High Impact Corrugated Boxes Market Segmentation, Regional Insights, and Competitive Landscape

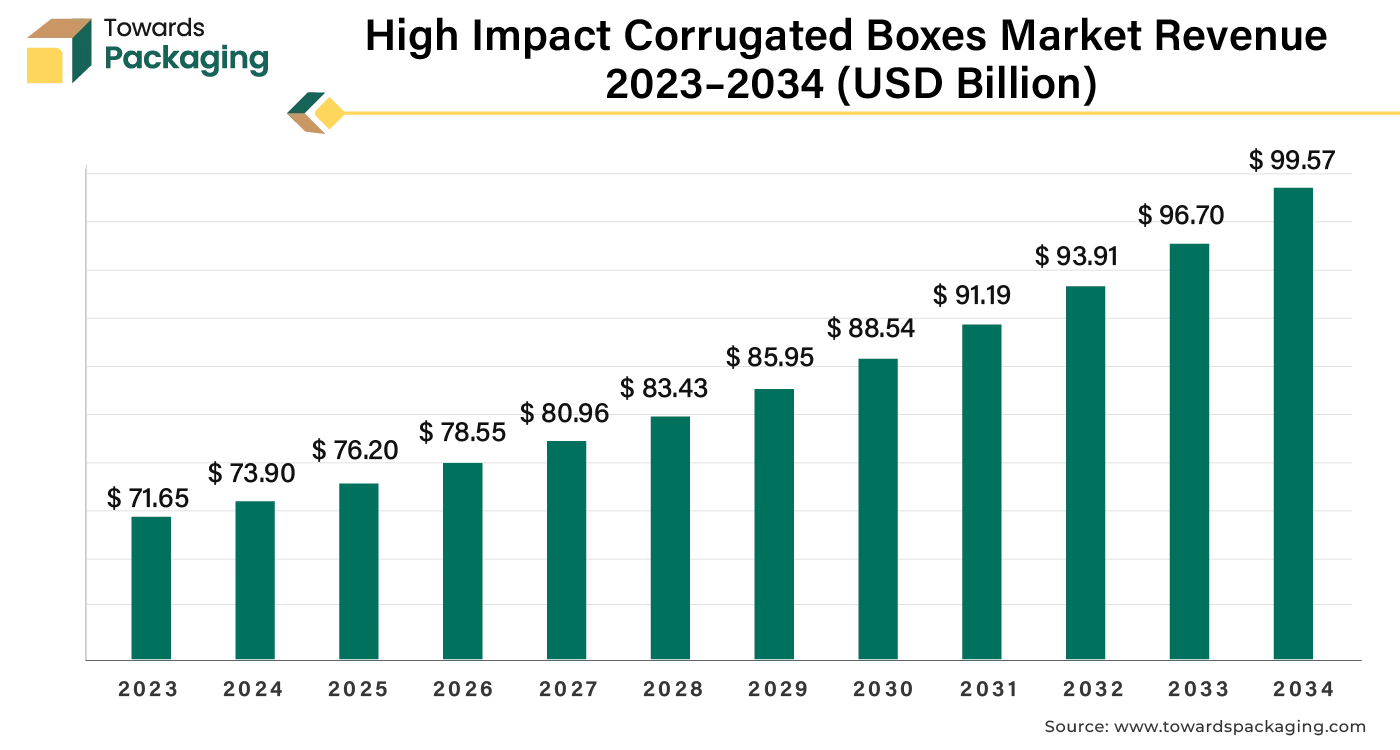

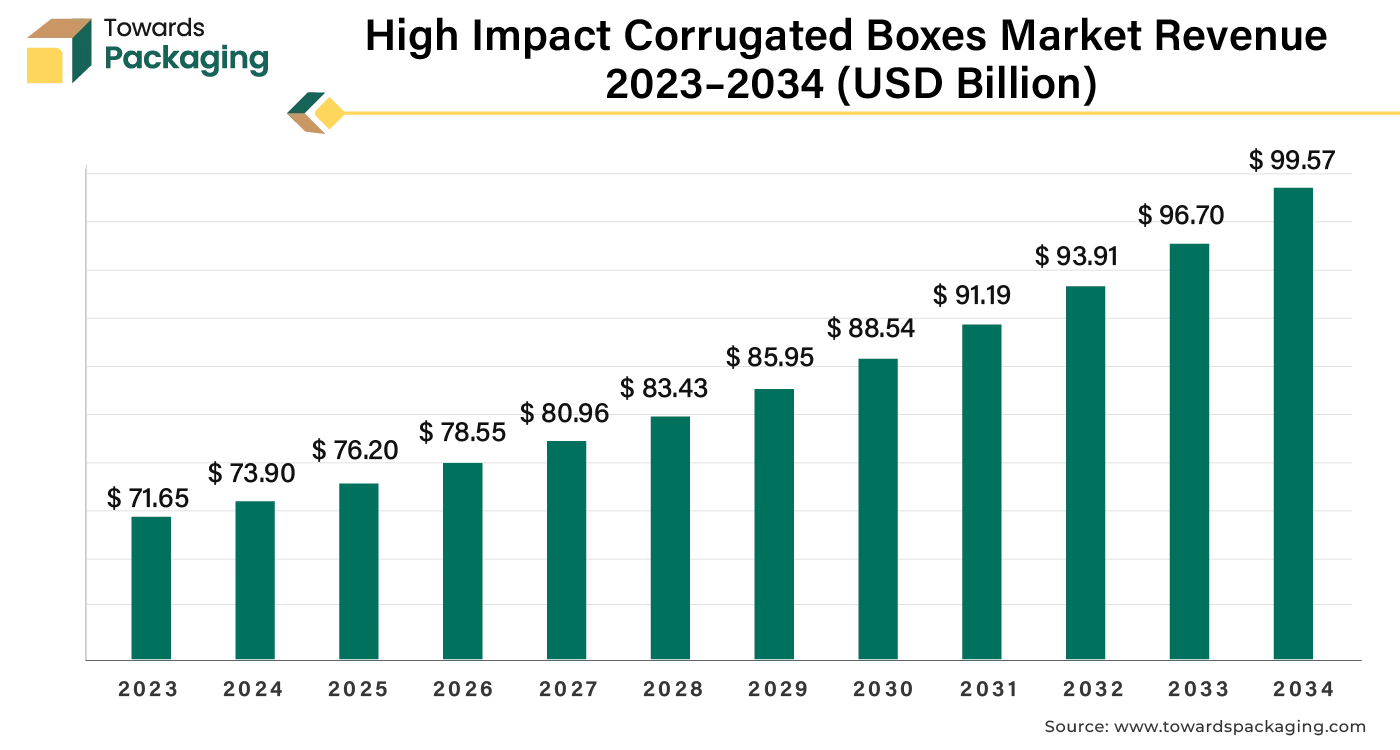

The high impact corrugated boxes market is forecasted to expand from USD 78.46 billion in 2026 to USD 102.73 billion by 2035, growing at a CAGR of 3.04% from 2026 to 2035. This report provides an in-depth analysis of product types (slotted, folder, telescope, die-cut), board types (single face, single wall, double wall, triple wall), and end-use industries such as food & beverages, electronics, healthcare, and automotive.

