Folding Carton in Healthcare Market Size, Share, Trends and Forecast Analysis

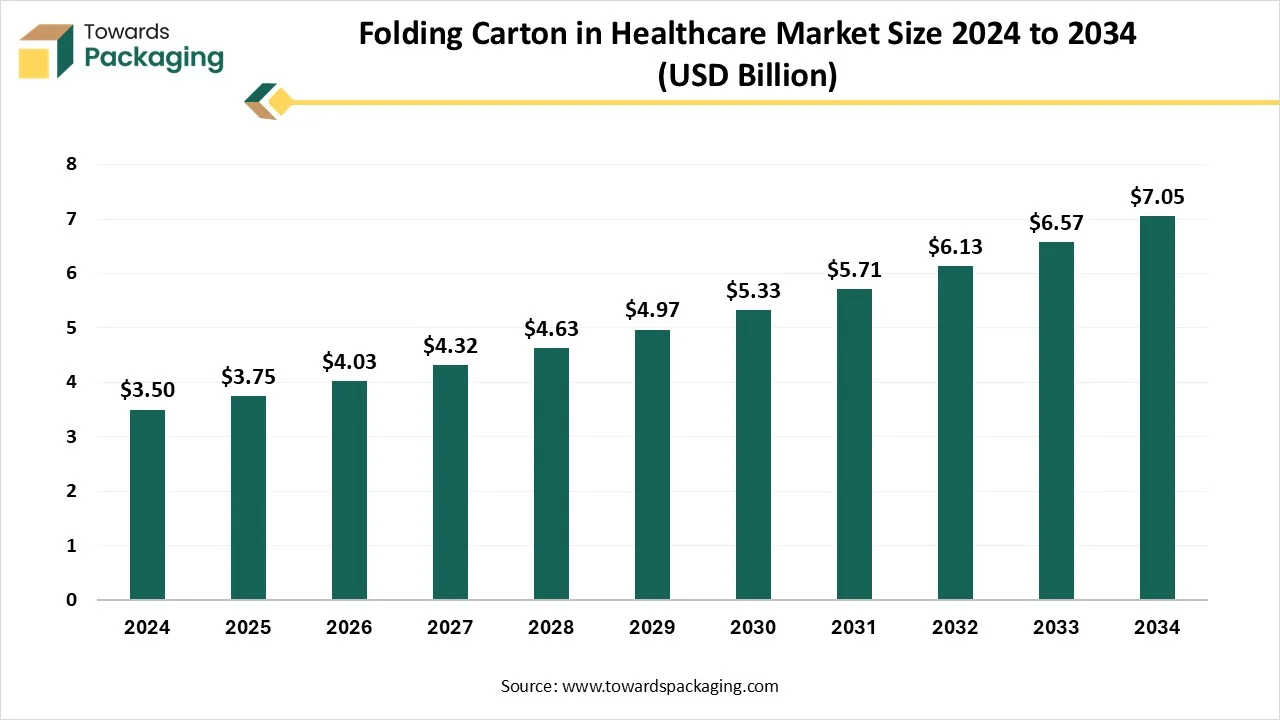

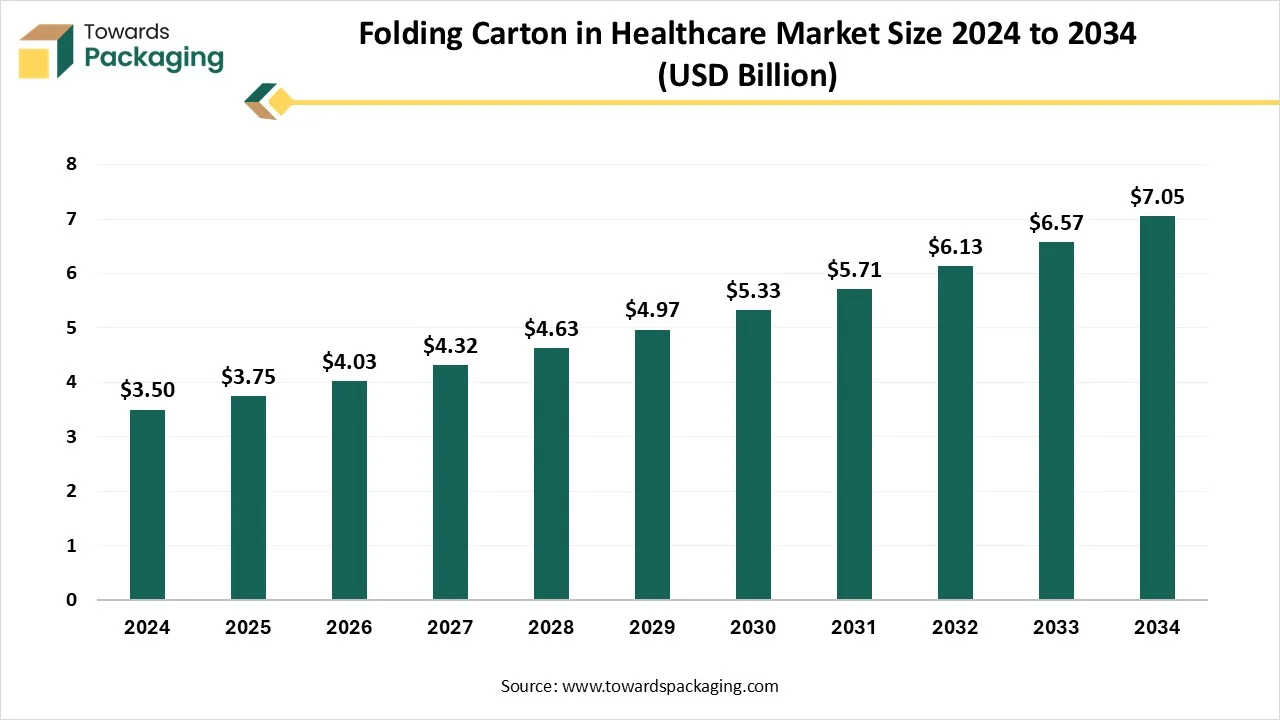

The folding carton in healthcare market is expected to increase from USD 4.03 billion in 2026 to USD 7.56 billion by 2035, growing at a CAGR of 7.25% throughout the forecast period from 2026 to 2035. The demand is due to growth in chronic diseases, and the aging population is encouraging the demand for over-the-counter and prescription drugs, which promotes the demand for folding carton packaging in the healthcare industry.

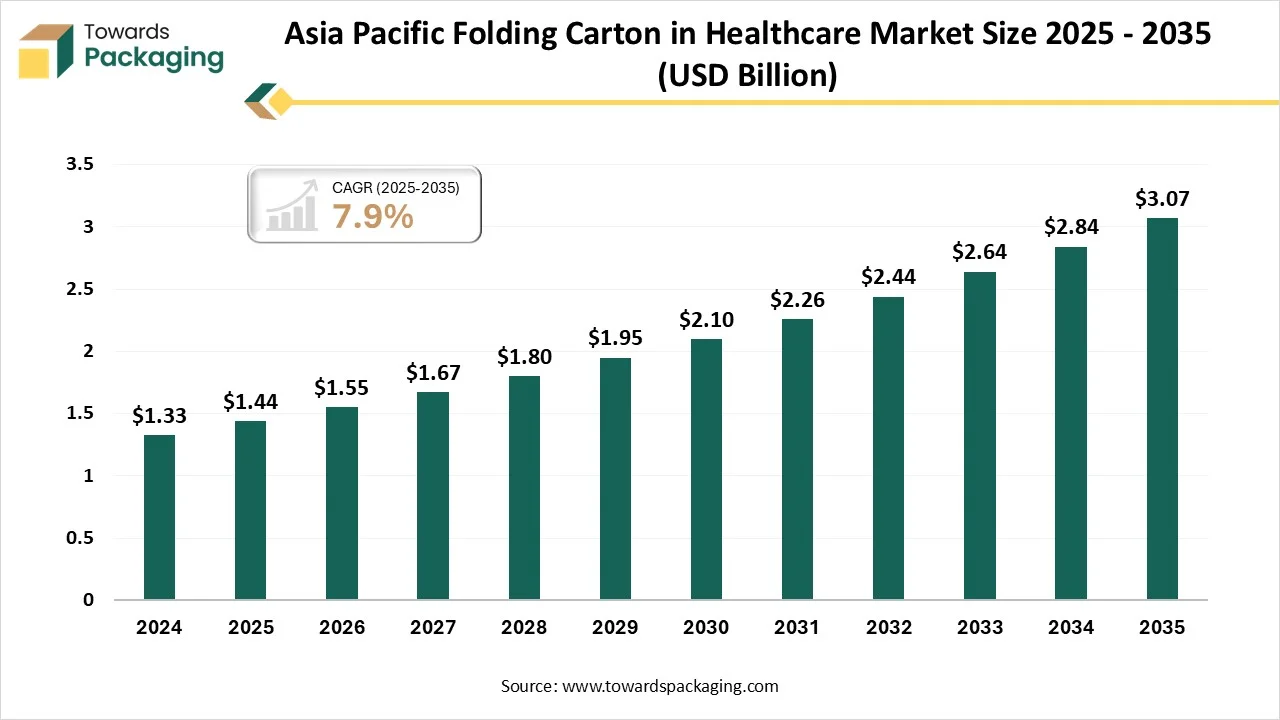

Asia Pacific holds the greatest share in 2024, and North America is the fastest-growing region. The market is expanding quickly. The most common application type was pharmaceutical products, but nutraceuticals are predicted to rise significantly. Standard folding cartons were dominated by product type, and the market for specialty folding cartons will grow considerably. The paperboard (coated) accounted for the largest material type, while the recycled paperboard is set to grow quickly. By printing technology, offset printing has dominated the folding carton in healthcare market, while the digital printing segment is the fastest growing. By end-use industry, the pharmaceutical industry is the dominating one, while medical device packaging is the fastest-growing segment.

