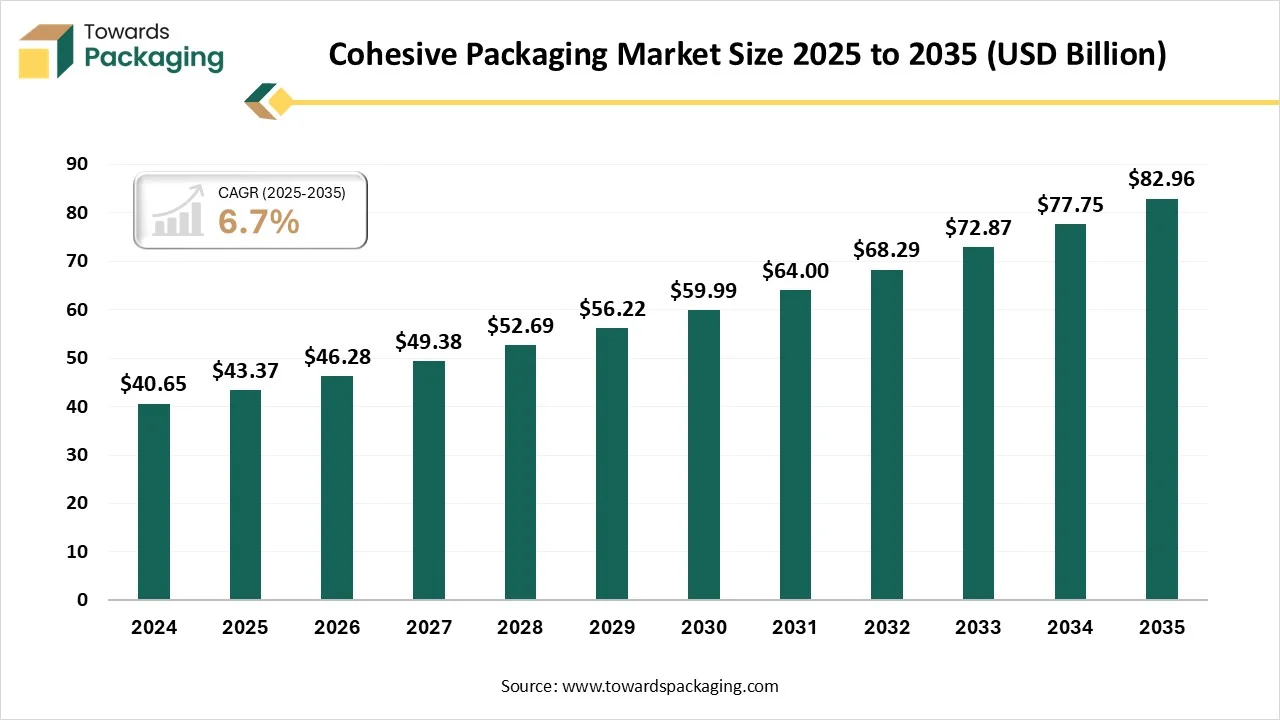

The cohesive packaging market is forecasted to expand from USD 46.28 billion in 2026 to USD 82.96 billion by 2035, growing at a CAGR of 6.7% from 2026 to 2035. The growth of cohesive packaging is due to the developing potential to serve sustainability, versatility, and efficiency that aligns with current demands for lower costs and the eco-friendly materials, such as biodegradable and recyclable materials.

The cohesive packaging market comprises packaging solutions that use cohesive coatings or materials that bond securely to themselves without adhesives, heat, or water. These solutions provide product protection, tamper-evidence, and easy handling, heavy used in logistics, food & beverage, e-commerce, pharmaceuticals, and industrial packaging. Cohesive packaging supports sustainability goals by reducing additional materials and improving recyclability, while enhancing packaging efficiency, safety, and operational cost savings across supply chains.

| Industries | Products | Packaging Features |

| Pharmaceutical | medication, for example, medication blister pill cards. medical devices, biologics, vaccines, bandages | non-allergenic, superior sealability, it ensures sterility of products, can be adapted to different temperatures |

| Food | chocolate, protein bars, confectionery, granola, cereal, frozen food, granola bars, cereal bars, frozen ice cream, cereal | strong sealing properties, non-heat sealing, high-speed production |

| Cosmetics and Personal Care | skincare and cosmetic products, wet wipes, disposable gloves | Non-heat sealing avoids the degradation of products by heat sealing, strong sealing properties |

| Industrial and Electronic | electronic components, precision equipment, mechanical parts, tools | superior sealability, excellent dust, moisture, and static protection |

PerfectaCOL Gm is a potato starch-reliant adhesive that is crafted to align with the urgent demands of dry food packaging. It's heat-pressure sealable and an oil and grease barricade. This creativity creates a relevant alternative for the synthetic heat-pressure sealable cohesive and even the hotmelts, which is an ideal solution for ensuring product sustainability and integrity.

