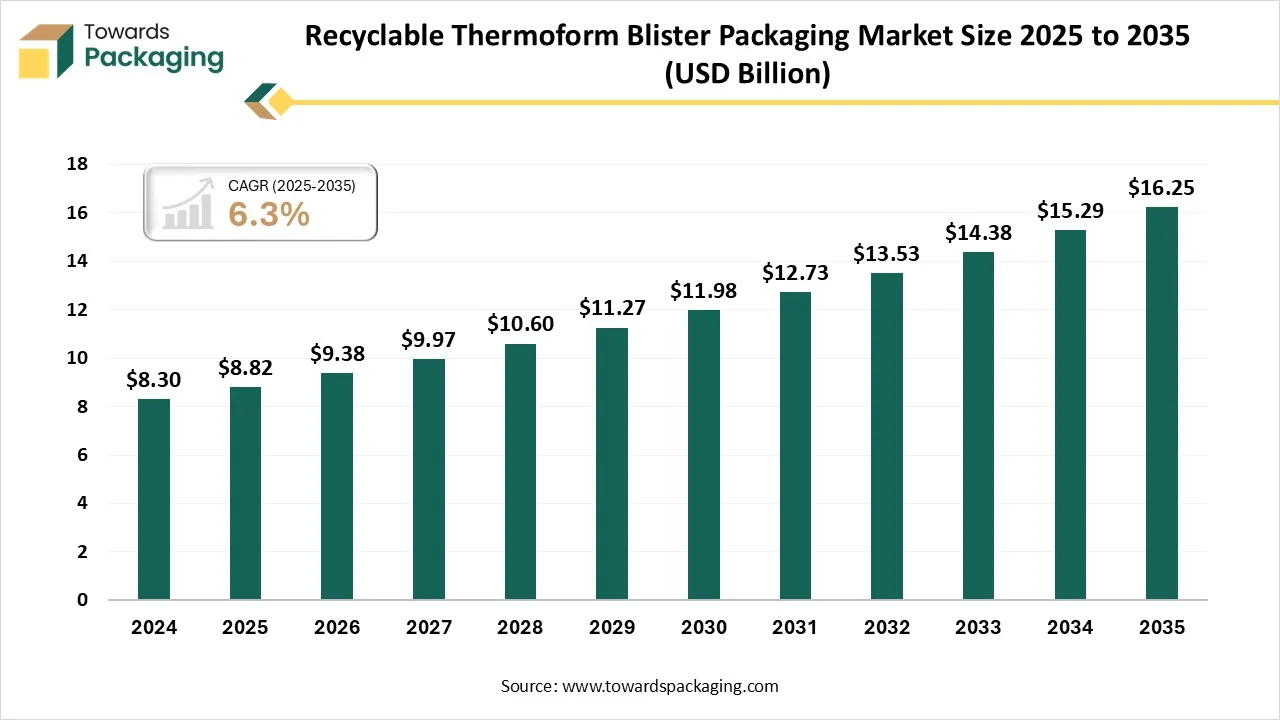

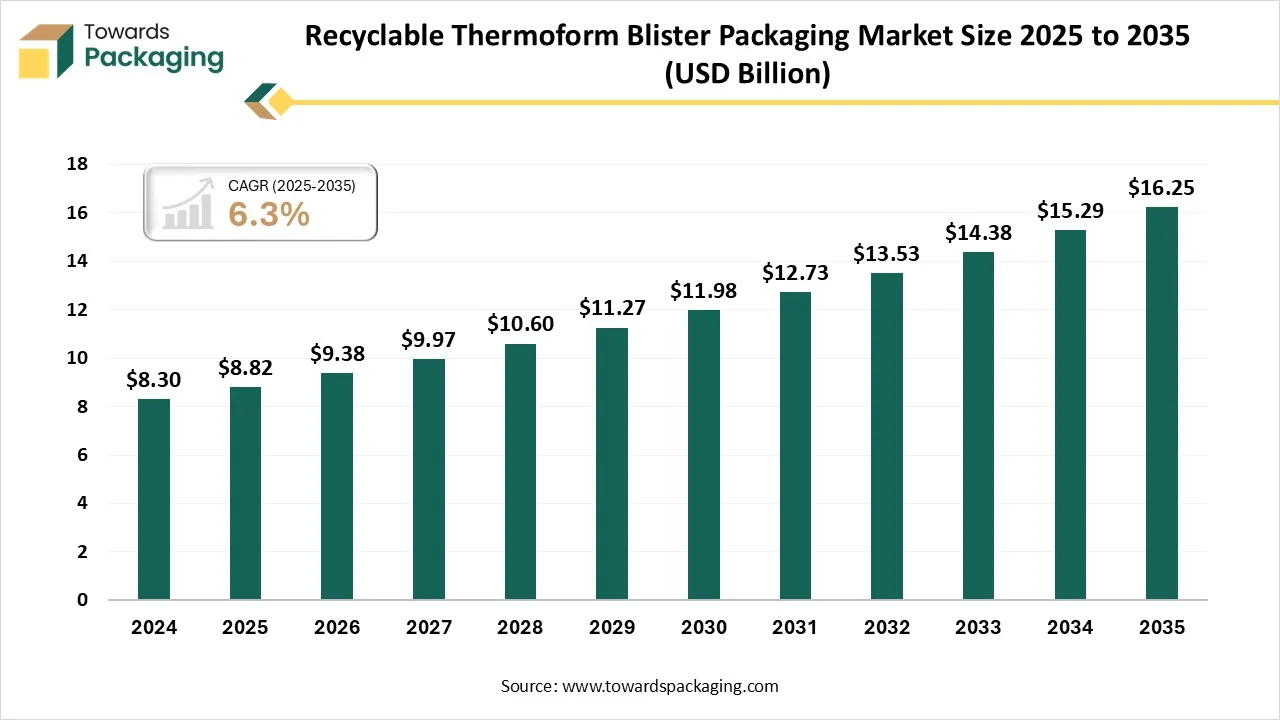

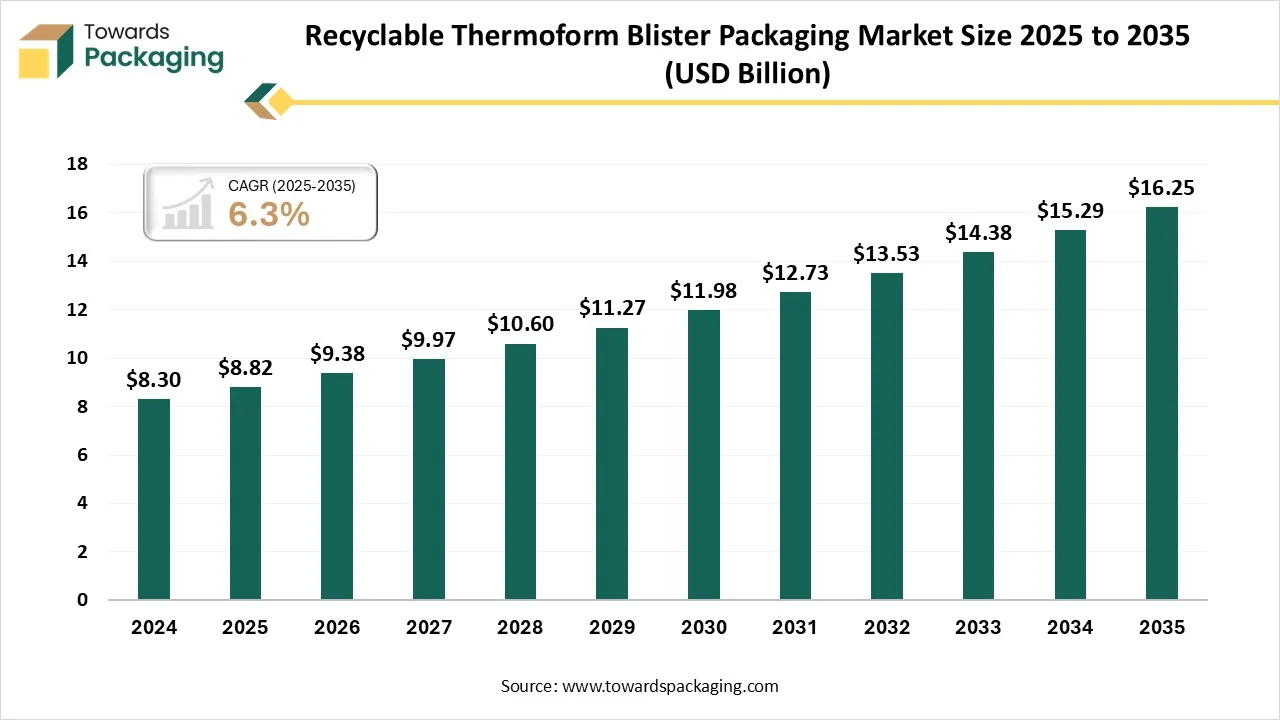

The recyclable thermoform blister packaging market is forecasted to expand from USD 9.38 billion in 2026 to USD 16.25 billion by 2035, growing at a CAGR of 6.3% from 2026 to 2035. The rising demand for sustainable, clear, and protective packaging has evolved the demand for the market. The huge demand for defensive, tamper-resistance packaging for medicines, influencing invention in smart blisters.

- In terms of revenue, the market is valued at USD 9.38 billion in 2026.

- The market is projected to reach USD 16.25 billion by 2035.

- Rapid growth at a CAGR of 6.3% will be observed in the period between 2026 and 2035.

- By region, Asia Pacific dominated the global market by holding highest market share in 2025.

- By region, North America is expected to grow at a fastest CAGR from 2026 to 2035.

- By material type, the recyclable PET (polyethylene terephthalate) segment contributed the biggest market share in 2025.

- By material type, the recyclable rPET (recycled PET) segment will be expanding at a fastest CAGR in between 2026 and 2035.

