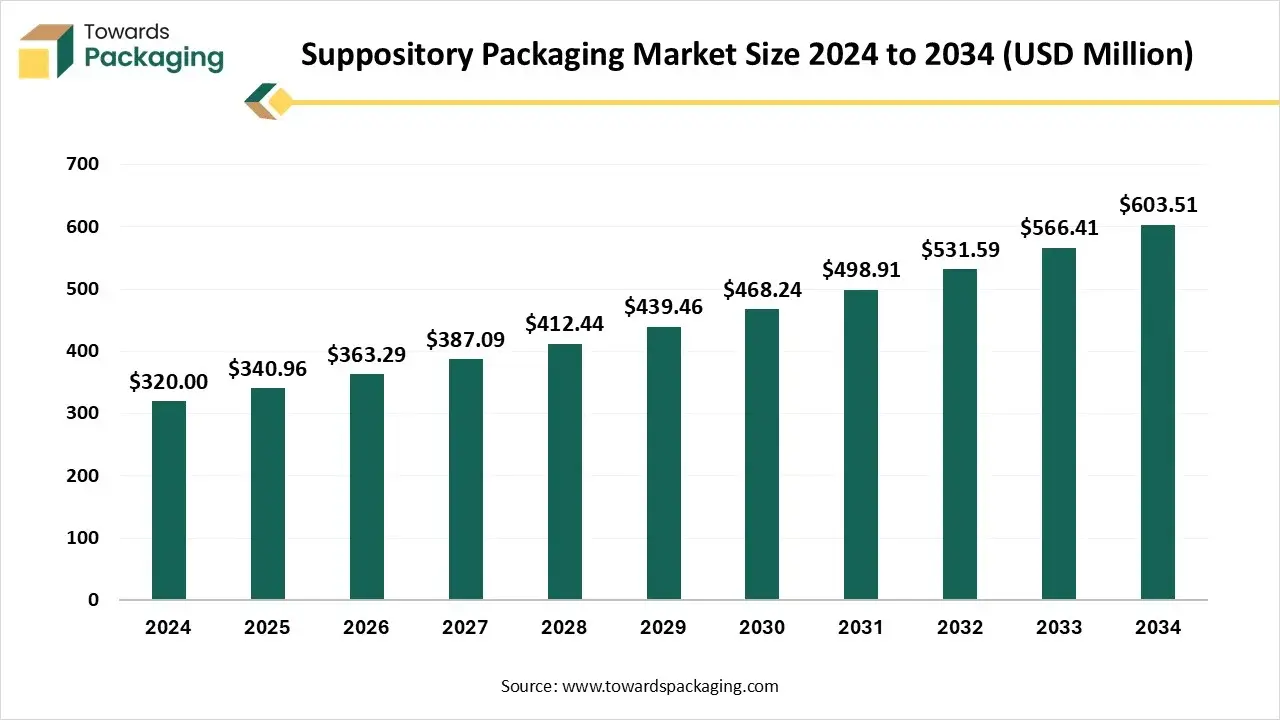

The suppository packaging market is forecast to grow from USD 340.96 million in 2025 to USD 643.04 million by 2035, driven by a CAGR of 6.55% from 2025 to 2034. The market is driven due to rising urge for alternative drug delivery procedures. Suppositories serve effective treatment options, specifically for patients with difficulty swallowing pills.

The market is driven by factors such as the increasing geriatric population, rising prevalence of chronic diseases, and the growing demand for patient-centric and child-resistant packaging solutions.