Key Takeaways

- In terms of revenue, the market is valued at USD 3.75 billion in 2025.

- The market is projected to reach USD 7.56 billion by 2035.

- Rapid growth at a CAGR of 7.25% will be observed in the period between 2025 and 2034.

- Asia Pacific dominated the global market with the largest revenue share in 2024.

- North America is expected to grow at a notable CAGR from 2025 to 2034.

- By product type, the standard folding carton segment contributed 55% revenue share in 2024.

- By product type, the specialty folding carton segment is expected to grow rapidly in the coming years.

- By material type, the paperboard segment dominated the market in 2024 with a 50% share.

- By material type, the recycled paperboard segment is expected to grow significantly over the studied period.

- By printing technology, the offset printing segment dominated the market in 2024, with a share of 40%.

- By printing technology, digital printing is expected to grow significantly over the studied period.

- By application, the pharmaceutical products segment contributed the biggest revenue share of 40% in 2024.

- By application, the nutraceuticals segment will expand at a significant CAGR between 2025 and 2034.

- By end-use industry, the pharmaceutical industry segment had dominated the market by share 45% in the year 2024.

- By end-use industry, the medical device industry is the fastest-growing segment over the upcoming years.

Market Overview

Folding Cartons in Healthcare are paperboard packaging solutions that are folded into various shapes to store, protect, and transport pharmaceutical products, medical devices, personal care items, and other healthcare-related products. These cartons are designed to maintain the integrity of the contents, ensuring product safety and compliance with regulatory standards. They are widely used due to their cost-effectiveness, eco-friendliness, and customizable design options.

A folding carton healthcare, which can also be referred to as a box, is a kind of packaging made from paperboard that is then folded and packed to store your products. Folding cartons serve as the primary layer of protection and serve as an important marketing area. They protect our products, attract users, and attract users. They are perfect packaging solutions in all sectors, and for good reasons., They are extremely versatile in function and form, can be crafted in creative ways, and are ideal carriers of information and advertising.

Folding Carton in Healthcare Market Trends

- Retail Packaging: Retail packaging is crafted to attract users while ensuring the product's integrity and safety. In the healthcare industry, it mixes elements such as dosage instructions, drug facts, and brand information, ensuring compliance and consumer loyalty. This kind of packaging is most effective for over-the-counter medications, medical devices, and supplements meant for personal use, allowing for easy consumer use and access.

- Folding Carton: Folding carton packaging is an adaptable and cost-effective solution, prevalently utilised in the healthcare industry. It includes paperboard, which is printed, cut, folded, and laminated to make box shapes suitable for different products. This kind of packaging is perfect for lightweight healthcare products such as health supplements, small medical devices, and pharmaceuticals.

- Plastic Thermoforming: Plastic thermoforming is a process of taking a plastic sheet and making it ductile for shaping it into a particular mold. In the healthcare sector, this packaging design is ideal for making custom-moulded trays, clamshells, and blisters too. These plastic trays serve as secure housing for medical devices, pharmaceutical products, and surgical instruments.

- Corrugated Boxes: Corrugated cardboard packaging consists of a fluted corrugated sheet and one or two flat linerboards, providing strength and durability. The healthcare sector utilises this packaging for equipment, bulk medical supplies, and pharmaceuticals that need strong protection during storage and transit.

- Case Packs: Case packs include grouping many units of a product into a single, heavy package for distribution. This kind of packaging is widely utilised in the healthcare industry for effective handling and storage. It serves as a practical solution for packaging high-volume items like gauze, medical gloves, and disposable masks.

- Permanent Displays: Permanent displays are storing, long -term fixtures crafted to display healthcare products noticeably and attractively. These displays are incorporated into healthcare settings or retail surroundings to track product visibility and accessibility over extended periods. They are perfect for displaying items needed often, such as first-aid supplies, vitamins, and over-the-counter medications.

AI Integration in Folding Carton in Healthcare Market

The absorption of human integrity and expertise with high-level technology (IoT, artificial intelligence) can lower OPEX by updating repetitive tasks, reducing manual labor, and lowering production costs. Auditable ESG reporting serves the main advantages to packaging transformers by developing transparency and accountability in their operations. This level of checking not only assists in creating trust with stakeholders, including customers and investors, but also ensures compliance with regulatory standards.

AI-obsessive quality control systems employ machine vision technology for defect analysis, mainly reducing waste and ensuring constant product quality. These systems can check defects with substantial accuracy, allowing for efficient corrective actions and lowering the demand for rework. Furthermore, assisting customers in the transformation to sustainable packaging not only meets environmental aims but also serves the main financial rewards. By contributing to eco-friendly packaging solutions, organizations can tap into a rising industry of environmentally conscious consumers, hence growing their user base and developing brand loyalty.