Hence, potato starch is a natural, renewable content that allows packaging to align with circularity standards. Under industrial composting surroundings, cohesives depending on PerfectaCOL have gained 97% biodegradation in 30 days, which makes them perfect for single-use and food-contact packaging.

Synthetic resins are an achievement of current adhesives, which serve perfect bonding potential and reliability as compared to natural options. While several are petrochemical-dependent, there are the latest bio-based alternatives that gain attention to solve eco-friendly issues.

Cohesive packaging links to a Cold Seal” machine in which the adhesive sticks only to cunt and not to the item that is being packed. This makes a quick, protective bond by using the pressure, without the demand for heat. A pressure-sensitive coating generally has natural rubber latex, which is integrated with acrylic emulsions or resins.

Logistics people use “cohesive” materials, which are covered with natural rubber latex or the synthetic polymers that get stuck to themselves and not the product. This solves many running steps, such as high-speed automation, which have cohesive materials that are perfect for receiving speeds of 15-35 packages per minute with an accurate pressure-activated packaging.

The plastic-based cohesive packaging segment has dominated the market with 61.4% share in 2025, as cohesive bubble is a perfect covering and cushioning material, which is utilised to prevent products from damage, abrasion, and vibration too. Cohesive foam is a flexible and lightweight material that can be used in a number of encapsulation, wrapping, or surface protection uses. Such cushioning, flexibility, and protective materials are made accessible in a range of integration, roll options, and thickness, which is ideal for covering and applications like furniture, retail goods, and books and documents too.

The paper-based cohesive packaging segment is expected to experience the fastest CAGR during the forecast period. Self-Seal paper is the cohesive kind of kraft paper, which is the most perfect and economical packaging selection that seals itself without leaving behind any issues. It ensures smooth and safe packaging as it is a special adhesive-coated kraft paper which does not glue to the product but creates an enclosure to serve protection from dirt and dust too.

| Segment | Market Share (%) |

| Cohesive Films & Wraps | 42.1% |

| Cohesive Bags & Mailers | 30.0% |

| Cohesive Sheets | 20.0% |

| Others | 7.9% |

The cohesive films and wraps segment has dominated the cohesive packaging market with a 42.1% share in 2025, as it is perfect for packaging material when it tears, is water resistant, and puncture resistant, which is important. Every line of cohesive film is perfect for various packaging demands. White/silver film is the most prevalent for making packages with the assistance of shipping security and tamper resistance, too. Cohesive film serves as a fast and flexible wrapping material in order to accommodate a huge variety of products like shoes & footwear, hardware parts and supplies, and apparel and soft goods too.

The cohesive bags & mailers segment is expected to experience the fastest CAGR during the forecast period. Padded bags are crafted to serve extra protection for the shipping goods like mobile phones, electronics, and books. Such mailers have fibre padding which stretches and absorbs shock and prevents the goods from changing shape during transportation. Such mailer bags have updated the e-commerce landscape completely. Another is polyethylene mailer bags, which are known to be strong and robust. They are tamper-resistant, weather-resistant, and frequently used for shipping books, clothes, toys, and other items.

The logistics & transportation segment has completely dominated the market with 36.5% share in year 2025 as the cohesive packaging solutions are hence transforming at higher level as how companies protect, secure and showcase the products. Like traditional packaging, such systems use high-level adhesive films, and the materials that get stuck together smoothly, lower the waste and develop efficiency too. From retail to e-commerce, cohesive packaging is becoming a staple for organizations whose goal is to update their supply chains and develop the customer experience.

The e-commerce packaging segment is expected to experience the fastest CAGR during the forecast period. Peal-and-Seal packaging is a kind of packaging in which the seal is made by using an adhesive strip that can be conveniently peeled away. In this way, organizations can quickly and protectively seal their items without depending on consumables like staples, tape, and tools too. Prevalent kinds of peel -and-seal packaging are filled with bags, envelopes, and cartons. Such a user-friendly packaging option ensures that products are securely protected and packed while being easy for every customer and packer to carry. It is a straightforward solution for any e-commerce operations. From developing packaging speed and lowering the costs in order to develop customer satisfaction and security, such packaging options serve various advantages that take the business to the next level.

The logistics and warehousing companies segment has dominated the cohesive packaging market with 38.7% share in 2025, as cohesive materials such as corrugated film, bubble wrap, and paper wrap make a custom-fit seal wound and tight around an item. They only protect it from dirt, dust, and abrasion without demanding staples or tape, too. Due to the packaging conforming to the product that has an exact shape, it lessens “void fill”. This enables more items that fit into the shipping trucks and containers, which lowers the total fuel consumption and transportation costs too.