The suppository packaging market involves the global industry providing specialized packaging solutions for suppositories solid dosage forms administered via body cavities such as rectal, vaginal, or urethral. These packaging solutions are designed to protect the product from contamination, ensure hygienic handling, and facilitate ease of administration.

| Metric | Details |

| Market Size in 2025 | USD 340.96 Million |

| Projected Market Size in 2035 | USD 643.04 Million |

| CAGR (2026 - 2035) | 6.55% |

| Leading Region | North America |

| Market Segmentation | By Material Type, By Packaging Type, By End-User Industry, By Distribution Channel and By Region |

| Top Key Players | Amcor plc, Berry Global Inc., WestRock Company, Smurfit Kappa Group, Smurfit Kappa, NextPharma Technologies, CordenPharma, Recipharm AB, Hudi Pharma, Adragos Pharma GmbH, LGM Pharma, Aluberg S.p.A. |

The mixture of AI and IoT in the suppository packaging industry is ready to update manufacturing, production, and revenue development in the upcoming years. AI-driven automation develops accuracy in packaging, lowering the material wastage and optimizing efficiency, while IoT-enabled smart sensors update real-time monitoring of packaging lines, ensuring regulatory compliance and quality control too. Predictive tracking, powered by Artificial intelligence, lowers downtime and develops operational efficiency, which points to cost savings.

Furthermore, data analytics from IoT machines assist producers in simplifying supply chains, lessening lead times, and growing output potential. As pharmaceutical organizations accept these high-level technologies, manufacturing costs are expected to decrease, while developed compliance and efficiency could drive bigger market expansion and revenue growth.

The suppository filling machine is a machine particularly used for precisely filling drugs or other active ingredients into suppository molds, which is widely used in drug manufacturing. Suppositories penetrate the human body through dissolution or absorption and play a crucial role in diagnosis. The suppository filling machine ensures the quality of medicines through smooth and accurate filling technology. The safety and correctness are its main needs, directly linked to the treatment that affects the health of the patients.

Also, the safety of the suppository filling machine is diligently related to preventing cross-contamination. To bypass drug pollutants, the machine uses convenient materials and characteristics and a closed-loop operation system so as to prevent communication between the external and drug environment.

The most rising challenge is the lack of suppositories and research. Other challenges include packaging and storage issues. Certain oil-based suppositories must be kept frigid in warm surroundings to avoid melting or crystallization. Hydrogel-based suppositories must have packaging to keep them from absorbing moisture. Furthermore, there are limitations during the formulation of suppositories. For instance, it can be challenging to check which inactive will keep the dose high and still track the shape, stability, and solubility. Additionally, the availability and cost of the materials utilised in the production of suppositories can be an issue, particularly in certain countries.

The plastics-based packaging segment dominated the suppository packaging market with approximately 42% share in 2024 as pharmaceutical plastic containers are utilised for packing suppositories and vaginities, and ready-made medicines too. They can be in direct link with the product. The pharmaceutical plastic containers are created from materials that are described in Ph. Eur, and they align with the criteria of the usage assessment, which are also outlined. A laminate of polyvinyl chloride and polyethylene was widely used. The PVC film serves to provide rigidity and creates the cavity, while the PE surface layer acts as the packaging surface. Some suppliers, like Valmactic Srl, deliver films created from single materials such as PET or PP to develop recyclability.

The Aluminum-based packaging segment is expected to be the fastest in the market during the forecast period. This is the best solution in which semi-solid preparations linked to the pharmaceutical industry take place. Hence, this path of packaging is known as the most regular way and is still utilised. It is exceptional to write that there are different new options of packaging that are established, but none of them can beat the aluminum suppository packaging. The prime reason behind this is that it is convenient to carry, store, and apply.

They are available in different diameters, sizes, and lengths, and all are designed to suit the various aims and materials to be stored. Not only in pharma, but there are different sectors that usually use aluminium packaging for their product packaging and storing work.

The blister packs segment dominated the market with approximately 55% share in 2024, as medical blister packaging points to the packaging of drugs such as capsules, tablets, and ampoules into the flexible blister packs. These blister packs are crafted with food-grade materials, which are completely safe for every kind of drug. Its goal is to deliver unit-dose packaging to a particular medication. Market easy handling, and assist in preventing drugs in solid dosage against surrounding factors.