Market Dynamics

Driver

The trend towards accepting folding cartons over regular plastic packaging is not just a response to user demand for greener solutions, but also impulsive by advancements in material technology and growing acceptance of the economic and environmental benefits of using renewable resources. According to current research, industries, governments, and consumers alike are identifying the demand to move away from plastic packaging to greener options, with a particular importance on materials that are conveniently recyclable and biodegradable. One of the most striking moves has been the growth of the folding carton. Regularly used for products like cereal boxes, folding cartons have now found their place in terms of food packaging, substituting plastic containers for products like snacks, ready-to-eat meals, and beverages. The crucial reason for this is that folding cartons serve environmental benefits over plastic.

Restraint

Folding cartons are likely to be damaged because of their sensitive nature and can become conveniently ripped or dented when mishandled. They are particularly not as rigid as metal or plastic materials used for either kind of packaging. Gathering them in a time-consuming procedure, which can be labour-intensive and boring too. Folding cartons can also take up enough space, as they demand to be kept flat until ready for usage. Additionally, their patterns and design may not deliver enough security from particular types of contamination or damage, like water. Generally, they are made of cardboard or paper, which means they are perfectly suitable for packaging large products.

Opportunity

Folding carton packaging transformers want to boost their effectiveness at this stage. They want detailed insights for their tools, with better tracking elements resulting in less patching and perfect resource management. With the correct machine, machines are linked to the cutting die through a data chip fitted directly in the tool. This enables an instant acceptance of the job and to accept production-ready job recipes, always remembering the newest setting. This way, transformers can also gather data and manage machine performance anytime and anywhere. Proactive tooling management assists in avoiding manufacturing and quality problems.

Segmental Insights

How did the Standard Folding Carton Dominate the Product Type for Folding Cartons in Healthcare Market?

Standard folding cartons are widely utilised in the healthcare sector for packaging pharmaceuticals, wellness, and medical device products due to their cost-effectiveness, easy customization, and lightweight structure. These cartons provide adequate protection, space for important regulatory information such as instructions, dosage, and expiry dates. Their compatibility with high-speed packaging lines and compliance with Good Manufacturing Practices make them a selected choice for mass production. Moreover, growth in anti-counterfeit features and sustainable materials is developing their relevance in current healthcare packaging.

Speciality Folding Cartons are the Fastest Growing Product Type

Speciality folding cartons go beyond standard packaging by including high-level features such as tamper-evident closures, child-resistant locks, high-end finishes, and multi-compartment designs. In the healthcare sector, they are used for sensitive, luxury, or tailored medicines, serving enhanced product protection, compliance, and branding too. These cartons often include RFID tags, barcodes, Braille text, and unique die-cuts. Their potential to integrate functional and aesthetic elements makes them perfect for clinical trial kits, high-value pharmaceuticals, and biotech products.

How did the Paperboard (coated) Material Type Dominate the Folding Carton in Healthcare Market?

Paperboard folding cartons are created from a single layer of paperboard, which makes them lightweight and convenient to assemble. These cartons are prevalent for retail products because of their simple and clean appearance. They are specifically famous in the cosmetics, food, and pharmaceutical sectors, in which they serve attention-grabbing and functional packaging solutions. Paperboard folding cartons can be conveniently tailored with different printing and finishing procedures, enabling brands to make visually appealing packaging that distinguishes itself on the shelf.

Recycled Paperboard is the Fastest-growing Material Type

These cartons are being created from 100% post-consumer recycled content, in which materials are reused and repurposed instead of being discarded. Recycled cartons assist in reducing the use of raw materials and, as a result, protect natural resources by using less paper. They are recyclable materials prevalently used in folding carton packaging, serving as an environmentally friendly option to virgin paperboard and plastic. It is created from 100% post-consumer recycled fibers, lowering the demand for new materials and promoting a circular economy. Recycled paperboard is a famous choice for different products, including cereal boxes, multi-use packaging, and pasta boxes.

How did Offset Printing Technology Dominate the Folding Carton in Healthcare Market?

Offset printing shifts ink from an engraved aluminum plate to a rubber blanket, which is then applied to the final surface. The procedure is known for its consistency and colour accuracy, making it perfect for organizations in sectors such as cosmetics or luxury food products that need high-quality and vibrant packaging. It is also cost-effective for huge print runs but includes higher setup costs and longer lead times. High-level colour management can assist in updating color matching and lower waste because it ensures measured quality to receive the desired outcome. G7 Proof and Drawdowns can go a long way to make sure the press operators know exactly what is needed of them on the press.

Digital Printing is the Fastest-growing Printing Technology

When it comes to paper cartons, digital printing moves images directly into different substrates and now competes with regular offset printing in resolution and color precision. This procedure serves custom packaging solutions with variable data, making it perfect for cost-effective short-run and on-demand projects. Its environmental advantages, such as reduced ink waste and the usage of eco-friendly inks, further develop its appearance. Current digital printing trends count on its integration with augmented reality (AR), which allows for communicative and engaging experiences that smoothly mix digital and physical elements. Furthermore, digital printing also protects our brand against counterfeiting by including covert and overt solutions on our packaging. Digital printing can generate different inks or microtext, which are quite impossible to replicate.