It covers regional performance across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, identifying growth hotspots like China, India, and the U.S. The study includes trade data, value chain mapping, supplier profiles, and a competitive assessment of major players like International Paper, WestRock, and Smurfit Kappa, highlighting their production strategies and innovations in sustainable packaging.

The market is proliferating due to the increasing business of food and beverages, cosmetics, and several e-commerce companies which require high-impact corrugated boxes for packaging. The growing trend of online ordering systems is boosting the high impact corrugated boxes market.

Major Key Insights of the High Impact Corrugated Boxes Market

- Asia Pacific led the market with the largest share in 2024.

- By product type, slotted boxes dominated the market with the largest share in 2024.

- By board type, the single wall board segment is expected to grow at a significant rate during the forecast period.

- By end type, the food & beverage segment dominated the green packaging film market in 2024.

High Impact Corrugated Boxes Market Sturdy Packaging

The high impact corrugated boxes market holds a pivotal position in the packaging sector, primarily fueled by its robust, cost-effective, and long-lasting features. These durable boxes are specifically designed to securely transport heavy and delicate items, including electronic devices, glassware, automotive parts, and more. Their reliable construction ensures safe handling, transportation, and storage. The rising trend of online shopping through various e-commerce platforms has significantly contributed to the surge in demand for corrugated boxes. With the increasing preference for online shopping, the need for corrugated packaging is expected to witness substantial growth from 2024 to 2034.

A large volume of packaging is utilized by e-commerce businesses, and the expansion of these platforms is driven by consumers opting for online purchases over traditional shopping, primarily due to convenience and time efficiency. This shift is closely linked to the growth of the high impact corrugated boxes market. Additionally, the rising global trade and growing logistics sector are further accelerating the demand for these boxes. Their ability to be customized in terms of size, shape, stiffness, and other properties makes them ideal for a diverse range of industries.

Major Driving Factors for High Impact Corrugated Boxes Market

- The rising number of e-commerce business significantly influence the packaging market. The quality of protection it provides to goods at the time of delivery ensures the safety of products.

- Technological development has driven the high impact corrugated boxes market.

- The option of branding and customized boxes available with multiple shapes, sizes, and prints which enhance the possibility for brands to showcase and drive the market.

- Expansion of trade across the world with durable packaging has raised the demand for such boxes as the delivery services also increased.

How Can AI Improve the High Impact Corrugated Boxes Market?

Artificial intelligence has the potential to significantly enhance the high impact corrugated boxes market in various ways, including manufacturing, market analysis, customized designs, and more. AI analytics can process large datasets, integrating customer preferences, market trends, and brand strategies, enabling designers to create distinctive and attractive packaging solutions. Simulations allow for visualization of packaging boxes in different environments, conserving resources and time while ensuring alignment with target consumers.

The impact of artificial intelligence extends to engineering, where AI systems equipped with computer vision can quickly identify defects in corrugated box materials, minimizing waste and product recalls. Furthermore, AI improves packaging processes by optimizing material usage and reducing excess, resulting in cost savings and better sustainability. Artificial intelligence also revolutionizes packaging logistics by maximizing weight capacity in shipping containers, minimizing packaging materials, and lowering the carbon footprint of each product. This sustainable approach aligns with the principles of the triple bottom line economic, environmental, and social success.

Driver

Expansion of e-commerce business globally

Corrugated boxes for product shipment are in high demand due to the growing popularity of online shopping. A speedier delivery system increases the risk of product damage. In such instances, a sturdy box for safe product travel, such as corrugated boxes, is required. The expansion of the e-commerce sector has increased the demand for trustworthy packaging materials. Sustainable packaging boxes are ones that feature a packaging strategy and practices that lower the danger of unsafe shipment and the use of undesired products by utilizing environmentally friendly materials.

Restraint

High Cost Materials

The primary challenges and restrictions in the high impact corrugated box market include exploding raw material charges, stringent environmental regulations, and increased competition from other industries. The variable raw substance charges are a major challenge for producers, since they must constantly manage their charges in order to remain competitive. The rigorous environmental regulations are a challenge since they impede the production and usage of specific materials and chemicals. The increased competition from the unknown category is a challenge because they provide lower prices and superior quality products.

Opportunity

Rising Concerns about Safety in Retail industry

The high-impact corrugated boxes market has witnessed substantial growth driven by several key opportunities. A major factor contributing to this expansion is the growing retail sector, which boosts the demand for durable and protective packaging to ensure product safety. The surge in online shopping is further creating opportunities for producing high-quality boxes that meet market needs.

Additionally, the production of sustainable, recyclable, and biodegradable corrugated boxes is broadening the scope for market players. The shift towards eco-friendly products is encouraging the development of sustainable packaging, such as corrugated boxes. High-quality packaging not only results in greater customer satisfaction but also motivates manufacturers to introduce more advanced products. Integrating NFC technologies and the Internet of Things (IoT) facilitates real-time customer feedback and enhances interaction, making packaging more informative.

- In February 2024, SPAR Hungary introduced eco-friendly, reusable boxes for transporting fruits and vegetables, aiming to reduce waste and promote recycling.

McDonald’s Efforts on Eco-Friendly Material Case Study

- In September 2023, EDF and McDonald’s teamed up with various companies to create sustainable packaging solutions. The collaboration aims to introduce innovative methods for producing cost-effective and eco-friendly corrugated boxes. Back in the 1980s, McDonald’s faced immense public pressure to reduce packaging waste, particularly during food preparation and within the supply chain.

In response, McDonald’s partnered with EDF to assess the solid waste produced across its restaurants, distribution centers, and supply systems. This assessment led to the removal of over 300 million pounds of packaging, including polystyrene clamshells, and initiated the recycling of corrugated boxes, cutting waste by nearly 30% in its restaurants. Through the 2023 partnership, numerous companies contributed creative solutions, significantly reducing waste in production, distribution, and supply operations. These innovations, which are both cost-effective and biodegradable, have garnered positive consumer feedback.

Segment Insights

Slotted Box Leading to the High Impact Corrugated Boxes Market in 2024

In 2024, the slotted box segment dominated the high-impact corrugated boxes market. Slotted boxes are the most frequent type of box used in the packing and shipping industry. These are extremely effective designs that can be used for the majority of product delivery, thus demand is high, and there is plenty of room for growth in the industry. The flaps on the slotted boxes are the same length, and two flaps on the outside side are half the width, allowing the box to close properly.

Slotted boxes feature a simple design with easy closing and opening flaps, which increases their popularity in the packaging industry. These are helpful for a variety of uses, including storage, transportation, and many more, due to their simple design and ability to properly convey objects without causing damage. The increasing demand is also owing to the availability of numerous sizes and lighter weights, which is a crucial requirement for most packaging and transportation organizations. Such boxes are simple to manufacture and efficient in a variety of ways, including lower shipping costs, less storage, and better space utilization.

The Single Face Board, to Grow as a Leading Segment

- In 2023, the single face board segment dominated the high-impact corrugated box market. These corrugated boxes are offered in a single layer of corrugated media sandwiched between two liners; this pattern is designed to give a balance of flexibility and strength. The quality of such a single face board protects from harm by cushioning, providing confidence when packing and transporting sensitive things. It offers high impact resistance, which decreases the risk of transporting objects like as electronics, pharmaceuticals, glass, and many other items.