The e-commerce and retail companies' packaging segment is expected to experience the fastest CAGR during the forecast period. Packaging meant for the e-commerce and retail industry includes 1 or 2 adhesive strips for packaging before shipping to the user and is capable of resealing before being officially returned by the consumer to the seller. This crucially assists packaging returns for users. Furthermore, they are filled with tear tape to promote the opening of the packaging, which is known as tear-off or tear-off ribbon, a narrow self-adhesive tape utilised for opening the packaging. Its work is to help the release of the packages, which avoids the demand for knives or scissors and reduces the need for main force.

North America dominated the cohesive packaging market with 45.8% share in 2025, as it has come up with an important segment in the huge packaging sector, which is driven by the growing urge for smooth, sustainable, and inventive packaging materials. As organizations find that in order to update supply chains and develop product safety, cohesive adhesives are well known for their rigid bonding potential without the demand for further developers, who are gaining attention.

How is the Cohesive Packaging Market Growing in Canada?

Canada is constructing a cohesive national packaging method that uses federal rules like recycled content and labelling, including provincial EPR machines. The importance should be given to actual-world access. For the confectionery companies, this points to concentrating early and making sure that actual tracking and recyclability compliance are present at the SKU level.

Asia Pacific expects the fastest growth in the market during the forecast period, as the growth of e-commerce and food delivery services is meeting the urge for protective, lightweight, and tamper-evident packaging that has cohesive materials, which enable “wrap-and-go” completion, which reduces the labor and material waste too. The cohesive packaging is heavily utilised for the sensitive medical machines and the semiconductor elements as it serves as a protective seal without any demand for heat, which can damage high-value contents. The regional players are investing excessively in intelligent technologies and AI-enabled design in order to smooth the production and serve high-printability grades for the luxury consumer goods.

Why is India using the Cohesive Packaging Market Importantly?

Cohesive packaging materials that do not require any further adhesives or are developing as a high-development segment in India’s huge packaging sector. These materials are heavily used for cold-seal warps and self -healing millers too. Their capability is to serve instant and pressure -sensitive bonding without any heat, which makes them perfect for high-speed automated lines in fast-commerce completion centers.

The cohesive packaging market in the European region is growing as the main driver is developing demand across different sectors, such as e-commerce, packaging, and industrial applications. The sector’s expansion is being driven by developing eco-friendly awareness and the move towards biodegradable and sustainable materials. Main factors that encourage this growth include technological growth in paper production, the growing acceptance of environmentally friendly packaging solutions, and strict regulations that promote the usage of recyclable materials.

Germany Cohesive Packaging Market Trend

The main driver is the developing focus on sustainability, with the German government’s encouragement for the lower plastic usage under the Packaging Act, named VerpackG, which makes a strong incentive for the sector to move towards eco-friendly materials. Furthermore, rising user choice for environmentally friendly items is leading to a major acceptance in the implementation of recyclable and biodegradable packaging selections across different sectors, which include pharmaceuticals, food, and consumer goods.

In current year 2025, the urge for cohesive packaging materials which has glued only to themselves without further heat or adhesives is quickly developing across the Middle East and Africa. This demand is initially driven by e-commerce development and a regional move towards smooth and sustainable solutions. Also, there is developing alertness and strict regulations which are encouraging brands towards recyclable cohesive paper which is gaining the attention of main things due to biodegradable properties and its potential to substitute plastic tapes or glues. The production industry in UAE and the Saudi Arabia are accepting cohesive solutions to smooth the packaging of the spaces and electronics.

UAE Cohesive Packaging Market Trend

The UAE's cohesive packaging is meant for the sustained development through future years, as driven by the growing demand for environmentally friendly packaging solutions across several industries, which include retail, food, and electronics. Industry inventions, such as biodegradable, lightweight, and intelligent packaging materials, will further develop market entry methods that match overall sustainability commitments.

In South America, the cohesive packaging market is growing steadily as it is constantly gaining attention as nations such as Mexico, Brazil, and Argentina make developments in industrial modernization and technology acceptance, too. While the region faces problems just as policy inconsistency and restricted infrastructure, rising funding and government assistance are growing prospects. The main factors, such as automotive, energy, and construction, are driving the usage of advanced technologies.

Brazil Cohesive Packaging Market Trend

The regulatory bodies, such as Brazil’s National Environment Agency (IBAMA0 which are making strict standards on the packaging waste and the chemical product, the compelling industry games are to accept quickly. The overall encouragement for the circular principles, which is being assisted by organizations like the WHO and EPA, underlines the importance of lowering plastic waste and promoting reuse.

By Material Type

By Product Type

By Application

By End User

By Region

February 2026

February 2026

February 2026

February 2026