How did the Pharmaceutical Products Application Type Dominate the Folding Carton in Healthcare Market?

Pharmaceutical products have dominated the market because of the demand for over-the-counter pharmaceuticals, medicines, healthcare goods, and medical equipment, which are different types of healthcare and pharmaceutical products. These products are packaged securely and safely using folding carton packaging. To track the effectiveness and integrity of packaged goods, folding cartons serve as a defence against moisture, contamination, and light. To develop the production of products, they can additionally count on tamper-evident features like security seals and holes. The main goal of pharmaceutical folding cartons is to make sure that medicines are perfectly protected during their phase from the production line to the user. For instance, blister packs having capsules or pills are often established in solid cartons, which prevent physical injury and exposure to light and moisture. These protective evaluations are crucial for maintaining the goodness of the drug and making sure it stays effective whenever consumed.

Nutraceuticals are the Fastest-growing Application Type

Nutraceuticals that include functional foods and dietary supplements often have sensitive ingredients that can reduce or become toxic when exposed to light, moisture, or air. Folding cartons serve as a protective barrier against these characteristics, helping to maintain the product's quality and capability. They serve a large surface space for branding and product information. They can be published with attention-grabbing graphics, nutritional information, and product descriptions, helping to differentiate the product and attract users. Folding cartons are convenient to transport, store, and open, too. They can be crafted with a tear-open attribute and an easy dispensing option, which makes them user-friendly for users.

How did the Pharmaceutical End-use Industry Dominate the Folding Carton in Healthcare Market?

The pharmaceutical end-use industry has dominated the market as folding cartons are utilised for packaging over-the-counter medications and prescription products. Their potential to be personalized with safety seals and transparent product information makes them a perfect choice. In the pharmaceutical industry, compliance and accuracy are important. Folding cratons like reverse Tuck End Boxes and Boxes with Inserts serve as protected and tamper-evident solutions. They are utilised for packaging medical supplies and pharmaceutical drugs due to their strong designs to ensure product integrity and safety for users. These cartons are crafted to meet the strict packaging standards with the needed labeling regarding the medicines printed on them.

The Medical Device Industry is the Fastest-growing End-use Industry

Royal Paper Box is a perfect choice in terms of the medical device sector for our paperboard packaging needs. It has a rigid track record of assisting clinical trials and product disclosure for leading devices and drugs in the market. It is crafted to meet the particular demands of your clinical trials. State-of-the-art finishing lines ensure thorough checking of the royal box, which ensures confirmation of glue dispersion, precise ink colour, accurate registration, and reliable bar code verification. Features such as tamper-evidence, barcoding, and compartmentalization enhance safety and traceability. In addition, folding cartons can be custom-printed with instructions, usage information, and branding, improving user experience and assisting healthcare professionals in device identification and usage, too.