Compared to two or three-layered wall corrugated board, it requires fewer materials to create, making it lighter in weight and more affordable. Because of the lower manufacturing costs, it is more ideal for market players who demand high-quality, dependable packaging wraps at a reasonable price. Furthermore, its ability to accommodate a variety of customized options and sizes makes it ideal for a wide range of organizations that require packaging alternatives that may assist promote their brand while also protecting their products.

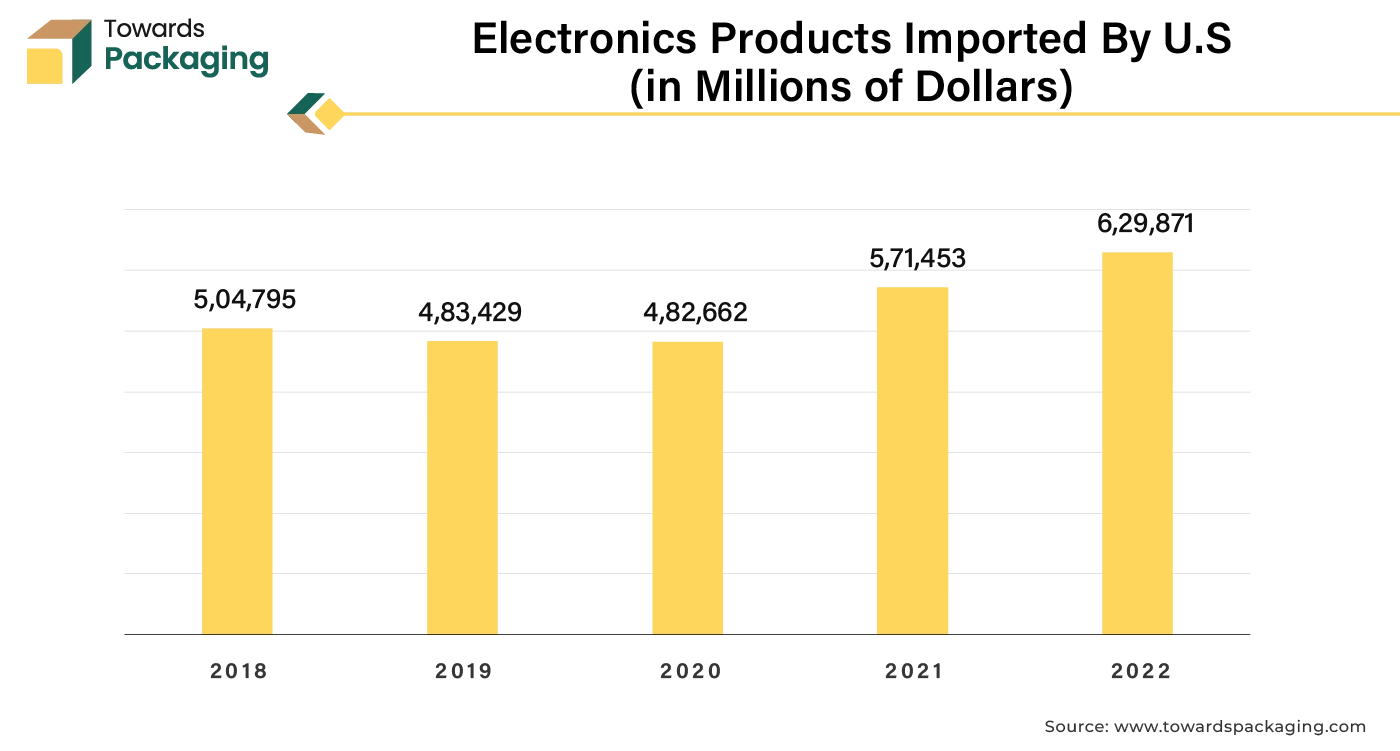

Electrical & Electronics Segment Led the Market

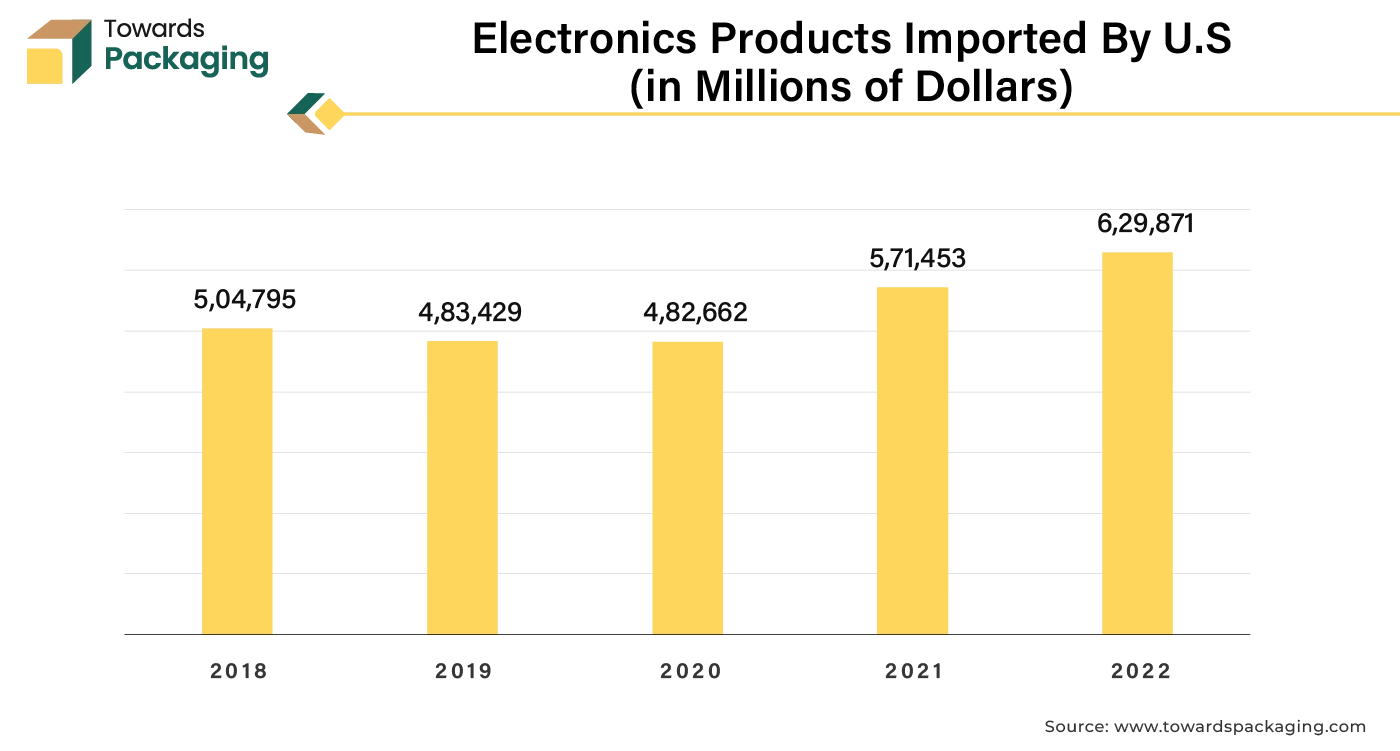

- In 2024, the electrical and electronics segment dominated the high impact corrugated box market. This sector requires high-quality, robust packaging boxes to ensure proper and safe transportation of valuable and sensitive commodities. Continuous technological advancements and increased global demand for electrical items are driving the popularity of these packaging materials. Because of the ability to customize and the demand for electronic products in the e-commerce industry, there is a high demand for packaging boxes in this market.