- By product form /type, the clamshell blister trays segment contributed the biggest market share in 2025.

- By product form /type, the custom complex blister forms segment will be expanding at a fastest CAGR in between 2026 and 2035.

- By end-use industry, the pharmaceuticals & healthcare segment contributed the biggest market share in 2025.

- By end-use industry, the electronics & consumer goods segment will be expanding at a fastest CAGR in between 2026 and 2035.

Recyclable thermoform blister packaging includes heat to mould visible plastic such as PET and PP into hollows for goods, then locks them to a support, but unlike old-style multi-substantial packs, these are planned for a circular economy utilizing mono-materials or simply separable elements, permitting the plastic blister to be recycled and frequently with bottles or many other plastics, decreasing waste and ecological impact.

- Market Growth Overview: The market is experiencing recyclable packaging, innovation in material, senior-friendly designs, and increasing concern among consumers towards protection of products.

- Major Market Players: The market comprises Pactiv Evergreen, Placon, Tekni-Plex, WestRock, Sealed Air, Sonoco Products Company, and many other.

- Startup Ecosystem: The startup industries are focusing on automation and AI, enhanced traceability, developing recycled PET materials, and advancement in packaging process.

Technological transformation in the recyclable thermoform blister packaging market plays a significant role in its expansion. Increasing shift towards mono-materials such as mono-polypropylene and polyethylene terephthalate. It is permitting these packs to be handled in present plastic recycling brooks. Inventions are emphasized on enhancing the protective possessions of these advanced sustainable resources to match or surpass outdated packing performance. AI tools analyse equipment presentation in real-time to antedate machinery subjects, decreasing downtime and enhancing production dependability.

- Vietnam: It is the top-most exporter of Blister Packaging worldwide with 31,225 shipments.

- China: It is in the second position as an exporter of the Blister Packaging globally with 7,917 shipments.