By Region

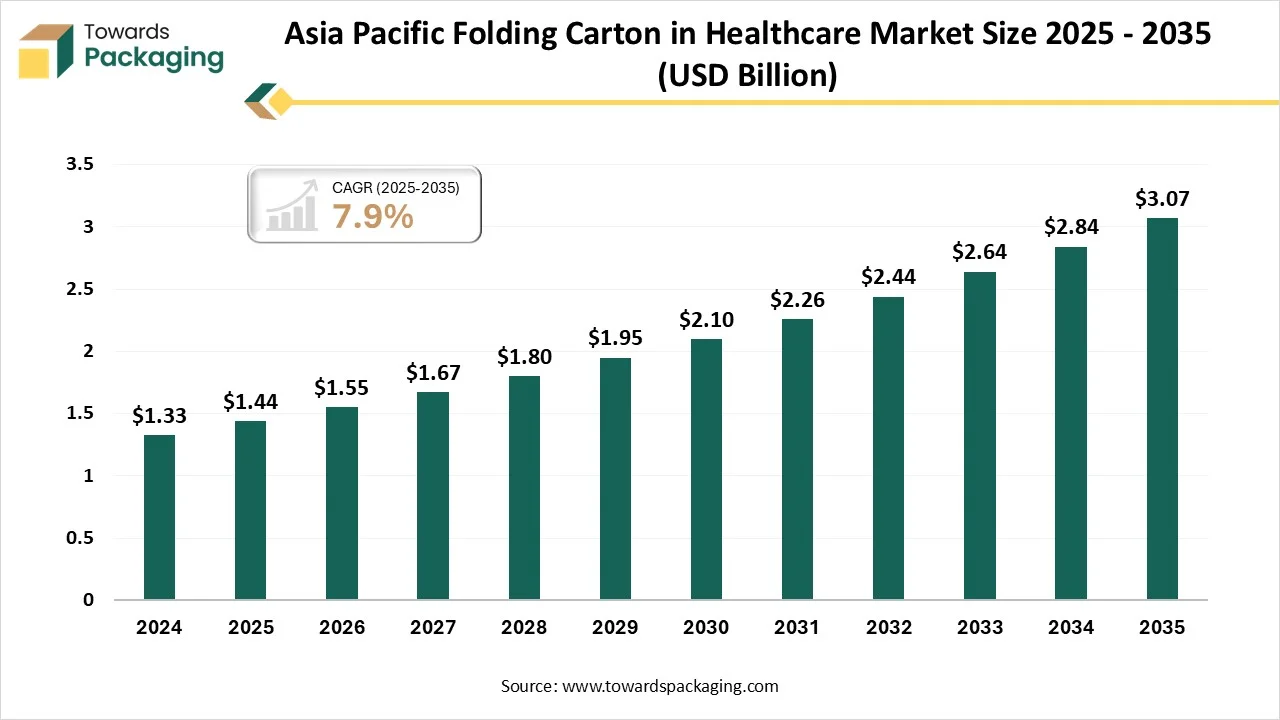

How did Asia Pacific Dominate the Folding Carton in Healthcare Market?

The demand for folding cartons in the Asia Pacific is experiencing significant growth, driven by fast urbanisation, a stretching middle-class population, and the rising emphasis on sustainable packaging solutions. Countries like China, India, Japan, and South Korea, and the ASEAN nations are at the frontline of this demand surge, hugely due to growing consumption of packaged goods across different industries, including food &beverages, personal care, pharmaceuticals, and consumer electronics.

In the food and beverage sector, folding cartons are widely used for packaging cereals, frozen foods, and beverages, too. The growing trends of convenient foods, driven by changing lifestyles and busy urban schedules, are further accelerating this growth. Innovation in design and printing technology, such as smart packaging features, is also enhancing the look of folding cartons across the region. With increasing awareness about hygiene, branding, and consumer safety, the Asia Pacific folding carton market is expected to continue its upward trend in the upcoming years.

North America is the Fastest-growing Region in the Market

The folding carton market in North America is witnessing constant growth, primarily driven by sustainability issues, luxury packaging demand, and the expansion of the e-commerce sector. Countries like the United States and Canada are seeing increased acceptance of folding cartons across main industries, including food and beverages, pharmaceuticals, personal care, and consumer electronics. Sustainability remains a main driver in North America. Users and Barbados are increasingly moving away from plastic and non-recyclable materials. Folding cartons made from recycled or responsibly sourced paperboard align well with circular economy goals and corporate sustainability targets.