Innovation and Consumer Demand Asia Pacific to Sustain the Dominance

Asia Pacific, particularly countries like China, India, and Japan, is experiencing explosive growth in e-commerce. This surge in online shopping demands highly durable corrugated boxes to ensure the safe delivery of goods, leading to increased production and consumption of high-impact packaging. The region is home to some of the largest manufacturing and industrial sectors, especially in China and India. These industries require high impact corrugated boxes for shipping and protecting heavy machinery, electronics, and automotive components, fueling market growth.

Asia Pacific benefits from abundant raw materials, particularly paper and pulp, which are essential for producing corrugated boxes. Additionally, the region's low-cost labor and advanced manufacturing capabilities allow for cost-efficient production, making it a global supplier of corrugated packaging solutions. Asia Pacific is a leading exporter of goods, from electronics and textiles to automotive parts. The need for durable packaging for these exports has driven the demand for high impact corrugated boxes that can withstand long transit and protect fragile or heavy items.

China Market Trends

China high impact corrugated boxes market is driven by the massive manufacturing base and booming e-commerce industry in the country. China has the largest e-commerce market in the world, led by platforms like Alibaba, JD.com, and Pinduoduo. This explosive online retail growth has dramatically increased demand for durable, lightweight, and cost-effective packaging especially corrugated boxes, which are essential for shipping goods safely and efficiently.

China is known as the "world's factory." Its high volume of industrial production and exports fuels the need for large-scale packaging solutions, including corrugated boxes. Rapid urban growth and rising middle-class income levels have increased domestic consumption, again pushing demand for packaged goods. Investments in logistics, supply chain networks, and export-friendly policies make it easier for packaging manufacturers to scale up operations. Availability of low-cost raw materials (like paper pulp) and labor allows Chinese firms to produce corrugated boxes at competitive prices. There's a rising trend in eco-friendly packaging in China, and corrugated boxes being recyclable fit well with these green initiatives.

Growing E-commerce Company North America's to Grow Rapidly

North America is projected to grow at a significant pace in the high impact corrugated boxes market during the forecast period. The increasing demand for online ordering systems in the region is steadily rising due to factors like improving economic conditions, urbanization, population growth, and the emergence of start-ups. The region's demand for these corrugated boxes is growing, as they are both cost-effective and provide excellent protection for delicate items, making them ideal for shipping purposes.

Key market players in North America are focusing on producing high-quality, innovative boxes that emphasize sustainability and flexibility, catering to a broad range of customers. In countries like the U.S. and Canada, leading companies such as Deluxe Packaging, Inc., Associated Bag Milwaukee, Volk Packaging Corporation Biddeford, and Opus Packaging Caledonia, among others, are introducing new solutions to develop eco-friendly and recyclable boxes, while ensuring no compromise on quality.

U.S. Market Trends

U.S. high impact corrugated boxes market is driven by the strong logistics & supply chain infrastructure in the country. The United States remains a dominant player in the high-impact corrugated boxes market due to a combination of technological innovation, a mature logistics system, and strong demand from key industries.

The U.S. corrugated packaging industry is driven by high-tech, automated production systems that improve efficiency, customization, and product quality. This makes it a leader in producing high-impact, performance-oriented corrugated boxes tailored to complex shipping needs. Like China, the U.S. has a robust e-commerce sector (led by Amazon, Walmart, etc.). The demand for high-durability packaging for shipping electronics, perishables, and consumer goods has fuelled growth in high-impact corrugated solutions. The U.S. is home to many major sectors that rely on advanced packaging: food & beverage, electronics, pharmaceuticals and automotive. Each of these sectors requires specialized, high-strength corrugated boxes for safety and regulatory compliance. The U.S. has strict environmental regulations, pushing companies to develop eco-friendly, recyclable, and reusable corrugated packaging.

Innovation in materials and processes gives the U.S. a competitive edge in sustainable packaging. With a well-developed transport and warehousing system, the U.S. supports a highly efficient flow of goods. Corrugated box manufacturers benefit from streamlined supply chains, allowing them to meet demand faster and more reliably. High-end U.S. brands increasingly use corrugated boxes for custom-branded, high-quality unboxing experiences, especially in D2C (direct-to-consumer) channels. This adds to the demand for high-impact, premium-looking corrugated packaging.

Sustainable Packaging in Europe Region to Expand

Europe is projected to experience the fastest growth during the forecast period, driven by increasing interest in sustainable packaging. As environmental awareness continues to rise globally, both business owners and consumers are showing a preference for eco-friendly products. This has led to a significant demand for sustainable corrugated boxes, particularly those that are biodegradable and recyclable.

Strict packaging guidelines in this region are promoting the production of eco-conscious corrugated packaging solutions. Several key players in the market, such as Ramya Reprographic Pvt. Ltd., TGI Packaging Pvt. Ltd., Canpac Trends Pvt. Ltd., Shanthi Packaging, Vihaa Print and Pack Pvt. Ltd., Aaradhya Enterprise, Hariwansh Packaging Pvt. Ltd., and others, are actively advancing the manufacturing of these corrugated boxes.

- February 2024: Kite Packaging introduced a new corrugated fan fold, a long cardboard sheet that is scored and folded at regular intervals.

- April 2024: Flora launched the world’s first plastic-free paper tub in the UK, offering their customers entirely plastic-free, recyclable packaging options for all products.

Corrugated Packaging Market

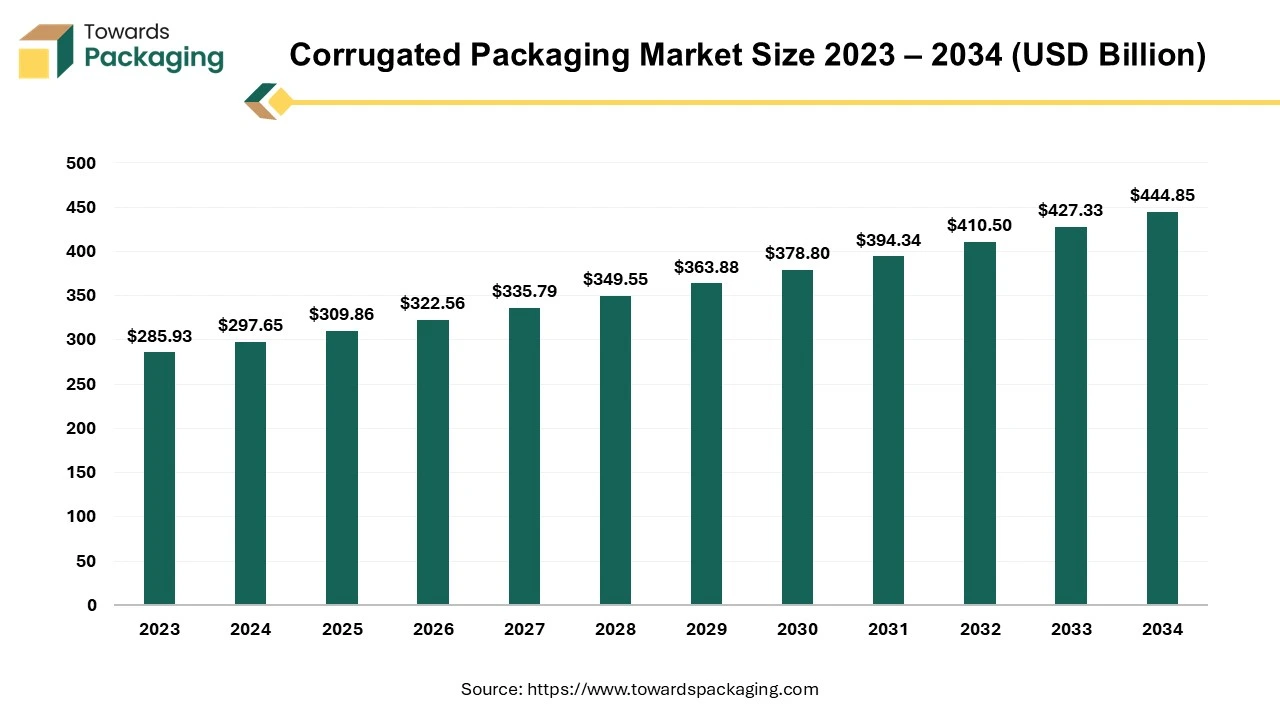

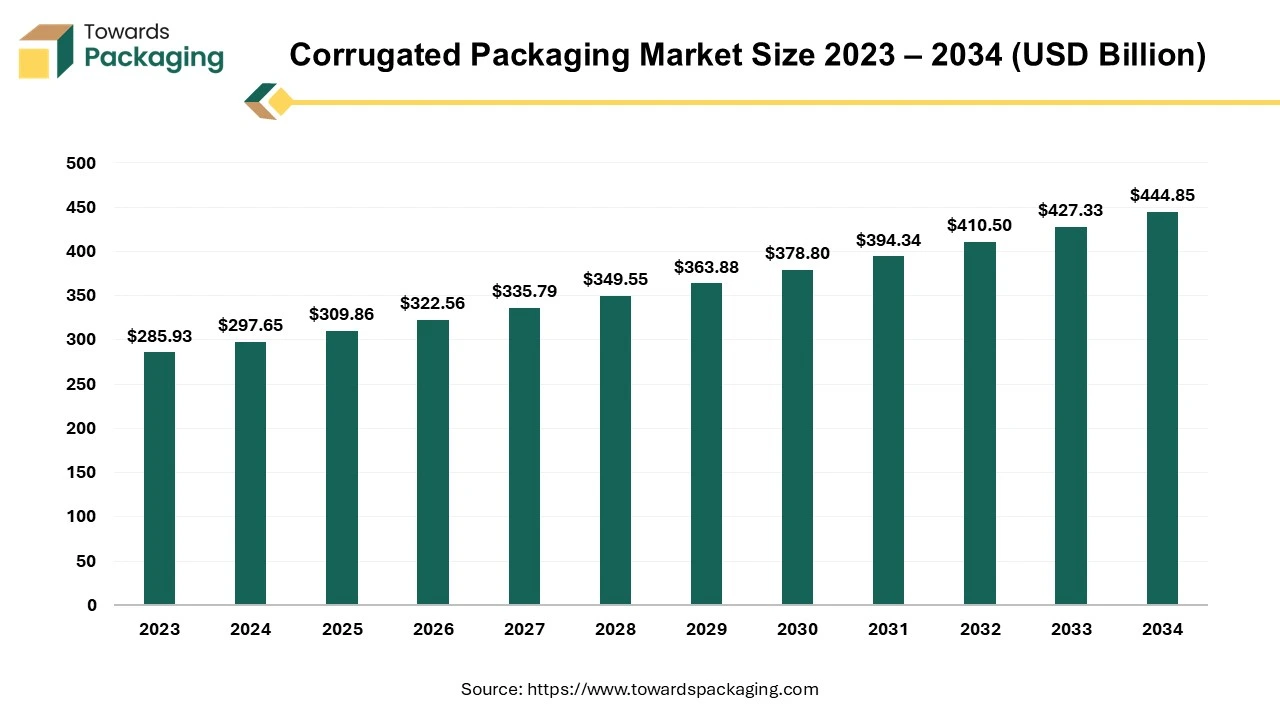

The corrugated packaging market is expected to expand from USD 309.86 billion in 2025 to USD 444.85 billion by 2034, growing at a CAGR of 4.10% from 2025 to 2034. Rapid expansion in online retail and the need for sturdy, cost-effective shipping solutions drive strong demand. Growing environmental regulations also push companies to adopt eco-friendly alternatives, fueling market growth.

Corrugated packaging refers to a type of lightweight, durable, and eco-friendly packaging manufactured from corrugated fiberboard, which consists of a fluted (wavy) middle layer sandwiched between two flat linerboards. This structure provides strength, impact resistance, and cushioning, making it ideal for shipping, storage, and product protection. Corrugated fiberboard is made up of three main components: liner board, fluting (Medium), and adhesives. The key benefits of corrugated packaging have been mentioned here as follows: strength, durability, cost-effective, lightweight, and versatility.

Corrugated Boxes for Transit Packaging Market

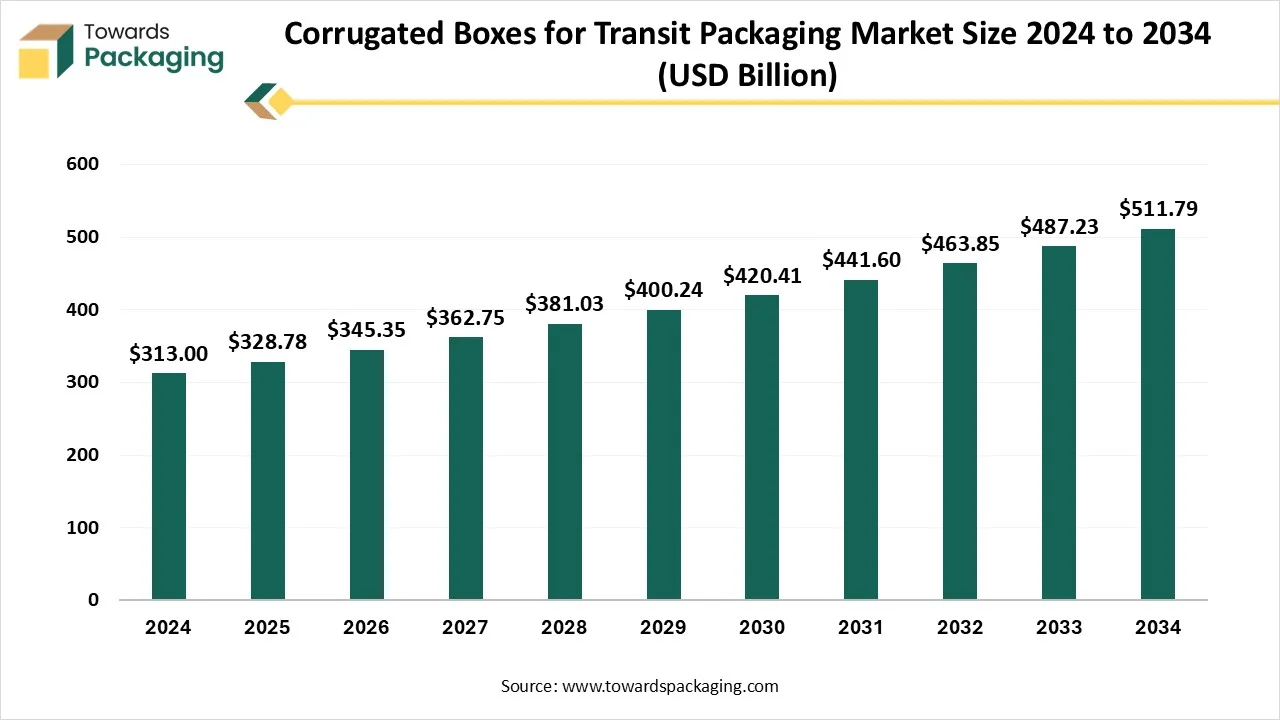

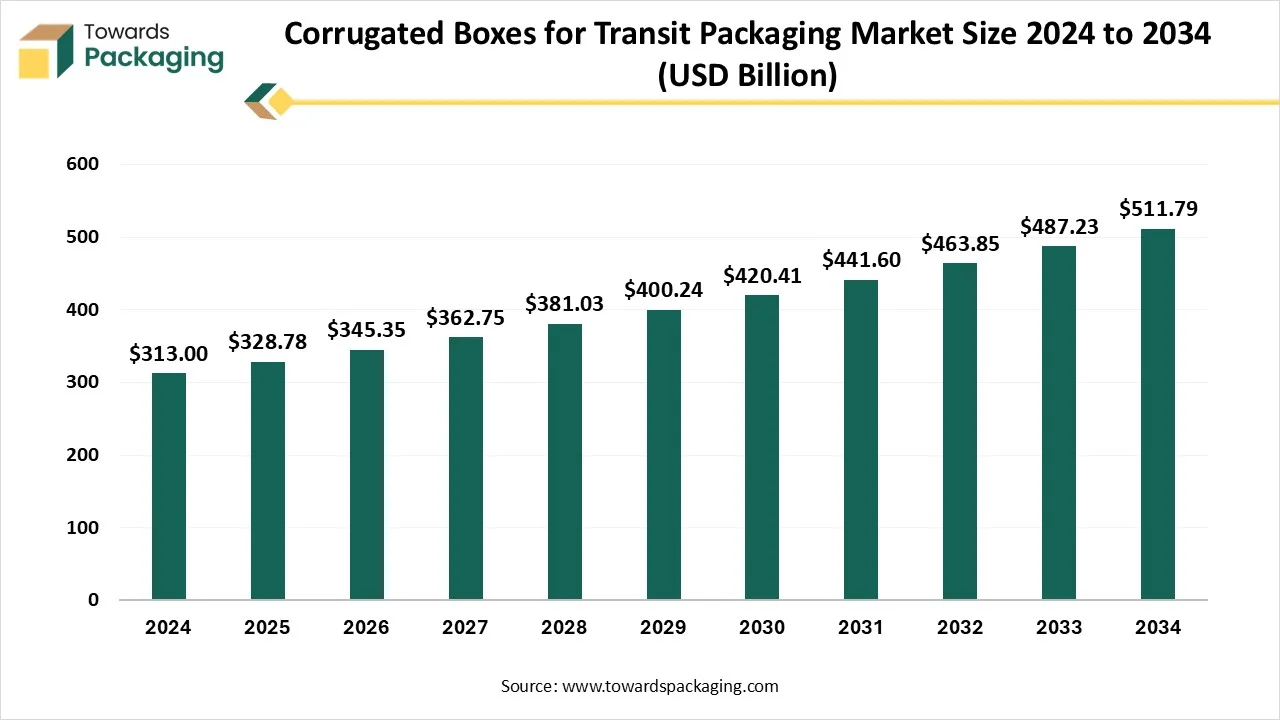

The corrugated boxes for transit packaging market is projected to reach USD 511.79 billion by 2034, expanding from USD 328.78 billion in 2025, at an annual growth rate of 5.04% during the forecast period from 2025 to 2034. The rising e-commerce activities and requirement for sustainable packaging resolution.

The global corrugated boxes for transit packaging market includes the production, sale, and distribution of corrugated boxes specifically designed for shipping and transportation of goods. These boxes are made from fluted corrugated sheets that provide strength, durability, and protection for products during transit. They are widely used across industries such as e-commerce, food & beverage, consumer goods, pharmaceuticals, electronics, and industrial goods. Growth is driven by increasing e-commerce shipments, global trade expansion, sustainable packaging trends, and rising demand for lightweight and recyclable packaging solutions.