Blister packs of suppositories can be created of 2-ply laminates that have aluminium Foil and PE or PVC or PE as two substrates. In every case, there is a top and bottom foil that the pack occurs with the PE side. There are two types of needed opening ease, namely peelability or tearability.

The foil wraps segment are expected to be the fastest in the market during the forecast period. Aluminium foil packs have become an essential solution for secure packaging and sealing demands across sectors. From pharmaceutical bottles to food packaging, these thin metallic packs and tapes serve a huge range of benefits that other materials simply can’t match.

An aluminum foil pack frequently makes a tamper-evident, leak-proof, and airtight closure on containers. Similarly, foil-backed tapes stick to layers in order to barrier out moisture and air. On the other hand, the aluminium foil itself is waterproof and non-porous, meaning liquids and water repellents cannot enter it. Also, a foil wrap is well known for its perfect barrier properties.

The pharmaceuticals industry segment dominated the suppository packaging market with approximately 60% share in 2024, as suppositories are the kind of medications that we insert into our bodies. They are small, thin, and generally round, oval, or cone-like in shape. A suppository is usually made of cocoa butter or gelatin, which has medication present inside. Once it's inside your body, the exterior shell is melted by your body heat, which releases the medicine. The medication is absorbed by going into your bloodstream or directly into the space in which you place it. Suppositories don’t always work faster than oral medications.

E-commerce platforms segment expected to be the fastest-growing in the market during the forecast period. E-commerce has driven attention in suppository packaging by giving importance to convenience, safety, and sustainability, and by delivering a stage for direct-to-user sales. As the suppository industry grows, e-commerce has become an initial driver of development by solving the specific needs of online sales for pharmaceuticals. Also, E-commerce has driven the demand for more rigid and smooth packaging materials. Integration materials like polyethylene/ aluminium serve as perfect barriers against light, moisture, and oxygen, which can compromise the integrity of suppositories during shipping. Online retailers must balance product preservation with cost-efficiency. Dimensional weight pricing from transporting carriers has encouraged organisations to accept minimal, correctly sized packaging to lower shipping costs.

Also, the growth of e-commerce has enabled pharmaceutical organisations to explore D2C models for particular products. A strong e-commerce presence enables them to manage logistics, collect valuable customer data, and construct brand loyalty.

The offline channel segment dominated the market with approximately 70% share in 2024 as it selectively takes place through regular supply chains such as pharmacies, hospitals, drugstores, and wholesale medical distributors, too. Producers supply packaged suppositories to distributors, who then serve them to retail pharmacies and healthcare facilities. This channel ensures product availability in the local industry, which assists bulk purchasing, and constructs trust through face-to-face communication with medical professionals and pharmacists. Offline distribution remains the main in regions where digital entry is less and in which patients depend on direct contact and fast product access.

The online channel segment predicted to be the fastest in the market during the forecast period. Online channel distribution of suppository packaging runs through e-commerce stages, pharmacy apps, and producers' direct-to-user websites; it serves convenience by enabling patients, healthcare providers, and institutions to order products with home delivery and digital payment options. This channel is growing rapidly due to growing internet penetration, growing acceptance of telemedicine, and user preference for discrete buying of sensitive healthcare items. Online distribution also allows a huge market reach, subscription-based supply, and competitive pricing as compared to regular offline sales.

North America dominated the suppository packaging market in 2024 as the demand for this is steadily growing, assisted by an aging population, higher prevalence of gastrointestinal and rectal disorders, and growing usage of over-the-counter rectal and vaginal medications. Consumers in the region value packaging that ensures hygiene, ease of application, and tamper opposition, which is driving innovation in single-dose blister formats and higher barrier laminated films. On the production side, manufacturers are increasingly adopting advanced machinery for accurate dosing and uniform sealing, while also experimenting with eco-friendly and recyclable materials to match sustainability goals. This mixture of growing healthcare demands and innovation in packaging design is shaping a rigid market outlook for suppository packaging across the U.S and Canada.

Asia Pacific is expected to be the fastest-growing in the market during the forecast period. The demand for suppository packaging is accelerating fast, driven by heavy healthcare access, rising pharmaceutical production in countries like China, Japan, India, and South Korea, and growing prevalence of chronic illness among aging populations. Manufacturers are scaling up output to keep space, and packaging manufacturers are investing in materials with rigid barriers (against light, moisture, and oxygen) to ensure drug stability under various conditions.

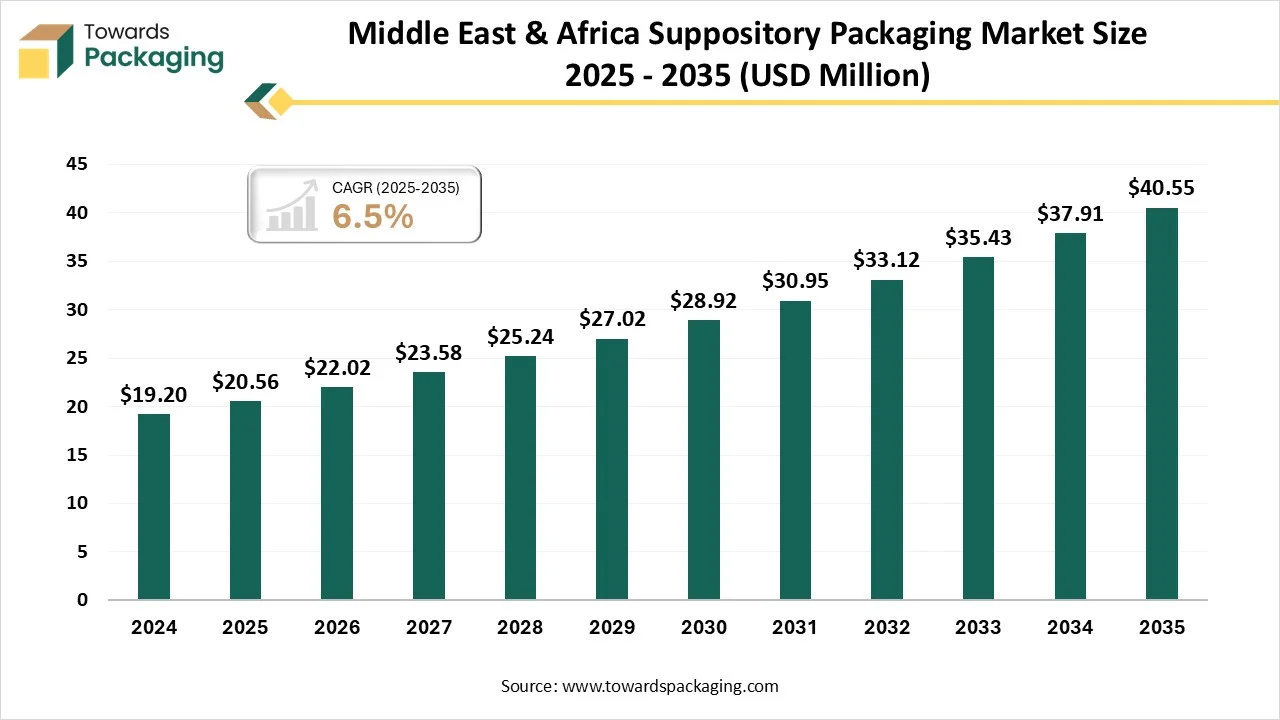

Global suppository packaging market investments are due to rapid development in the Asia Pacific Region and innovation from established pharmaceutical centres in Europe and North America. A growing elderly population and growing concentration on non-oral drug delivery procedures are the main drivers, encouraging funding in sustainable materials, high-level technology, and patient-centric designs.

The region is a European leader, with its strong pharmaceutical production sector and rigid regulatory environment driving demand for high-quality packaging.

Tier 1

Tier 2

Tier 3

By Material Type

By Packaging Type

By End-User Industry

By Distribution Channel

By Region

February 2026

February 2026

February 2026

February 2026