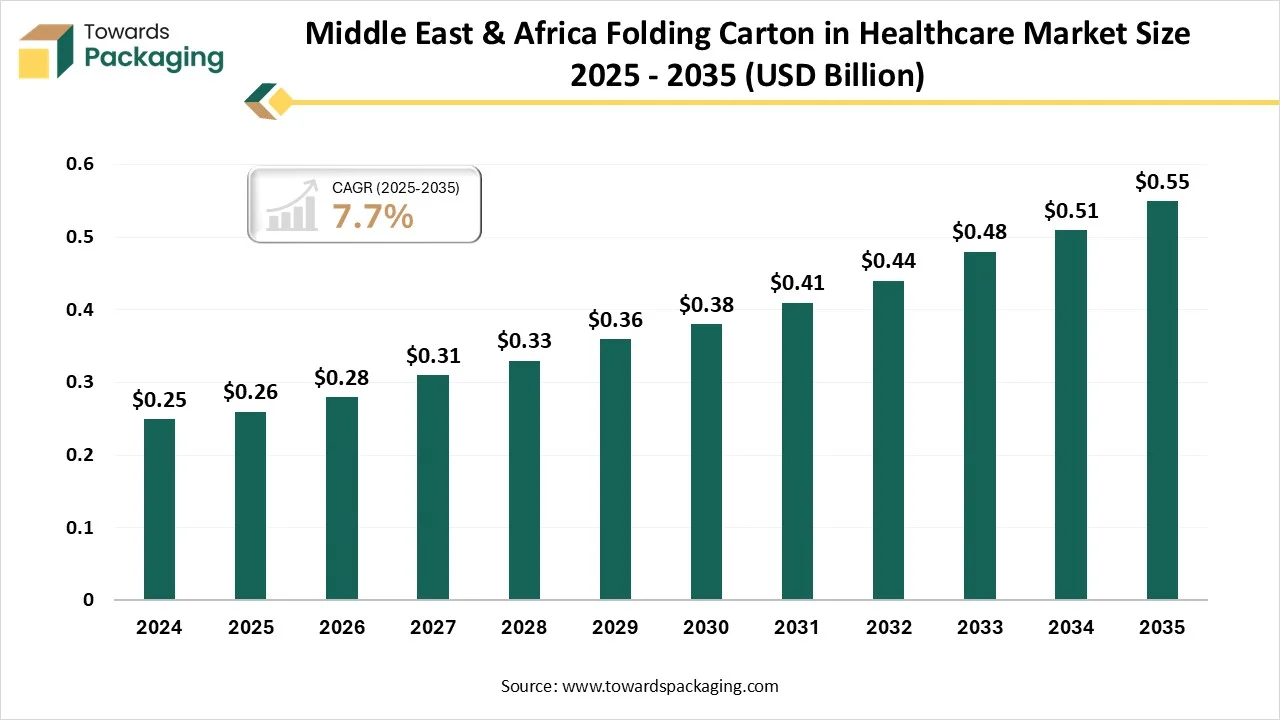

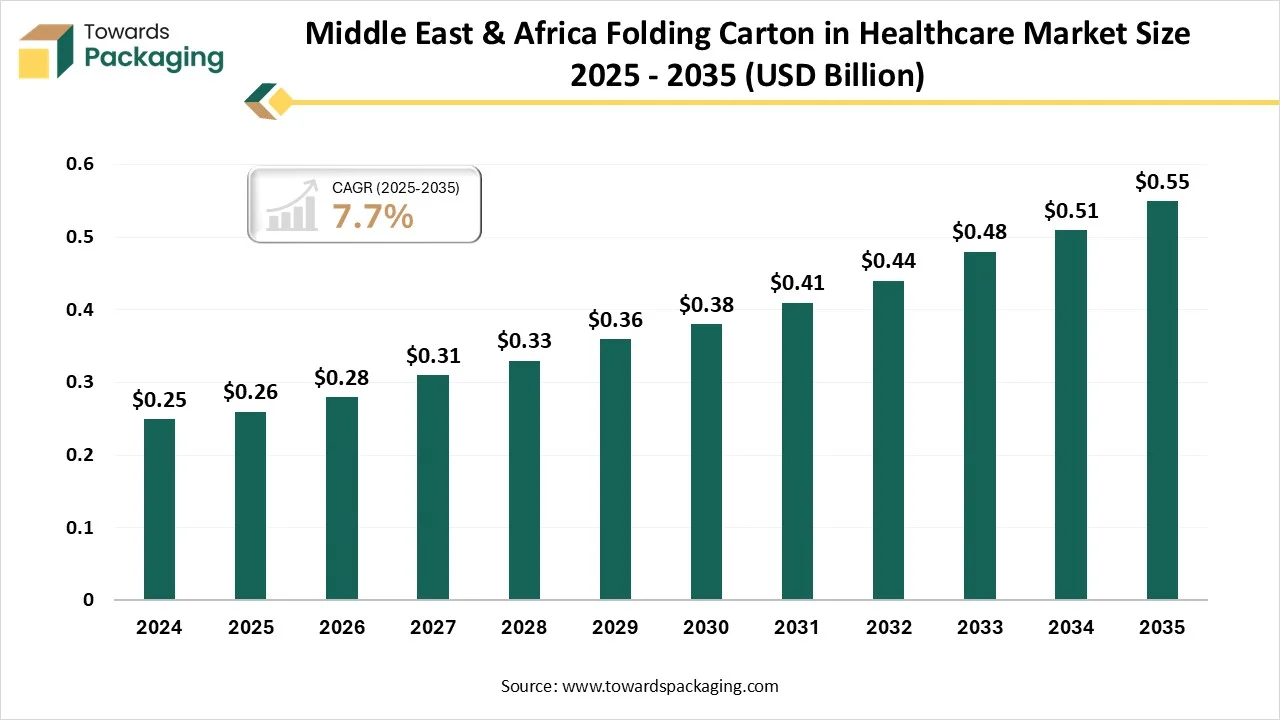

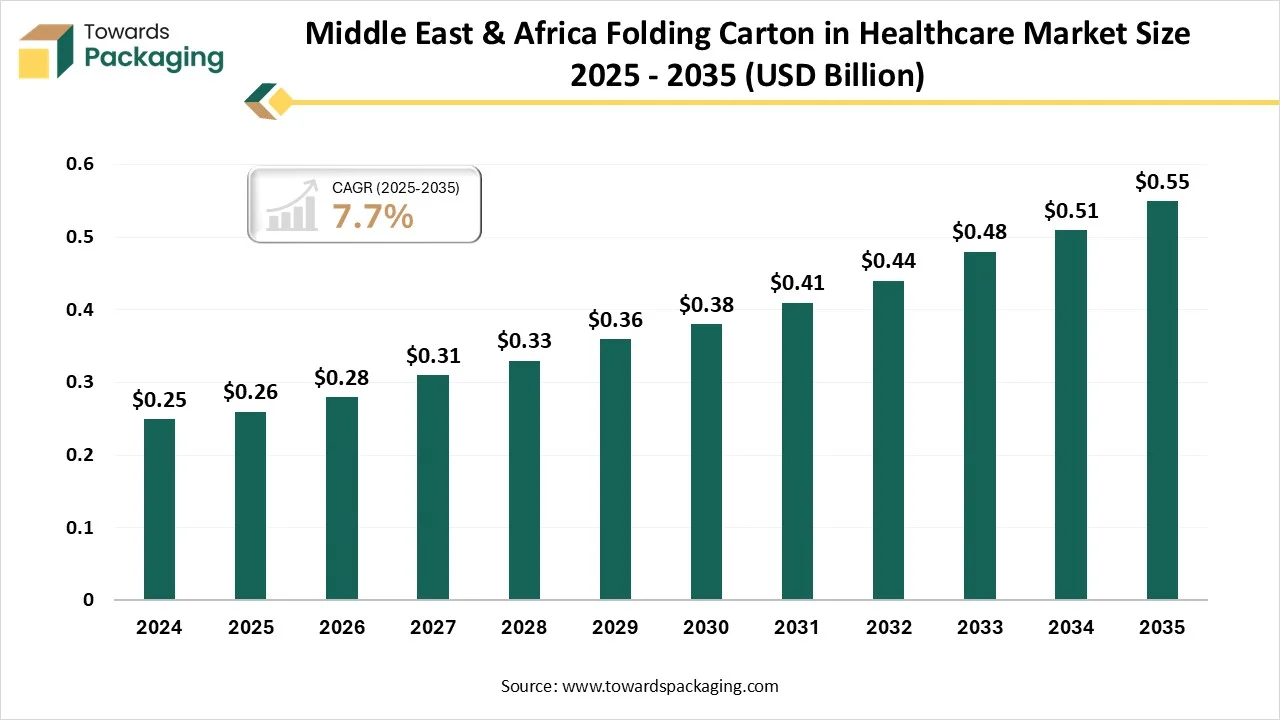

Middle East & Africa Folding Carton in Healthcare Market Size 2025 - 2035 (USD Billion)

Leading Players in the Folding Carton in Healthcare Market

- Smurfit Kappa Group

- Mondi Group

- International Paper

- WestRock Company

- Georgia-Pacific LLC

- Packaging Corporation of America (PCA)

- Sonoco Products Company

- Stora Enso Oyj

- DS Smith Plc

- Avery Dennison Corporation

- Mayr-Melnhof Karton AG

- Sappi Limited

- Graphic Packaging International

- Rengo Co., Ltd.

- Huber Packaging Group

- Clearwater Paper Corporation

- Progroup AG

- UFP Technologies, Inc.

- VPK Packaging Group

- Kraft Foods Packaging (Kraft Heinz)

Industry leader Announcement in the Industry

- On 25 July 2025, Heidelberg finalized an agreement with the POLAR Group to gain the technology, brand rights, and intellectual property (IP) linked with the POLAR Mohr brand, along with regular assets. This transaction is predicted to be completed within the coming weeks.

- On 1 July 2025, Hybrid Software disclosed the current offering in its flagship PACKZ Software. The latest PACKZ 11 launch has introduced PACKZ MAX, having integrated Harlequin RIP technology in order to screen control from within the PACKZ PDF editor.

Recent Developments

- On 29 November 2024, Tetra Pak, a top company in the food packaging and processing sector, revealed the launch of a first-of-its-kind recycling line for carton packages in the United Arab Emirates, in partnership with Union Paper Mills (UPM ), a top player in the paper recycling industry.