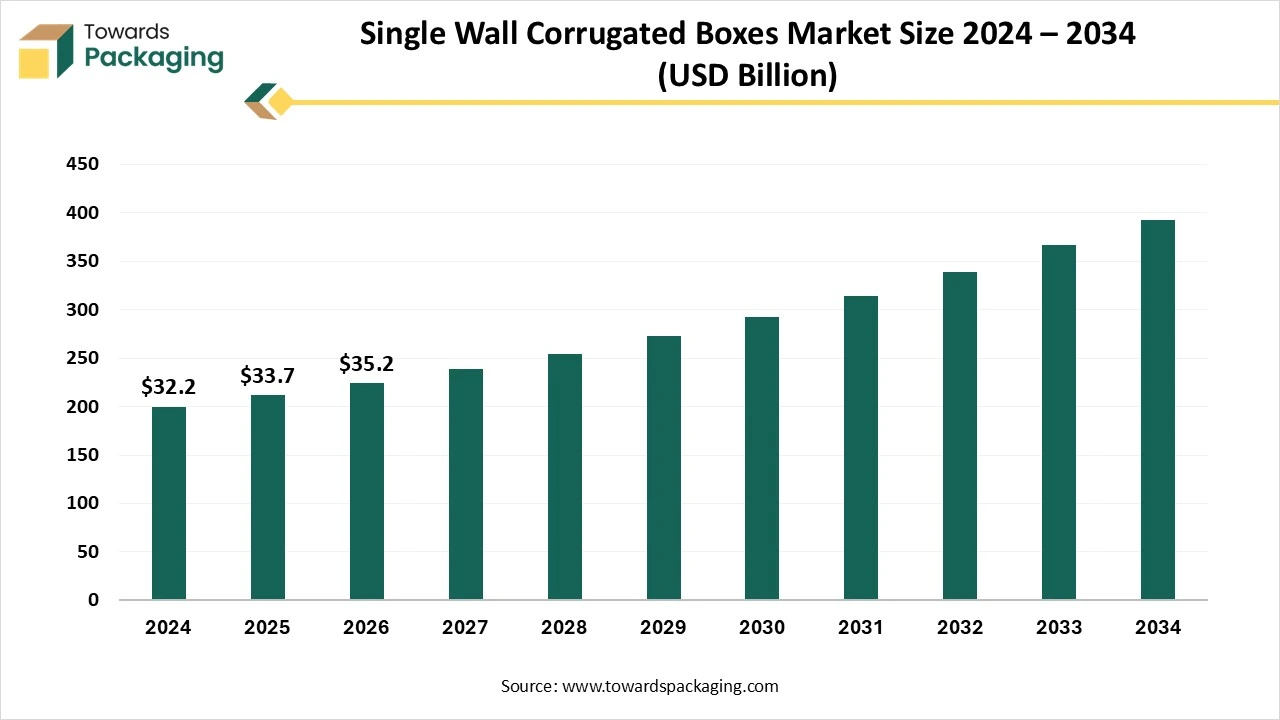

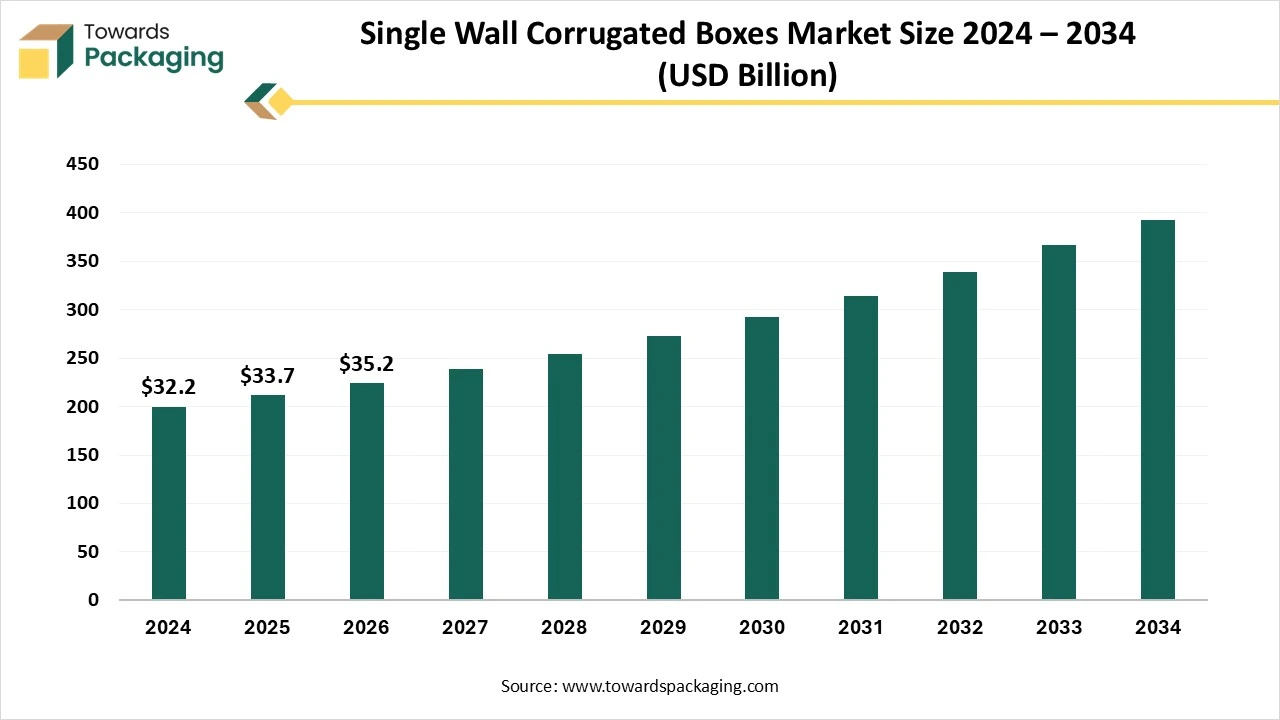

Single Wall Corrugated Boxes Market

The global single-wall corrugated boxes market is booming, poised for a revenue surge into the hundreds of millions from 2025 to 2034, driving a revolution in sustainable transportation. The rising expansion of the retail and e-commerce sector is expected to drive the global single-wall corrugated boxes market over the forecast period.

In the packaging industry, Single-wall corrugated boxes are the most commonly used packaging solution, offering a good balance of cost-effectiveness and strength. Single-wall corrugated boxes generally consist of a single inner layer, a single outer layer, and a fluted medium sandwiched between the two. Single Wall Corrugated Boxes are widely used across various industries such as e-commerce and retail, food and beverage, consumer goods and electronics, and others. Single-wall boxes are lightweight and cheaper than double-wall or triple-wall boxes. They are well-suited for shipping lightweight or non-fragile items.