- Germany: It is the third leading exporter of the Blister Packaging worldwide with approximately 189 shipments.

Raw Material Sourcing

The major raw materials utilized in this market are polyethylene terephthalate, recycled PET, polypropylene, and cyclic Olefin Copolymers. High recyclability, excellent clarity, and impact resistance are often utilized for customers with goods and food.

- Key Players: Klöckner Pentaplast (KP), Huhtamaki

Component Manufacturing

The component manufacturing in this market comprises recyclable materials, lidding materials, and heat-seal coating and inks. The well-suited lidding resource is temper-sealed to the establishing film to generate an airtight seal.

- Key Players: Billerud, DS Smith

Logistics and Distribution

This segment comprises manufacturing and assembling, packaging and transport, and visibility & compliance. It requires a dedicated reverse logistics system and customer collection programs to attain circularity.

- Key Players: Nefab, AmSky

Segmental Insights

Material Type Insights

Why Recyclable PET (PolyethyleneTerephthalate) Segment Dominated the Recyclable Thermoform Blister Packaging Market In 2025?

The recyclable PET (polyethylene terephthalate) segment dominated the market with highest share in 2025 due to establishment of circular economy and high recyclability. It provides excellent barrier properties, transparency, durability, and lightweight. It provides an exclusive mixture of excellent functional properties such as durability and clarity and also recognized scalable recycling substructure. It offers excellent physical and chemical properties important for packaging, particularly for food & beverages.

The recyclable rPET (recycled PET) segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to increasing ecological concern and strict regulatory guidelines. It offers sustainability, regulatory mandates, and efficiency in technological process. Its sturdiness confirms goods endure transit, while its sustainability brings into line with the rising customer values.

Why Clamshell Blister Trays Segment Dominated the Recyclable Thermoform Blister Packaging Market In 2025?

The clamshell blister trays segment dominated the market with highest share in 2025 due to its versatility, superior protection, and durability. The transparent property of clamshells represents goods efficiency, important for e-commerce and retail sector, influencing customer appeal and decreasing packaging waste. It provides huge barriers against contaminants, moisture, and dust, encompassing shelf life and preserving goods quality, crucial for pharmaceuticals and fresh foods. These trays offer easy-to-spot interfering signs and help single-dose packaging, enhancing patient security and supply chain process.

The custom complex blister forms segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to its strict safety and regulatory requirements. Custom designs are important to fulfil exact regulatory values that cannot be fulfilled with common, off-the-shelf formats. This confirms product efficiency and extends shelf life. Custom intricate forms are exclusively situated to help these high-margin usages.

End-Use Industry Type Insights

Why Pharmaceuticals & Healthcare Segment Dominated the Recyclable Thermoform Blister Packaging Market In 2025?

The pharmaceuticals & healthcare segment dominated the market with highest share in 2025 due to rising demand for enhanced patient safety and compliance. High-end barriers against contaminations, moisture, and oxygen confirm medicine quality and enhance shelf life, which is important for sensitive medicines. Sealed blisters offer visible safety, fulfilling strict health guidelines and opposing fake medicines. A shift in the direction of blisters for solid dosages provides better individual safety and transportability.

The electronics & consumer goods segment is expected to grow at the fastest CAGR during the forecast period. This segment is growing due to sustainability push, market extension, protection of products, and cost-efficacy. Clear thermoformed blisters permit customers to observe the product, while offering sufficient space for instructions, branding, and graphics, improving appearance and trust. These packaging protect subtle electrical products from dust, shock, and moisture, important for high-value products at the time of transportation and on-shelf presentation. The rising focus on sustainability, generated a suitable storm for its acceptance.

Regional Insights

How Asia Pacific is Dominating in the Recyclable Thermoform Blister Packaging Market?

Asia Pacific held the largest share in the recyclable thermoform blister packaging market share in 2025, due to rising sustainability push. Growing ecological consciousness and government creativities endorse sustainable resources and recyclable patterns, this region is accepting rapidly. Thermoforming's capability to generate modified shapes inexpensively fulfils diverse goods requirements. Rising healthcare requirements, chronic diseases, and enhanced demand for exact dosing boost blister packets for medical devices and drugs.

Why Recyclable Thermoform Blister Packaging Market is Dominating in China?

Increasing sustainability and modernization enhanced the demand for recyclable thermoform blister packaging market in China. Blister packs provide a cost-efficient, defensive, and visually appealing option for various goods, from small electronical products to food items. Rapid online shopping and urbanization enhance the demand for packed food, electronics, and FMCGs, needing strong, transparent blister packets for visual appearance and shield. Its high drugs manufacturing, rising chronic diseases, and aging population fuel the demand for defensive, tamper-resistance blister packages.

Why Recyclable Thermoform Blister Packaging Market is Growing Rapidly in North America?

Advanced features and rising sustainability push have influenced the demand for the market. Continuous busy lifestyles boost the demand for ready-to-consume meals, frozen food products, and fresh produce trays, all utilizing thermoformed packaging for enhanced shelf life and prevention. The enhancement of tech sectors and online shopping needs customizable, lightweight, and protective, thermoformed packaging for devices and components. Incorporation of smart technology such as QR codes, and RFID within blister packages improves tracking and patient meeting, a noteworthy trend in healthcare packing.

How Recyclable Thermoform Blister Packaging Market is Expanding in the U.S.?

Increasing pharmaceutical and retail sector have driven the demand of the market in the U.S. Rising ingestion of ready-to-consume, portion-measured, and convenience food products directly fuels demand for the thermoformed containers and trays. The necessity for peg-hook-friendly, visible, and cost-operative packaging for personal care products, electronics, and batteries influence the market. Thermoforming provides pattern flexibility, lighter weight, and lesser charges comparison with injection moulding which is making it attractive.

Which Factor is Responsible for Notable Growth of Recyclable Thermoform Blister Packaging Market in Europe?

The primary factors influencing the growth of market are strong ecological guidelines and government initiatives. The industry is observing noteworthy invention in resources science and production processes to fulfilling sustainability aims while preserving functionality. Inventions in barricade technologies for these sustainable resources to confirm product prevention, particularly for sensitive goods such as pharmaceuticals. Growing customer demand for environment-friendly and sustainable packaging options.

Why Germany is Utilizing Recyclable Thermoform Blister Packaging Market Significantly?

Continuous material innovation has fuelled the development of the market. Durable, lightweight thermoforms guard products at the time of online shipping, fuelling their utilization beyond old-style retail. Thermoforms offer shelf-life enhancement, contamination defence, and attractive performance for suitable food products, filling high standards. This region is a major pharmacy hub, and blisters provides hygiene, tamper-resistance, anti-counterfeit structures, and exact dosing, important for drugs.

Why Adoption of Recyclable Thermoform Blister Packaging Market is Growing in Middle East & Africa?

Rising healthcare sector and have enhanced the adoption of market in Middle East & Africa. Increasing obesity, diabetes, and various other chronic diseases rising demand for operative single-dose, tamper-proof pharmacy packaging. Stringent guidelines on medicine safety favour blister packaging for pharmacy. Development in online medicines sales and self-drug fuels requirement for safe, suitable packaging. Rising ecological consciousness boosts for recyclable resources. Enhanced healthcare infrastructures fuel the demand for such packaging.

Why Recyclable Thermoform Blister Packaging Market is Growing Rapidly in Saudi Arabia?

Increasing consumer consciousness and is the major reason behind the growth of market in Saudi Arabia. The extension of primary industries imposes safe, reliable, and sustainable, packaging options. The healthcare industry needs sterile, traceable, and tamper-evident packing for drugs and medical equipment. The rising retail and e-commerce sectors need lightweight, durable, and defensive packaging for goods at the time of transportation. Investments are inspiring producers to accept sustainable resources and practices.

What Enhance the Adoption of Recyclable Thermoform Blister Packaging Market in South America?

Increasing sustainability and technological advancement has influenced the growth of the market in South America. Growth of paper-based networks and fiber-based blister forms by industries. Allows personalized, branding, and easy usage of traceability codes. Thermoforms endure a cost-effective option for several industries, in spite of sustainability changes. Enhanced requirement for exact, tamper-resistance, and hygienic packing for developing drug delivery processes.

Brazil Recyclable Thermoform Blister Packaging Market Trends

The recyclable thermoform blister packaging market in Brazil is part of the broader blister and thermoform packaging sector, which is expanding steadily due to strong demand from industries such as pharmaceuticals, healthcare, consumer goods, and electronics, and is increasingly shaped by sustainability trends. Brazil is one of the largest blister packaging markets in South America, holding a significant share of regional demand and benefitting from growth in domestic pharmaceutical production and retail distribution networks.

Recent Developments

- In April 2023, SUDPACK announced the launch of recyclable, mono-polypropylene blisters packaging options. It has developed for packaging in life science industries, pharmaceutical, and medical goods.

- In August 2025, Amcor announced the expansion of healthcare packaging in Asia. It provides superior-quality and sterile medical packaging. It is considered as a first plant in Asia to influence air-knife technology.

- Amcor Plc: It is the leading producer, especially with recyclable Polyethylene (PE) thermoform blister packaging (AmSky™) for pharma.

- Sonoco Products Company: It is a significant global provider of thermoform packaging.

- WestRock Company: It is a major player in rigid and flexible packaging solutions.

- Huhtamaki Oyj: It offers various thermoform packaging solutions.

- Klockner Pentaplast: It is known for rigid films, including recyclable options for blister packaging.

- Others: Berry Global Inc., DS Smith Plc, Constantia Flexibles, Tekni-Plex Inc., Pactiv LLC, and many others.

By Material Type

- Recyclable PET (Polyethylene Terephthalate)

- Mono-material PET thermoforms

- High-clarity PET blister sheets

- Lightweight PET blister films

- Recyclable rPET (Recycled PET)

- Post-consumer recycled (PCR) rPET

- High-PCR content thermoform sheets

- Food-grade rPET blisters

- Recyclable PP (Polypropylene)

- Mono-PP blister trays

- High-heat resistance PP blisters

- Microwave-safe PP thermoforms

- Recyclable PE (Polyethylene)

- HDPE thermoform blisters

- LDPE flexible thermoforms

- PE mono-material blister packs

- PLA / Bio-based Thermoform Materials

- PLA blister trays

- Compostable bio-based thermoforms

- PLA blend thermoform sheets

By Product Form / Type

- Clamshell Blister Trays

- Hinged clamshell blisters

- Snap-lock clamshell trays

- Skin Pack Blisters

- Vacuum skin blisters

- Card-backed skin packs

- Tray & Blister Combinations

- Tray with lidding blister

- Hybrid tray–blister packs

- Blister Cards

- Paperboard-backed blister cards

- Fully recyclable blister cards

- Custom Complex Blister Forms

- Multi-cavity blisters

- Custom-molded structural blisters

By End-Use Industry

- Pharmaceuticals & Healthcare

- Tablet & capsule packaging

- Medical device blisters

- OTC product blisters

- Electronics & Consumer Goods

- Accessories packaging

- Small electronic components

- Food & Beverage

- Fresh produce trays

- Ready-to-eat food blisters

- Personal Care & Cosmetics

- Cosmetic kits & tools

- Personal grooming products

- Industrial & Hardware Products

- Fasteners & tools

- Spare parts packaging

- Toys & Specialty Goods

- Toy accessories

- Hobby & collectible packaging

By Region

- North America

- U.S.

- Canada

- Mexico

- Rest of North America

- South America

- Brazil

- Argentina

- Rest of South America

- Europe

- Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

- Eastern Europe

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

- Asia Pacific

- China

- Taiwan

- India

- Japan

- Australia and New Zealand

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

- MEA

- GCC Countries

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

- Rest of MEA