- On 29 July 2025, Sun Chemical had disclosed SunCure Advance ECO UV sheetfed inks for folding carton uses. Made to run on high-speed presses, these inks feature perfect press color stability, low misting, and fast curing, assisting in lowering paperboard waste during the make-ready procedure and after the press stops.

- On 6 March 2025, Nazdar Ink Technologies, a coating supplier and inks to the flexible packaging, folding carton, and label markets, has confirmed it will showcase its various range of inks developed for narrow-web printing uses and launch new products at the upcoming LabelExpo Mexico.

Segmentation of Folding Carton in Healthcare Market

By Product Type

- Standard Folding Cartons

- Tuck End Cartons

- Reverse Tuck End Cartons

- Straight Tuck End Cartons

- Display Cartons

- Counter Display Cartons

- Shelf Display Cartons

- Specialty Folding Cartons

- Tamper-evident Cartons

- Child-resistant Cartons

- Eco-friendly Cartons

By Material Type

- Paperboard

- Coated Paperboard

- Uncoated Paperboard

- Grease-resistant Paperboard

- Corrugated Paperboard

- Recycled Paperboard

- Plastic Coated Paperboard

By Printing Technology

- Offset Printing

- Flexographic Printing

- Digital Printing

- Gravure Printing

- Screen Printing

By Application

- Pharmaceutical Products

- Prescription Drugs

- Over-the-counter (OTC) Drugs

- Medical Devices

- Diagnostic Devices

- Surgical Instruments

- Personal Care Products

- Skincare Products

- Hair Care Products

- Nutraceuticals

- Dietary Supplements

- Functional Foods

- Other Healthcare Products

- Wound Care Products

- Medical Adhesives

By End-Use Industry

- Pharmaceutical Industry

- Medical Device Industry

- Nutraceutical Industry

- Personal Care & Cosmetics Industry

By Region

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait