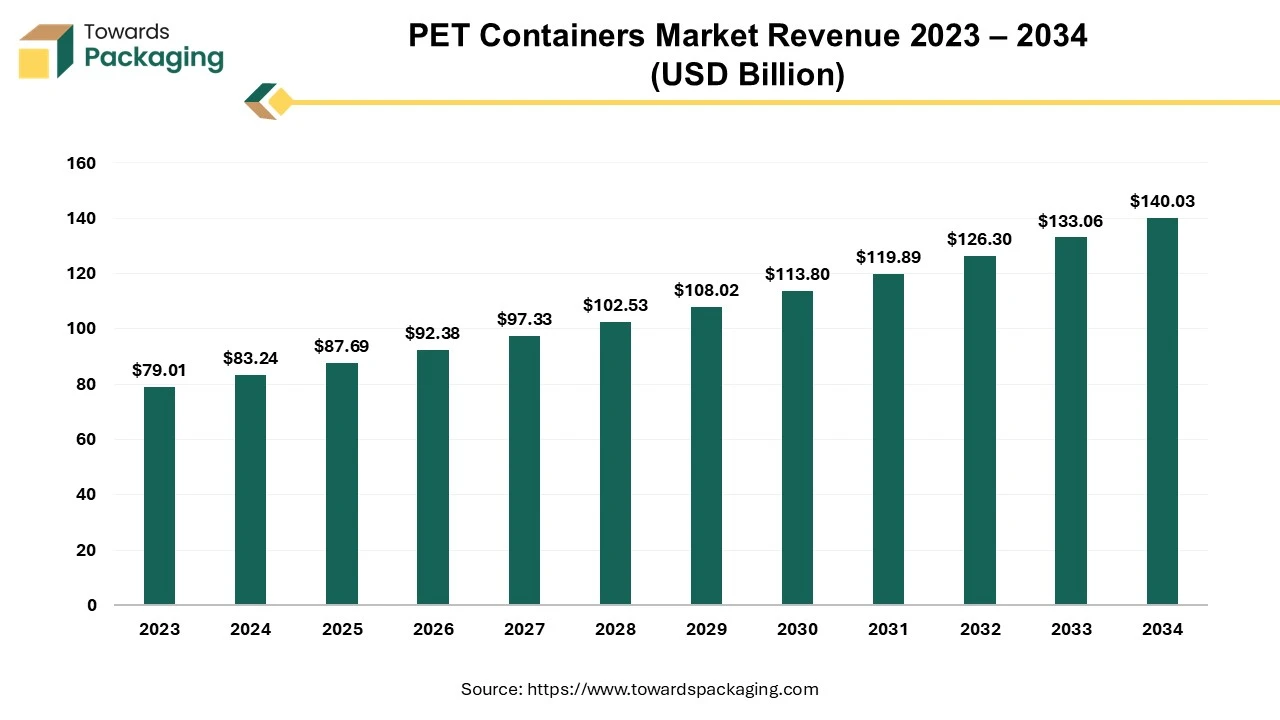

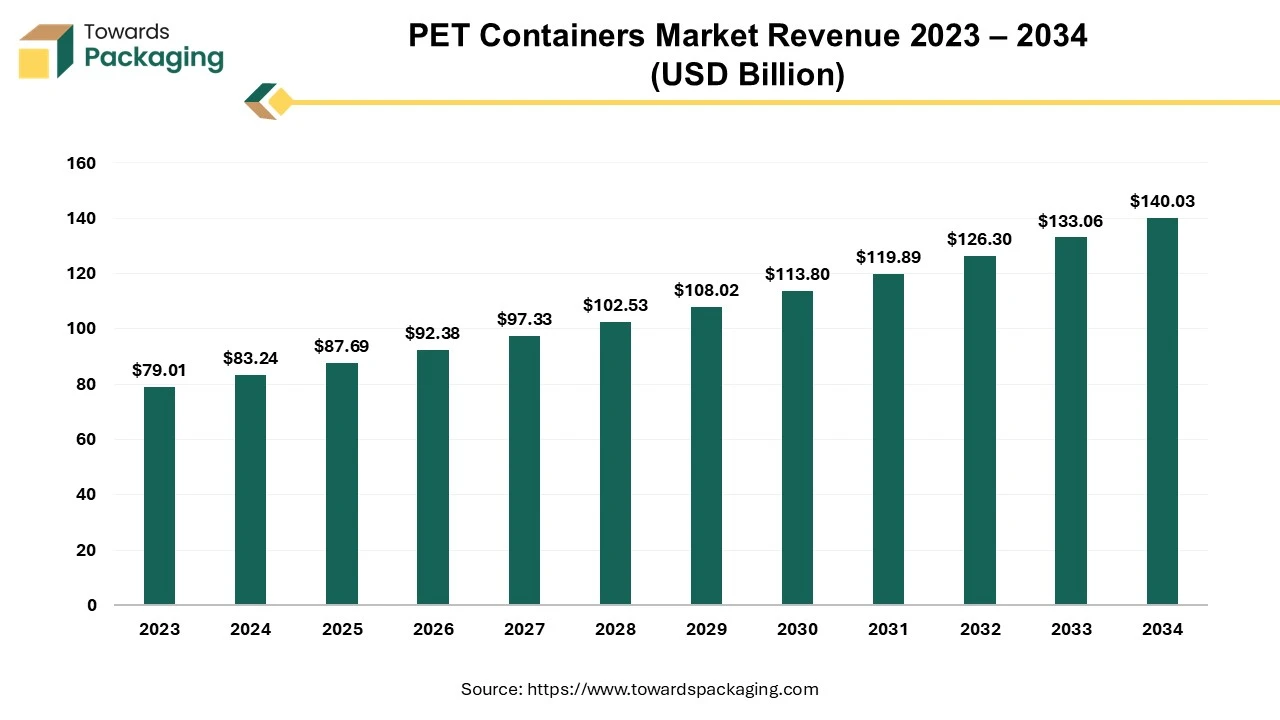

The PET containers market is forecast to grow from USD 87.69 billion in 2025 to USD 140.03 billion by 2034, driven by a CAGR of 5.35% from 2025 to 2034.

The key players operating in the market are focused on adopting inorganic growth strategies like acquisition and merger to develop advance technology for manufacturing PET containers which is estimated to drive the global PET containers market over the forecast period.

Terephthalic acid and ethylene glycol are combined via poly-condensation to create the white yet blue resin known as polyethylene terephthalate (PET), a linear thermoplastic long-chain polymer composed of repeating units. Plastic PET is a crucial raw ingredient for synthetic textiles. PET is a type of polyester used for blow-molded bottles and jars, fiber, and injection-molded components. Specific grades with the necessary characteristics for the various applications are provided. Polyethylene Terephthalate (PET) is utilized in the production of synthetic fibers, food and beverage containers, and other thermoforming applications. It may exist as an amorphous (transparent) or semi-crystalline (opaque and white) material, depending on its processing and thermal history.

By Type

By Application

By Region

February 2026

February 2026

February 2026

January 2026