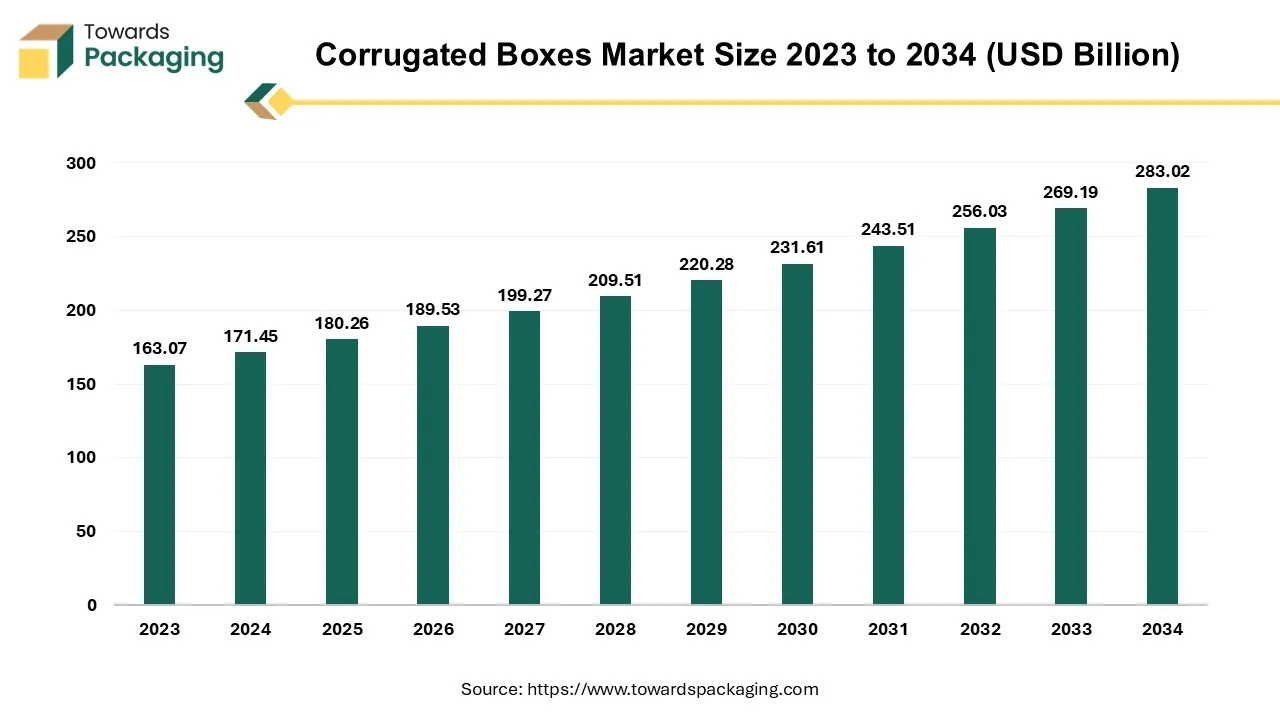

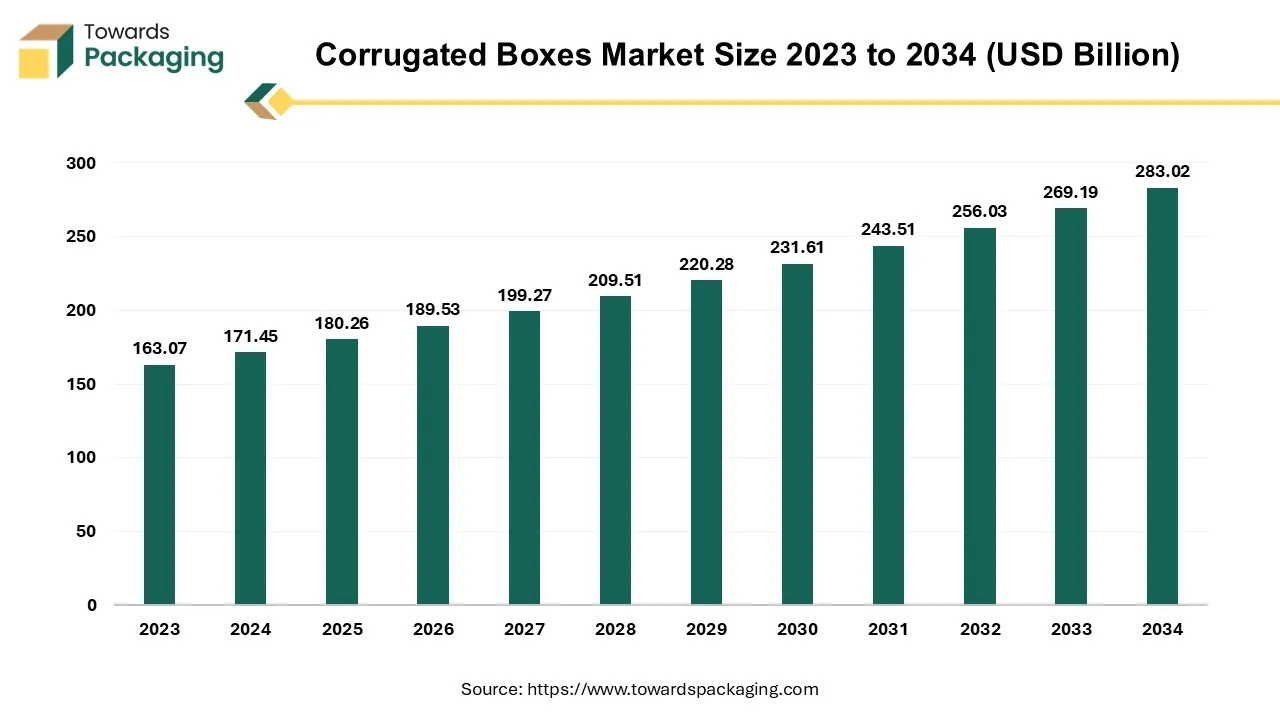

Corrugated Boxes Market

The global corrugated boxes market is projected to reach USD 283.02 billion by 2034, expanding from USD 180.26 billion in 2025, at an annual growth rate of 5.14% during the forecast period from 2025 to 2034. Increasing trend towards sustainable packaging is significant factor anticipated to drive the growth of the corrugated boxes market over the forecast period.

A corrugated box is a disposable container with three layers of material on its sides an outside layer, an inner layer, and a middle layer. When weighted materials are placed inside a corrugated box, the intermediate layer, which is fluted is designed in stiff, wave-shaped arches that act as supports and cushions. The process of aligning corrugated plastic or fiberboard (also known as corrugated cardboard) design elements with the functional, processing, and end-use requirements is known as corrugated box design. Packaging engineers strive to keep overall system costs under control while satisfying a box's performance criteria.

Key Companies in the High Impact Corrugated Boxes Market:

New Advancement in High Impact Corrugated Boxes Market

- From May 29-31, 2025, visit CorrVision Expo at the Pune International Exhibition & Convention Centre (PIECC), located in Moshi, Pune. Prepare to see live machinery and related solutions for box-making, packaging, and corrugated case manufacturing technologies. Live demonstrations of cutting-edge machinery, auxiliary equipment, consumables, raw materials, and comprehensive solutions will all be included in the event.

- In May 2025, Amazon revealed that it would install cutting-edge equipment to create custom-fit packaging throughout its European network, allowing for the creation of personalized paper bags and cardboard boxes for client deliveries. Amazon emphasized the new packaging's sustainability advantages, including as lowering emissions by optimizing vehicle space to allow for more deliveries with fewer vehicles, in addition to lowering waste and material usage.

- In January 2025, At the 2025 Maha Kumbh Mela in Prayagraj, Uttar Pradesh, Amazon India plans to carry out a sustainability-driven project by giving guests portable mattresses constructed from recycled cardboard boxes. By fusing creativity with community service during the 45-day event in January and February, which attracts millions of devotees, this action enhances Amazon's retail presence in India. In order to meet the need for comfort and rest during the large-scale event, the repurposed beds will be given out for free. Amazon India has determined strategic locations for the distribution of these beds within the festival grounds in coordination with the Maha Kumbh authorities. To help people in need, a sizable amount will be positioned at the lost and found facility.

- In early 2023, International Paper launched its EcoShield Corrugated Boxes, designed to offer high-impact protection with enhanced sustainability features. These boxes are made with fully recyclable materials and feature a water-resistant coating without the use of wax, meeting the increasing demand for eco-friendly packaging in e-commerce and retail.

- In mid-2023, Smurfit Kappa introduced TopClip, a high-impact corrugated packaging solution designed specifically for the beverage industry. This innovative packaging replaces plastic shrink wrap, providing a durable and environmentally friendly alternative while maintaining product safety during transit. It also supports large-scale brands in reducing their plastic footprint.

- In 2022, DS Smith launched its Crash-Lock Corrugated Boxes, offering enhanced impact resistance for fragile and valuable products. These boxes are especially tailored for industries such as consumer electronics and pharmaceuticals, where durability and protection during transportation are critical. The product received widespread adoption due to its easy-to-assemble design and superior strength.

High Impact Corrugated Boxes Market

By Product Type

- Slotted Box

- Folder Box

- Telescope Box

- Die Cut Box

By Board Type

- Single Face Board

- Single Wall Board

- Double Wall Board

- Triple Wall Board

By End Use

- Food & Beverage

- Electrical & Electronics

- Homecare

- Automotive & Allied Industries

- Healthcare

- Personal Care & Cosmetics

- Other Industries

By Region

- North America

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

- Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

- Latin America

- Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait